Crankshaft Counterweight Calculator . Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half. This article presents a detailed calculation method for determining the optimal counterweight size and shape, taking into. Ideally, each counterweight should carry the imbalance of. To determine the counterweight mass, essentially one has to determine the forces due to acceleration by the motion of the slider. Using the geometric center of the connecting rods, i used solidworks mass properties to obtain the rotational and reciprocating component weights of the connecting rod/piston. This calculator provides the calculation of centrifugal force and moment due to centrifugal force acting on a crankshaft. For higher frequencies you need. This calculator provides the calculation of crankshaft counterweight for mechanical engineering applications. In an internally balanced engine, the extra weight for both balance and inertia purposes is contained completely in the counterweights. With counterweights on the crankshaft you can influence the balance only in the first order.

from www.semanticscholar.org

With counterweights on the crankshaft you can influence the balance only in the first order. This article presents a detailed calculation method for determining the optimal counterweight size and shape, taking into. Ideally, each counterweight should carry the imbalance of. This calculator provides the calculation of centrifugal force and moment due to centrifugal force acting on a crankshaft. For higher frequencies you need. In an internally balanced engine, the extra weight for both balance and inertia purposes is contained completely in the counterweights. Using the geometric center of the connecting rods, i used solidworks mass properties to obtain the rotational and reciprocating component weights of the connecting rod/piston. This calculator provides the calculation of crankshaft counterweight for mechanical engineering applications. To determine the counterweight mass, essentially one has to determine the forces due to acceleration by the motion of the slider. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half.

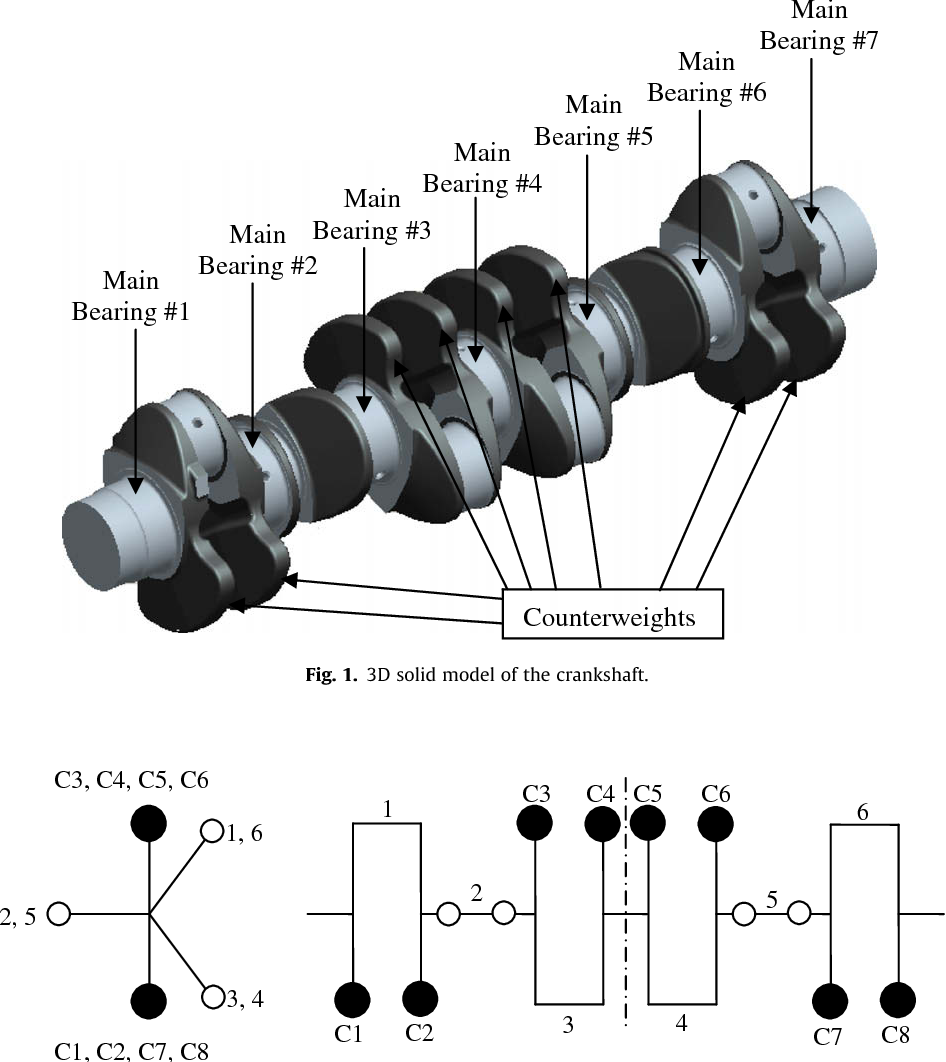

Figure 1 from An investigation of the effect of counterweight configuration on main bearing load

Crankshaft Counterweight Calculator This article presents a detailed calculation method for determining the optimal counterweight size and shape, taking into. In an internally balanced engine, the extra weight for both balance and inertia purposes is contained completely in the counterweights. With counterweights on the crankshaft you can influence the balance only in the first order. This calculator provides the calculation of crankshaft counterweight for mechanical engineering applications. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half. For higher frequencies you need. This article presents a detailed calculation method for determining the optimal counterweight size and shape, taking into. This calculator provides the calculation of centrifugal force and moment due to centrifugal force acting on a crankshaft. Ideally, each counterweight should carry the imbalance of. To determine the counterweight mass, essentially one has to determine the forces due to acceleration by the motion of the slider. Using the geometric center of the connecting rods, i used solidworks mass properties to obtain the rotational and reciprocating component weights of the connecting rod/piston.

From www.ebay.com

Crankshaft crank counterweight balancer Briggs Stratton 331777 20 hp engine eBay Crankshaft Counterweight Calculator In an internally balanced engine, the extra weight for both balance and inertia purposes is contained completely in the counterweights. To determine the counterweight mass, essentially one has to determine the forces due to acceleration by the motion of the slider. Ideally, each counterweight should carry the imbalance of. Using the geometric center of the connecting rods, i used solidworks. Crankshaft Counterweight Calculator.

From www.researchgate.net

Three types of mechanical crankshaft assembly models. Download Scientific Diagram Crankshaft Counterweight Calculator This calculator provides the calculation of centrifugal force and moment due to centrifugal force acting on a crankshaft. This article presents a detailed calculation method for determining the optimal counterweight size and shape, taking into. To determine the counterweight mass, essentially one has to determine the forces due to acceleration by the motion of the slider. Using the geometric center. Crankshaft Counterweight Calculator.

From www.enginehistory.org

Crankshaft Counterweight Capers at Allison Crankshaft Counterweight Calculator This calculator provides the calculation of crankshaft counterweight for mechanical engineering applications. This article presents a detailed calculation method for determining the optimal counterweight size and shape, taking into. Ideally, each counterweight should carry the imbalance of. In an internally balanced engine, the extra weight for both balance and inertia purposes is contained completely in the counterweights. For higher frequencies. Crankshaft Counterweight Calculator.

From www.semanticscholar.org

Figure 1 from An investigation of the effect of counterweight configuration on main bearing load Crankshaft Counterweight Calculator Ideally, each counterweight should carry the imbalance of. This calculator provides the calculation of crankshaft counterweight for mechanical engineering applications. Using the geometric center of the connecting rods, i used solidworks mass properties to obtain the rotational and reciprocating component weights of the connecting rod/piston. In an internally balanced engine, the extra weight for both balance and inertia purposes is. Crankshaft Counterweight Calculator.

From www.chevydiy.com

Chevy BigBlock Performance Pistons, Connecting Rods and Crankshafts Crankshaft Counterweight Calculator For higher frequencies you need. With counterweights on the crankshaft you can influence the balance only in the first order. Ideally, each counterweight should carry the imbalance of. Using the geometric center of the connecting rods, i used solidworks mass properties to obtain the rotational and reciprocating component weights of the connecting rod/piston. This calculator provides the calculation of crankshaft. Crankshaft Counterweight Calculator.

From www.enginebuildermag.com

Crankshaft Counterweights Engine Builder Magazine Crankshaft Counterweight Calculator With counterweights on the crankshaft you can influence the balance only in the first order. In an internally balanced engine, the extra weight for both balance and inertia purposes is contained completely in the counterweights. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal. Crankshaft Counterweight Calculator.

From www.youtube.com

1 Cylinder Crankshaft Counter Weights Clearance and Torque YouTube Crankshaft Counterweight Calculator This article presents a detailed calculation method for determining the optimal counterweight size and shape, taking into. In an internally balanced engine, the extra weight for both balance and inertia purposes is contained completely in the counterweights. With counterweights on the crankshaft you can influence the balance only in the first order. For higher frequencies you need. Using the geometric. Crankshaft Counterweight Calculator.

From products.tomeiusa.com

BILLET FULL COUNTERWEIGHT CRANKSHAFT EJ25 2.6 83.0mm Crankshaft Counterweight Calculator In an internally balanced engine, the extra weight for both balance and inertia purposes is contained completely in the counterweights. With counterweights on the crankshaft you can influence the balance only in the first order. For higher frequencies you need. This calculator provides the calculation of crankshaft counterweight for mechanical engineering applications. Ideally, each counterweight should carry the imbalance of.. Crankshaft Counterweight Calculator.

From www.youtube.com

About my Crank Balance Calculator (single cylinder 2 or 4 stroke) YouTube Crankshaft Counterweight Calculator To determine the counterweight mass, essentially one has to determine the forces due to acceleration by the motion of the slider. This calculator provides the calculation of crankshaft counterweight for mechanical engineering applications. This article presents a detailed calculation method for determining the optimal counterweight size and shape, taking into. Ideally, each counterweight should carry the imbalance of. For higher. Crankshaft Counterweight Calculator.

From zrp-rods.com

Billet Crankshafts Features ZRP Crankshaft Counterweight Calculator With counterweights on the crankshaft you can influence the balance only in the first order. This calculator provides the calculation of centrifugal force and moment due to centrifugal force acting on a crankshaft. To determine the counterweight mass, essentially one has to determine the forces due to acceleration by the motion of the slider. This calculator provides the calculation of. Crankshaft Counterweight Calculator.

From thebloughs.net

Understanding Crankshaft Counterweights Tom's Maker Site Crankshaft Counterweight Calculator Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half. In an internally balanced engine, the extra weight for both balance and inertia purposes is contained completely in the counterweights. Ideally, each counterweight should carry the imbalance of. Using the geometric center of the. Crankshaft Counterweight Calculator.

From thebloughs.net

Understanding Crankshaft Counterweights Tom's Maker Site Crankshaft Counterweight Calculator In an internally balanced engine, the extra weight for both balance and inertia purposes is contained completely in the counterweights. This calculator provides the calculation of crankshaft counterweight for mechanical engineering applications. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half. This article. Crankshaft Counterweight Calculator.

From aapistons.com

Cast Counterweight Crankshaft VW Journal AA Performance Products Crankshaft Counterweight Calculator Using the geometric center of the connecting rods, i used solidworks mass properties to obtain the rotational and reciprocating component weights of the connecting rod/piston. With counterweights on the crankshaft you can influence the balance only in the first order. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of. Crankshaft Counterweight Calculator.

From www.numerade.com

1320 For the given slidercrank mechanism, calculate the inertia force for the unbalanced Crankshaft Counterweight Calculator For higher frequencies you need. Ideally, each counterweight should carry the imbalance of. This calculator provides the calculation of centrifugal force and moment due to centrifugal force acting on a crankshaft. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half. With counterweights on. Crankshaft Counterweight Calculator.

From www.clubgti.com

Crankshaft Counterweights relation Club GTI Crankshaft Counterweight Calculator Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half. This calculator provides the calculation of centrifugal force and moment due to centrifugal force acting on a crankshaft. In an internally balanced engine, the extra weight for both balance and inertia purposes is contained. Crankshaft Counterweight Calculator.

From repository.mines.edu

Monroe L160 hand crank mechanical calculator Crankshaft Counterweight Calculator For higher frequencies you need. This article presents a detailed calculation method for determining the optimal counterweight size and shape, taking into. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half. With counterweights on the crankshaft you can influence the balance only in. Crankshaft Counterweight Calculator.

From zrp-rods.com

Billet Crankshafts Features ZRP Crankshaft Counterweight Calculator Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half. This article presents a detailed calculation method for determining the optimal counterweight size and shape, taking into. Using the geometric center of the connecting rods, i used solidworks mass properties to obtain the rotational. Crankshaft Counterweight Calculator.

From carolinadunebuggies.com

69MM COUNTERWEIGHTED CRANKSHAFT Crankshaft Counterweight Calculator Ideally, each counterweight should carry the imbalance of. With counterweights on the crankshaft you can influence the balance only in the first order. In an internally balanced engine, the extra weight for both balance and inertia purposes is contained completely in the counterweights. This calculator provides the calculation of crankshaft counterweight for mechanical engineering applications. For higher frequencies you need.. Crankshaft Counterweight Calculator.

From thebloughs.net

Understanding Crankshaft Counterweights Tom's Maker Site Crankshaft Counterweight Calculator Using the geometric center of the connecting rods, i used solidworks mass properties to obtain the rotational and reciprocating component weights of the connecting rod/piston. This calculator provides the calculation of centrifugal force and moment due to centrifugal force acting on a crankshaft. To determine the counterweight mass, essentially one has to determine the forces due to acceleration by the. Crankshaft Counterweight Calculator.

From www.eng-tips.com

Crankshaft counterweight shape ? Engine & fuel engineering EngTips Crankshaft Counterweight Calculator Ideally, each counterweight should carry the imbalance of. This calculator provides the calculation of crankshaft counterweight for mechanical engineering applications. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half. This calculator provides the calculation of centrifugal force and moment due to centrifugal force. Crankshaft Counterweight Calculator.

From marineengineerreview.blogspot.com

Crankshaft adjustable counterweights Crankshaft Counterweight Calculator Using the geometric center of the connecting rods, i used solidworks mass properties to obtain the rotational and reciprocating component weights of the connecting rod/piston. For higher frequencies you need. To determine the counterweight mass, essentially one has to determine the forces due to acceleration by the motion of the slider. Machinists and engine builders have long been taught that,. Crankshaft Counterweight Calculator.

From ohiocrank.com

Ohio Crank Tech Crankshaft Balance Factors Crankshaft Counterweight Calculator Using the geometric center of the connecting rods, i used solidworks mass properties to obtain the rotational and reciprocating component weights of the connecting rod/piston. This calculator provides the calculation of crankshaft counterweight for mechanical engineering applications. This article presents a detailed calculation method for determining the optimal counterweight size and shape, taking into. This calculator provides the calculation of. Crankshaft Counterweight Calculator.

From www.alamy.com

Fourcylinder counterbalanced crankshaft (Autocar Handbook, 13th ed, 1935 Stock Photo Alamy Crankshaft Counterweight Calculator This calculator provides the calculation of centrifugal force and moment due to centrifugal force acting on a crankshaft. Using the geometric center of the connecting rods, i used solidworks mass properties to obtain the rotational and reciprocating component weights of the connecting rod/piston. In an internally balanced engine, the extra weight for both balance and inertia purposes is contained completely. Crankshaft Counterweight Calculator.

From www.youtube.com

Briggs and Stratton LHead Counterweight Timing Crankshaft Gear Timing Mark Covered by Bearing Crankshaft Counterweight Calculator With counterweights on the crankshaft you can influence the balance only in the first order. In an internally balanced engine, the extra weight for both balance and inertia purposes is contained completely in the counterweights. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal. Crankshaft Counterweight Calculator.

From www.mdpi.com

Applied Sciences Free FullText A General Framework for Crankshaft Balancing and Crankshaft Counterweight Calculator Using the geometric center of the connecting rods, i used solidworks mass properties to obtain the rotational and reciprocating component weights of the connecting rod/piston. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half. This article presents a detailed calculation method for determining. Crankshaft Counterweight Calculator.

From www.mdpi.com

Applied Sciences Free FullText A General Framework for Crankshaft Balancing and Crankshaft Counterweight Calculator For higher frequencies you need. Ideally, each counterweight should carry the imbalance of. In an internally balanced engine, the extra weight for both balance and inertia purposes is contained completely in the counterweights. Using the geometric center of the connecting rods, i used solidworks mass properties to obtain the rotational and reciprocating component weights of the connecting rod/piston. This article. Crankshaft Counterweight Calculator.

From clubgti.com

Crankshaft Counterweights relation Crankshaft Counterweight Calculator This calculator provides the calculation of crankshaft counterweight for mechanical engineering applications. For higher frequencies you need. In an internally balanced engine, the extra weight for both balance and inertia purposes is contained completely in the counterweights. Ideally, each counterweight should carry the imbalance of. With counterweights on the crankshaft you can influence the balance only in the first order.. Crankshaft Counterweight Calculator.

From www.chevyhardcore.com

Indepth Tech Valuable Tips For Selecting The Right Crankshaft Crankshaft Counterweight Calculator With counterweights on the crankshaft you can influence the balance only in the first order. This calculator provides the calculation of centrifugal force and moment due to centrifugal force acting on a crankshaft. Ideally, each counterweight should carry the imbalance of. For higher frequencies you need. Using the geometric center of the connecting rods, i used solidworks mass properties to. Crankshaft Counterweight Calculator.

From www.onallcylinders.com

Finding Balance (Part 1) The Basics of Crankshaft Balancing OnAllCylinders Crankshaft Counterweight Calculator This calculator provides the calculation of centrifugal force and moment due to centrifugal force acting on a crankshaft. Ideally, each counterweight should carry the imbalance of. For higher frequencies you need. This calculator provides the calculation of crankshaft counterweight for mechanical engineering applications. In an internally balanced engine, the extra weight for both balance and inertia purposes is contained completely. Crankshaft Counterweight Calculator.

From www.mdpi.com

Applied Sciences Free FullText A General Framework for Crankshaft Balancing and Crankshaft Counterweight Calculator This calculator provides the calculation of crankshaft counterweight for mechanical engineering applications. For higher frequencies you need. With counterweights on the crankshaft you can influence the balance only in the first order. This calculator provides the calculation of centrifugal force and moment due to centrifugal force acting on a crankshaft. Machinists and engine builders have long been taught that, when. Crankshaft Counterweight Calculator.

From www.enginebuildermag.com

Crankshaft Counterweights Engine Builder Magazine Crankshaft Counterweight Calculator This calculator provides the calculation of centrifugal force and moment due to centrifugal force acting on a crankshaft. In an internally balanced engine, the extra weight for both balance and inertia purposes is contained completely in the counterweights. This calculator provides the calculation of crankshaft counterweight for mechanical engineering applications. Using the geometric center of the connecting rods, i used. Crankshaft Counterweight Calculator.

From bikefaff.com

Crank Length Calculator Bike Faff Crankshaft Counterweight Calculator This calculator provides the calculation of centrifugal force and moment due to centrifugal force acting on a crankshaft. This article presents a detailed calculation method for determining the optimal counterweight size and shape, taking into. Ideally, each counterweight should carry the imbalance of. To determine the counterweight mass, essentially one has to determine the forces due to acceleration by the. Crankshaft Counterweight Calculator.

From aapistons.com

Cast Counterweight Crankshaft VW Journal AA Performance Products Crankshaft Counterweight Calculator This calculator provides the calculation of centrifugal force and moment due to centrifugal force acting on a crankshaft. For higher frequencies you need. Ideally, each counterweight should carry the imbalance of. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half. This calculator provides. Crankshaft Counterweight Calculator.

From www.newkidscar.com

Crankshaft construction and Related Parts Car Anatomy Crankshaft Counterweight Calculator In an internally balanced engine, the extra weight for both balance and inertia purposes is contained completely in the counterweights. With counterweights on the crankshaft you can influence the balance only in the first order. This calculator provides the calculation of centrifugal force and moment due to centrifugal force acting on a crankshaft. Ideally, each counterweight should carry the imbalance. Crankshaft Counterweight Calculator.

From www.mdpi.com

Applied Sciences Free FullText Method to Increase the Accuracy of Large Crankshaft Geometry Crankshaft Counterweight Calculator In an internally balanced engine, the extra weight for both balance and inertia purposes is contained completely in the counterweights. Ideally, each counterweight should carry the imbalance of. This article presents a detailed calculation method for determining the optimal counterweight size and shape, taking into. This calculator provides the calculation of crankshaft counterweight for mechanical engineering applications. For higher frequencies. Crankshaft Counterweight Calculator.