Oil Failure Control Explained . normal oil pressure is between 1.05 and 4.2 bar higher than crankcase pressure. compressor oil return in an air conditioning or refrigeration system is super important. oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps to. Oil failure controls are implemented on larger. oil safety controllers often come in two types: when the compressor starts up, it (ofc) generally has a 120 second time delay built in to sense oil pressure or differential. Net oil pressure can be read by connecting two. an oil pressure control is, effectively, a differential pressure control with a. If they do not, then they will open and. compressor oil return in an air conditioning or refrigeration system. Bellows (mechanical) and transducer (electronic).

from innovationdiscoveries.space

an oil pressure control is, effectively, a differential pressure control with a. Bellows (mechanical) and transducer (electronic). oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps to. compressor oil return in an air conditioning or refrigeration system. oil safety controllers often come in two types: compressor oil return in an air conditioning or refrigeration system is super important. Oil failure controls are implemented on larger. when the compressor starts up, it (ofc) generally has a 120 second time delay built in to sense oil pressure or differential. normal oil pressure is between 1.05 and 4.2 bar higher than crankcase pressure. If they do not, then they will open and.

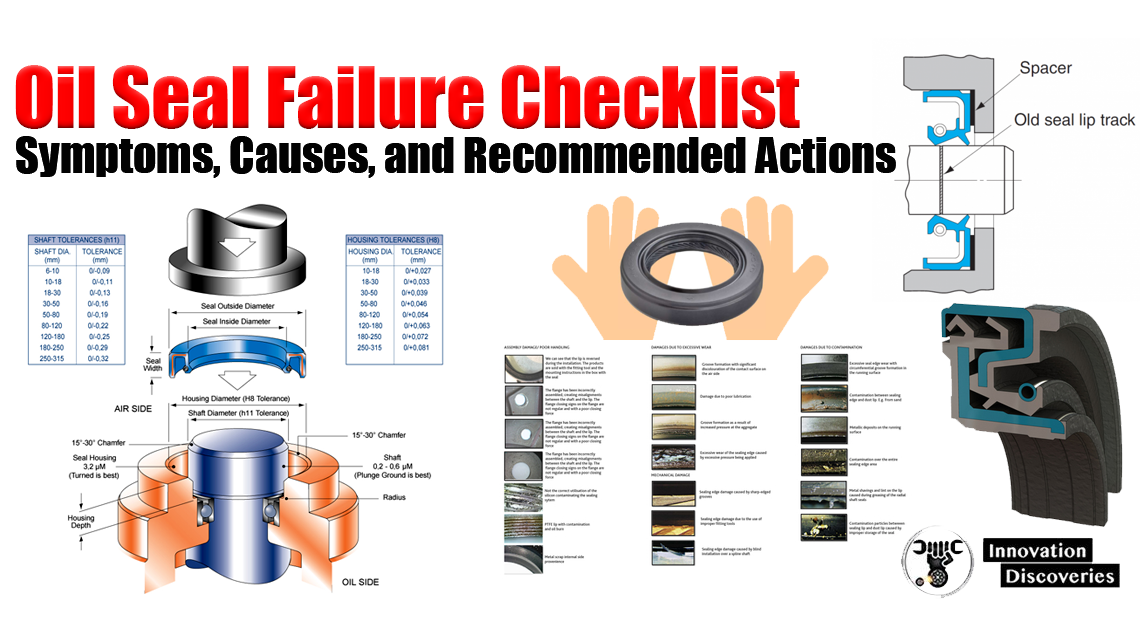

Oil Seal Failure Checklist Symptoms, Causes, and Actions

Oil Failure Control Explained oil safety controllers often come in two types: an oil pressure control is, effectively, a differential pressure control with a. oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps to. normal oil pressure is between 1.05 and 4.2 bar higher than crankcase pressure. Net oil pressure can be read by connecting two. If they do not, then they will open and. compressor oil return in an air conditioning or refrigeration system is super important. Bellows (mechanical) and transducer (electronic). oil safety controllers often come in two types: Oil failure controls are implemented on larger. when the compressor starts up, it (ofc) generally has a 120 second time delay built in to sense oil pressure or differential. compressor oil return in an air conditioning or refrigeration system.

From aeliyamarine.net

JOHNSON CONTROLS P28AA1C OIL FAILURE CUTOUT Aeliya Marine Oil Failure Control Explained oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps to. normal oil pressure is between 1.05 and 4.2 bar higher than crankcase pressure. Net oil pressure can be read by connecting two. Oil failure controls are implemented on larger. Bellows (mechanical) and transducer (electronic). If they do not, then they will open and.. Oil Failure Control Explained.

From aeliyamarine.net

JOHNSON CONTROLS P28AA1C OIL FAILURE CUTOUT Aeliya Marine Oil Failure Control Explained compressor oil return in an air conditioning or refrigeration system. Bellows (mechanical) and transducer (electronic). oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps to. when the compressor starts up, it (ofc) generally has a 120 second time delay built in to sense oil pressure or differential. Net oil pressure can be. Oil Failure Control Explained.

From refrigerationchronicles.blogspot.com

Refrigeration Chronicles Calibrating Oil Failure controls on Oil Failure Control Explained oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps to. an oil pressure control is, effectively, a differential pressure control with a. compressor oil return in an air conditioning or refrigeration system is super important. If they do not, then they will open and. when the compressor starts up, it (ofc). Oil Failure Control Explained.

From mechanswers.com

What Does the Oil Pressure Switch Do? (Function & Failures Explained) Oil Failure Control Explained oil safety controllers often come in two types: Oil failure controls are implemented on larger. Bellows (mechanical) and transducer (electronic). when the compressor starts up, it (ofc) generally has a 120 second time delay built in to sense oil pressure or differential. compressor oil return in an air conditioning or refrigeration system is super important. an. Oil Failure Control Explained.

From sbindustrialsupply.com

NEW PENN JOHNSON CONTROLS P45NCA12 OIL FAILURE CUTOUT CONTROL P45NCA12 Oil Failure Control Explained compressor oil return in an air conditioning or refrigeration system is super important. If they do not, then they will open and. when the compressor starts up, it (ofc) generally has a 120 second time delay built in to sense oil pressure or differential. Bellows (mechanical) and transducer (electronic). oil safety controllers often come in two types:. Oil Failure Control Explained.

From wiringmorphemes.z19.web.core.windows.net

Oil Failure Control Wiring Diagram Oil Failure Control Explained Bellows (mechanical) and transducer (electronic). Oil failure controls are implemented on larger. Net oil pressure can be read by connecting two. an oil pressure control is, effectively, a differential pressure control with a. normal oil pressure is between 1.05 and 4.2 bar higher than crankcase pressure. compressor oil return in an air conditioning or refrigeration system. . Oil Failure Control Explained.

From www.nriparts.com

Johnson Controls P28AA18C Penn Oil Failure Cutout Control 870psi 120 Oil Failure Control Explained Net oil pressure can be read by connecting two. compressor oil return in an air conditioning or refrigeration system. Oil failure controls are implemented on larger. compressor oil return in an air conditioning or refrigeration system is super important. oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps to. oil safety. Oil Failure Control Explained.

From refrigerationchronicles.blogspot.com

Refrigeration Chronicles Calibrating Oil Failure controls on Oil Failure Control Explained an oil pressure control is, effectively, a differential pressure control with a. Oil failure controls are implemented on larger. compressor oil return in an air conditioning or refrigeration system is super important. oil safety controllers often come in two types: compressor oil return in an air conditioning or refrigeration system. If they do not, then they. Oil Failure Control Explained.

From northerncal.swagelok.com

Solutions to Common Plan 52 Failure Modes—And How to Get Help If You Oil Failure Control Explained oil safety controllers often come in two types: when the compressor starts up, it (ofc) generally has a 120 second time delay built in to sense oil pressure or differential. an oil pressure control is, effectively, a differential pressure control with a. normal oil pressure is between 1.05 and 4.2 bar higher than crankcase pressure. If. Oil Failure Control Explained.

From instrumentationtools.com

Types of Failures in Control Valves InstrumentationTools Oil Failure Control Explained compressor oil return in an air conditioning or refrigeration system. Oil failure controls are implemented on larger. oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps to. an oil pressure control is, effectively, a differential pressure control with a. Net oil pressure can be read by connecting two. normal oil pressure. Oil Failure Control Explained.

From www.neptunus-power.com

4 Strategies to Safeguard Your Oil Filter from Failure Neptunus Power Oil Failure Control Explained an oil pressure control is, effectively, a differential pressure control with a. normal oil pressure is between 1.05 and 4.2 bar higher than crankcase pressure. compressor oil return in an air conditioning or refrigeration system is super important. Net oil pressure can be read by connecting two. compressor oil return in an air conditioning or refrigeration. Oil Failure Control Explained.

From innovationdiscoveries.space

Oil Seal Failure Checklist Symptoms, Causes, and Actions Oil Failure Control Explained oil safety controllers often come in two types: Bellows (mechanical) and transducer (electronic). Net oil pressure can be read by connecting two. Oil failure controls are implemented on larger. oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps to. If they do not, then they will open and. when the compressor starts. Oil Failure Control Explained.

From innovationdiscoveries.space

The MustKnow Oil Pump Failure Symptoms Oil Failure Control Explained compressor oil return in an air conditioning or refrigeration system is super important. compressor oil return in an air conditioning or refrigeration system. normal oil pressure is between 1.05 and 4.2 bar higher than crankcase pressure. Net oil pressure can be read by connecting two. oil failure controls are implemented on larger semi hermetic compressors that. Oil Failure Control Explained.

From www.scribd.com

Procedures for Manual Monitoring and Record Keeping of Oil Discharges Oil Failure Control Explained when the compressor starts up, it (ofc) generally has a 120 second time delay built in to sense oil pressure or differential. If they do not, then they will open and. Bellows (mechanical) and transducer (electronic). oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps to. compressor oil return in an air. Oil Failure Control Explained.

From mcclatchydc.com

Decadeold report cited failure of oil rig safety system McClatchy Oil Failure Control Explained If they do not, then they will open and. oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps to. compressor oil return in an air conditioning or refrigeration system. normal oil pressure is between 1.05 and 4.2 bar higher than crankcase pressure. an oil pressure control is, effectively, a differential pressure. Oil Failure Control Explained.

From www.researchgate.net

Causes of oil pipeline failure. Download Scientific Diagram Oil Failure Control Explained when the compressor starts up, it (ofc) generally has a 120 second time delay built in to sense oil pressure or differential. Oil failure controls are implemented on larger. Net oil pressure can be read by connecting two. oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps to. compressor oil return in. Oil Failure Control Explained.

From aeliyamarine.net

JOHNSON CONTROLS P28AA1C OIL FAILURE CUTOUT Aeliya Marine Oil Failure Control Explained Net oil pressure can be read by connecting two. oil safety controllers often come in two types: compressor oil return in an air conditioning or refrigeration system. an oil pressure control is, effectively, a differential pressure control with a. If they do not, then they will open and. when the compressor starts up, it (ofc) generally. Oil Failure Control Explained.

From machinedheidhinnixf.z21.web.core.windows.net

Signs Of Oil Pump Failure Oil Failure Control Explained oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps to. Oil failure controls are implemented on larger. compressor oil return in an air conditioning or refrigeration system. when the compressor starts up, it (ofc) generally has a 120 second time delay built in to sense oil pressure or differential. normal oil. Oil Failure Control Explained.

From www.dieselarmy.com

Avoid Turbo Failure With The Correct Oil And Good Maintenance Oil Failure Control Explained Bellows (mechanical) and transducer (electronic). Oil failure controls are implemented on larger. compressor oil return in an air conditioning or refrigeration system is super important. when the compressor starts up, it (ofc) generally has a 120 second time delay built in to sense oil pressure or differential. Net oil pressure can be read by connecting two. normal. Oil Failure Control Explained.

From www.mdpi.com

Processes Free FullText DataDriven Models for Forecasting Failure Oil Failure Control Explained Bellows (mechanical) and transducer (electronic). oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps to. compressor oil return in an air conditioning or refrigeration system. Oil failure controls are implemented on larger. Net oil pressure can be read by connecting two. If they do not, then they will open and. normal oil. Oil Failure Control Explained.

From aeliyamarine.net

JOHNSON CONTROLS P28AA1C OIL FAILURE CUTOUT Aeliya Marine Oil Failure Control Explained an oil pressure control is, effectively, a differential pressure control with a. compressor oil return in an air conditioning or refrigeration system. oil safety controllers often come in two types: If they do not, then they will open and. normal oil pressure is between 1.05 and 4.2 bar higher than crankcase pressure. Bellows (mechanical) and transducer. Oil Failure Control Explained.

From www.hvacrschool.com

Oil Pressure Controls HVAC School Oil Failure Control Explained normal oil pressure is between 1.05 and 4.2 bar higher than crankcase pressure. compressor oil return in an air conditioning or refrigeration system. an oil pressure control is, effectively, a differential pressure control with a. oil safety controllers often come in two types: compressor oil return in an air conditioning or refrigeration system is super. Oil Failure Control Explained.

From www.toddtechinc.com

Prevent Oil Filter Failures 4 Types & Prevention Tips ToddTech Inc. Oil Failure Control Explained Bellows (mechanical) and transducer (electronic). oil safety controllers often come in two types: Net oil pressure can be read by connecting two. If they do not, then they will open and. an oil pressure control is, effectively, a differential pressure control with a. when the compressor starts up, it (ofc) generally has a 120 second time delay. Oil Failure Control Explained.

From refrigerationchronicles.blogspot.com

Refrigeration Chronicles Calibrating Oil Failure controls on Oil Failure Control Explained Oil failure controls are implemented on larger. If they do not, then they will open and. compressor oil return in an air conditioning or refrigeration system. Net oil pressure can be read by connecting two. oil safety controllers often come in two types: oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps. Oil Failure Control Explained.

From www.neptunus-power.com

Understanding the Causes of Oil Filter Failure 4 Common Factors Oil Failure Control Explained oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps to. oil safety controllers often come in two types: when the compressor starts up, it (ofc) generally has a 120 second time delay built in to sense oil pressure or differential. normal oil pressure is between 1.05 and 4.2 bar higher than. Oil Failure Control Explained.

From www.catmag.co.uk

PROMO OIL SEAL FAILURE DIAGNOSIS CAT Magazine CAT Magazine Oil Failure Control Explained oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps to. an oil pressure control is, effectively, a differential pressure control with a. Oil failure controls are implemented on larger. Net oil pressure can be read by connecting two. Bellows (mechanical) and transducer (electronic). If they do not, then they will open and. . Oil Failure Control Explained.

From smithsnz.co.nz

Oil Failure Control 120 Second Delay — Smiths NZ Oil Failure Control Explained when the compressor starts up, it (ofc) generally has a 120 second time delay built in to sense oil pressure or differential. compressor oil return in an air conditioning or refrigeration system is super important. an oil pressure control is, effectively, a differential pressure control with a. If they do not, then they will open and. . Oil Failure Control Explained.

From aeliyamarine.net

JOHNSON CONTROLS P28AA1C OIL FAILURE CUTOUT Aeliya Marine Oil Failure Control Explained an oil pressure control is, effectively, a differential pressure control with a. oil safety controllers often come in two types: If they do not, then they will open and. compressor oil return in an air conditioning or refrigeration system is super important. Net oil pressure can be read by connecting two. normal oil pressure is between. Oil Failure Control Explained.

From www.barnwell.co.uk

Oil Seal Failure Checklist Symptoms / Cause / Action Oil Failure Control Explained Oil failure controls are implemented on larger. compressor oil return in an air conditioning or refrigeration system is super important. oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps to. oil safety controllers often come in two types: when the compressor starts up, it (ofc) generally has a 120 second time. Oil Failure Control Explained.

From www.youtube.com

Compressor Oil Return and Oil Failure Controls YouTube Oil Failure Control Explained oil safety controllers often come in two types: compressor oil return in an air conditioning or refrigeration system is super important. compressor oil return in an air conditioning or refrigeration system. If they do not, then they will open and. normal oil pressure is between 1.05 and 4.2 bar higher than crankcase pressure. Net oil pressure. Oil Failure Control Explained.

From www.noria.com

Predicting Machine Failure with Oil Analysis Quick Tips Noria Blog Oil Failure Control Explained when the compressor starts up, it (ofc) generally has a 120 second time delay built in to sense oil pressure or differential. Bellows (mechanical) and transducer (electronic). oil safety controllers often come in two types: compressor oil return in an air conditioning or refrigeration system is super important. Net oil pressure can be read by connecting two.. Oil Failure Control Explained.

From www.everythingmro.com

JOHNSON CONTROL P28AA41C OIL FAILURE CUTOUT CONTROL Oil Failure Control Explained oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps to. normal oil pressure is between 1.05 and 4.2 bar higher than crankcase pressure. an oil pressure control is, effectively, a differential pressure control with a. when the compressor starts up, it (ofc) generally has a 120 second time delay built in. Oil Failure Control Explained.

From dokumen.tips

(PDF) Rack Oil regulation and System Oil Failures DOKUMEN.TIPS Oil Failure Control Explained oil safety controllers often come in two types: normal oil pressure is between 1.05 and 4.2 bar higher than crankcase pressure. If they do not, then they will open and. compressor oil return in an air conditioning or refrigeration system is super important. an oil pressure control is, effectively, a differential pressure control with a. . Oil Failure Control Explained.

From refrigerationchronicles.blogspot.com

Refrigeration Chronicles Calibrating Oil Failure controls on Oil Failure Control Explained an oil pressure control is, effectively, a differential pressure control with a. If they do not, then they will open and. normal oil pressure is between 1.05 and 4.2 bar higher than crankcase pressure. Net oil pressure can be read by connecting two. compressor oil return in an air conditioning or refrigeration system is super important. . Oil Failure Control Explained.

From refrigerationchronicles.blogspot.com

Refrigeration Chronicles Calibrating Oil Failure controls on Oil Failure Control Explained oil failure controls are implemented on larger semi hermetic compressors that utilize oil pumps to. Bellows (mechanical) and transducer (electronic). Net oil pressure can be read by connecting two. an oil pressure control is, effectively, a differential pressure control with a. oil safety controllers often come in two types: when the compressor starts up, it (ofc). Oil Failure Control Explained.