Equipment Availability In Maintenance Management . System availability is a metric used to measure the percentage of time an asset can be used for production. Availability and reliability are related, though different metrics used to measure asset performance. System availability (also known as equipment availability or asset availability) is a metric that measures the probability that a system is not. It is a key metric in. It provides the probability that an asset is in operable condition at a given time (it is not undergoing maintenance or repairs). Machine availability measures the percentage of time equipment is available for production. It calculates the probability that a system isn’t broken or down for preventive maintenance when it’s needed for production. Reliability measures how frequently assets fail. Availability measures the amount of time assets spend in production vs. Asset availability is a measure of the amount of time a piece of equipment or machinery is available for use. Regular maintenance and quick issue resolution are essential strategies for maximizing machine availability. High machine availability is critical for maintaining consistent production output and minimizing downtime. Availability is a unique parameter that combines both reliability and maintainability parameters. Why are these parameters studied together?

from gocodes.com

System availability is a metric used to measure the percentage of time an asset can be used for production. Why are these parameters studied together? Reliability measures how frequently assets fail. Availability and reliability are related, though different metrics used to measure asset performance. Availability measures the amount of time assets spend in production vs. Regular maintenance and quick issue resolution are essential strategies for maximizing machine availability. It calculates the probability that a system isn’t broken or down for preventive maintenance when it’s needed for production. Asset availability is a measure of the amount of time a piece of equipment or machinery is available for use. Availability is a unique parameter that combines both reliability and maintainability parameters. High machine availability is critical for maintaining consistent production output and minimizing downtime.

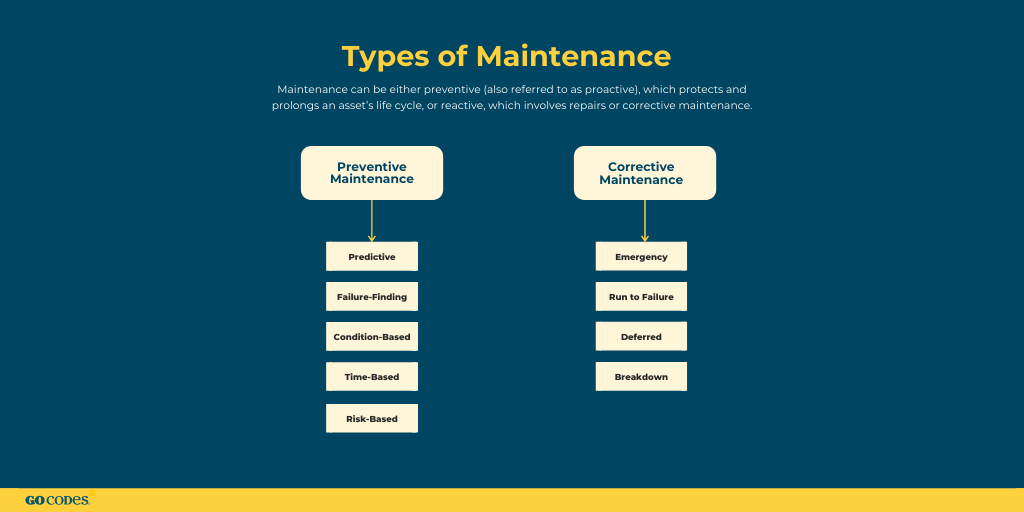

Types of Maintenance Different Strategies Explained

Equipment Availability In Maintenance Management Asset availability is a measure of the amount of time a piece of equipment or machinery is available for use. It provides the probability that an asset is in operable condition at a given time (it is not undergoing maintenance or repairs). Reliability measures how frequently assets fail. Machine availability measures the percentage of time equipment is available for production. System availability is a metric used to measure the percentage of time an asset can be used for production. It calculates the probability that a system isn’t broken or down for preventive maintenance when it’s needed for production. Availability measures the amount of time assets spend in production vs. Regular maintenance and quick issue resolution are essential strategies for maximizing machine availability. Availability is a unique parameter that combines both reliability and maintainability parameters. Availability and reliability are related, though different metrics used to measure asset performance. Asset availability is a measure of the amount of time a piece of equipment or machinery is available for use. It is a key metric in. Why are these parameters studied together? High machine availability is critical for maintaining consistent production output and minimizing downtime. System availability (also known as equipment availability or asset availability) is a metric that measures the probability that a system is not.

From swisspowersolutions.com

HIGH AVAILABILITY MAINTENANCE MODEL Swiss Power Solutions Equipment Availability In Maintenance Management Why are these parameters studied together? System availability (also known as equipment availability or asset availability) is a metric that measures the probability that a system is not. Availability measures the amount of time assets spend in production vs. High machine availability is critical for maintaining consistent production output and minimizing downtime. Reliability measures how frequently assets fail. Availability is. Equipment Availability In Maintenance Management.

From www.cmmssoftware.leantransitionsolutions.com

Maintenance management System CMMS Software TITAN Equipment Availability In Maintenance Management Availability measures the amount of time assets spend in production vs. Machine availability measures the percentage of time equipment is available for production. Availability and reliability are related, though different metrics used to measure asset performance. It provides the probability that an asset is in operable condition at a given time (it is not undergoing maintenance or repairs). High machine. Equipment Availability In Maintenance Management.

From www.assetinfinity.com

What Are the Objectives & Functions of Maintenance Management? Equipment Availability In Maintenance Management High machine availability is critical for maintaining consistent production output and minimizing downtime. Availability and reliability are related, though different metrics used to measure asset performance. Availability is a unique parameter that combines both reliability and maintainability parameters. Availability measures the amount of time assets spend in production vs. Machine availability measures the percentage of time equipment is available for. Equipment Availability In Maintenance Management.

From leanmanufacturing.online

Prioritizing the Equipment and Selecting the Maintenance System Equipment Availability In Maintenance Management It is a key metric in. It calculates the probability that a system isn’t broken or down for preventive maintenance when it’s needed for production. High machine availability is critical for maintaining consistent production output and minimizing downtime. It provides the probability that an asset is in operable condition at a given time (it is not undergoing maintenance or repairs).. Equipment Availability In Maintenance Management.

From www.reliableplant.com

Maintenance Management An Overview Reliable Plant Equipment Availability In Maintenance Management System availability (also known as equipment availability or asset availability) is a metric that measures the probability that a system is not. It calculates the probability that a system isn’t broken or down for preventive maintenance when it’s needed for production. High machine availability is critical for maintaining consistent production output and minimizing downtime. Asset availability is a measure of. Equipment Availability In Maintenance Management.

From facilio.com

Maintenance Management Meaning, Types, Steps to Optimize Equipment Availability In Maintenance Management System availability (also known as equipment availability or asset availability) is a metric that measures the probability that a system is not. Availability is a unique parameter that combines both reliability and maintainability parameters. Machine availability measures the percentage of time equipment is available for production. Regular maintenance and quick issue resolution are essential strategies for maximizing machine availability. Reliability. Equipment Availability In Maintenance Management.

From www.slideserve.com

PPT MAINTENANCE MANAGEMENT PowerPoint Presentation, free download Equipment Availability In Maintenance Management It calculates the probability that a system isn’t broken or down for preventive maintenance when it’s needed for production. Availability is a unique parameter that combines both reliability and maintainability parameters. Asset availability is a measure of the amount of time a piece of equipment or machinery is available for use. Regular maintenance and quick issue resolution are essential strategies. Equipment Availability In Maintenance Management.

From www.getapp.com

Best Equipment Maintenance Software 2024 Reviews on 307+ Tools GetApp Equipment Availability In Maintenance Management System availability (also known as equipment availability or asset availability) is a metric that measures the probability that a system is not. It provides the probability that an asset is in operable condition at a given time (it is not undergoing maintenance or repairs). Machine availability measures the percentage of time equipment is available for production. It is a key. Equipment Availability In Maintenance Management.

From timly.com

The Smart Maintenance Management for Machines and Tools Equipment Availability In Maintenance Management Availability and reliability are related, though different metrics used to measure asset performance. Asset availability is a measure of the amount of time a piece of equipment or machinery is available for use. Machine availability measures the percentage of time equipment is available for production. High machine availability is critical for maintaining consistent production output and minimizing downtime. Availability is. Equipment Availability In Maintenance Management.

From gocodes.com

Types of Maintenance Different Strategies Explained Equipment Availability In Maintenance Management It calculates the probability that a system isn’t broken or down for preventive maintenance when it’s needed for production. Availability is a unique parameter that combines both reliability and maintainability parameters. Availability measures the amount of time assets spend in production vs. High machine availability is critical for maintaining consistent production output and minimizing downtime. It provides the probability that. Equipment Availability In Maintenance Management.

From siconseils.ca

Maintenance & Reliability Best Practices Systemex Industrial Equipment Availability In Maintenance Management Availability and reliability are related, though different metrics used to measure asset performance. Availability is a unique parameter that combines both reliability and maintainability parameters. High machine availability is critical for maintaining consistent production output and minimizing downtime. It calculates the probability that a system isn’t broken or down for preventive maintenance when it’s needed for production. It is a. Equipment Availability In Maintenance Management.

From www.slideteam.net

Must Have Maintenance Schedule Template with Samples and Examples Equipment Availability In Maintenance Management Asset availability is a measure of the amount of time a piece of equipment or machinery is available for use. Reliability measures how frequently assets fail. It calculates the probability that a system isn’t broken or down for preventive maintenance when it’s needed for production. Machine availability measures the percentage of time equipment is available for production. High machine availability. Equipment Availability In Maintenance Management.

From excel-templates.com

Maintenance Management Process Equipment Availability In Maintenance Management Asset availability is a measure of the amount of time a piece of equipment or machinery is available for use. Availability measures the amount of time assets spend in production vs. System availability is a metric used to measure the percentage of time an asset can be used for production. Reliability measures how frequently assets fail. System availability (also known. Equipment Availability In Maintenance Management.

From limblecmms.com

Complete Guide to Facility Maintenance Equipment Availability In Maintenance Management Availability and reliability are related, though different metrics used to measure asset performance. High machine availability is critical for maintaining consistent production output and minimizing downtime. Reliability measures how frequently assets fail. It provides the probability that an asset is in operable condition at a given time (it is not undergoing maintenance or repairs). System availability is a metric used. Equipment Availability In Maintenance Management.

From biblus.accasoftware.com

Maintenance management definitions, types and objectives BibLus Equipment Availability In Maintenance Management Asset availability is a measure of the amount of time a piece of equipment or machinery is available for use. High machine availability is critical for maintaining consistent production output and minimizing downtime. Regular maintenance and quick issue resolution are essential strategies for maximizing machine availability. It is a key metric in. System availability is a metric used to measure. Equipment Availability In Maintenance Management.

From alcorfund.com

Equipment Maintenance Management Software A CostEffective Solution Equipment Availability In Maintenance Management System availability (also known as equipment availability or asset availability) is a metric that measures the probability that a system is not. Availability is a unique parameter that combines both reliability and maintainability parameters. System availability is a metric used to measure the percentage of time an asset can be used for production. Availability measures the amount of time assets. Equipment Availability In Maintenance Management.

From www.roadtoreliability.com

9 Types of Maintenance choosing the right maintenance types Equipment Availability In Maintenance Management Asset availability is a measure of the amount of time a piece of equipment or machinery is available for use. Regular maintenance and quick issue resolution are essential strategies for maximizing machine availability. Availability is a unique parameter that combines both reliability and maintainability parameters. Why are these parameters studied together? Machine availability measures the percentage of time equipment is. Equipment Availability In Maintenance Management.

From www.g3pconsulting.com

Reliability Maintenance Management g3p Lean Asset Management Consulting Equipment Availability In Maintenance Management Regular maintenance and quick issue resolution are essential strategies for maximizing machine availability. Availability is a unique parameter that combines both reliability and maintainability parameters. Reliability measures how frequently assets fail. Availability measures the amount of time assets spend in production vs. It provides the probability that an asset is in operable condition at a given time (it is not. Equipment Availability In Maintenance Management.

From www.samin-na.com

Maintenance Management KPI’s www yabo88 com Equipment Availability In Maintenance Management It is a key metric in. Why are these parameters studied together? System availability is a metric used to measure the percentage of time an asset can be used for production. Availability measures the amount of time assets spend in production vs. Availability and reliability are related, though different metrics used to measure asset performance. System availability (also known as. Equipment Availability In Maintenance Management.

From www.tiaravib.com

Best Practice Formulation TRUC 2018 for Asset Maintenance Reliability Equipment Availability In Maintenance Management Availability is a unique parameter that combines both reliability and maintainability parameters. Reliability measures how frequently assets fail. It is a key metric in. System availability is a metric used to measure the percentage of time an asset can be used for production. System availability (also known as equipment availability or asset availability) is a metric that measures the probability. Equipment Availability In Maintenance Management.

From desklib.com

Maintenance Management Strategy Desklib Equipment Availability In Maintenance Management Why are these parameters studied together? It is a key metric in. System availability is a metric used to measure the percentage of time an asset can be used for production. It calculates the probability that a system isn’t broken or down for preventive maintenance when it’s needed for production. System availability (also known as equipment availability or asset availability). Equipment Availability In Maintenance Management.

From www.mdpi.com

Processes Free FullText Integration of Maintenance Management Equipment Availability In Maintenance Management Availability is a unique parameter that combines both reliability and maintainability parameters. Why are these parameters studied together? It is a key metric in. Availability and reliability are related, though different metrics used to measure asset performance. High machine availability is critical for maintaining consistent production output and minimizing downtime. Availability measures the amount of time assets spend in production. Equipment Availability In Maintenance Management.

From helensowerby.wixsite.com

Maintenance Management Software for Rental & Construction Equipment Equipment Availability In Maintenance Management Availability is a unique parameter that combines both reliability and maintainability parameters. It provides the probability that an asset is in operable condition at a given time (it is not undergoing maintenance or repairs). System availability is a metric used to measure the percentage of time an asset can be used for production. It calculates the probability that a system. Equipment Availability In Maintenance Management.

From facilio.com

Maintenance Management Definition, types, benefits, and more Equipment Availability In Maintenance Management System availability (also known as equipment availability or asset availability) is a metric that measures the probability that a system is not. Availability measures the amount of time assets spend in production vs. Availability and reliability are related, though different metrics used to measure asset performance. Machine availability measures the percentage of time equipment is available for production. Asset availability. Equipment Availability In Maintenance Management.

From www.examples.com

Maintenance Strategy Plan 10+ Examples, Format, Pdf Equipment Availability In Maintenance Management Availability is a unique parameter that combines both reliability and maintainability parameters. High machine availability is critical for maintaining consistent production output and minimizing downtime. System availability (also known as equipment availability or asset availability) is a metric that measures the probability that a system is not. Asset availability is a measure of the amount of time a piece of. Equipment Availability In Maintenance Management.

From www.axessgroup.com

Maintenance Management Axess Group Equipment Availability In Maintenance Management Availability measures the amount of time assets spend in production vs. Why are these parameters studied together? Machine availability measures the percentage of time equipment is available for production. Reliability measures how frequently assets fail. Availability is a unique parameter that combines both reliability and maintainability parameters. System availability (also known as equipment availability or asset availability) is a metric. Equipment Availability In Maintenance Management.

From itchronicles.com

Importance of Maintenance Management Why You Need It Equipment Availability In Maintenance Management Regular maintenance and quick issue resolution are essential strategies for maximizing machine availability. Reliability measures how frequently assets fail. System availability (also known as equipment availability or asset availability) is a metric that measures the probability that a system is not. Availability and reliability are related, though different metrics used to measure asset performance. It is a key metric in.. Equipment Availability In Maintenance Management.

From ezo.io

Equipment Maintenance Best Practices Basics, Objectives and Functions Equipment Availability In Maintenance Management Availability is a unique parameter that combines both reliability and maintainability parameters. Availability measures the amount of time assets spend in production vs. Regular maintenance and quick issue resolution are essential strategies for maximizing machine availability. High machine availability is critical for maintaining consistent production output and minimizing downtime. System availability (also known as equipment availability or asset availability) is. Equipment Availability In Maintenance Management.

From www.daacoworks.com

Digitize the Preventive Maintenance Workflow Equipment Availability In Maintenance Management Availability is a unique parameter that combines both reliability and maintainability parameters. Regular maintenance and quick issue resolution are essential strategies for maximizing machine availability. System availability (also known as equipment availability or asset availability) is a metric that measures the probability that a system is not. It provides the probability that an asset is in operable condition at a. Equipment Availability In Maintenance Management.

From www.whatissixsigma.net

What is Overall Equipment Effectiveness (OEE)? Equipment Availability In Maintenance Management Availability is a unique parameter that combines both reliability and maintainability parameters. Asset availability is a measure of the amount of time a piece of equipment or machinery is available for use. It is a key metric in. Reliability measures how frequently assets fail. Why are these parameters studied together? High machine availability is critical for maintaining consistent production output. Equipment Availability In Maintenance Management.

From handytooladviser.com

What is Inherent Availability in Maintenance & Reliability Equipment Availability In Maintenance Management Machine availability measures the percentage of time equipment is available for production. Availability measures the amount of time assets spend in production vs. Availability is a unique parameter that combines both reliability and maintainability parameters. It calculates the probability that a system isn’t broken or down for preventive maintenance when it’s needed for production. It provides the probability that an. Equipment Availability In Maintenance Management.

From slidesdocs.com

Importance Of Maintenance And Equipment Management Excel Template And Equipment Availability In Maintenance Management System availability (also known as equipment availability or asset availability) is a metric that measures the probability that a system is not. High machine availability is critical for maintaining consistent production output and minimizing downtime. Availability is a unique parameter that combines both reliability and maintainability parameters. Machine availability measures the percentage of time equipment is available for production. It. Equipment Availability In Maintenance Management.

From www.maintenancelead.com

What is Maintenance Management Equipment Availability In Maintenance Management It calculates the probability that a system isn’t broken or down for preventive maintenance when it’s needed for production. Reliability measures how frequently assets fail. System availability (also known as equipment availability or asset availability) is a metric that measures the probability that a system is not. It is a key metric in. Availability and reliability are related, though different. Equipment Availability In Maintenance Management.

From www.examples.com

Maintenance Strategy Plan 10+ Examples, Format, Pdf Equipment Availability In Maintenance Management Availability is a unique parameter that combines both reliability and maintainability parameters. Asset availability is a measure of the amount of time a piece of equipment or machinery is available for use. Why are these parameters studied together? System availability (also known as equipment availability or asset availability) is a metric that measures the probability that a system is not.. Equipment Availability In Maintenance Management.

From ftmaintenance.com

What is Maintenance Management? An InDepth Look at Maintenance Equipment Availability In Maintenance Management Asset availability is a measure of the amount of time a piece of equipment or machinery is available for use. Availability measures the amount of time assets spend in production vs. Reliability measures how frequently assets fail. Machine availability measures the percentage of time equipment is available for production. It is a key metric in. System availability (also known as. Equipment Availability In Maintenance Management.