Solder Balls Chips . Originating from ibm, it excels in emc/emi, i/o density, and heat dissipation. The process of solder ball mounting involves attaching solder balls onto a wlcsp for packaging. Via consecutive flow/quench or reflow procedures, solder balls are produced. Solder balls, as the soldering material, are placed on the bottom of the chip and melted during the manufacturing process to join. In integrated circuit (ic) packaging, a solder bump, also a solder ball, or referred simply as “ball” or “bumps”, is a ball of solder that provides the. The ball is typically just off the side of the one of the pads. The key distinction from placing. Fcbga, despite manufacturing challenges, offers improved reliability and efficiency compared to traditional bga. A spherical piece of solder, a solder ball, is used to join chip packages to pcbs.

from www.aliexpress.com

Via consecutive flow/quench or reflow procedures, solder balls are produced. The ball is typically just off the side of the one of the pads. In integrated circuit (ic) packaging, a solder bump, also a solder ball, or referred simply as “ball” or “bumps”, is a ball of solder that provides the. Originating from ibm, it excels in emc/emi, i/o density, and heat dissipation. The key distinction from placing. Fcbga, despite manufacturing challenges, offers improved reliability and efficiency compared to traditional bga. A spherical piece of solder, a solder ball, is used to join chip packages to pcbs. Solder balls, as the soldering material, are placed on the bottom of the chip and melted during the manufacturing process to join. The process of solder ball mounting involves attaching solder balls onto a wlcsp for packaging.

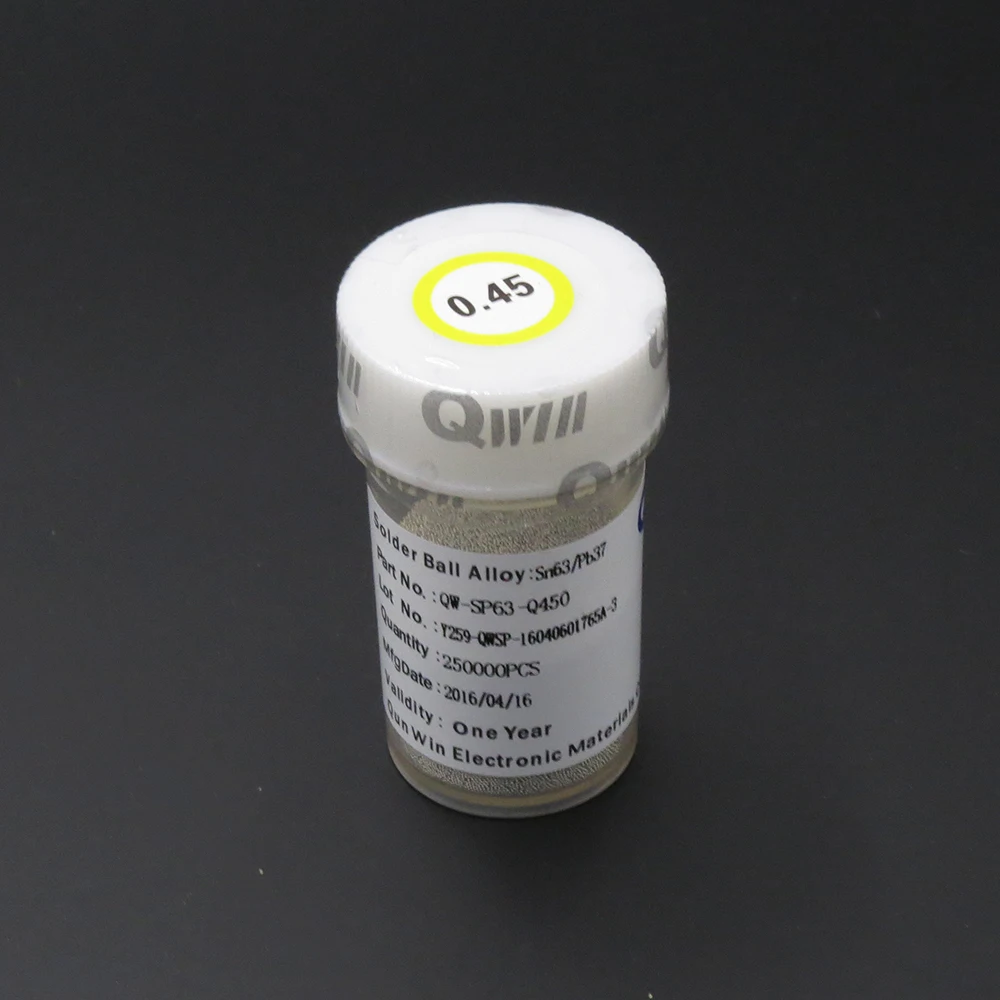

Qwin 250k 0.45mm Pcb Chip Set Chips Bga Reballing Solder Balls Leaded

Solder Balls Chips The key distinction from placing. Fcbga, despite manufacturing challenges, offers improved reliability and efficiency compared to traditional bga. The ball is typically just off the side of the one of the pads. Via consecutive flow/quench or reflow procedures, solder balls are produced. In integrated circuit (ic) packaging, a solder bump, also a solder ball, or referred simply as “ball” or “bumps”, is a ball of solder that provides the. Originating from ibm, it excels in emc/emi, i/o density, and heat dissipation. Solder balls, as the soldering material, are placed on the bottom of the chip and melted during the manufacturing process to join. The process of solder ball mounting involves attaching solder balls onto a wlcsp for packaging. A spherical piece of solder, a solder ball, is used to join chip packages to pcbs. The key distinction from placing.

From www.walmart.com

OTVIAP BGA Solder Ball Leadfree Reballing Soldering PCB Heat Universal Solder Balls Chips The ball is typically just off the side of the one of the pads. Solder balls, as the soldering material, are placed on the bottom of the chip and melted during the manufacturing process to join. Via consecutive flow/quench or reflow procedures, solder balls are produced. The process of solder ball mounting involves attaching solder balls onto a wlcsp for. Solder Balls Chips.

From www.amazon.com

7 Bottles Tin Solder Ball, BGA Solder Balls Solder Ball BGA Reballing Solder Balls Chips The ball is typically just off the side of the one of the pads. Fcbga, despite manufacturing challenges, offers improved reliability and efficiency compared to traditional bga. In integrated circuit (ic) packaging, a solder bump, also a solder ball, or referred simply as “ball” or “bumps”, is a ball of solder that provides the. The process of solder ball mounting. Solder Balls Chips.

From www.amazon.in

Buy PMTC 250k 0.35mm Lead Solder Balls Chip Set IC Soldering Balls for Solder Balls Chips A spherical piece of solder, a solder ball, is used to join chip packages to pcbs. Via consecutive flow/quench or reflow procedures, solder balls are produced. The key distinction from placing. In integrated circuit (ic) packaging, a solder bump, also a solder ball, or referred simply as “ball” or “bumps”, is a ball of solder that provides the. The process. Solder Balls Chips.

From www.gpufix.de

Quality parts for your projects. RAM chips, Power stages, DrMos, Reball Solder Balls Chips Via consecutive flow/quench or reflow procedures, solder balls are produced. Fcbga, despite manufacturing challenges, offers improved reliability and efficiency compared to traditional bga. The key distinction from placing. Solder balls, as the soldering material, are placed on the bottom of the chip and melted during the manufacturing process to join. The process of solder ball mounting involves attaching solder balls. Solder Balls Chips.

From circuitsassembly.com

Circuits Assembly Online Magazine Understanding and Eliminating Mid Solder Balls Chips The ball is typically just off the side of the one of the pads. The key distinction from placing. Via consecutive flow/quench or reflow procedures, solder balls are produced. A spherical piece of solder, a solder ball, is used to join chip packages to pcbs. Solder balls, as the soldering material, are placed on the bottom of the chip and. Solder Balls Chips.

From www.alibaba.com

Bga Solder Balls Chip Soldering Leadfree Solder Beads 0.25mm 0.3mm 0 Solder Balls Chips The ball is typically just off the side of the one of the pads. Originating from ibm, it excels in emc/emi, i/o density, and heat dissipation. Fcbga, despite manufacturing challenges, offers improved reliability and efficiency compared to traditional bga. A spherical piece of solder, a solder ball, is used to join chip packages to pcbs. Via consecutive flow/quench or reflow. Solder Balls Chips.

From www.henkel-adhesives.com

Eliminating MidChip Solder Balls A Practical Guide to Understanding Solder Balls Chips The ball is typically just off the side of the one of the pads. In integrated circuit (ic) packaging, a solder bump, also a solder ball, or referred simply as “ball” or “bumps”, is a ball of solder that provides the. A spherical piece of solder, a solder ball, is used to join chip packages to pcbs. The process of. Solder Balls Chips.

From www.u-obd.com

Leaded BGA Chip reballing solder ball 250K per bottle multiple size Solder Balls Chips The process of solder ball mounting involves attaching solder balls onto a wlcsp for packaging. In integrated circuit (ic) packaging, a solder bump, also a solder ball, or referred simply as “ball” or “bumps”, is a ball of solder that provides the. Via consecutive flow/quench or reflow procedures, solder balls are produced. The key distinction from placing. Originating from ibm,. Solder Balls Chips.

From www.wevolver.com

Solder Reflow An InDepth Guide to the Process and Techniques Solder Balls Chips The process of solder ball mounting involves attaching solder balls onto a wlcsp for packaging. The key distinction from placing. The ball is typically just off the side of the one of the pads. Originating from ibm, it excels in emc/emi, i/o density, and heat dissipation. Solder balls, as the soldering material, are placed on the bottom of the chip. Solder Balls Chips.

From www.alibaba.com

Bga Solder Balls Chip Soldering Leadfree Solder Beads 0.25mm 0.3mm 0 Solder Balls Chips A spherical piece of solder, a solder ball, is used to join chip packages to pcbs. Fcbga, despite manufacturing challenges, offers improved reliability and efficiency compared to traditional bga. Solder balls, as the soldering material, are placed on the bottom of the chip and melted during the manufacturing process to join. The ball is typically just off the side of. Solder Balls Chips.

From northridgefix.com

25,000 Leaded Solder balls for BGA Reballing Choose from 0.35mm, 0.45mm Solder Balls Chips The key distinction from placing. The ball is typically just off the side of the one of the pads. Fcbga, despite manufacturing challenges, offers improved reliability and efficiency compared to traditional bga. A spherical piece of solder, a solder ball, is used to join chip packages to pcbs. Originating from ibm, it excels in emc/emi, i/o density, and heat dissipation.. Solder Balls Chips.

From pluto.la

Working with BGAs Soldering, Reballing, and Rework Pluto Solder Balls Chips Via consecutive flow/quench or reflow procedures, solder balls are produced. Solder balls, as the soldering material, are placed on the bottom of the chip and melted during the manufacturing process to join. A spherical piece of solder, a solder ball, is used to join chip packages to pcbs. Originating from ibm, it excels in emc/emi, i/o density, and heat dissipation.. Solder Balls Chips.

From www.youtube.com

0.2mm diameter solder ball placement YouTube Solder Balls Chips A spherical piece of solder, a solder ball, is used to join chip packages to pcbs. Via consecutive flow/quench or reflow procedures, solder balls are produced. The ball is typically just off the side of the one of the pads. Originating from ibm, it excels in emc/emi, i/o density, and heat dissipation. In integrated circuit (ic) packaging, a solder bump,. Solder Balls Chips.

From www.aliexpress.com

250k Qwin Leadedfree Solder Ball 0.4mm 0.45mm 0.5mm 0.6mm For Bga Solder Balls Chips Fcbga, despite manufacturing challenges, offers improved reliability and efficiency compared to traditional bga. A spherical piece of solder, a solder ball, is used to join chip packages to pcbs. Solder balls, as the soldering material, are placed on the bottom of the chip and melted during the manufacturing process to join. Via consecutive flow/quench or reflow procedures, solder balls are. Solder Balls Chips.

From www.nextpcb.com

Solder Ball Basic Explanation is Here Solder Balls Chips Via consecutive flow/quench or reflow procedures, solder balls are produced. The process of solder ball mounting involves attaching solder balls onto a wlcsp for packaging. Originating from ibm, it excels in emc/emi, i/o density, and heat dissipation. Fcbga, despite manufacturing challenges, offers improved reliability and efficiency compared to traditional bga. The key distinction from placing. Solder balls, as the soldering. Solder Balls Chips.

From www.chipquik.com

Chip Quik Solder Spheres Sn63/Pb37 .030" (0.76mm) diameter 25K Bottle Solder Balls Chips In integrated circuit (ic) packaging, a solder bump, also a solder ball, or referred simply as “ball” or “bumps”, is a ball of solder that provides the. Solder balls, as the soldering material, are placed on the bottom of the chip and melted during the manufacturing process to join. The ball is typically just off the side of the one. Solder Balls Chips.

From www.aliexpress.com

Qwin 250k 0.5mm Pcb Chip Set Chips Bga Reballing Solder Balls Leaded Solder Balls Chips Fcbga, despite manufacturing challenges, offers improved reliability and efficiency compared to traditional bga. Via consecutive flow/quench or reflow procedures, solder balls are produced. Solder balls, as the soldering material, are placed on the bottom of the chip and melted during the manufacturing process to join. The ball is typically just off the side of the one of the pads. A. Solder Balls Chips.

From www.caplinq.com

Solder Spheres Soldering Materials CAPLINQ Corporation Solder Balls Chips The process of solder ball mounting involves attaching solder balls onto a wlcsp for packaging. Fcbga, despite manufacturing challenges, offers improved reliability and efficiency compared to traditional bga. The key distinction from placing. Solder balls, as the soldering material, are placed on the bottom of the chip and melted during the manufacturing process to join. Originating from ibm, it excels. Solder Balls Chips.

From www.anzer-usa.com

Q What is MidChip Solder Balling Anzer USA Blog Solder Balls Chips The key distinction from placing. Via consecutive flow/quench or reflow procedures, solder balls are produced. A spherical piece of solder, a solder ball, is used to join chip packages to pcbs. In integrated circuit (ic) packaging, a solder bump, also a solder ball, or referred simply as “ball” or “bumps”, is a ball of solder that provides the. Originating from. Solder Balls Chips.

From www.electronicsandyou.com

Basic Soldering Guide How to Solder Electronic Components Solder Balls Chips Fcbga, despite manufacturing challenges, offers improved reliability and efficiency compared to traditional bga. A spherical piece of solder, a solder ball, is used to join chip packages to pcbs. The ball is typically just off the side of the one of the pads. Originating from ibm, it excels in emc/emi, i/o density, and heat dissipation. Via consecutive flow/quench or reflow. Solder Balls Chips.

From www.alibaba.com

Bga Solder Balls Chip Soldering Leadfree Solder Beads 0.25mm 0.3mm 0 Solder Balls Chips Originating from ibm, it excels in emc/emi, i/o density, and heat dissipation. The key distinction from placing. The ball is typically just off the side of the one of the pads. Solder balls, as the soldering material, are placed on the bottom of the chip and melted during the manufacturing process to join. Via consecutive flow/quench or reflow procedures, solder. Solder Balls Chips.

From www.aliexpress.com

Qwin 250k 0.45mm Pcb Chip Set Chips Bga Reballing Solder Balls Leaded Solder Balls Chips The key distinction from placing. The process of solder ball mounting involves attaching solder balls onto a wlcsp for packaging. The ball is typically just off the side of the one of the pads. Via consecutive flow/quench or reflow procedures, solder balls are produced. A spherical piece of solder, a solder ball, is used to join chip packages to pcbs.. Solder Balls Chips.

From www.walmart.com

Mgaxyff BGA Solder Ball Leadfree Reballing Soldering PCB Heat Solder Balls Chips Solder balls, as the soldering material, are placed on the bottom of the chip and melted during the manufacturing process to join. The ball is typically just off the side of the one of the pads. Originating from ibm, it excels in emc/emi, i/o density, and heat dissipation. The process of solder ball mounting involves attaching solder balls onto a. Solder Balls Chips.

From www.researchgate.net

Xray inspection of solder balls under PMIC chips on SM2. Mounted PMIC Solder Balls Chips The key distinction from placing. The process of solder ball mounting involves attaching solder balls onto a wlcsp for packaging. In integrated circuit (ic) packaging, a solder bump, also a solder ball, or referred simply as “ball” or “bumps”, is a ball of solder that provides the. Solder balls, as the soldering material, are placed on the bottom of the. Solder Balls Chips.

From www.partswala.us

250K PMTC Lead Free Solder Balls 0.55mm Leadfree BGA Reballing Ball Solder Balls Chips Via consecutive flow/quench or reflow procedures, solder balls are produced. In integrated circuit (ic) packaging, a solder bump, also a solder ball, or referred simply as “ball” or “bumps”, is a ball of solder that provides the. Originating from ibm, it excels in emc/emi, i/o density, and heat dissipation. The ball is typically just off the side of the one. Solder Balls Chips.

From www.indiamart.com

Bga Chip Solder Balls in Nehru Place, New Delhi, Icchipset ID 8804920630 Solder Balls Chips The key distinction from placing. The ball is typically just off the side of the one of the pads. Originating from ibm, it excels in emc/emi, i/o density, and heat dissipation. Fcbga, despite manufacturing challenges, offers improved reliability and efficiency compared to traditional bga. The process of solder ball mounting involves attaching solder balls onto a wlcsp for packaging. In. Solder Balls Chips.

From www.amazon.ca

Silver Solder Precut Chips, 4.5 Gram (about 2000pcs) 1x1mm Solder Chips Solder Balls Chips The process of solder ball mounting involves attaching solder balls onto a wlcsp for packaging. Via consecutive flow/quench or reflow procedures, solder balls are produced. A spherical piece of solder, a solder ball, is used to join chip packages to pcbs. The ball is typically just off the side of the one of the pads. Solder balls, as the soldering. Solder Balls Chips.

From www.aliexpress.com

250K Lead free Solder Balls 0.35MM for Reballing of Most Common Used Solder Balls Chips The process of solder ball mounting involves attaching solder balls onto a wlcsp for packaging. Originating from ibm, it excels in emc/emi, i/o density, and heat dissipation. Fcbga, despite manufacturing challenges, offers improved reliability and efficiency compared to traditional bga. The key distinction from placing. Via consecutive flow/quench or reflow procedures, solder balls are produced. The ball is typically just. Solder Balls Chips.

From www.youtube.com

Best Technique For Soldering & Inspecting BGA Chips Voltlog 352 Solder Balls Chips A spherical piece of solder, a solder ball, is used to join chip packages to pcbs. The key distinction from placing. The process of solder ball mounting involves attaching solder balls onto a wlcsp for packaging. Originating from ibm, it excels in emc/emi, i/o density, and heat dissipation. Fcbga, despite manufacturing challenges, offers improved reliability and efficiency compared to traditional. Solder Balls Chips.

From en.wikipedia.org

Solder ball Wikipedia Solder Balls Chips The process of solder ball mounting involves attaching solder balls onto a wlcsp for packaging. The key distinction from placing. The ball is typically just off the side of the one of the pads. Via consecutive flow/quench or reflow procedures, solder balls are produced. Solder balls, as the soldering material, are placed on the bottom of the chip and melted. Solder Balls Chips.

From www.microsoldering.com

0.20mm Sn63/Pb37 BGA Solder Balls 25,000 Units Micro Soldering Solder Balls Chips A spherical piece of solder, a solder ball, is used to join chip packages to pcbs. The key distinction from placing. Originating from ibm, it excels in emc/emi, i/o density, and heat dissipation. The process of solder ball mounting involves attaching solder balls onto a wlcsp for packaging. In integrated circuit (ic) packaging, a solder bump, also a solder ball,. Solder Balls Chips.

From www.alibaba.com

Bga Solder Balls Chip Soldering Leadfree Solder Beads 0.25mm 0.3mm 0 Solder Balls Chips In integrated circuit (ic) packaging, a solder bump, also a solder ball, or referred simply as “ball” or “bumps”, is a ball of solder that provides the. The ball is typically just off the side of the one of the pads. Via consecutive flow/quench or reflow procedures, solder balls are produced. Originating from ibm, it excels in emc/emi, i/o density,. Solder Balls Chips.

From www.u-obd.com

Pb Free 11 sorts solder balls BGA Solder ball kit Solder Balls Chips Fcbga, despite manufacturing challenges, offers improved reliability and efficiency compared to traditional bga. Solder balls, as the soldering material, are placed on the bottom of the chip and melted during the manufacturing process to join. The ball is typically just off the side of the one of the pads. A spherical piece of solder, a solder ball, is used to. Solder Balls Chips.

From www.instron.cn

Solder Ball Compression Test Instron Solder Balls Chips A spherical piece of solder, a solder ball, is used to join chip packages to pcbs. Originating from ibm, it excels in emc/emi, i/o density, and heat dissipation. The process of solder ball mounting involves attaching solder balls onto a wlcsp for packaging. In integrated circuit (ic) packaging, a solder bump, also a solder ball, or referred simply as “ball”. Solder Balls Chips.

From www.amazon.com.au

BEST 25K Leaded BGA Soldering Balls Reball Reballing Ball Sn63 Pb37 Solder Balls Chips In integrated circuit (ic) packaging, a solder bump, also a solder ball, or referred simply as “ball” or “bumps”, is a ball of solder that provides the. The ball is typically just off the side of the one of the pads. Via consecutive flow/quench or reflow procedures, solder balls are produced. A spherical piece of solder, a solder ball, is. Solder Balls Chips.