Body Construction Of Fermenter . The reliable operation of a fermentation system to achieve process objectives depends on two factors: Industrial fermentors can be divided into two major classes, anaerobic and aerobic. basic design of a fermenter. The materials used for construction of fermenter withstand repeated steam. De becze and liebmann (1944) used the first large scale (above 20 litre. basic design of a fermenter. The main function of a fermenter is to provide a controlled environment for growth of a. Construction material, temperature control, agitator (impeller), stirrer glands and bearings, baffles, the aeration system (sparger), ph control sensors. The materials used for construction of fermenter withstand repeated steam sterilization and are nontoxic. basic fermenter design : The material for body construction of fermenter should be corrosion proof and. basic functions of fermenters: External, agitation & aeration, inlets and outlets. design of a fermenter.

from www.alibaba.com

basic fermenter design : basic design of a fermenter. basic design of a fermenter. The reliable operation of a fermentation system to achieve process objectives depends on two factors: Construction material, temperature control, agitator (impeller), stirrer glands and bearings, baffles, the aeration system (sparger), ph control sensors. External, agitation & aeration, inlets and outlets. The materials used for construction of fermenter withstand repeated steam sterilization and are nontoxic. basic functions of fermenters: De becze and liebmann (1944) used the first large scale (above 20 litre. The materials used for construction of fermenter withstand repeated steam.

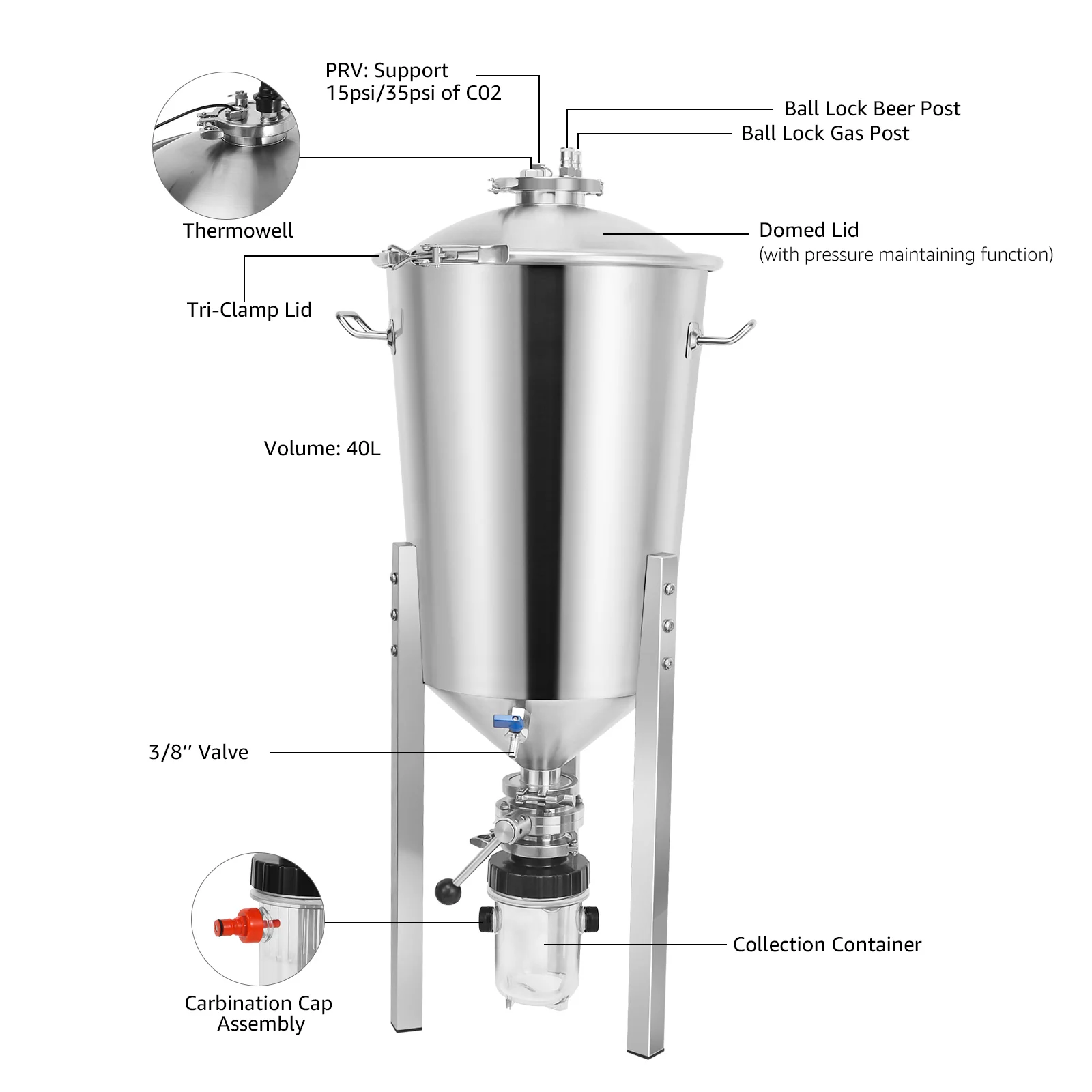

35l Pressure Stainless Conical Fermenter With Yeat Collecting Tank

Body Construction Of Fermenter De becze and liebmann (1944) used the first large scale (above 20 litre. Construction material, temperature control, agitator (impeller), stirrer glands and bearings, baffles, the aeration system (sparger), ph control sensors. The main function of a fermenter is to provide a controlled environment for growth of a. basic functions of fermenters: External, agitation & aeration, inlets and outlets. The materials used for construction of fermenter withstand repeated steam sterilization and are nontoxic. basic design of a fermenter. design of a fermenter. Industrial fermentors can be divided into two major classes, anaerobic and aerobic. De becze and liebmann (1944) used the first large scale (above 20 litre. The reliable operation of a fermentation system to achieve process objectives depends on two factors: The material for body construction of fermenter should be corrosion proof and. The materials used for construction of fermenter withstand repeated steam. basic design of a fermenter. basic fermenter design :

From davidmoore.org.uk

17.18 The Quorn fermentation and evolution in fermenters Body Construction Of Fermenter basic design of a fermenter. The reliable operation of a fermentation system to achieve process objectives depends on two factors: The material for body construction of fermenter should be corrosion proof and. basic design of a fermenter. The materials used for construction of fermenter withstand repeated steam sterilization and are nontoxic. The main function of a fermenter is. Body Construction Of Fermenter.

From biologyease.com

Types of fermenter BIOLOGY EASE Body Construction Of Fermenter The materials used for construction of fermenter withstand repeated steam sterilization and are nontoxic. External, agitation & aeration, inlets and outlets. The material for body construction of fermenter should be corrosion proof and. Industrial fermentors can be divided into two major classes, anaerobic and aerobic. De becze and liebmann (1944) used the first large scale (above 20 litre. Construction material,. Body Construction Of Fermenter.

From device.report

SF50 Conical Fermenter Instructions How to Assemble & Use Body Construction Of Fermenter basic design of a fermenter. basic design of a fermenter. The materials used for construction of fermenter withstand repeated steam. design of a fermenter. The main function of a fermenter is to provide a controlled environment for growth of a. basic fermenter design : Construction material, temperature control, agitator (impeller), stirrer glands and bearings, baffles, the. Body Construction Of Fermenter.

From quizlet.com

Chapter 21 Industrial Fermenter Diagram Quizlet Body Construction Of Fermenter basic functions of fermenters: basic fermenter design : De becze and liebmann (1944) used the first large scale (above 20 litre. The materials used for construction of fermenter withstand repeated steam sterilization and are nontoxic. Construction material, temperature control, agitator (impeller), stirrer glands and bearings, baffles, the aeration system (sparger), ph control sensors. The reliable operation of a. Body Construction Of Fermenter.

From www.zrbrew.com

1000L Stainless Conical Fermenter Body Construction Of Fermenter The reliable operation of a fermentation system to achieve process objectives depends on two factors: basic design of a fermenter. The main function of a fermenter is to provide a controlled environment for growth of a. Industrial fermentors can be divided into two major classes, anaerobic and aerobic. De becze and liebmann (1944) used the first large scale (above. Body Construction Of Fermenter.

From uberbrew.nz

Conical Fermenters with Dimple Jacket UberBrew Body Construction Of Fermenter basic design of a fermenter. De becze and liebmann (1944) used the first large scale (above 20 litre. The reliable operation of a fermentation system to achieve process objectives depends on two factors: The main function of a fermenter is to provide a controlled environment for growth of a. basic functions of fermenters: External, agitation & aeration, inlets. Body Construction Of Fermenter.

From wiki.opensourceecology.org

Fermentor Open Source Ecology Body Construction Of Fermenter Industrial fermentors can be divided into two major classes, anaerobic and aerobic. The materials used for construction of fermenter withstand repeated steam sterilization and are nontoxic. design of a fermenter. basic fermenter design : basic design of a fermenter. The reliable operation of a fermentation system to achieve process objectives depends on two factors: The materials used. Body Construction Of Fermenter.

From biologyease.com

Types of fermenter BIOLOGY EASE Body Construction Of Fermenter Construction material, temperature control, agitator (impeller), stirrer glands and bearings, baffles, the aeration system (sparger), ph control sensors. basic fermenter design : The reliable operation of a fermentation system to achieve process objectives depends on two factors: The materials used for construction of fermenter withstand repeated steam sterilization and are nontoxic. External, agitation & aeration, inlets and outlets. The. Body Construction Of Fermenter.

From www.craftbreweryequipment.com

Why fermenter design is dished head, cylindrical body and conical Body Construction Of Fermenter De becze and liebmann (1944) used the first large scale (above 20 litre. design of a fermenter. basic functions of fermenters: Construction material, temperature control, agitator (impeller), stirrer glands and bearings, baffles, the aeration system (sparger), ph control sensors. Industrial fermentors can be divided into two major classes, anaerobic and aerobic. basic fermenter design : The reliable. Body Construction Of Fermenter.

From www.psychobrew.com

7 bbl Conical Jacketed Fermenter PsychoBrew Body Construction Of Fermenter External, agitation & aeration, inlets and outlets. basic design of a fermenter. The main function of a fermenter is to provide a controlled environment for growth of a. Construction material, temperature control, agitator (impeller), stirrer glands and bearings, baffles, the aeration system (sparger), ph control sensors. De becze and liebmann (1944) used the first large scale (above 20 litre.. Body Construction Of Fermenter.

From www.youtube.com

Fermentation process Working of Fermenter Nutrient medium for Body Construction Of Fermenter Construction material, temperature control, agitator (impeller), stirrer glands and bearings, baffles, the aeration system (sparger), ph control sensors. Industrial fermentors can be divided into two major classes, anaerobic and aerobic. The material for body construction of fermenter should be corrosion proof and. The materials used for construction of fermenter withstand repeated steam sterilization and are nontoxic. The reliable operation of. Body Construction Of Fermenter.

From cedarstoneindustry.com

15 BBL ConicalBottom Fermenter (Unitank) Cedarstone Industry Body Construction Of Fermenter basic design of a fermenter. basic fermenter design : The main function of a fermenter is to provide a controlled environment for growth of a. The reliable operation of a fermentation system to achieve process objectives depends on two factors: basic design of a fermenter. The materials used for construction of fermenter withstand repeated steam. basic. Body Construction Of Fermenter.

From quizlet.com

Diagram of Industrial fermenter labelling Quizlet Body Construction Of Fermenter The materials used for construction of fermenter withstand repeated steam sterilization and are nontoxic. External, agitation & aeration, inlets and outlets. Industrial fermentors can be divided into two major classes, anaerobic and aerobic. basic functions of fermenters: basic fermenter design : The reliable operation of a fermentation system to achieve process objectives depends on two factors: design. Body Construction Of Fermenter.

From www.probrewer.com

30bbl Specific Mechanical Fermenter ProBrewer Body Construction Of Fermenter basic functions of fermenters: The reliable operation of a fermentation system to achieve process objectives depends on two factors: The materials used for construction of fermenter withstand repeated steam. External, agitation & aeration, inlets and outlets. The material for body construction of fermenter should be corrosion proof and. De becze and liebmann (1944) used the first large scale (above. Body Construction Of Fermenter.

From www.slideserve.com

PPT What is a Fermenter? PowerPoint Presentation, free download ID Body Construction Of Fermenter De becze and liebmann (1944) used the first large scale (above 20 litre. Construction material, temperature control, agitator (impeller), stirrer glands and bearings, baffles, the aeration system (sparger), ph control sensors. The main function of a fermenter is to provide a controlled environment for growth of a. The material for body construction of fermenter should be corrosion proof and. . Body Construction Of Fermenter.

From www.fermenterchina.com

Airlift stainless steel fermenter BLBIOSQ BaiLun Biotechnology Co., Ltd Body Construction Of Fermenter Construction material, temperature control, agitator (impeller), stirrer glands and bearings, baffles, the aeration system (sparger), ph control sensors. basic design of a fermenter. basic fermenter design : External, agitation & aeration, inlets and outlets. The materials used for construction of fermenter withstand repeated steam sterilization and are nontoxic. Industrial fermentors can be divided into two major classes, anaerobic. Body Construction Of Fermenter.

From www.psychobrew.com

2.5 bbl Conical Jacketed Fermenter PsychoBrew Body Construction Of Fermenter The main function of a fermenter is to provide a controlled environment for growth of a. Industrial fermentors can be divided into two major classes, anaerobic and aerobic. design of a fermenter. The material for body construction of fermenter should be corrosion proof and. Construction material, temperature control, agitator (impeller), stirrer glands and bearings, baffles, the aeration system (sparger),. Body Construction Of Fermenter.

From bailunbio.en.made-in-china.com

1 Bbl Stirred Tank Fermentation Catalyst Conical Fermenter Bioreactor Body Construction Of Fermenter Construction material, temperature control, agitator (impeller), stirrer glands and bearings, baffles, the aeration system (sparger), ph control sensors. The materials used for construction of fermenter withstand repeated steam sterilization and are nontoxic. De becze and liebmann (1944) used the first large scale (above 20 litre. basic functions of fermenters: design of a fermenter. The materials used for construction. Body Construction Of Fermenter.

From www.biotechfront.com

Basic Fermenter Design External, Agitation & Aeration, Inlets and Body Construction Of Fermenter The main function of a fermenter is to provide a controlled environment for growth of a. The material for body construction of fermenter should be corrosion proof and. The materials used for construction of fermenter withstand repeated steam. Industrial fermentors can be divided into two major classes, anaerobic and aerobic. basic functions of fermenters: basic design of a. Body Construction Of Fermenter.

From biologyease.com

Types of fermenter BIOLOGY EASE Body Construction Of Fermenter The reliable operation of a fermentation system to achieve process objectives depends on two factors: The materials used for construction of fermenter withstand repeated steam. External, agitation & aeration, inlets and outlets. basic functions of fermenters: The materials used for construction of fermenter withstand repeated steam sterilization and are nontoxic. Industrial fermentors can be divided into two major classes,. Body Construction Of Fermenter.

From www.researchgate.net

Fermenter setup for CL fermentation with foam fractionation. During Body Construction Of Fermenter External, agitation & aeration, inlets and outlets. The materials used for construction of fermenter withstand repeated steam. basic functions of fermenters: The main function of a fermenter is to provide a controlled environment for growth of a. The reliable operation of a fermentation system to achieve process objectives depends on two factors: Industrial fermentors can be divided into two. Body Construction Of Fermenter.

From www.savemyexams.co.uk

Industrial Fermenters (5.8) Edexcel IGCSE Biology Revision Notes 2019 Body Construction Of Fermenter The reliable operation of a fermentation system to achieve process objectives depends on two factors: basic functions of fermenters: basic design of a fermenter. Construction material, temperature control, agitator (impeller), stirrer glands and bearings, baffles, the aeration system (sparger), ph control sensors. The material for body construction of fermenter should be corrosion proof and. The main function of. Body Construction Of Fermenter.

From edu-pharma.blogspot.com

Fermentation Body Construction Of Fermenter The main function of a fermenter is to provide a controlled environment for growth of a. The reliable operation of a fermentation system to achieve process objectives depends on two factors: De becze and liebmann (1944) used the first large scale (above 20 litre. basic functions of fermenters: External, agitation & aeration, inlets and outlets. Industrial fermentors can be. Body Construction Of Fermenter.

From bioreactor-fermenter.com

Working Principle And Feature Of Airlift Fermenter LABOAO Body Construction Of Fermenter design of a fermenter. basic fermenter design : The reliable operation of a fermentation system to achieve process objectives depends on two factors: The materials used for construction of fermenter withstand repeated steam. basic design of a fermenter. basic functions of fermenters: The material for body construction of fermenter should be corrosion proof and. Construction material,. Body Construction Of Fermenter.

From www.scribd.com

Construction of Fermenter PDF Soft Matter Physical Sciences Body Construction Of Fermenter The main function of a fermenter is to provide a controlled environment for growth of a. The materials used for construction of fermenter withstand repeated steam sterilization and are nontoxic. basic fermenter design : basic functions of fermenters: De becze and liebmann (1944) used the first large scale (above 20 litre. Industrial fermentors can be divided into two. Body Construction Of Fermenter.

From mavink.com

Industrial Fermenter Diagram Body Construction Of Fermenter basic design of a fermenter. The materials used for construction of fermenter withstand repeated steam sterilization and are nontoxic. design of a fermenter. basic design of a fermenter. De becze and liebmann (1944) used the first large scale (above 20 litre. basic functions of fermenters: External, agitation & aeration, inlets and outlets. basic fermenter design. Body Construction Of Fermenter.

From morewinepro.com

MB 40 bbl Conical Unitank Fermenter T.C. Sanitary Ports All Body Construction Of Fermenter basic fermenter design : The main function of a fermenter is to provide a controlled environment for growth of a. Industrial fermentors can be divided into two major classes, anaerobic and aerobic. basic functions of fermenters: De becze and liebmann (1944) used the first large scale (above 20 litre. basic design of a fermenter. basic design. Body Construction Of Fermenter.

From brovarni.com

Cylinderconical tank (CCT or fermenter) at 4000 liters Body Construction Of Fermenter The materials used for construction of fermenter withstand repeated steam. External, agitation & aeration, inlets and outlets. De becze and liebmann (1944) used the first large scale (above 20 litre. design of a fermenter. The materials used for construction of fermenter withstand repeated steam sterilization and are nontoxic. The main function of a fermenter is to provide a controlled. Body Construction Of Fermenter.

From www.criveller.com

Fermenters / BBT's Brew Tanks Criveller Group Body Construction Of Fermenter basic design of a fermenter. External, agitation & aeration, inlets and outlets. basic fermenter design : design of a fermenter. The materials used for construction of fermenter withstand repeated steam. Construction material, temperature control, agitator (impeller), stirrer glands and bearings, baffles, the aeration system (sparger), ph control sensors. basic functions of fermenters: De becze and liebmann. Body Construction Of Fermenter.

From quizlet.com

FERMENTERS Diagram Quizlet Body Construction Of Fermenter design of a fermenter. basic functions of fermenters: External, agitation & aeration, inlets and outlets. basic design of a fermenter. The materials used for construction of fermenter withstand repeated steam. basic design of a fermenter. The materials used for construction of fermenter withstand repeated steam sterilization and are nontoxic. The main function of a fermenter is. Body Construction Of Fermenter.

From www.thebulkfoods.com

Mb 7 Bbl Conical Unitank Fermenter T.C. Sanitary Ports All Fittings Body Construction Of Fermenter basic functions of fermenters: basic fermenter design : The materials used for construction of fermenter withstand repeated steam. Construction material, temperature control, agitator (impeller), stirrer glands and bearings, baffles, the aeration system (sparger), ph control sensors. External, agitation & aeration, inlets and outlets. design of a fermenter. The material for body construction of fermenter should be corrosion. Body Construction Of Fermenter.

From www.alibaba.com

35l Pressure Stainless Conical Fermenter With Yeat Collecting Tank Body Construction Of Fermenter design of a fermenter. basic fermenter design : The material for body construction of fermenter should be corrosion proof and. The reliable operation of a fermentation system to achieve process objectives depends on two factors: De becze and liebmann (1944) used the first large scale (above 20 litre. The materials used for construction of fermenter withstand repeated steam. Body Construction Of Fermenter.

From www.researchgate.net

2 Continuous stirredtank reactors (Fermenter Equipment design Body Construction Of Fermenter The materials used for construction of fermenter withstand repeated steam. basic fermenter design : Industrial fermentors can be divided into two major classes, anaerobic and aerobic. design of a fermenter. basic design of a fermenter. The material for body construction of fermenter should be corrosion proof and. The reliable operation of a fermentation system to achieve process. Body Construction Of Fermenter.

From brewhaequipment.com

Stainless jacketed homebrewery conical fermenter (fermentor) Body Construction Of Fermenter basic design of a fermenter. The material for body construction of fermenter should be corrosion proof and. basic design of a fermenter. Construction material, temperature control, agitator (impeller), stirrer glands and bearings, baffles, the aeration system (sparger), ph control sensors. The main function of a fermenter is to provide a controlled environment for growth of a. External, agitation. Body Construction Of Fermenter.

From microbiologynotes.org

Overview of fermenter design and construction Microbiology Notes Body Construction Of Fermenter The main function of a fermenter is to provide a controlled environment for growth of a. design of a fermenter. Industrial fermentors can be divided into two major classes, anaerobic and aerobic. External, agitation & aeration, inlets and outlets. basic fermenter design : basic design of a fermenter. The materials used for construction of fermenter withstand repeated. Body Construction Of Fermenter.