Automated Optical Inspection Wafer . 4 stage macro wafer inspection. The confovis waferinspect aoi system is designed to perform aoi wafer inspection on unstructured and structured wafers. The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. It is not required to manually put in rigid filter. Side & backside mounted aoi wafer inspection modules. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. By combining automated optical inspection (aoi) and metrology the confovis waferinspect aoi offers individual solutions for defect inspection and classification as well as for 3d. 200mm aoi wafer inspection with makyoh optics. By combining automated optical inspection (aoi) and metrology, confovis aoi offers solutions for defect inspection and classification as well as.

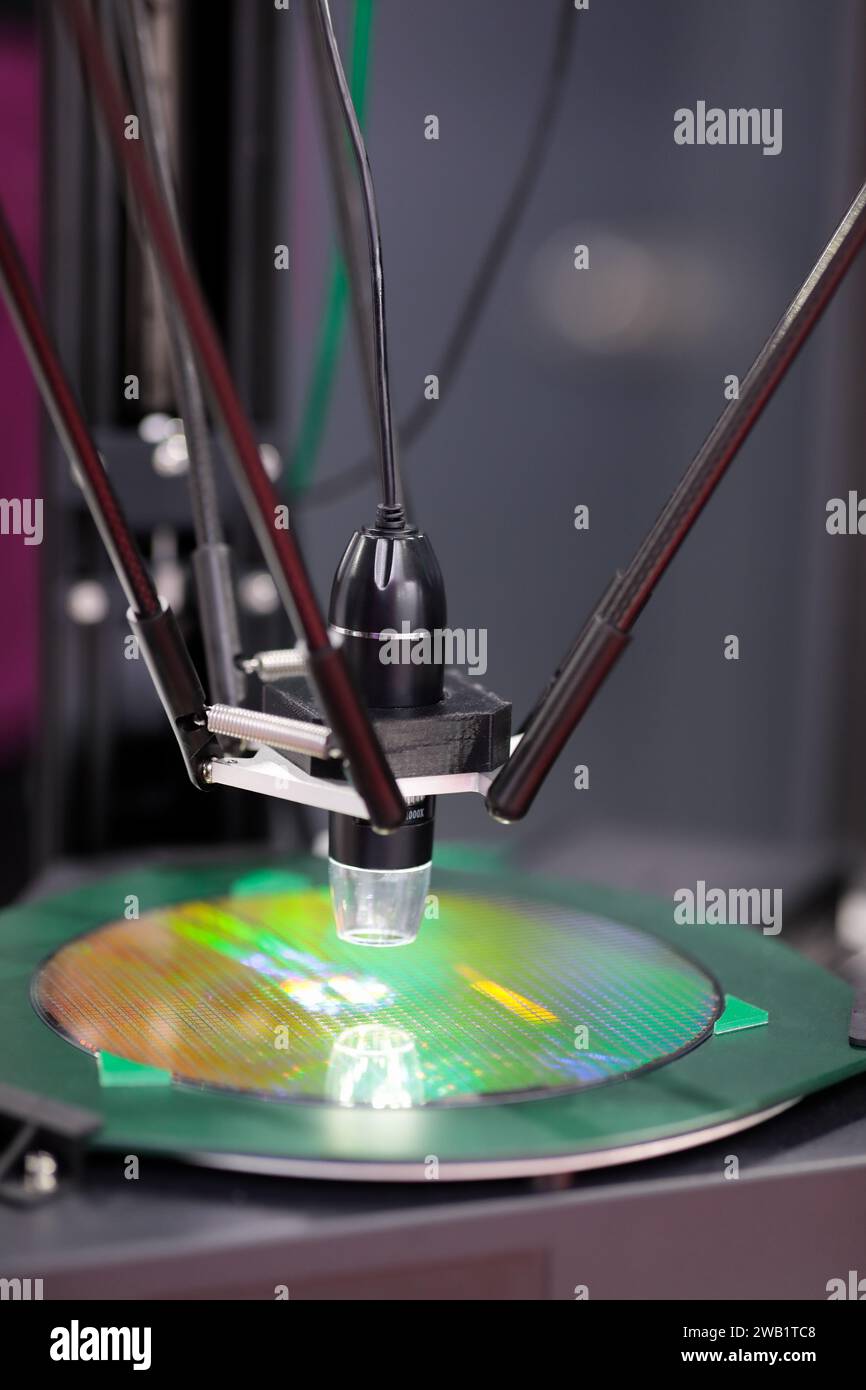

from www.alamy.com

Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. By combining automated optical inspection (aoi) and metrology the confovis waferinspect aoi offers individual solutions for defect inspection and classification as well as for 3d. 200mm aoi wafer inspection with makyoh optics. The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. The confovis waferinspect aoi system is designed to perform aoi wafer inspection on unstructured and structured wafers. It is not required to manually put in rigid filter. By combining automated optical inspection (aoi) and metrology, confovis aoi offers solutions for defect inspection and classification as well as. Side & backside mounted aoi wafer inspection modules. 4 stage macro wafer inspection.

Semiconductor silicon wafer defect inspection. Automated optical

Automated Optical Inspection Wafer Side & backside mounted aoi wafer inspection modules. 200mm aoi wafer inspection with makyoh optics. By combining automated optical inspection (aoi) and metrology the confovis waferinspect aoi offers individual solutions for defect inspection and classification as well as for 3d. 4 stage macro wafer inspection. By combining automated optical inspection (aoi) and metrology, confovis aoi offers solutions for defect inspection and classification as well as. Side & backside mounted aoi wafer inspection modules. It is not required to manually put in rigid filter. The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. The confovis waferinspect aoi system is designed to perform aoi wafer inspection on unstructured and structured wafers. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from.

From www.laserfocusworld.com

Dual Sided Wafer Chip Inspection System (Model 7940) Laser Focus World Automated Optical Inspection Wafer 200mm aoi wafer inspection with makyoh optics. 4 stage macro wafer inspection. By combining automated optical inspection (aoi) and metrology the confovis waferinspect aoi offers individual solutions for defect inspection and classification as well as for 3d. The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. Side &. Automated Optical Inspection Wafer.

From www.confovis.com

Wafer Bump Inspection Confovis GmbH Automated Optical Inspection Wafer By combining automated optical inspection (aoi) and metrology the confovis waferinspect aoi offers individual solutions for defect inspection and classification as well as for 3d. By combining automated optical inspection (aoi) and metrology, confovis aoi offers solutions for defect inspection and classification as well as. The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains. Automated Optical Inspection Wafer.

From www.acculex.net

Bright Field Wafer Inspection System Automated Optical Inspection Wafer It is not required to manually put in rigid filter. 4 stage macro wafer inspection. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. Side & backside mounted aoi wafer inspection modules. 200mm aoi wafer inspection with makyoh optics. The wafer defect inspection system detects physical defects and pattern defects. Automated Optical Inspection Wafer.

From cortexrobotics.my

Wafer Inspection Machines How They Work? Cortex Robotics Automated Optical Inspection Wafer Side & backside mounted aoi wafer inspection modules. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. It is not required to manually put in rigid filter. The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. By combining. Automated Optical Inspection Wafer.

From www.sipotek.net

Sipotek Automatic Visual Inspection Machine For Injectable Products In Automated Optical Inspection Wafer 4 stage macro wafer inspection. The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. Side & backside mounted aoi wafer inspection modules. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. It is not required to manually put. Automated Optical Inspection Wafer.

From epp-europe-news.com

Latest microelectronics, semiconductor and automated optical inspection Automated Optical Inspection Wafer 200mm aoi wafer inspection with makyoh optics. 4 stage macro wafer inspection. By combining automated optical inspection (aoi) and metrology, confovis aoi offers solutions for defect inspection and classification as well as. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. Side & backside mounted aoi wafer inspection modules. It. Automated Optical Inspection Wafer.

From caltexsystems.com

Wafer Inspection System Caltex Digital Microscopes Automated Optical Inspection Wafer The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. It is not required to manually put in rigid filter. 4 stage macro wafer inspection. Side & backside mounted aoi wafer inspection modules. By combining automated optical inspection (aoi) and metrology the confovis waferinspect aoi offers individual solutions for. Automated Optical Inspection Wafer.

From www.elmomc.com

Increasing Wafer Probe Testing Throughput by Means of Servo Elmo Automated Optical Inspection Wafer It is not required to manually put in rigid filter. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. By combining automated optical inspection (aoi) and metrology the confovis. Automated Optical Inspection Wafer.

From www.azom.com

Automated Wafer Metrology Tool from DWFritz Automation Quote, RFQ Automated Optical Inspection Wafer The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. 4 stage macro wafer inspection. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. 200mm aoi wafer inspection with makyoh optics. By combining automated optical inspection (aoi) and metrology,. Automated Optical Inspection Wafer.

From www.laserfocusworld.com

Wafer inspection system allows defect inspection up to 200 mm Laser Automated Optical Inspection Wafer It is not required to manually put in rigid filter. By combining automated optical inspection (aoi) and metrology the confovis waferinspect aoi offers individual solutions for defect inspection and classification as well as for 3d. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. The confovis waferinspect aoi system is. Automated Optical Inspection Wafer.

From www.equipx.net

Zeiss/HSEB Axiospect 300 Automated Wafer Inspection and Review Tool Automated Optical Inspection Wafer The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. By combining automated optical inspection (aoi) and metrology, confovis aoi offers solutions for defect inspection and classification as well as. 200mm aoi wafer inspection with makyoh optics. Side & backside mounted aoi wafer inspection modules. Automated optical inspection (aoi). Automated Optical Inspection Wafer.

From www.mento-aoi.com

Automated Optical Inspection PCB AOI Machine Wafer Tester Automated Optical Inspection Wafer The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. By combining automated optical inspection (aoi) and metrology, confovis aoi offers solutions for defect inspection and classification as well as. The confovis waferinspect aoi system is designed to perform aoi wafer inspection on unstructured and structured wafers. 200mm aoi. Automated Optical Inspection Wafer.

From www.sipotek.net

Automated optical inspection machine for threedimensional mechanical Automated Optical Inspection Wafer 200mm aoi wafer inspection with makyoh optics. By combining automated optical inspection (aoi) and metrology, confovis aoi offers solutions for defect inspection and classification as well as. The confovis waferinspect aoi system is designed to perform aoi wafer inspection on unstructured and structured wafers. Side & backside mounted aoi wafer inspection modules. The wafer defect inspection system detects physical defects. Automated Optical Inspection Wafer.

From cn.tradekey.com

Automatic Optical Inspection Machine AOI By Hexi Electronic Equipment Automated Optical Inspection Wafer Side & backside mounted aoi wafer inspection modules. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. 4 stage macro wafer inspection. 200mm aoi wafer inspection with makyoh optics. The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects.. Automated Optical Inspection Wafer.

From www.directindustry.com

Macro defect inspection machine F30™ Onto Innovation Inc. surface Automated Optical Inspection Wafer It is not required to manually put in rigid filter. The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. The confovis waferinspect aoi system is designed to perform aoi. Automated Optical Inspection Wafer.

From ims-nl.com

Integrated Photonics IMS High Precision Manufacturing Equipment Automated Optical Inspection Wafer By combining automated optical inspection (aoi) and metrology the confovis waferinspect aoi offers individual solutions for defect inspection and classification as well as for 3d. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. It is not required to manually put in rigid filter. 4 stage macro wafer inspection. Side. Automated Optical Inspection Wafer.

From www.rsipvision.com

Automated Optical Inspection and computer vision in Semiconductors Automated Optical Inspection Wafer 4 stage macro wafer inspection. Side & backside mounted aoi wafer inspection modules. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. The confovis waferinspect aoi system is designed to perform aoi wafer inspection on unstructured and structured wafers. It is not required to manually put in rigid filter. The. Automated Optical Inspection Wafer.

From www.directindustry.com

Optical inspection machine Puma™ KLA TENCOR for patterned Automated Optical Inspection Wafer 200mm aoi wafer inspection with makyoh optics. 4 stage macro wafer inspection. By combining automated optical inspection (aoi) and metrology, confovis aoi offers solutions for defect inspection and classification as well as. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. It is not required to manually put in rigid. Automated Optical Inspection Wafer.

From cortexrobotics.my

Enhancing Wafer Quality with Advanced AOI Technology CORTEX ROBOTICS Automated Optical Inspection Wafer By combining automated optical inspection (aoi) and metrology the confovis waferinspect aoi offers individual solutions for defect inspection and classification as well as for 3d. It is not required to manually put in rigid filter. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. Side & backside mounted aoi wafer. Automated Optical Inspection Wafer.

From buzzorange.com

漏檢率趨近於零!台達 AI 視覺檢測解決方案高效掌握瑕疵零件,大幅提升產品良率 TechOrange 科技報橘 Automated Optical Inspection Wafer Side & backside mounted aoi wafer inspection modules. By combining automated optical inspection (aoi) and metrology the confovis waferinspect aoi offers individual solutions for defect inspection and classification as well as for 3d. By combining automated optical inspection (aoi) and metrology, confovis aoi offers solutions for defect inspection and classification as well as. It is not required to manually put. Automated Optical Inspection Wafer.

From www.alamy.com

Semiconductor silicon wafer defect inspection. Automated optical Automated Optical Inspection Wafer By combining automated optical inspection (aoi) and metrology, confovis aoi offers solutions for defect inspection and classification as well as. 200mm aoi wafer inspection with makyoh optics. Side & backside mounted aoi wafer inspection modules. 4 stage macro wafer inspection. The confovis waferinspect aoi system is designed to perform aoi wafer inspection on unstructured and structured wafers. It is not. Automated Optical Inspection Wafer.

From www.photonics.com

Wafer Inspection System Onto Innovation Apr 2019 Photonics Spectra Automated Optical Inspection Wafer By combining automated optical inspection (aoi) and metrology the confovis waferinspect aoi offers individual solutions for defect inspection and classification as well as for 3d. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the. Automated Optical Inspection Wafer.

From cortexrobotics.my

Wafer Inspection Machines How They Work? Cortex Robotics Automated Optical Inspection Wafer The confovis waferinspect aoi system is designed to perform aoi wafer inspection on unstructured and structured wafers. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. 200mm aoi wafer inspection with makyoh optics. It is not required to manually put in rigid filter. By combining automated optical inspection (aoi) and. Automated Optical Inspection Wafer.

From vitrox.com

New Generation of Wafer Inspection System Wi8i G2 is here! Automated Optical Inspection Wafer Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. 4 stage macro wafer inspection. By combining automated optical inspection (aoi) and metrology the confovis waferinspect aoi offers individual solutions for defect inspection and classification as well as for 3d. Side & backside mounted aoi wafer inspection modules. It is not. Automated Optical Inspection Wafer.

From www.visionpro.com

Machine Vision Products to Introduce their latest Die Wire, WireBond Automated Optical Inspection Wafer Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. Side & backside mounted aoi wafer inspection modules. 4 stage macro wafer inspection. By combining automated optical inspection (aoi) and metrology, confovis aoi offers solutions for defect inspection and classification as well as. 200mm aoi wafer inspection with makyoh optics. The. Automated Optical Inspection Wafer.

From www.bridgetronic.com

CamtekFalcon 200 SOptical Wafer Inspection System49207 Bridge Automated Optical Inspection Wafer The confovis waferinspect aoi system is designed to perform aoi wafer inspection on unstructured and structured wafers. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. By combining automated optical inspection (aoi) and metrology, confovis aoi offers solutions for defect inspection and classification as well as. Side & backside mounted. Automated Optical Inspection Wafer.

From www.pvatepla-spa.com

PVA SPA Specialized Solutions Automated Optical Inspection Wafer The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. The confovis waferinspect aoi system is designed to perform aoi wafer inspection on unstructured and structured wafers. It is not required to manually put in rigid filter. By combining automated optical inspection (aoi) and metrology, confovis aoi offers solutions. Automated Optical Inspection Wafer.

From www.challentech.com.tw

Used Equipment Automated Optical Inspection Wafer It is not required to manually put in rigid filter. The confovis waferinspect aoi system is designed to perform aoi wafer inspection on unstructured and structured wafers. By combining automated optical inspection (aoi) and metrology the confovis waferinspect aoi offers individual solutions for defect inspection and classification as well as for 3d. 200mm aoi wafer inspection with makyoh optics. By. Automated Optical Inspection Wafer.

From www.wvis.com.tw

Wafer Inspection System With Vision Inspection System Co.,Ltd. Automated Optical Inspection Wafer By combining automated optical inspection (aoi) and metrology, confovis aoi offers solutions for defect inspection and classification as well as. By combining automated optical inspection (aoi) and metrology the confovis waferinspect aoi offers individual solutions for defect inspection and classification as well as for 3d. The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains. Automated Optical Inspection Wafer.

From www.azom.com

Wafer analysis of laser grooving Automated Optical Inspection Wafer Side & backside mounted aoi wafer inspection modules. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. It is not required to manually put in rigid filter. 4 stage macro wafer inspection. By combining automated optical inspection (aoi) and metrology, confovis aoi offers solutions for defect inspection and classification as. Automated Optical Inspection Wafer.

From epp-europe-news.com

Automated wafer Xray inspection system Automated Optical Inspection Wafer By combining automated optical inspection (aoi) and metrology, confovis aoi offers solutions for defect inspection and classification as well as. The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. Side & backside mounted aoi wafer inspection modules. Automated optical inspection (aoi) is a powerful quality improvement tool to. Automated Optical Inspection Wafer.

From www.youtube.com

Fullyautomated, very compact LED Wafer Inspection Metrology System Automated Optical Inspection Wafer Side & backside mounted aoi wafer inspection modules. 4 stage macro wafer inspection. 200mm aoi wafer inspection with makyoh optics. The confovis waferinspect aoi system is designed to perform aoi wafer inspection on unstructured and structured wafers. The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. It is. Automated Optical Inspection Wafer.

From www.bridgetronic.com

Nanometrics9010Mask & Wafer Inspection Machine59712 Bridge Tronic Automated Optical Inspection Wafer 200mm aoi wafer inspection with makyoh optics. The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. It is not required to manually put in rigid filter. By combining automated optical inspection (aoi) and metrology the confovis waferinspect aoi offers individual solutions for defect inspection and classification as well. Automated Optical Inspection Wafer.

From www.visionpro.com

Introducing the MVP 900 Series. Automated Optical Inspection for Wafer Automated Optical Inspection Wafer By combining automated optical inspection (aoi) and metrology, confovis aoi offers solutions for defect inspection and classification as well as. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. The confovis waferinspect aoi system is designed to perform aoi wafer inspection on unstructured and structured wafers. By combining automated optical. Automated Optical Inspection Wafer.

From imgbin.com

Wafer Bonding Electronics Inspection Machine PNG, Clipart, Automated Automated Optical Inspection Wafer The wafer defect inspection system detects physical defects and pattern defects on wafers and obtains the position coordinates of the defects. The confovis waferinspect aoi system is designed to perform aoi wafer inspection on unstructured and structured wafers. Automated optical inspection (aoi) is a powerful quality improvement tool to screen out die with any visual defect from. By combining automated. Automated Optical Inspection Wafer.