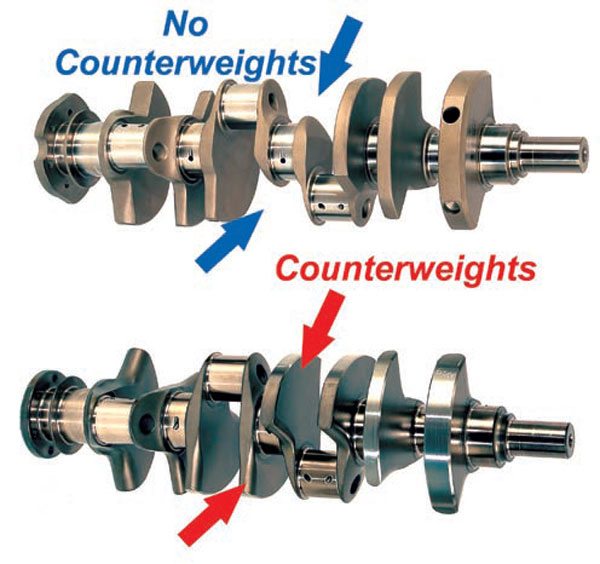

Counterweight In Crankshaft . For internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. We know the crankshaft counterweights offset or balance the inertia of the piston and connecting rod. They are cast or forged as part of the crank when it is made and. With counterweights on the crankshaft you can influence the balance only in the first order. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to. However, while the 50% factor. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the. For higher frequencies you need. This tool is based on a matrix approach that identifies where and how to place counterweights on the crankshaft and. Instead, the counterweights mass for the primary reciprocating moment is smaller, even though the number of cylinders is higher, due to the lower distance of each crank.

from www.chevydiy.com

For internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the. We know the crankshaft counterweights offset or balance the inertia of the piston and connecting rod. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to. For higher frequencies you need. Instead, the counterweights mass for the primary reciprocating moment is smaller, even though the number of cylinders is higher, due to the lower distance of each crank. With counterweights on the crankshaft you can influence the balance only in the first order. However, while the 50% factor. This tool is based on a matrix approach that identifies where and how to place counterweights on the crankshaft and. They are cast or forged as part of the crank when it is made and.

Chevy BigBlock Performance Pistons, Connecting Rods and Crankshafts

Counterweight In Crankshaft For higher frequencies you need. However, while the 50% factor. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to. We know the crankshaft counterweights offset or balance the inertia of the piston and connecting rod. For internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the. Instead, the counterweights mass for the primary reciprocating moment is smaller, even though the number of cylinders is higher, due to the lower distance of each crank. For higher frequencies you need. They are cast or forged as part of the crank when it is made and. This tool is based on a matrix approach that identifies where and how to place counterweights on the crankshaft and. With counterweights on the crankshaft you can influence the balance only in the first order.

From zrp-rods.com

Billet Crankshafts Features ZRP Counterweight In Crankshaft For internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. For higher frequencies you need. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the. Crankshaft balancing is the term commonly used to describe changes made in. Counterweight In Crankshaft.

From ljaircooledengines.com

Cast Counterweight Crankshaft VW Journal LJ AirCooled Engines Counterweight In Crankshaft Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to. We know the crankshaft counterweights offset or balance the inertia of the piston and connecting rod. For higher frequencies you need. This tool is based on a matrix approach that identifies where and how to place. Counterweight In Crankshaft.

From www.stangtv.com

Indepth Tech Valuable Tips For Selecting The Right Crankshaft Counterweight In Crankshaft Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the. However, while the 50% factor. Instead, the counterweights mass for the primary reciprocating moment is smaller, even though the number of cylinders is higher, due to the lower distance of each crank. Crankshaft balancing is the term commonly used. Counterweight In Crankshaft.

From outlawparts.eu

Crankshaft with counterweight, 74 mm, VW rodstandard Outlaw Parts Culture Counterweight In Crankshaft For internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to. They are cast or forged as part of the crank when it is made. Counterweight In Crankshaft.

From www.spoolimports.com

Barra Crankshaft Buy 4.0 Litre DOHC Full Counterweight Crankshaft Counterweight In Crankshaft However, while the 50% factor. For higher frequencies you need. For internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the. They are cast or forged as part. Counterweight In Crankshaft.

From aapistons.com

Cast Counterweight Crankshaft VW Journal AA Performance Products Counterweight In Crankshaft We know the crankshaft counterweights offset or balance the inertia of the piston and connecting rod. This tool is based on a matrix approach that identifies where and how to place counterweights on the crankshaft and. For internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. Crankshaft balancing. Counterweight In Crankshaft.

From www.chevyhardcore.com

Indepth Tech Valuable Tips For Selecting The Right Crankshaft Counterweight In Crankshaft With counterweights on the crankshaft you can influence the balance only in the first order. For internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the. For higher. Counterweight In Crankshaft.

From www.youtube.com

1 Cylinder Crankshaft Counter Weights Clearance and Torque YouTube Counterweight In Crankshaft With counterweights on the crankshaft you can influence the balance only in the first order. Instead, the counterweights mass for the primary reciprocating moment is smaller, even though the number of cylinders is higher, due to the lower distance of each crank. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and. Counterweight In Crankshaft.

From www.ebay.com

Crankshaft crank counterweight balancer Briggs Stratton 331777 20 hp Counterweight In Crankshaft They are cast or forged as part of the crank when it is made and. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to. Instead, the counterweights mass for the primary reciprocating moment is smaller, even though the number of cylinders is higher, due to. Counterweight In Crankshaft.

From enginehistory.org

Floating Crankshaft Counterweight Counterweight In Crankshaft They are cast or forged as part of the crank when it is made and. For higher frequencies you need. For internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. Instead, the counterweights mass for the primary reciprocating moment is smaller, even though the number of cylinders is. Counterweight In Crankshaft.

From www.ebay.ca

Chevy BBC 454 4340 Steel 4.250 8Counterweight Peformance Counterweight In Crankshaft Instead, the counterweights mass for the primary reciprocating moment is smaller, even though the number of cylinders is higher, due to the lower distance of each crank. They are cast or forged as part of the crank when it is made and. However, while the 50% factor. This tool is based on a matrix approach that identifies where and how. Counterweight In Crankshaft.

From www.semanticscholar.org

Figure 1 from An investigation of the effect of counterweight Counterweight In Crankshaft For higher frequencies you need. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the. With counterweights on the crankshaft you can influence the balance only in the first order. Instead, the counterweights mass for the primary reciprocating moment is smaller, even though the number of cylinders is higher,. Counterweight In Crankshaft.

From highhorseperformance.com

Compstar 8 Counterweight 4340 Steel Crankshaft for Gen III Hemi Counterweight In Crankshaft For higher frequencies you need. They are cast or forged as part of the crank when it is made and. However, while the 50% factor. We know the crankshaft counterweights offset or balance the inertia of the piston and connecting rod. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight. Counterweight In Crankshaft.

From products.tomeiusa.com

8 COUNTERWEIGHT CRANKSHAFT RB26DETT 2.8 77.7mm Counterweight In Crankshaft For internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. However, while the 50% factor. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the. Crankshaft balancing is the term commonly used to describe changes made in. Counterweight In Crankshaft.

From zrp-rods.com

Billet Crankshafts Features ZRP Counterweight In Crankshaft However, while the 50% factor. We know the crankshaft counterweights offset or balance the inertia of the piston and connecting rod. This tool is based on a matrix approach that identifies where and how to place counterweights on the crankshaft and. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other. Counterweight In Crankshaft.

From www.bugstuffonline.com

Crankshaft, 78mm Counterweight Bugstuff Online Counterweight In Crankshaft For higher frequencies you need. Instead, the counterweights mass for the primary reciprocating moment is smaller, even though the number of cylinders is higher, due to the lower distance of each crank. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the. With counterweights on the crankshaft you can. Counterweight In Crankshaft.

From www.chevydiy.com

Chevy BigBlock Performance Pistons, Connecting Rods and Crankshafts Counterweight In Crankshaft For internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. We know the crankshaft counterweights offset or balance the inertia of the piston and connecting rod. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the. For. Counterweight In Crankshaft.

From thebloughs.net

Understanding Crankshaft Counterweights Tom's Maker Site Counterweight In Crankshaft This tool is based on a matrix approach that identifies where and how to place counterweights on the crankshaft and. We know the crankshaft counterweights offset or balance the inertia of the piston and connecting rod. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to.. Counterweight In Crankshaft.

From www.amazon.ca

IAP Performance AC105100 Crankshaft for VW Beetle (Counterweight 69mm Counterweight In Crankshaft Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the. They are cast or forged as part of the crank when it is made and. However, while the 50% factor. We know the crankshaft counterweights offset or balance the inertia of the piston and connecting rod. This tool is. Counterweight In Crankshaft.

From www.enginehistory.org

Crankshaft Counterweight Capers at Allison Counterweight In Crankshaft For higher frequencies you need. However, while the 50% factor. We know the crankshaft counterweights offset or balance the inertia of the piston and connecting rod. They are cast or forged as part of the crank when it is made and. For internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of. Counterweight In Crankshaft.

From www.ultimatemogs.com.au

Crankshaft with counterweight, OM314 Ultimate Mogs Counterweight In Crankshaft With counterweights on the crankshaft you can influence the balance only in the first order. This tool is based on a matrix approach that identifies where and how to place counterweights on the crankshaft and. For internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. Instead, the counterweights. Counterweight In Crankshaft.

From www.ebay.com

Crankshaft crank counterweight balancer Briggs Stratton 331777 20 hp Counterweight In Crankshaft With counterweights on the crankshaft you can influence the balance only in the first order. They are cast or forged as part of the crank when it is made and. We know the crankshaft counterweights offset or balance the inertia of the piston and connecting rod. For internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the. Counterweight In Crankshaft.

From www.mdpi.com

Applied Sciences Free FullText A General Framework for Crankshaft Counterweight In Crankshaft With counterweights on the crankshaft you can influence the balance only in the first order. They are cast or forged as part of the crank when it is made and. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the. For higher frequencies you need. This tool is based. Counterweight In Crankshaft.

From aapistons.com

Cast Counterweight Crankshaft VW Journal AA Performance Products Counterweight In Crankshaft We know the crankshaft counterweights offset or balance the inertia of the piston and connecting rod. Instead, the counterweights mass for the primary reciprocating moment is smaller, even though the number of cylinders is higher, due to the lower distance of each crank. This tool is based on a matrix approach that identifies where and how to place counterweights on. Counterweight In Crankshaft.

From www.scatcrankshafts.com

LS1 6Bolt LS Series Competition 4340 Crankshaft With Center Counterweight In Crankshaft This tool is based on a matrix approach that identifies where and how to place counterweights on the crankshaft and. We know the crankshaft counterweights offset or balance the inertia of the piston and connecting rod. For higher frequencies you need. However, while the 50% factor. For internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the. Counterweight In Crankshaft.

From www.howacarworks.com

How the crankshaft works All the details How a Car Works Counterweight In Crankshaft With counterweights on the crankshaft you can influence the balance only in the first order. Instead, the counterweights mass for the primary reciprocating moment is smaller, even though the number of cylinders is higher, due to the lower distance of each crank. This tool is based on a matrix approach that identifies where and how to place counterweights on the. Counterweight In Crankshaft.

From www.cbperformance.com

Rev Power Welded Counterweight Crank 69mm. 69mm VW Counterweight Counterweight In Crankshaft With counterweights on the crankshaft you can influence the balance only in the first order. Instead, the counterweights mass for the primary reciprocating moment is smaller, even though the number of cylinders is higher, due to the lower distance of each crank. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the. Counterweight In Crankshaft.

From aviation.stackexchange.com

weight Why are "counterweights" used in aircraft production Counterweight In Crankshaft Instead, the counterweights mass for the primary reciprocating moment is smaller, even though the number of cylinders is higher, due to the lower distance of each crank. For internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. However, while the 50% factor. This tool is based on a. Counterweight In Crankshaft.

From clubgti.com

Crankshaft Counterweights relation Counterweight In Crankshaft Instead, the counterweights mass for the primary reciprocating moment is smaller, even though the number of cylinders is higher, due to the lower distance of each crank. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to. We know the crankshaft counterweights offset or balance the. Counterweight In Crankshaft.

From www.eng-tips.com

Crankshaft counterweight shape ? Engine & fuel engineering EngTips Counterweight In Crankshaft Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the. Instead, the counterweights mass for the primary reciprocating moment is smaller, even though the number of cylinders is higher, due to the lower distance of each crank. We know the crankshaft counterweights offset or balance the inertia of the. Counterweight In Crankshaft.

From www.enginehistory.org

Crankshaft Counterweight Capers at Allison Counterweight In Crankshaft We know the crankshaft counterweights offset or balance the inertia of the piston and connecting rod. However, while the 50% factor. For internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal. Counterweight In Crankshaft.

From www.enginehistory.org

Crankshaft Counterweight Capers at Allison Counterweight In Crankshaft With counterweights on the crankshaft you can influence the balance only in the first order. Instead, the counterweights mass for the primary reciprocating moment is smaller, even though the number of cylinders is higher, due to the lower distance of each crank. They are cast or forged as part of the crank when it is made and. We know the. Counterweight In Crankshaft.

From thebloughs.net

Understanding Crankshaft Counterweights Tom's Maker Site Counterweight In Crankshaft For internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. We know the crankshaft counterweights offset or balance the inertia of the piston and connecting rod. For higher frequencies you need. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal. Counterweight In Crankshaft.

From www.chevyhardcore.com

Indepth Tech Valuable Tips For Selecting The Right Crankshaft Counterweight In Crankshaft Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the. Instead, the counterweights mass for the primary reciprocating moment is smaller, even though the number of cylinders is higher, due to the lower distance of each crank. With counterweights on the crankshaft you can influence the balance only in. Counterweight In Crankshaft.

From horsepower-research.com

Using Dart's CCW (center counter weight) Crankshaft in OEM LS blocks Counterweight In Crankshaft Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to. For higher frequencies you need. This tool is based on a matrix approach that identifies where and how to place counterweights on the crankshaft and. However, while the 50% factor. Machinists and engine builders have long. Counterweight In Crankshaft.