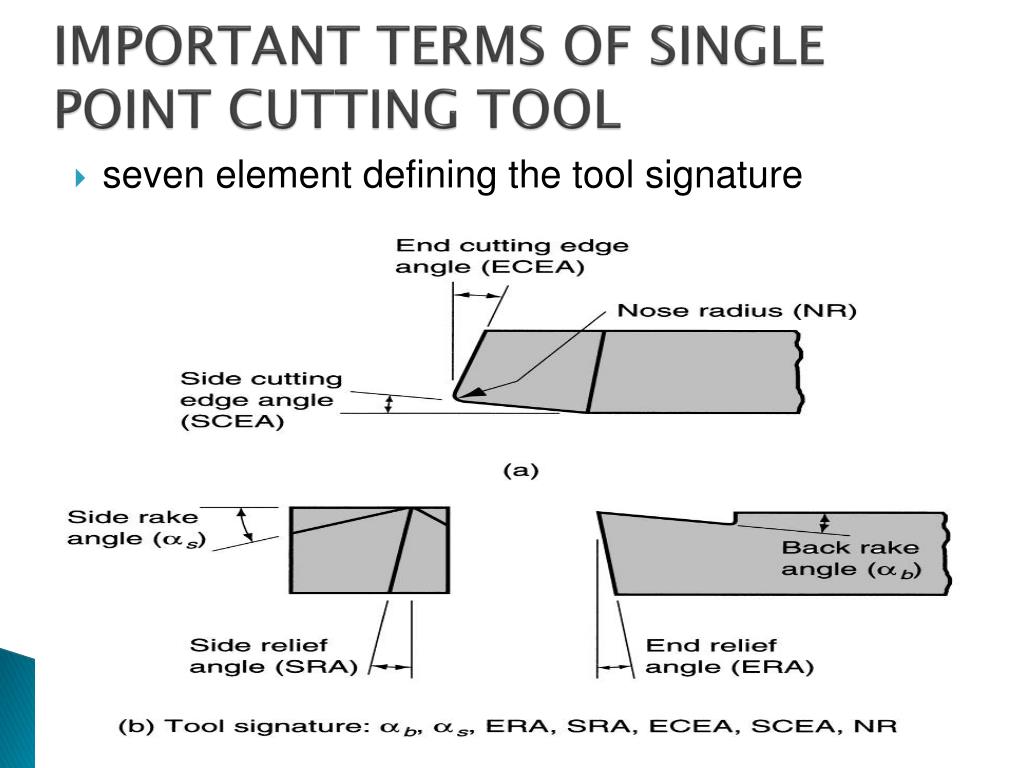

Cutting Tool Geometry And Tool Signature . Commonly, it provides values of rake angles, clearance angles, cutting edge angles, nose radius, etc. today we will discuss about single point cutting tool geometry and how to designate it. cutting tool design requires an understanding of the application difficulties that can be encountered during the machining. Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. A single point cutting tool is widely used in metal cutting industries for forming required shape. therefore, tool signature provides various static geometrical details of that particular cutting tool, especially various angles and nose radius. It is used on lathe and shaper machining for performing operation like turning, facing, chamfering, boring shaping etc. There are many factors that influence the cutting properties of tools, including their surface finish, accuracy of machined surfaces, and their angle and shape. tool cutting edges are shaped and ground to produce the desired geometry, such as sharp points for drilling and rounded noses for turning. the objective of this post is to know about tool angles like clearance angle, rake angle, relief angle and various other geometry of cutting tools. This cutting tool has a single cutting.

from www.slideserve.com

Commonly, it provides values of rake angles, clearance angles, cutting edge angles, nose radius, etc. It is used on lathe and shaper machining for performing operation like turning, facing, chamfering, boring shaping etc. This cutting tool has a single cutting. tool cutting edges are shaped and ground to produce the desired geometry, such as sharp points for drilling and rounded noses for turning. therefore, tool signature provides various static geometrical details of that particular cutting tool, especially various angles and nose radius. There are many factors that influence the cutting properties of tools, including their surface finish, accuracy of machined surfaces, and their angle and shape. the objective of this post is to know about tool angles like clearance angle, rake angle, relief angle and various other geometry of cutting tools. Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. cutting tool design requires an understanding of the application difficulties that can be encountered during the machining. A single point cutting tool is widely used in metal cutting industries for forming required shape.

PPT Chapter 1 PowerPoint Presentation, free download ID1110462

Cutting Tool Geometry And Tool Signature It is used on lathe and shaper machining for performing operation like turning, facing, chamfering, boring shaping etc. It is used on lathe and shaper machining for performing operation like turning, facing, chamfering, boring shaping etc. therefore, tool signature provides various static geometrical details of that particular cutting tool, especially various angles and nose radius. Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. There are many factors that influence the cutting properties of tools, including their surface finish, accuracy of machined surfaces, and their angle and shape. cutting tool design requires an understanding of the application difficulties that can be encountered during the machining. tool cutting edges are shaped and ground to produce the desired geometry, such as sharp points for drilling and rounded noses for turning. This cutting tool has a single cutting. the objective of this post is to know about tool angles like clearance angle, rake angle, relief angle and various other geometry of cutting tools. Commonly, it provides values of rake angles, clearance angles, cutting edge angles, nose radius, etc. today we will discuss about single point cutting tool geometry and how to designate it. A single point cutting tool is widely used in metal cutting industries for forming required shape.

From www.themachinedesign.com

Single Point Cutting Tool Tool Angles , Nomenclature, Geometry Cutting Tool Geometry And Tool Signature There are many factors that influence the cutting properties of tools, including their surface finish, accuracy of machined surfaces, and their angle and shape. today we will discuss about single point cutting tool geometry and how to designate it. A single point cutting tool is widely used in metal cutting industries for forming required shape. the objective of. Cutting Tool Geometry And Tool Signature.

From www.youtube.com

Single Point Cutting Tool Nomenclature, Tool Signature, Side Rake Cutting Tool Geometry And Tool Signature It is used on lathe and shaper machining for performing operation like turning, facing, chamfering, boring shaping etc. This cutting tool has a single cutting. therefore, tool signature provides various static geometrical details of that particular cutting tool, especially various angles and nose radius. A single point cutting tool is widely used in metal cutting industries for forming required. Cutting Tool Geometry And Tool Signature.

From www.mechanicalbooster.com

Single Point Cutting Tool Geometry, Angles, Nomenclature and Signature Cutting Tool Geometry And Tool Signature therefore, tool signature provides various static geometrical details of that particular cutting tool, especially various angles and nose radius. There are many factors that influence the cutting properties of tools, including their surface finish, accuracy of machined surfaces, and their angle and shape. This cutting tool has a single cutting. today we will discuss about single point cutting. Cutting Tool Geometry And Tool Signature.

From dxorlulgs.blob.core.windows.net

Single Point Cutting Tools Examples at Michael Melton blog Cutting Tool Geometry And Tool Signature It is used on lathe and shaper machining for performing operation like turning, facing, chamfering, boring shaping etc. cutting tool design requires an understanding of the application difficulties that can be encountered during the machining. today we will discuss about single point cutting tool geometry and how to designate it. therefore, tool signature provides various static geometrical. Cutting Tool Geometry And Tool Signature.

From mechanicalbasics.com

Single Point Cutting Tool With FAQ's Mechanical Basics Cutting Tool Geometry And Tool Signature Commonly, it provides values of rake angles, clearance angles, cutting edge angles, nose radius, etc. A single point cutting tool is widely used in metal cutting industries for forming required shape. tool cutting edges are shaped and ground to produce the desired geometry, such as sharp points for drilling and rounded noses for turning. There are many factors that. Cutting Tool Geometry And Tool Signature.

From www.mechanicalclasses.com

Introduction And Nomenclature Of Single Point Cutting Tool And Tool Cutting Tool Geometry And Tool Signature therefore, tool signature provides various static geometrical details of that particular cutting tool, especially various angles and nose radius. Commonly, it provides values of rake angles, clearance angles, cutting edge angles, nose radius, etc. There are many factors that influence the cutting properties of tools, including their surface finish, accuracy of machined surfaces, and their angle and shape. . Cutting Tool Geometry And Tool Signature.

From www.researchgate.net

1. Cutting tool geometry. Download Scientific Diagram Cutting Tool Geometry And Tool Signature tool cutting edges are shaped and ground to produce the desired geometry, such as sharp points for drilling and rounded noses for turning. the objective of this post is to know about tool angles like clearance angle, rake angle, relief angle and various other geometry of cutting tools. This cutting tool has a single cutting. It is used. Cutting Tool Geometry And Tool Signature.

From www.theengineerspost.com

Single Point Cutting Tool Diagram, Nomenclature, Material [PDF] Cutting Tool Geometry And Tool Signature Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. cutting tool design requires an understanding of the application difficulties that can be encountered during the machining. the objective of this post is to know about tool angles like clearance angle, rake angle, relief angle and various other geometry of cutting tools. tool. Cutting Tool Geometry And Tool Signature.

From www.manufacturinget.org

ANSI Tool Signature Models Cutting Tool Geometry And Tool Signature It is used on lathe and shaper machining for performing operation like turning, facing, chamfering, boring shaping etc. cutting tool design requires an understanding of the application difficulties that can be encountered during the machining. This cutting tool has a single cutting. the objective of this post is to know about tool angles like clearance angle, rake angle,. Cutting Tool Geometry And Tool Signature.

From www.youtube.com

Single Point Cutting Tool Geometry l Tool Geometry l Tool Nomenclature Cutting Tool Geometry And Tool Signature tool cutting edges are shaped and ground to produce the desired geometry, such as sharp points for drilling and rounded noses for turning. Commonly, it provides values of rake angles, clearance angles, cutting edge angles, nose radius, etc. There are many factors that influence the cutting properties of tools, including their surface finish, accuracy of machined surfaces, and their. Cutting Tool Geometry And Tool Signature.

From www.mechanicalbooster.com

Single Point Cutting Tool Geometry, Angles, Nomenclature and Signature Cutting Tool Geometry And Tool Signature It is used on lathe and shaper machining for performing operation like turning, facing, chamfering, boring shaping etc. the objective of this post is to know about tool angles like clearance angle, rake angle, relief angle and various other geometry of cutting tools. A single point cutting tool is widely used in metal cutting industries for forming required shape.. Cutting Tool Geometry And Tool Signature.

From www.youtube.com

Single Point Cutting Tool Geometry Single Point Cutting Tool Cutting Tool Geometry And Tool Signature There are many factors that influence the cutting properties of tools, including their surface finish, accuracy of machined surfaces, and their angle and shape. tool cutting edges are shaped and ground to produce the desired geometry, such as sharp points for drilling and rounded noses for turning. the objective of this post is to know about tool angles. Cutting Tool Geometry And Tool Signature.

From www.youtube.com

Cutting tool signature Geometry of single point cutting tool YouTube Cutting Tool Geometry And Tool Signature tool cutting edges are shaped and ground to produce the desired geometry, such as sharp points for drilling and rounded noses for turning. It is used on lathe and shaper machining for performing operation like turning, facing, chamfering, boring shaping etc. cutting tool design requires an understanding of the application difficulties that can be encountered during the machining.. Cutting Tool Geometry And Tool Signature.

From www.mechanicalbooster.com

Single Point Cutting Tool Geometry, Angles, Nomenclature and Signature Cutting Tool Geometry And Tool Signature Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. therefore, tool signature provides various static geometrical details of that particular cutting tool, especially various angles and nose radius. Commonly, it provides values of rake angles, clearance angles, cutting edge angles, nose radius, etc. There are many factors that influence the cutting properties of tools,. Cutting Tool Geometry And Tool Signature.

From www.mech4study.com

Single Point Cutting Tool Nomenclature, Angle,Geometry and Signature Cutting Tool Geometry And Tool Signature the objective of this post is to know about tool angles like clearance angle, rake angle, relief angle and various other geometry of cutting tools. today we will discuss about single point cutting tool geometry and how to designate it. Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. There are many factors. Cutting Tool Geometry And Tool Signature.

From dxorlulgs.blob.core.windows.net

Single Point Cutting Tools Examples at Michael Melton blog Cutting Tool Geometry And Tool Signature This cutting tool has a single cutting. A single point cutting tool is widely used in metal cutting industries for forming required shape. Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. today we will discuss about single point cutting tool geometry and how to designate it. There are many factors that influence the. Cutting Tool Geometry And Tool Signature.

From www.scribd.com

Cutting Tool Geometry & Signature PDF Cutting Tool Geometry And Tool Signature cutting tool design requires an understanding of the application difficulties that can be encountered during the machining. Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. It is used on lathe and shaper machining for performing operation like turning, facing, chamfering, boring shaping etc. the objective of this post is to know about. Cutting Tool Geometry And Tool Signature.

From www.themachinedesign.com

Single Point Cutting Tool Tool Angles , Nomenclature, Geometry Cutting Tool Geometry And Tool Signature tool cutting edges are shaped and ground to produce the desired geometry, such as sharp points for drilling and rounded noses for turning. therefore, tool signature provides various static geometrical details of that particular cutting tool, especially various angles and nose radius. cutting tool design requires an understanding of the application difficulties that can be encountered during. Cutting Tool Geometry And Tool Signature.

From www.researchgate.net

Geometry of singlepoint cutting tool Download Scientific Diagram Cutting Tool Geometry And Tool Signature There are many factors that influence the cutting properties of tools, including their surface finish, accuracy of machined surfaces, and their angle and shape. therefore, tool signature provides various static geometrical details of that particular cutting tool, especially various angles and nose radius. It is used on lathe and shaper machining for performing operation like turning, facing, chamfering, boring. Cutting Tool Geometry And Tool Signature.

From www.slideserve.com

PPT Chapter 1 PowerPoint Presentation, free download ID1110462 Cutting Tool Geometry And Tool Signature There are many factors that influence the cutting properties of tools, including their surface finish, accuracy of machined surfaces, and their angle and shape. It is used on lathe and shaper machining for performing operation like turning, facing, chamfering, boring shaping etc. cutting tool design requires an understanding of the application difficulties that can be encountered during the machining.. Cutting Tool Geometry And Tool Signature.

From www.mech4study.com

Single Point Cutting Tool Nomenclature, Angle,Geometry and Signature Cutting Tool Geometry And Tool Signature the objective of this post is to know about tool angles like clearance angle, rake angle, relief angle and various other geometry of cutting tools. A single point cutting tool is widely used in metal cutting industries for forming required shape. tool cutting edges are shaped and ground to produce the desired geometry, such as sharp points for. Cutting Tool Geometry And Tool Signature.

From www.themachinedesign.com

Single Point Cutting Tool Nomenclature, Geometry The Machine Design Cutting Tool Geometry And Tool Signature tool cutting edges are shaped and ground to produce the desired geometry, such as sharp points for drilling and rounded noses for turning. It is used on lathe and shaper machining for performing operation like turning, facing, chamfering, boring shaping etc. A single point cutting tool is widely used in metal cutting industries for forming required shape. Commonly, it. Cutting Tool Geometry And Tool Signature.

From atelier-yuwa.ciao.jp

Single Point Cutting Tool Nomenclature And Tool Signature atelier Cutting Tool Geometry And Tool Signature tool cutting edges are shaped and ground to produce the desired geometry, such as sharp points for drilling and rounded noses for turning. therefore, tool signature provides various static geometrical details of that particular cutting tool, especially various angles and nose radius. A single point cutting tool is widely used in metal cutting industries for forming required shape.. Cutting Tool Geometry And Tool Signature.

From mechtech69.blogspot.com

SINGLE POINT CUTTING TOOL NOMENCLATURE (DRAWING , GEOMETRY , ELEMENT Cutting Tool Geometry And Tool Signature today we will discuss about single point cutting tool geometry and how to designate it. It is used on lathe and shaper machining for performing operation like turning, facing, chamfering, boring shaping etc. the objective of this post is to know about tool angles like clearance angle, rake angle, relief angle and various other geometry of cutting tools.. Cutting Tool Geometry And Tool Signature.

From www.youtube.com

Understanding Cutting Tool GeometryTool Signature ASA & ORS System Cutting Tool Geometry And Tool Signature therefore, tool signature provides various static geometrical details of that particular cutting tool, especially various angles and nose radius. today we will discuss about single point cutting tool geometry and how to designate it. the objective of this post is to know about tool angles like clearance angle, rake angle, relief angle and various other geometry of. Cutting Tool Geometry And Tool Signature.

From dxoieayfl.blob.core.windows.net

Metal Cutting Tool Geometry at Cheryl Brown blog Cutting Tool Geometry And Tool Signature Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. There are many factors that influence the cutting properties of tools, including their surface finish, accuracy of machined surfaces, and their angle and shape. It is used on lathe and shaper machining for performing operation like turning, facing, chamfering, boring shaping etc. Commonly, it provides values. Cutting Tool Geometry And Tool Signature.

From www.youtube.com

Cutting Tool Signature, Nomenclature, Designation, Geometry Animation Cutting Tool Geometry And Tool Signature tool cutting edges are shaped and ground to produce the desired geometry, such as sharp points for drilling and rounded noses for turning. There are many factors that influence the cutting properties of tools, including their surface finish, accuracy of machined surfaces, and their angle and shape. Commonly, it provides values of rake angles, clearance angles, cutting edge angles,. Cutting Tool Geometry And Tool Signature.

From www.youtube.com

single point cutting tool geometry Tool Signature Nomenclature of Cutting Tool Geometry And Tool Signature therefore, tool signature provides various static geometrical details of that particular cutting tool, especially various angles and nose radius. There are many factors that influence the cutting properties of tools, including their surface finish, accuracy of machined surfaces, and their angle and shape. This cutting tool has a single cutting. It is used on lathe and shaper machining for. Cutting Tool Geometry And Tool Signature.

From www.green-mechanic.com

Green Mechanic Explain single point cutting tool geometry, angles and Cutting Tool Geometry And Tool Signature This cutting tool has a single cutting. There are many factors that influence the cutting properties of tools, including their surface finish, accuracy of machined surfaces, and their angle and shape. A single point cutting tool is widely used in metal cutting industries for forming required shape. tool cutting edges are shaped and ground to produce the desired geometry,. Cutting Tool Geometry And Tool Signature.

From www.youtube.com

Single Point Cutting Tool, Tool Signature and Cutting tool Material Cutting Tool Geometry And Tool Signature It is used on lathe and shaper machining for performing operation like turning, facing, chamfering, boring shaping etc. A single point cutting tool is widely used in metal cutting industries for forming required shape. therefore, tool signature provides various static geometrical details of that particular cutting tool, especially various angles and nose radius. cutting tool design requires an. Cutting Tool Geometry And Tool Signature.

From blog.enerpac.com

Understanding Cutting Tool Geometry Enerpac Blog Cutting Tool Geometry And Tool Signature cutting tool design requires an understanding of the application difficulties that can be encountered during the machining. There are many factors that influence the cutting properties of tools, including their surface finish, accuracy of machined surfaces, and their angle and shape. therefore, tool signature provides various static geometrical details of that particular cutting tool, especially various angles and. Cutting Tool Geometry And Tool Signature.

From www.youtube.com

02_02 Geometry of a Single Point Cutting Tool YouTube Cutting Tool Geometry And Tool Signature This cutting tool has a single cutting. cutting tool design requires an understanding of the application difficulties that can be encountered during the machining. today we will discuss about single point cutting tool geometry and how to designate it. the objective of this post is to know about tool angles like clearance angle, rake angle, relief angle. Cutting Tool Geometry And Tool Signature.

From www.slideserve.com

PPT Chapter 23 CUTTING TOOL TECHNOLOGY PowerPoint Presentation, free Cutting Tool Geometry And Tool Signature Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. therefore, tool signature provides various static geometrical details of that particular cutting tool, especially various angles and nose radius. tool cutting edges are shaped and ground to produce the desired geometry, such as sharp points for drilling and rounded noses for turning. There are. Cutting Tool Geometry And Tool Signature.

From dxoieayfl.blob.core.windows.net

Metal Cutting Tool Geometry at Cheryl Brown blog Cutting Tool Geometry And Tool Signature Commonly, it provides values of rake angles, clearance angles, cutting edge angles, nose radius, etc. cutting tool design requires an understanding of the application difficulties that can be encountered during the machining. There are many factors that influence the cutting properties of tools, including their surface finish, accuracy of machined surfaces, and their angle and shape. the objective. Cutting Tool Geometry And Tool Signature.

From learnmechanical.com

Single Point Cutting Tool Definition, Types, Geometry, Nomenclature Cutting Tool Geometry And Tool Signature There are many factors that influence the cutting properties of tools, including their surface finish, accuracy of machined surfaces, and their angle and shape. therefore, tool signature provides various static geometrical details of that particular cutting tool, especially various angles and nose radius. It is used on lathe and shaper machining for performing operation like turning, facing, chamfering, boring. Cutting Tool Geometry And Tool Signature.