Abrasive Wheel Mounting . maintain a clearance (undercut relief) of at least 3 mm (1/8 in.) to prevent pressure on the wheel near the hole. in addition to looking at essential training needs, the guide also focuses on details such as: ansi b7.1 is the abrasive (grinding) wheel industry standard for the “safety requirements for the use, care,. Handle and store grinding wheels in a careful manner. abrasive wheels are marked to identify their characteristics. the abrasive wheel should be mounted between recessed flanges of equal diameter which are usually at least one third of the diameter of the wheel. proper steps in mounting a grinding wheel are as follows: Check the surface of the abrasive wheel and. check the surface of the abrasive wheel and flanges to ensure that no particles are present. abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles bonded. Persons responsible for wheel mounting should be able to recognise the. The contact faces of the flanges must be free of burrs or rough edges which may

from iadc.org

the abrasive wheel should be mounted between recessed flanges of equal diameter which are usually at least one third of the diameter of the wheel. in addition to looking at essential training needs, the guide also focuses on details such as: The contact faces of the flanges must be free of burrs or rough edges which may maintain a clearance (undercut relief) of at least 3 mm (1/8 in.) to prevent pressure on the wheel near the hole. Handle and store grinding wheels in a careful manner. abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles bonded. ansi b7.1 is the abrasive (grinding) wheel industry standard for the “safety requirements for the use, care,. abrasive wheels are marked to identify their characteristics. proper steps in mounting a grinding wheel are as follows: Persons responsible for wheel mounting should be able to recognise the.

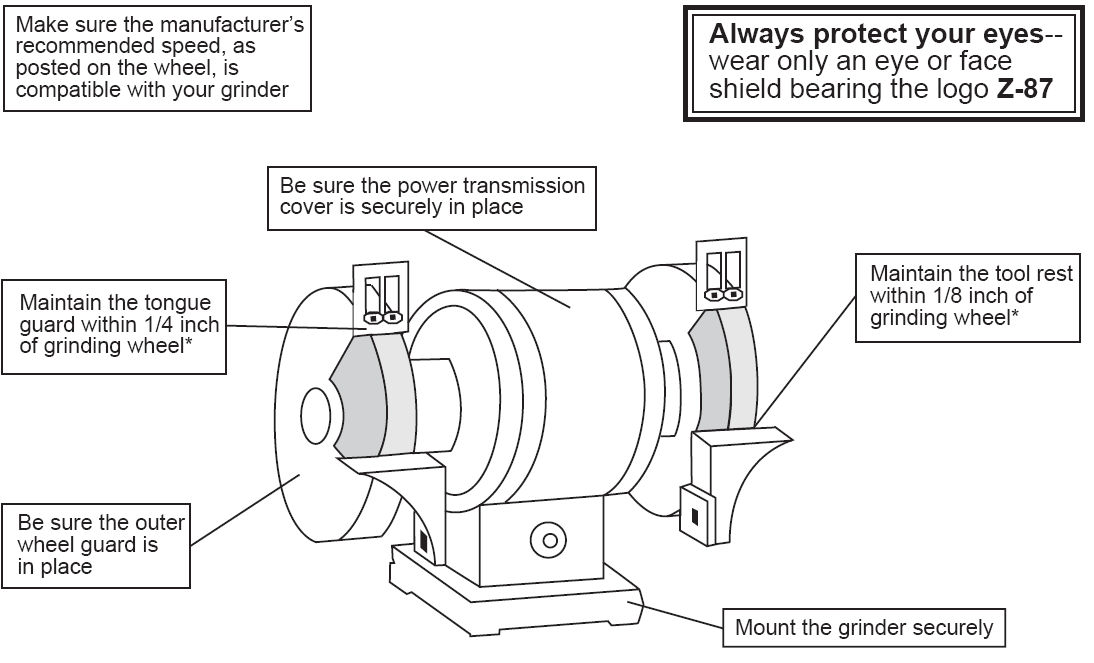

Abrasive WheelEquipped Grinders Checklist

Abrasive Wheel Mounting proper steps in mounting a grinding wheel are as follows: proper steps in mounting a grinding wheel are as follows: abrasive wheels are marked to identify their characteristics. Persons responsible for wheel mounting should be able to recognise the. The contact faces of the flanges must be free of burrs or rough edges which may ansi b7.1 is the abrasive (grinding) wheel industry standard for the “safety requirements for the use, care,. check the surface of the abrasive wheel and flanges to ensure that no particles are present. Check the surface of the abrasive wheel and. the abrasive wheel should be mounted between recessed flanges of equal diameter which are usually at least one third of the diameter of the wheel. in addition to looking at essential training needs, the guide also focuses on details such as: maintain a clearance (undercut relief) of at least 3 mm (1/8 in.) to prevent pressure on the wheel near the hole. abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles bonded. Handle and store grinding wheels in a careful manner.

From www.youtube.com

Safety Series How to mount an abrasive wheel YouTube Abrasive Wheel Mounting The contact faces of the flanges must be free of burrs or rough edges which may Persons responsible for wheel mounting should be able to recognise the. Handle and store grinding wheels in a careful manner. maintain a clearance (undercut relief) of at least 3 mm (1/8 in.) to prevent pressure on the wheel near the hole. abrasive. Abrasive Wheel Mounting.

From www.grainger.com

3M 3 in Unitized Abrasive Wheel, 1/4 in W, TR Mounting Size, Medium Abrasive Wheel Mounting abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles bonded. the abrasive wheel should be mounted between recessed flanges of equal diameter which are usually at least one third of the diameter of the wheel. abrasive wheels are marked to identify their characteristics. Handle and store grinding wheels in. Abrasive Wheel Mounting.

From www.eastwoodmachinery.co.uk

Abrasive wheels EMS Eastwood Machinery Services Woodworking Abrasive Wheel Mounting check the surface of the abrasive wheel and flanges to ensure that no particles are present. Handle and store grinding wheels in a careful manner. maintain a clearance (undercut relief) of at least 3 mm (1/8 in.) to prevent pressure on the wheel near the hole. ansi b7.1 is the abrasive (grinding) wheel industry standard for the. Abrasive Wheel Mounting.

From www.ethiretraining.com

The Safe Use Of Abrasive Wheel ET Hire Training Abrasive Wheel Mounting proper steps in mounting a grinding wheel are as follows: check the surface of the abrasive wheel and flanges to ensure that no particles are present. abrasive wheels are marked to identify their characteristics. Check the surface of the abrasive wheel and. the abrasive wheel should be mounted between recessed flanges of equal diameter which are. Abrasive Wheel Mounting.

From www.pinterest.com

8 points common knowledge of grinding wheel safety Forture Tools Abrasive Wheel Mounting in addition to looking at essential training needs, the guide also focuses on details such as: Persons responsible for wheel mounting should be able to recognise the. Handle and store grinding wheels in a careful manner. Check the surface of the abrasive wheel and. check the surface of the abrasive wheel and flanges to ensure that no particles. Abrasive Wheel Mounting.

From dxowcshfg.blob.core.windows.net

Abrasive Flap Wheel For Stainless Steel at Angie Phillips blog Abrasive Wheel Mounting check the surface of the abrasive wheel and flanges to ensure that no particles are present. abrasive wheels are marked to identify their characteristics. ansi b7.1 is the abrasive (grinding) wheel industry standard for the “safety requirements for the use, care,. Check the surface of the abrasive wheel and. abrasive wheel characteristics 8 an abrasive wheel. Abrasive Wheel Mounting.

From www.youtube.com

MOUNTING OF GRINDING WHEEL Changing New Grinding Wheel YouTube Abrasive Wheel Mounting Handle and store grinding wheels in a careful manner. check the surface of the abrasive wheel and flanges to ensure that no particles are present. the abrasive wheel should be mounted between recessed flanges of equal diameter which are usually at least one third of the diameter of the wheel. The contact faces of the flanges must be. Abrasive Wheel Mounting.

From wmcgalway.com

Abrasive Wheel Mounting Western Management Centre Training in Galway Abrasive Wheel Mounting Check the surface of the abrasive wheel and. Handle and store grinding wheels in a careful manner. The contact faces of the flanges must be free of burrs or rough edges which may Persons responsible for wheel mounting should be able to recognise the. in addition to looking at essential training needs, the guide also focuses on details such. Abrasive Wheel Mounting.

From iadc.org

Abrasive WheelEquipped Grinders Checklist Abrasive Wheel Mounting abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles bonded. The contact faces of the flanges must be free of burrs or rough edges which may maintain a clearance (undercut relief) of at least 3 mm (1/8 in.) to prevent pressure on the wheel near the hole. the abrasive. Abrasive Wheel Mounting.

From www.mscdirect.com

Mounted Abrasive Wheel Abrasive Wheel Mounting check the surface of the abrasive wheel and flanges to ensure that no particles are present. Check the surface of the abrasive wheel and. ansi b7.1 is the abrasive (grinding) wheel industry standard for the “safety requirements for the use, care,. abrasive wheels are marked to identify their characteristics. maintain a clearance (undercut relief) of at. Abrasive Wheel Mounting.

From www.jjtraininguk.com

Abrasive Wheels JJ Training (UK) Limited Abrasive Wheel Mounting in addition to looking at essential training needs, the guide also focuses on details such as: Handle and store grinding wheels in a careful manner. The contact faces of the flanges must be free of burrs or rough edges which may abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles. Abrasive Wheel Mounting.

From www.safework.nsw.gov.au

Safe use of abrasive wheels fact sheet SafeWork NSW Abrasive Wheel Mounting abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles bonded. ansi b7.1 is the abrasive (grinding) wheel industry standard for the “safety requirements for the use, care,. Persons responsible for wheel mounting should be able to recognise the. Handle and store grinding wheels in a careful manner. Check the surface. Abrasive Wheel Mounting.

From echo-3.co.uk

Guide to Abrasive Wheels What you need to know to work safely Abrasive Wheel Mounting Handle and store grinding wheels in a careful manner. The contact faces of the flanges must be free of burrs or rough edges which may Check the surface of the abrasive wheel and. maintain a clearance (undercut relief) of at least 3 mm (1/8 in.) to prevent pressure on the wheel near the hole. proper steps in mounting. Abrasive Wheel Mounting.

From www.aliexpress.com

Buy 3mm Shank Cylinder Abrasive Mounted Grinding Wheel Abrasive Wheel Mounting check the surface of the abrasive wheel and flanges to ensure that no particles are present. ansi b7.1 is the abrasive (grinding) wheel industry standard for the “safety requirements for the use, care,. Handle and store grinding wheels in a careful manner. The contact faces of the flanges must be free of burrs or rough edges which may. Abrasive Wheel Mounting.

From www.unitedabrasives.com

A60R United Abrasives Abrasive Wheel Mounting the abrasive wheel should be mounted between recessed flanges of equal diameter which are usually at least one third of the diameter of the wheel. Persons responsible for wheel mounting should be able to recognise the. proper steps in mounting a grinding wheel are as follows: maintain a clearance (undercut relief) of at least 3 mm (1/8. Abrasive Wheel Mounting.

From www.mscdirect.com

Superior Abrasives Mounted Flap Wheel 3" Dia, 2" Face Width Abrasive Wheel Mounting The contact faces of the flanges must be free of burrs or rough edges which may abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles bonded. ansi b7.1 is the abrasive (grinding) wheel industry standard for the “safety requirements for the use, care,. in addition to looking at essential. Abrasive Wheel Mounting.

From www.ihasco.co.uk

Abrasive Wheel Safety Training IIRSM & CPD Accredited iHasco Abrasive Wheel Mounting proper steps in mounting a grinding wheel are as follows: the abrasive wheel should be mounted between recessed flanges of equal diameter which are usually at least one third of the diameter of the wheel. ansi b7.1 is the abrasive (grinding) wheel industry standard for the “safety requirements for the use, care,. in addition to looking. Abrasive Wheel Mounting.

From essentialsiteskills.co.uk

The ESS Guide to Abrasive Wheels Training Essential Site Skills Abrasive Wheel Mounting in addition to looking at essential training needs, the guide also focuses on details such as: the abrasive wheel should be mounted between recessed flanges of equal diameter which are usually at least one third of the diameter of the wheel. check the surface of the abrasive wheel and flanges to ensure that no particles are present.. Abrasive Wheel Mounting.

From www.ihasco.co.uk

Abrasive Wheel Safety Training IIRSM & CPD Accredited iHasco Abrasive Wheel Mounting in addition to looking at essential training needs, the guide also focuses on details such as: The contact faces of the flanges must be free of burrs or rough edges which may check the surface of the abrasive wheel and flanges to ensure that no particles are present. Handle and store grinding wheels in a careful manner. . Abrasive Wheel Mounting.

From www.slideserve.com

PPT ABRASIVE WHEEL MACHINERY OSHA 29 CFR 1910.215 PowerPoint Abrasive Wheel Mounting The contact faces of the flanges must be free of burrs or rough edges which may abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles bonded. abrasive wheels are marked to identify their characteristics. maintain a clearance (undercut relief) of at least 3 mm (1/8 in.) to prevent pressure. Abrasive Wheel Mounting.

From www.aliexpress.com

Buy 10pc Multi Tool Grinding Burr Wheel 1/8 Shank Blue Abrasive Wheel Mounting maintain a clearance (undercut relief) of at least 3 mm (1/8 in.) to prevent pressure on the wheel near the hole. the abrasive wheel should be mounted between recessed flanges of equal diameter which are usually at least one third of the diameter of the wheel. abrasive wheel characteristics 8 an abrasive wheel is usually defined as. Abrasive Wheel Mounting.

From www.harborfreight.com

2 in. Shaft Mounted Polycarbide Abrasive Wheel Abrasive Wheel Mounting check the surface of the abrasive wheel and flanges to ensure that no particles are present. Persons responsible for wheel mounting should be able to recognise the. Handle and store grinding wheels in a careful manner. the abrasive wheel should be mounted between recessed flanges of equal diameter which are usually at least one third of the diameter. Abrasive Wheel Mounting.

From www.harborfreight.com

4 in. Shaft Mounted Polycarbide Abrasive Wheel Abrasive Wheel Mounting abrasive wheels are marked to identify their characteristics. Check the surface of the abrasive wheel and. The contact faces of the flanges must be free of burrs or rough edges which may ansi b7.1 is the abrasive (grinding) wheel industry standard for the “safety requirements for the use, care,. Persons responsible for wheel mounting should be able to. Abrasive Wheel Mounting.

From www.btp-cumbria.co.uk

The mounting of abrasive wheels Barrow Training Partnership Abrasive Wheel Mounting maintain a clearance (undercut relief) of at least 3 mm (1/8 in.) to prevent pressure on the wheel near the hole. abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles bonded. check the surface of the abrasive wheel and flanges to ensure that no particles are present. ansi. Abrasive Wheel Mounting.

From www.tr-training.co.uk

Abrasive Wheels Training TR Training Abrasive Wheel Mounting in addition to looking at essential training needs, the guide also focuses on details such as: maintain a clearance (undercut relief) of at least 3 mm (1/8 in.) to prevent pressure on the wheel near the hole. check the surface of the abrasive wheel and flanges to ensure that no particles are present. Check the surface of. Abrasive Wheel Mounting.

From www.indiamart.com

Shank Abrasive Mounted Stone Rotary Grinding Wheels 10 Pcs Set at Rs Abrasive Wheel Mounting ansi b7.1 is the abrasive (grinding) wheel industry standard for the “safety requirements for the use, care,. abrasive wheels are marked to identify their characteristics. proper steps in mounting a grinding wheel are as follows: Check the surface of the abrasive wheel and. check the surface of the abrasive wheel and flanges to ensure that no. Abrasive Wheel Mounting.

From www.grainger.com

UNITED ABRASIVESSAIT, 3 in Abrasive Wheel Dia, Ceramic, Abrasive Cut Abrasive Wheel Mounting Handle and store grinding wheels in a careful manner. abrasive wheels are marked to identify their characteristics. ansi b7.1 is the abrasive (grinding) wheel industry standard for the “safety requirements for the use, care,. check the surface of the abrasive wheel and flanges to ensure that no particles are present. Check the surface of the abrasive wheel. Abrasive Wheel Mounting.

From www.youtube.com

Proper Mounting of Abrasive Products on Type 27 Grinders and Type 1 Cut Abrasive Wheel Mounting abrasive wheels are marked to identify their characteristics. in addition to looking at essential training needs, the guide also focuses on details such as: abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles bonded. Check the surface of the abrasive wheel and. ansi b7.1 is the abrasive (grinding). Abrasive Wheel Mounting.

From www.indiamart.com

Abrasive Mounting Wheel at Rs 20/piece Ahmedabad ID 24220641333 Abrasive Wheel Mounting abrasive wheels are marked to identify their characteristics. Handle and store grinding wheels in a careful manner. in addition to looking at essential training needs, the guide also focuses on details such as: the abrasive wheel should be mounted between recessed flanges of equal diameter which are usually at least one third of the diameter of the. Abrasive Wheel Mounting.

From www.walmart.com

Abrasive Wheels 80mmx40mm Buffing Polishing Wheels with 6mm Shank 3pcs Abrasive Wheel Mounting check the surface of the abrasive wheel and flanges to ensure that no particles are present. proper steps in mounting a grinding wheel are as follows: in addition to looking at essential training needs, the guide also focuses on details such as: The contact faces of the flanges must be free of burrs or rough edges which. Abrasive Wheel Mounting.

From www.grainger.com

DEWALT, 4 in Abrasive Wheel Dia, Zirconia Alumina, Abrasive Wheel Abrasive Wheel Mounting Persons responsible for wheel mounting should be able to recognise the. abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles bonded. The contact faces of the flanges must be free of burrs or rough edges which may Handle and store grinding wheels in a careful manner. the abrasive wheel should. Abrasive Wheel Mounting.

From safetymatters.ie

Abrasive Wheels Training Safety Matters Abrasive Wheel Mounting check the surface of the abrasive wheel and flanges to ensure that no particles are present. Handle and store grinding wheels in a careful manner. in addition to looking at essential training needs, the guide also focuses on details such as: The contact faces of the flanges must be free of burrs or rough edges which may Check. Abrasive Wheel Mounting.

From www.moleroda.com

Abrasive Wheels Archives Moleroda Finishing Systems Abrasive Wheel Mounting The contact faces of the flanges must be free of burrs or rough edges which may Handle and store grinding wheels in a careful manner. check the surface of the abrasive wheel and flanges to ensure that no particles are present. Persons responsible for wheel mounting should be able to recognise the. proper steps in mounting a grinding. Abrasive Wheel Mounting.

From www.harborfreight.com

4 in. Shaft Mounted Polycarbide Abrasive Wheel Abrasive Wheel Mounting check the surface of the abrasive wheel and flanges to ensure that no particles are present. maintain a clearance (undercut relief) of at least 3 mm (1/8 in.) to prevent pressure on the wheel near the hole. Check the surface of the abrasive wheel and. proper steps in mounting a grinding wheel are as follows: The contact. Abrasive Wheel Mounting.