Copper Mold Tube Continuous Casting . Continuous casting (cc) for steel solidification processing is being used commercially for the last 60 years. abax steel offers copper mould tubes and plates for continuous casting of steel billets and slabs. copper moulds play an important role in the continuous casting process. the copper mould is one of the most important components of a continuous casting machine. Learn about the advantages, design and coating of. Their function is to receive the molten steel and guarantee. the copper mould tube is the core component of continuous casting. a finite element thermal stress model to compute the thermomechanical state of the solidifying shell during continuous casting of. Their function is to receive the molten steel and guarantee rapid heat. The copper plate of the copper mould tube is. copper moulds play an important role in the continuous casting process.

from www.diytrade.com

Learn about the advantages, design and coating of. the copper mould is one of the most important components of a continuous casting machine. The copper plate of the copper mould tube is. abax steel offers copper mould tubes and plates for continuous casting of steel billets and slabs. copper moulds play an important role in the continuous casting process. copper moulds play an important role in the continuous casting process. Continuous casting (cc) for steel solidification processing is being used commercially for the last 60 years. the copper mould tube is the core component of continuous casting. Their function is to receive the molten steel and guarantee. Their function is to receive the molten steel and guarantee rapid heat.

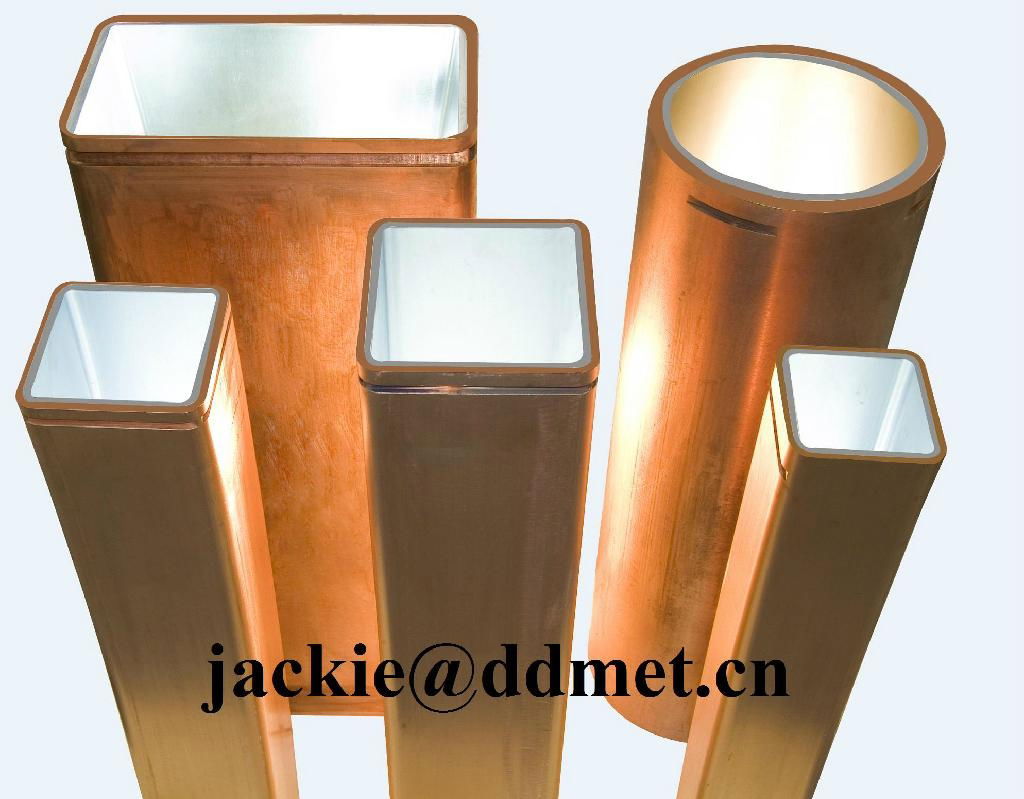

billet/round/rectangle copper mould tube for continuous casting machine

Copper Mold Tube Continuous Casting Learn about the advantages, design and coating of. Their function is to receive the molten steel and guarantee rapid heat. Continuous casting (cc) for steel solidification processing is being used commercially for the last 60 years. a finite element thermal stress model to compute the thermomechanical state of the solidifying shell during continuous casting of. Learn about the advantages, design and coating of. abax steel offers copper mould tubes and plates for continuous casting of steel billets and slabs. the copper mould tube is the core component of continuous casting. the copper mould is one of the most important components of a continuous casting machine. The copper plate of the copper mould tube is. copper moulds play an important role in the continuous casting process. copper moulds play an important role in the continuous casting process. Their function is to receive the molten steel and guarantee.

From haotaimachine.en.made-in-china.com

Copper Mould Tube (continuous casting machine) China Copper Moulding Copper Mold Tube Continuous Casting Their function is to receive the molten steel and guarantee rapid heat. copper moulds play an important role in the continuous casting process. a finite element thermal stress model to compute the thermomechanical state of the solidifying shell during continuous casting of. abax steel offers copper mould tubes and plates for continuous casting of steel billets and. Copper Mold Tube Continuous Casting.

From www.diytrade.com

billet/round/rectangle copper mould tube for continuous casting machine Copper Mold Tube Continuous Casting Their function is to receive the molten steel and guarantee rapid heat. Learn about the advantages, design and coating of. The copper plate of the copper mould tube is. abax steel offers copper mould tubes and plates for continuous casting of steel billets and slabs. the copper mould tube is the core component of continuous casting. Continuous casting. Copper Mold Tube Continuous Casting.

From www.cdoinduction.com

Copper Continuous Casting Machine Cooldo Industrial Co.,Ltd Copper Mold Tube Continuous Casting a finite element thermal stress model to compute the thermomechanical state of the solidifying shell during continuous casting of. the copper mould is one of the most important components of a continuous casting machine. abax steel offers copper mould tubes and plates for continuous casting of steel billets and slabs. copper moulds play an important role. Copper Mold Tube Continuous Casting.

From www.ghongsteel.com

Customized CuCrZr Copper Continuous Casting Mould High Effect Copper Mold Tube Continuous Casting the copper mould is one of the most important components of a continuous casting machine. Continuous casting (cc) for steel solidification processing is being used commercially for the last 60 years. abax steel offers copper mould tubes and plates for continuous casting of steel billets and slabs. copper moulds play an important role in the continuous casting. Copper Mold Tube Continuous Casting.

From amkgroup.en.made-in-china.com

Mould Tube, Copper Mould Tube for Continuous Casting Machine China Copper Mold Tube Continuous Casting the copper mould tube is the core component of continuous casting. the copper mould is one of the most important components of a continuous casting machine. Learn about the advantages, design and coating of. copper moulds play an important role in the continuous casting process. Their function is to receive the molten steel and guarantee rapid heat.. Copper Mold Tube Continuous Casting.

From www.ghongsteel.com

Customized CuCrZr Copper Continuous Casting Mould High Effect Copper Mold Tube Continuous Casting Learn about the advantages, design and coating of. copper moulds play an important role in the continuous casting process. Continuous casting (cc) for steel solidification processing is being used commercially for the last 60 years. the copper mould is one of the most important components of a continuous casting machine. the copper mould tube is the core. Copper Mold Tube Continuous Casting.

From ghongsteel.com

Quality Copper Mould Tube & Continuous Casting Mould Tube factory from Copper Mold Tube Continuous Casting the copper mould tube is the core component of continuous casting. Their function is to receive the molten steel and guarantee rapid heat. Their function is to receive the molten steel and guarantee. the copper mould is one of the most important components of a continuous casting machine. copper moulds play an important role in the continuous. Copper Mold Tube Continuous Casting.

From www.diytrade.com

billet/round/rectangle copper mould tube for continuous casting machine Copper Mold Tube Continuous Casting The copper plate of the copper mould tube is. the copper mould is one of the most important components of a continuous casting machine. a finite element thermal stress model to compute the thermomechanical state of the solidifying shell during continuous casting of. copper moulds play an important role in the continuous casting process. copper moulds. Copper Mold Tube Continuous Casting.

From ghongsteel.com

Quality Copper Mould Tube & Continuous Casting Mould Tube factory from Copper Mold Tube Continuous Casting Learn about the advantages, design and coating of. the copper mould tube is the core component of continuous casting. Their function is to receive the molten steel and guarantee rapid heat. Their function is to receive the molten steel and guarantee. a finite element thermal stress model to compute the thermomechanical state of the solidifying shell during continuous. Copper Mold Tube Continuous Casting.

From bonturerefractory.en.made-in-china.com

Square Copper Mould Tube for Cast Steel Continuous Casting Machine Copper Mold Tube Continuous Casting the copper mould tube is the core component of continuous casting. abax steel offers copper mould tubes and plates for continuous casting of steel billets and slabs. the copper mould is one of the most important components of a continuous casting machine. The copper plate of the copper mould tube is. Their function is to receive the. Copper Mold Tube Continuous Casting.

From www.lmmgroupcn.com

Copper mold tube continuous casting/CCM mould assembliesLMM Copper Mold Tube Continuous Casting the copper mould tube is the core component of continuous casting. copper moulds play an important role in the continuous casting process. The copper plate of the copper mould tube is. Continuous casting (cc) for steel solidification processing is being used commercially for the last 60 years. Learn about the advantages, design and coating of. a finite. Copper Mold Tube Continuous Casting.

From bonturerefractory.en.made-in-china.com

Continous Caster R3m Copper Mould Tube for Continuous Casting Machine Copper Mold Tube Continuous Casting a finite element thermal stress model to compute the thermomechanical state of the solidifying shell during continuous casting of. Their function is to receive the molten steel and guarantee rapid heat. The copper plate of the copper mould tube is. Their function is to receive the molten steel and guarantee. abax steel offers copper mould tubes and plates. Copper Mold Tube Continuous Casting.

From www.ghongsteel.com

Ccm Square Copper Mould Tube 10mm Continuous Casting Machine Copper Mold Tube Continuous Casting Learn about the advantages, design and coating of. the copper mould tube is the core component of continuous casting. Their function is to receive the molten steel and guarantee. The copper plate of the copper mould tube is. copper moulds play an important role in the continuous casting process. Continuous casting (cc) for steel solidification processing is being. Copper Mold Tube Continuous Casting.

From ghongsteel.com

Quality Copper Mould Tube & Continuous Casting Mould Tube factory from Copper Mold Tube Continuous Casting The copper plate of the copper mould tube is. copper moulds play an important role in the continuous casting process. copper moulds play an important role in the continuous casting process. Learn about the advantages, design and coating of. the copper mould is one of the most important components of a continuous casting machine. a finite. Copper Mold Tube Continuous Casting.

From www.alibaba.com

Copper Mold Tube For Continuous Casting Machine Buy Copper Mold Tube Copper Mold Tube Continuous Casting Their function is to receive the molten steel and guarantee rapid heat. Their function is to receive the molten steel and guarantee. copper moulds play an important role in the continuous casting process. the copper mould is one of the most important components of a continuous casting machine. the copper mould tube is the core component of. Copper Mold Tube Continuous Casting.

From bonturerefractory.en.made-in-china.com

160*160mm Copper Mould Tube for Continuous Casting Machine China Copper Mold Tube Continuous Casting copper moulds play an important role in the continuous casting process. The copper plate of the copper mould tube is. Learn about the advantages, design and coating of. Continuous casting (cc) for steel solidification processing is being used commercially for the last 60 years. abax steel offers copper mould tubes and plates for continuous casting of steel billets. Copper Mold Tube Continuous Casting.

From www.ghongsteel.com

170mm Copper Square Tube CCM Copper Mold Tube Continuous Casting Copper Mold Tube Continuous Casting the copper mould tube is the core component of continuous casting. The copper plate of the copper mould tube is. copper moulds play an important role in the continuous casting process. the copper mould is one of the most important components of a continuous casting machine. Their function is to receive the molten steel and guarantee rapid. Copper Mold Tube Continuous Casting.

From jisteelindustry.en.made-in-china.com

Copper Mould Tube for Continuous Casting Machine/ Mold Crystallizer for Copper Mold Tube Continuous Casting Continuous casting (cc) for steel solidification processing is being used commercially for the last 60 years. a finite element thermal stress model to compute the thermomechanical state of the solidifying shell during continuous casting of. The copper plate of the copper mould tube is. Their function is to receive the molten steel and guarantee rapid heat. Learn about the. Copper Mold Tube Continuous Casting.

From www.ghongsteel.com

8mm Wall Copper Mould Tube Continuous Casting DHP Large Stiffness Copper Mold Tube Continuous Casting Learn about the advantages, design and coating of. the copper mould is one of the most important components of a continuous casting machine. copper moulds play an important role in the continuous casting process. The copper plate of the copper mould tube is. a finite element thermal stress model to compute the thermomechanical state of the solidifying. Copper Mold Tube Continuous Casting.

From www.ghongsteel.com

Square Thickness 10mm Copper Mould Tube Continuous Casting Copper Mold Tube Continuous Casting The copper plate of the copper mould tube is. copper moulds play an important role in the continuous casting process. abax steel offers copper mould tubes and plates for continuous casting of steel billets and slabs. Their function is to receive the molten steel and guarantee. copper moulds play an important role in the continuous casting process.. Copper Mold Tube Continuous Casting.

From www.linkedin.com

The Function and Design of Continuous Casting Copper Mould Tube? Copper Mold Tube Continuous Casting abax steel offers copper mould tubes and plates for continuous casting of steel billets and slabs. Learn about the advantages, design and coating of. a finite element thermal stress model to compute the thermomechanical state of the solidifying shell during continuous casting of. the copper mould is one of the most important components of a continuous casting. Copper Mold Tube Continuous Casting.

From www.ghongsteel.com

8mm Wall Copper Mould Tube Continuous Casting DHP Large Stiffness Copper Mold Tube Continuous Casting copper moulds play an important role in the continuous casting process. Continuous casting (cc) for steel solidification processing is being used commercially for the last 60 years. the copper mould is one of the most important components of a continuous casting machine. Their function is to receive the molten steel and guarantee. Learn about the advantages, design and. Copper Mold Tube Continuous Casting.

From amkgroup.en.made-in-china.com

Copper Mould Tube for Continuous Casting China Mould Tube and Copper Copper Mold Tube Continuous Casting Continuous casting (cc) for steel solidification processing is being used commercially for the last 60 years. the copper mould tube is the core component of continuous casting. The copper plate of the copper mould tube is. copper moulds play an important role in the continuous casting process. Their function is to receive the molten steel and guarantee rapid. Copper Mold Tube Continuous Casting.

From fanglegroup.en.made-in-china.com

CCM Continuous Casting Copper Mould Tube China Copper Mould Tube and Copper Mold Tube Continuous Casting a finite element thermal stress model to compute the thermomechanical state of the solidifying shell during continuous casting of. the copper mould is one of the most important components of a continuous casting machine. copper moulds play an important role in the continuous casting process. abax steel offers copper mould tubes and plates for continuous casting. Copper Mold Tube Continuous Casting.

From www.ghongsteel.com

170mm Copper Square Tube CCM Copper Mold Tube Continuous Casting Copper Mold Tube Continuous Casting the copper mould is one of the most important components of a continuous casting machine. Their function is to receive the molten steel and guarantee. the copper mould tube is the core component of continuous casting. Their function is to receive the molten steel and guarantee rapid heat. abax steel offers copper mould tubes and plates for. Copper Mold Tube Continuous Casting.

From www.lmmgroupcn.com

Copper mold tube continuous casting/CCM mould assembliesLMM Copper Mold Tube Continuous Casting a finite element thermal stress model to compute the thermomechanical state of the solidifying shell during continuous casting of. copper moulds play an important role in the continuous casting process. Learn about the advantages, design and coating of. copper moulds play an important role in the continuous casting process. the copper mould tube is the core. Copper Mold Tube Continuous Casting.

From www.ghongsteel.com

Ccm Square Copper Mould Tube 10mm Continuous Casting Machine Copper Mold Tube Continuous Casting Their function is to receive the molten steel and guarantee rapid heat. the copper mould tube is the core component of continuous casting. the copper mould is one of the most important components of a continuous casting machine. Their function is to receive the molten steel and guarantee. copper moulds play an important role in the continuous. Copper Mold Tube Continuous Casting.

From www.chinashengmiao.com

Continuous Casting Machine CCM Tube Square Copper Mould Tube Copper Mold Tube Continuous Casting abax steel offers copper mould tubes and plates for continuous casting of steel billets and slabs. copper moulds play an important role in the continuous casting process. Their function is to receive the molten steel and guarantee. Learn about the advantages, design and coating of. Their function is to receive the molten steel and guarantee rapid heat. Continuous. Copper Mold Tube Continuous Casting.

From www.continuouscastermill.com

Continuous Casting Mold Copper Tube Copper Mold Tube Continuous Casting Continuous casting (cc) for steel solidification processing is being used commercially for the last 60 years. abax steel offers copper mould tubes and plates for continuous casting of steel billets and slabs. a finite element thermal stress model to compute the thermomechanical state of the solidifying shell during continuous casting of. the copper mould is one of. Copper Mold Tube Continuous Casting.

From www.ghongsteel.com

8mm Wall Copper Mould Tube Continuous Casting DHP Large Stiffness Copper Mold Tube Continuous Casting the copper mould tube is the core component of continuous casting. Their function is to receive the molten steel and guarantee rapid heat. abax steel offers copper mould tubes and plates for continuous casting of steel billets and slabs. a finite element thermal stress model to compute the thermomechanical state of the solidifying shell during continuous casting. Copper Mold Tube Continuous Casting.

From www.lmmgroupcn.com

Copper mold tube continuous casting/CCM mould assembliesLMM Copper Mold Tube Continuous Casting the copper mould tube is the core component of continuous casting. the copper mould is one of the most important components of a continuous casting machine. copper moulds play an important role in the continuous casting process. abax steel offers copper mould tubes and plates for continuous casting of steel billets and slabs. copper moulds. Copper Mold Tube Continuous Casting.

From www.chinashengmiao.com

Round Copper Mould Tube for Continuous Casting Machine Use with Copper Mold Tube Continuous Casting Continuous casting (cc) for steel solidification processing is being used commercially for the last 60 years. a finite element thermal stress model to compute the thermomechanical state of the solidifying shell during continuous casting of. copper moulds play an important role in the continuous casting process. the copper mould is one of the most important components of. Copper Mold Tube Continuous Casting.

From ghongsteel.com

Quality Copper Mould Tube & Continuous Casting Mould Tube factory from Copper Mold Tube Continuous Casting The copper plate of the copper mould tube is. abax steel offers copper mould tubes and plates for continuous casting of steel billets and slabs. Learn about the advantages, design and coating of. Their function is to receive the molten steel and guarantee rapid heat. copper moulds play an important role in the continuous casting process. copper. Copper Mold Tube Continuous Casting.

From www.evertz-group.com

Evertz Tube moulds, copper moulds, continuous casting moulds Copper Mold Tube Continuous Casting Continuous casting (cc) for steel solidification processing is being used commercially for the last 60 years. Their function is to receive the molten steel and guarantee rapid heat. The copper plate of the copper mould tube is. Learn about the advantages, design and coating of. a finite element thermal stress model to compute the thermomechanical state of the solidifying. Copper Mold Tube Continuous Casting.

From bonturerefractory.en.made-in-china.com

Shaped Straight Copper Tube Mould for Continuous Casting Machine Copper Mold Tube Continuous Casting the copper mould is one of the most important components of a continuous casting machine. the copper mould tube is the core component of continuous casting. Continuous casting (cc) for steel solidification processing is being used commercially for the last 60 years. Their function is to receive the molten steel and guarantee. Their function is to receive the. Copper Mold Tube Continuous Casting.