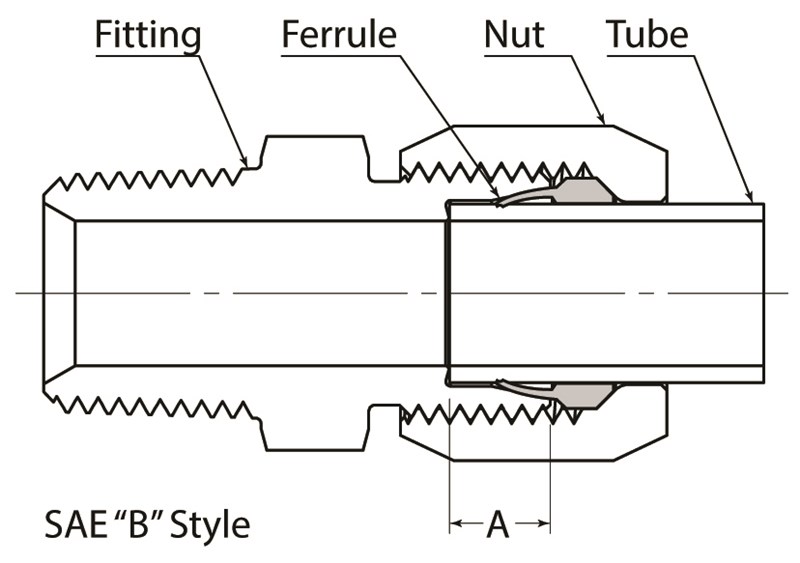

Difference Between Flare And Flareless Fittings . A flareless fitting, also referred to as a compression fitting, uses a single ferrule and a nut to make a connection, eliminating the need. Flare fittings use a coned receiver and a flared tube end. They are ideal for systems with high vibration, as they dampen vibration. Flareless fittings, on the other hand, are better suited for fittings that. Flareless fittings are used extensively to connect tubing to threaded components, such as valves and tools. Understanding the different types of flare fittings is crucial for professionals who work with hydraulic, pneumatic, gas, and refrigeration systems. Flareless fittings have a ferrule that bites into the tube. When compared to standard pipe fittings, flared. This blog will discuss both flared and flareless fittings and their specific types. What are the main differences between flare and flareless fittings? They have comprised of a nut, single or double ferrule and the fitting body. The nut and ferrule(s) slide over a tube with an od that matches the id of the receiving fitting.

from www.worldwidefittings.com

This blog will discuss both flared and flareless fittings and their specific types. Understanding the different types of flare fittings is crucial for professionals who work with hydraulic, pneumatic, gas, and refrigeration systems. What are the main differences between flare and flareless fittings? Flareless fittings have a ferrule that bites into the tube. They are ideal for systems with high vibration, as they dampen vibration. The nut and ferrule(s) slide over a tube with an od that matches the id of the receiving fitting. Flareless fittings, on the other hand, are better suited for fittings that. When compared to standard pipe fittings, flared. Flareless fittings are used extensively to connect tubing to threaded components, such as valves and tools. Flare fittings use a coned receiver and a flared tube end.

Steel Flareless Fittings World Wide Fittings

Difference Between Flare And Flareless Fittings A flareless fitting, also referred to as a compression fitting, uses a single ferrule and a nut to make a connection, eliminating the need. When compared to standard pipe fittings, flared. This blog will discuss both flared and flareless fittings and their specific types. They have comprised of a nut, single or double ferrule and the fitting body. Flareless fittings have a ferrule that bites into the tube. Flareless fittings are used extensively to connect tubing to threaded components, such as valves and tools. Understanding the different types of flare fittings is crucial for professionals who work with hydraulic, pneumatic, gas, and refrigeration systems. Flare fittings use a coned receiver and a flared tube end. What are the main differences between flare and flareless fittings? Flareless fittings, on the other hand, are better suited for fittings that. A flareless fitting, also referred to as a compression fitting, uses a single ferrule and a nut to make a connection, eliminating the need. They are ideal for systems with high vibration, as they dampen vibration. The nut and ferrule(s) slide over a tube with an od that matches the id of the receiving fitting.

From www.eaton.com

Tube fittings Hose fittings and connectors Eaton Models or Difference Between Flare And Flareless Fittings What are the main differences between flare and flareless fittings? A flareless fitting, also referred to as a compression fitting, uses a single ferrule and a nut to make a connection, eliminating the need. The nut and ferrule(s) slide over a tube with an od that matches the id of the receiving fitting. They are ideal for systems with high. Difference Between Flare And Flareless Fittings.

From www.scribd.com

AN & MS Flared & Flareless Tube Hydraulic Fittings Example of Part Difference Between Flare And Flareless Fittings This blog will discuss both flared and flareless fittings and their specific types. Flareless fittings, on the other hand, are better suited for fittings that. The nut and ferrule(s) slide over a tube with an od that matches the id of the receiving fitting. Understanding the different types of flare fittings is crucial for professionals who work with hydraulic, pneumatic,. Difference Between Flare And Flareless Fittings.

From www.agproud.com

Mechanics Corner Dry technology Oring face seal, flareless bitetype Difference Between Flare And Flareless Fittings A flareless fitting, also referred to as a compression fitting, uses a single ferrule and a nut to make a connection, eliminating the need. They have comprised of a nut, single or double ferrule and the fitting body. When compared to standard pipe fittings, flared. They are ideal for systems with high vibration, as they dampen vibration. Understanding the different. Difference Between Flare And Flareless Fittings.

From www.qchydraulics.com

flare vs compression fittings QC Hydraulics Difference Between Flare And Flareless Fittings Understanding the different types of flare fittings is crucial for professionals who work with hydraulic, pneumatic, gas, and refrigeration systems. A flareless fitting, also referred to as a compression fitting, uses a single ferrule and a nut to make a connection, eliminating the need. This blog will discuss both flared and flareless fittings and their specific types. What are the. Difference Between Flare And Flareless Fittings.

From www.qchydraulics.com

flare vs compression fittings QC Hydraulics Difference Between Flare And Flareless Fittings What are the main differences between flare and flareless fittings? They are ideal for systems with high vibration, as they dampen vibration. The nut and ferrule(s) slide over a tube with an od that matches the id of the receiving fitting. A flareless fitting, also referred to as a compression fitting, uses a single ferrule and a nut to make. Difference Between Flare And Flareless Fittings.

From www.cntopa.com

Flared or Flareless Fittings What is The Difference? Topa Difference Between Flare And Flareless Fittings Flare fittings use a coned receiver and a flared tube end. When compared to standard pipe fittings, flared. Flareless fittings have a ferrule that bites into the tube. They are ideal for systems with high vibration, as they dampen vibration. A flareless fitting, also referred to as a compression fitting, uses a single ferrule and a nut to make a. Difference Between Flare And Flareless Fittings.

From blog.thepipingmart.com

Flare Fittings vs Compression Fittings What's the Difference Difference Between Flare And Flareless Fittings The nut and ferrule(s) slide over a tube with an od that matches the id of the receiving fitting. What are the main differences between flare and flareless fittings? When compared to standard pipe fittings, flared. They are ideal for systems with high vibration, as they dampen vibration. Flareless fittings are used extensively to connect tubing to threaded components, such. Difference Between Flare And Flareless Fittings.

From www.cntopa.com

Flared or Flareless Fittings What is The Difference? Topa Difference Between Flare And Flareless Fittings Flareless fittings have a ferrule that bites into the tube. Understanding the different types of flare fittings is crucial for professionals who work with hydraulic, pneumatic, gas, and refrigeration systems. What are the main differences between flare and flareless fittings? A flareless fitting, also referred to as a compression fitting, uses a single ferrule and a nut to make a. Difference Between Flare And Flareless Fittings.

From www.trickstrend.com

Different Kinds of Fittings ORFS, AN, and Flareless The Tricks Trend Difference Between Flare And Flareless Fittings They have comprised of a nut, single or double ferrule and the fitting body. What are the main differences between flare and flareless fittings? Understanding the different types of flare fittings is crucial for professionals who work with hydraulic, pneumatic, gas, and refrigeration systems. The nut and ferrule(s) slide over a tube with an od that matches the id of. Difference Between Flare And Flareless Fittings.

From www.cntopa.com

Flared or Flareless Fittings What is The Difference? Topa Difference Between Flare And Flareless Fittings A flareless fitting, also referred to as a compression fitting, uses a single ferrule and a nut to make a connection, eliminating the need. Flareless fittings are used extensively to connect tubing to threaded components, such as valves and tools. Understanding the different types of flare fittings is crucial for professionals who work with hydraulic, pneumatic, gas, and refrigeration systems.. Difference Between Flare And Flareless Fittings.

From piperindustries.com

Piper Industries Flareless Fittings Difference Between Flare And Flareless Fittings They have comprised of a nut, single or double ferrule and the fitting body. This blog will discuss both flared and flareless fittings and their specific types. Flareless fittings have a ferrule that bites into the tube. Understanding the different types of flare fittings is crucial for professionals who work with hydraulic, pneumatic, gas, and refrigeration systems. Flare fittings use. Difference Between Flare And Flareless Fittings.

From www.superlokworld.com

Inside Scoop Comparing Double Ferrule & Single Ferrule Fittings Difference Between Flare And Flareless Fittings Understanding the different types of flare fittings is crucial for professionals who work with hydraulic, pneumatic, gas, and refrigeration systems. This blog will discuss both flared and flareless fittings and their specific types. They have comprised of a nut, single or double ferrule and the fitting body. The nut and ferrule(s) slide over a tube with an od that matches. Difference Between Flare And Flareless Fittings.

From www.pipingmaterial.ae

MS Hydraulic Fittings Military Standard flareless fittings suppliers Difference Between Flare And Flareless Fittings When compared to standard pipe fittings, flared. They have comprised of a nut, single or double ferrule and the fitting body. They are ideal for systems with high vibration, as they dampen vibration. Flareless fittings have a ferrule that bites into the tube. Understanding the different types of flare fittings is crucial for professionals who work with hydraulic, pneumatic, gas,. Difference Between Flare And Flareless Fittings.

From www.omega1.com

OmegaBite Advantages of Flareless Tube Fittings Difference Between Flare And Flareless Fittings What are the main differences between flare and flareless fittings? The nut and ferrule(s) slide over a tube with an od that matches the id of the receiving fitting. They are ideal for systems with high vibration, as they dampen vibration. Flareless fittings have a ferrule that bites into the tube. Flare fittings use a coned receiver and a flared. Difference Between Flare And Flareless Fittings.

From hydraxio.com

Flare VS Flareless Tube Fittings Hydraxio China SS Hydraulic Difference Between Flare And Flareless Fittings They are ideal for systems with high vibration, as they dampen vibration. This blog will discuss both flared and flareless fittings and their specific types. Flare fittings use a coned receiver and a flared tube end. They have comprised of a nut, single or double ferrule and the fitting body. A flareless fitting, also referred to as a compression fitting,. Difference Between Flare And Flareless Fittings.

From www.rhhardware.com

Flare vs. Flareless Choosing the Right Fitting Yuyao Ruihua Hardware Difference Between Flare And Flareless Fittings Understanding the different types of flare fittings is crucial for professionals who work with hydraulic, pneumatic, gas, and refrigeration systems. When compared to standard pipe fittings, flared. Flareless fittings are used extensively to connect tubing to threaded components, such as valves and tools. Flare fittings use a coned receiver and a flared tube end. Flareless fittings, on the other hand,. Difference Between Flare And Flareless Fittings.

From www.youtube.com

How to Measure Thread Sizes NPT Fittings, Flare Fittings, and Difference Between Flare And Flareless Fittings Flareless fittings, on the other hand, are better suited for fittings that. They have comprised of a nut, single or double ferrule and the fitting body. They are ideal for systems with high vibration, as they dampen vibration. When compared to standard pipe fittings, flared. Flareless fittings are used extensively to connect tubing to threaded components, such as valves and. Difference Between Flare And Flareless Fittings.

From brennaninc.com

Hydraulic Fitting Identification and Connection Types Difference Between Flare And Flareless Fittings What are the main differences between flare and flareless fittings? A flareless fitting, also referred to as a compression fitting, uses a single ferrule and a nut to make a connection, eliminating the need. The nut and ferrule(s) slide over a tube with an od that matches the id of the receiving fitting. Flareless fittings are used extensively to connect. Difference Between Flare And Flareless Fittings.

From www.mcneilinstruments.com

Difference between Flare Male Connector and Flare Union Tee Difference Between Flare And Flareless Fittings Flare fittings use a coned receiver and a flared tube end. Flareless fittings are used extensively to connect tubing to threaded components, such as valves and tools. Flareless fittings, on the other hand, are better suited for fittings that. They are ideal for systems with high vibration, as they dampen vibration. Understanding the different types of flare fittings is crucial. Difference Between Flare And Flareless Fittings.

From www.cntopa.com

Flared or Flareless Fittings What is The Difference? Topa Difference Between Flare And Flareless Fittings This blog will discuss both flared and flareless fittings and their specific types. Flare fittings use a coned receiver and a flared tube end. They have comprised of a nut, single or double ferrule and the fitting body. When compared to standard pipe fittings, flared. The nut and ferrule(s) slide over a tube with an od that matches the id. Difference Between Flare And Flareless Fittings.

From www.rhhardware.com

Flare vs. Flareless Choosing the Right Fitting Yuyao Ruihua Hardware Difference Between Flare And Flareless Fittings The nut and ferrule(s) slide over a tube with an od that matches the id of the receiving fitting. They are ideal for systems with high vibration, as they dampen vibration. Flareless fittings, on the other hand, are better suited for fittings that. This blog will discuss both flared and flareless fittings and their specific types. When compared to standard. Difference Between Flare And Flareless Fittings.

From www.smartlockfitting.com

Benefits of Flareless Fittings Learn More SmartLock Difference Between Flare And Flareless Fittings They have comprised of a nut, single or double ferrule and the fitting body. The nut and ferrule(s) slide over a tube with an od that matches the id of the receiving fitting. They are ideal for systems with high vibration, as they dampen vibration. Understanding the different types of flare fittings is crucial for professionals who work with hydraulic,. Difference Between Flare And Flareless Fittings.

From www.cntopa.com

Flared or Flareless Fittings What is The Difference? Topa Difference Between Flare And Flareless Fittings This blog will discuss both flared and flareless fittings and their specific types. When compared to standard pipe fittings, flared. Flareless fittings, on the other hand, are better suited for fittings that. What are the main differences between flare and flareless fittings? The nut and ferrule(s) slide over a tube with an od that matches the id of the receiving. Difference Between Flare And Flareless Fittings.

From armyaviation.tpub.com

Figure 27. Flareless and Flared Fittings. Difference Between Flare And Flareless Fittings When compared to standard pipe fittings, flared. Flareless fittings are used extensively to connect tubing to threaded components, such as valves and tools. A flareless fitting, also referred to as a compression fitting, uses a single ferrule and a nut to make a connection, eliminating the need. Flare fittings use a coned receiver and a flared tube end. They are. Difference Between Flare And Flareless Fittings.

From aviationmiscmanuals.tpub.com

Figure 418. MS Flareless Fittings Difference Between Flare And Flareless Fittings A flareless fitting, also referred to as a compression fitting, uses a single ferrule and a nut to make a connection, eliminating the need. Flareless fittings are used extensively to connect tubing to threaded components, such as valves and tools. What are the main differences between flare and flareless fittings? This blog will discuss both flared and flareless fittings and. Difference Between Flare And Flareless Fittings.

From www.worldwidefittings.com

Steel Flareless Fittings World Wide Fittings Difference Between Flare And Flareless Fittings What are the main differences between flare and flareless fittings? The nut and ferrule(s) slide over a tube with an od that matches the id of the receiving fitting. They have comprised of a nut, single or double ferrule and the fitting body. Flareless fittings, on the other hand, are better suited for fittings that. Flare fittings use a coned. Difference Between Flare And Flareless Fittings.

From www.qchydraulics.com

Flared vs Flareless Fittings QC Hydraulics Difference Between Flare And Flareless Fittings Flareless fittings have a ferrule that bites into the tube. They are ideal for systems with high vibration, as they dampen vibration. When compared to standard pipe fittings, flared. They have comprised of a nut, single or double ferrule and the fitting body. Flareless fittings, on the other hand, are better suited for fittings that. A flareless fitting, also referred. Difference Between Flare And Flareless Fittings.

From www.cntopa.com

Flared or Flareless Fittings What is The Difference? Topa Difference Between Flare And Flareless Fittings Flare fittings use a coned receiver and a flared tube end. Flareless fittings have a ferrule that bites into the tube. Understanding the different types of flare fittings is crucial for professionals who work with hydraulic, pneumatic, gas, and refrigeration systems. Flareless fittings, on the other hand, are better suited for fittings that. They are ideal for systems with high. Difference Between Flare And Flareless Fittings.

From avstop.com

MS Flareless Fittings Difference Between Flare And Flareless Fittings Flareless fittings have a ferrule that bites into the tube. This blog will discuss both flared and flareless fittings and their specific types. The nut and ferrule(s) slide over a tube with an od that matches the id of the receiving fitting. When compared to standard pipe fittings, flared. What are the main differences between flare and flareless fittings? Understanding. Difference Between Flare And Flareless Fittings.

From blog.thepipingmart.com

37 Degree Flare Fittings vs 45 Degree Flare Fittings What's the Difference Between Flare And Flareless Fittings A flareless fitting, also referred to as a compression fitting, uses a single ferrule and a nut to make a connection, eliminating the need. Flareless fittings are used extensively to connect tubing to threaded components, such as valves and tools. The nut and ferrule(s) slide over a tube with an od that matches the id of the receiving fitting. Flareless. Difference Between Flare And Flareless Fittings.

From www.qchydraulics.com

Inverted Flare vs Double Flare What's the Key Difference QC Hydraulics Difference Between Flare And Flareless Fittings They are ideal for systems with high vibration, as they dampen vibration. Understanding the different types of flare fittings is crucial for professionals who work with hydraulic, pneumatic, gas, and refrigeration systems. This blog will discuss both flared and flareless fittings and their specific types. Flareless fittings have a ferrule that bites into the tube. A flareless fitting, also referred. Difference Between Flare And Flareless Fittings.

From www.cntopa.com

Flared or Flareless Fittings What is The Difference? Topa Difference Between Flare And Flareless Fittings When compared to standard pipe fittings, flared. Flareless fittings, on the other hand, are better suited for fittings that. A flareless fitting, also referred to as a compression fitting, uses a single ferrule and a nut to make a connection, eliminating the need. They have comprised of a nut, single or double ferrule and the fitting body. Flare fittings use. Difference Between Flare And Flareless Fittings.

From www.cntopa.com

Flared or Flareless Fittings What is The Difference? Topa Difference Between Flare And Flareless Fittings A flareless fitting, also referred to as a compression fitting, uses a single ferrule and a nut to make a connection, eliminating the need. Flareless fittings have a ferrule that bites into the tube. The nut and ferrule(s) slide over a tube with an od that matches the id of the receiving fitting. Flareless fittings are used extensively to connect. Difference Between Flare And Flareless Fittings.

From hydraxio.com

Flare VS Flareless Tube Fittings Hydraxio China SS Hydraulic Difference Between Flare And Flareless Fittings What are the main differences between flare and flareless fittings? This blog will discuss both flared and flareless fittings and their specific types. Understanding the different types of flare fittings is crucial for professionals who work with hydraulic, pneumatic, gas, and refrigeration systems. They are ideal for systems with high vibration, as they dampen vibration. Flareless fittings, on the other. Difference Between Flare And Flareless Fittings.

From hydraxio.com

Flare VS Flareless Tube Fittings Hydraxio China SS Hydraulic Difference Between Flare And Flareless Fittings This blog will discuss both flared and flareless fittings and their specific types. Flareless fittings have a ferrule that bites into the tube. When compared to standard pipe fittings, flared. Understanding the different types of flare fittings is crucial for professionals who work with hydraulic, pneumatic, gas, and refrigeration systems. Flareless fittings, on the other hand, are better suited for. Difference Between Flare And Flareless Fittings.