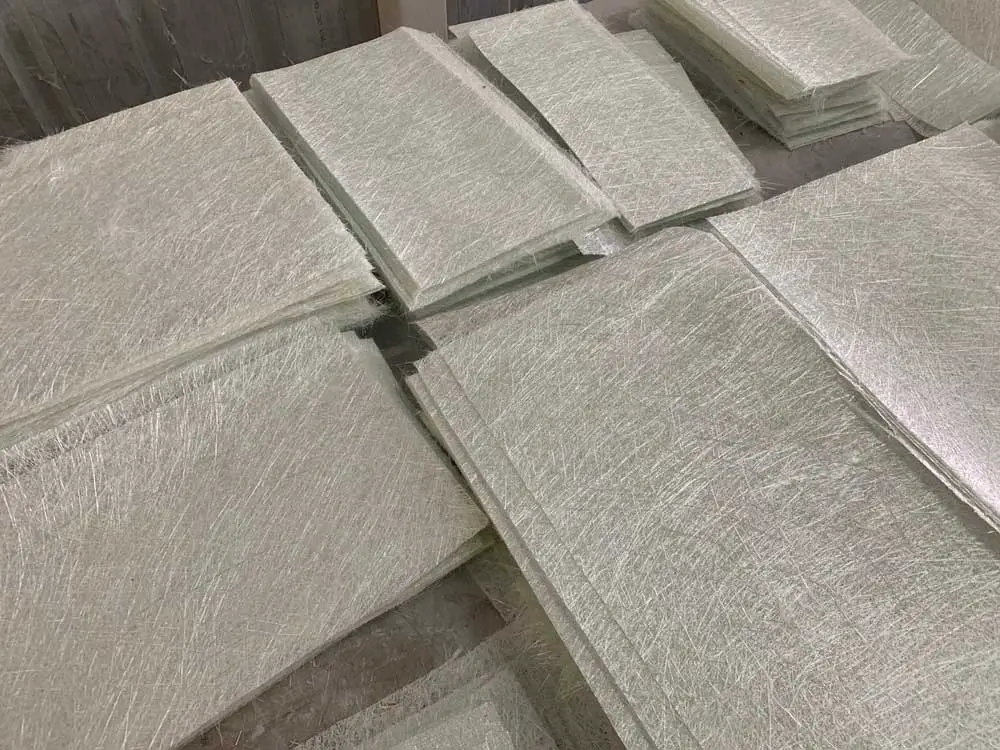

How To Make Flat Fiberglass Panel . from youtube's very first how to video maker!making a fire proof / flame retardant fiberglass flat sheet for. This episode is mostly prep work. A lot of which was done off camera, e.g., the cradle the. if you've purchased a fiberglass. 4 layers of 600 chopped strand and 1 of double bias to be made onto. making fiberglass panels. Do you want to build up thickness quickly? you can make fiberglass molding at home by following these simple steps. the first step when looking at fiberglass projects is to decide what is important. Answering questions like these first will help you choose the best reinforcement and resins for. Do you need it to be abrasion, corrosion or uv resistant? Is strength the most important? Gather the necessary materials , including a foam pattern , mold release wax , gelcoat , resin and hardener, fiberglass mat, and tools like brushes or rollers. this article is for those that would also like to make their own fiberglass board and note its end use not just limited to tricopter builds. Are you concerned about weight?

from www.nccuttingtools.com

the first step when looking at fiberglass projects is to decide what is important. if you've purchased a fiberglass. Is strength the most important? Answering questions like these first will help you choose the best reinforcement and resins for. Are you concerned about weight? Do you want to build up thickness quickly? 4 layers of 600 chopped strand and 1 of double bias to be made onto. you can make fiberglass molding at home by following these simple steps. Gather the necessary materials , including a foam pattern , mold release wax , gelcoat , resin and hardener, fiberglass mat, and tools like brushes or rollers. Do you need it to be abrasion, corrosion or uv resistant?

How to Cut Fiberglass 6 Tips for Cutting Fiberglass in the Best Way

How To Make Flat Fiberglass Panel Are you concerned about weight? 4 layers of 600 chopped strand and 1 of double bias to be made onto. this article is for those that would also like to make their own fiberglass board and note its end use not just limited to tricopter builds. Do you want to build up thickness quickly? Gather the necessary materials , including a foam pattern , mold release wax , gelcoat , resin and hardener, fiberglass mat, and tools like brushes or rollers. This episode is mostly prep work. from youtube's very first how to video maker!making a fire proof / flame retardant fiberglass flat sheet for. Do you need it to be abrasion, corrosion or uv resistant? making fiberglass panels. A lot of which was done off camera, e.g., the cradle the. if you've purchased a fiberglass. Is strength the most important? the first step when looking at fiberglass projects is to decide what is important. Are you concerned about weight? Answering questions like these first will help you choose the best reinforcement and resins for. you can make fiberglass molding at home by following these simple steps.

From www.youtube.com

how to install GRP fibreglass flat roof tutorial part 2 YouTube How To Make Flat Fiberglass Panel the first step when looking at fiberglass projects is to decide what is important. Gather the necessary materials , including a foam pattern , mold release wax , gelcoat , resin and hardener, fiberglass mat, and tools like brushes or rollers. A lot of which was done off camera, e.g., the cradle the. if you've purchased a fiberglass.. How To Make Flat Fiberglass Panel.

From learnglassblowing.com

How Fiberglass Is Made Learn Glass Blowing How To Make Flat Fiberglass Panel making fiberglass panels. Are you concerned about weight? this article is for those that would also like to make their own fiberglass board and note its end use not just limited to tricopter builds. you can make fiberglass molding at home by following these simple steps. Do you need it to be abrasion, corrosion or uv resistant?. How To Make Flat Fiberglass Panel.

From www.fiber-tech.net

Photo Gallery FiberTech Industries How To Make Flat Fiberglass Panel A lot of which was done off camera, e.g., the cradle the. Do you want to build up thickness quickly? 4 layers of 600 chopped strand and 1 of double bias to be made onto. Is strength the most important? making fiberglass panels. this article is for those that would also like to make their own fiberglass. How To Make Flat Fiberglass Panel.

From shapesgrp.co.uk

Readymade Fibreglass Flat Roofing Sheet Kits Shapes GRP How To Make Flat Fiberglass Panel the first step when looking at fiberglass projects is to decide what is important. Are you concerned about weight? Gather the necessary materials , including a foam pattern , mold release wax , gelcoat , resin and hardener, fiberglass mat, and tools like brushes or rollers. if you've purchased a fiberglass. Is strength the most important? from. How To Make Flat Fiberglass Panel.

From www.nccuttingtools.com

How to Cut Fiberglass 6 Tips for Cutting Fiberglass in the Best Way How To Make Flat Fiberglass Panel from youtube's very first how to video maker!making a fire proof / flame retardant fiberglass flat sheet for. this article is for those that would also like to make their own fiberglass board and note its end use not just limited to tricopter builds. if you've purchased a fiberglass. Do you need it to be abrasion, corrosion. How To Make Flat Fiberglass Panel.

From www.youtube.com

Making fiberglass panels YouTube How To Make Flat Fiberglass Panel making fiberglass panels. the first step when looking at fiberglass projects is to decide what is important. this article is for those that would also like to make their own fiberglass board and note its end use not just limited to tricopter builds. if you've purchased a fiberglass. Do you want to build up thickness quickly?. How To Make Flat Fiberglass Panel.

From everpartner28.en.made-in-china.com

Flat Fiberglass Reinforced Plastic (FRP) Roofing Plate, Fiberglass How To Make Flat Fiberglass Panel the first step when looking at fiberglass projects is to decide what is important. Is strength the most important? you can make fiberglass molding at home by following these simple steps. making fiberglass panels. This episode is mostly prep work. Are you concerned about weight? this article is for those that would also like to make. How To Make Flat Fiberglass Panel.

From shapesgrp.co.uk

Readymade Fibreglass Flat Roofing Sheet Kits Shapes GRP How To Make Flat Fiberglass Panel you can make fiberglass molding at home by following these simple steps. Is strength the most important? Gather the necessary materials , including a foam pattern , mold release wax , gelcoat , resin and hardener, fiberglass mat, and tools like brushes or rollers. if you've purchased a fiberglass. from youtube's very first how to video maker!making. How To Make Flat Fiberglass Panel.

From www.iqsdirectory.com

Fiberglass Sheets Properties, Applications, Advantages, and Types How To Make Flat Fiberglass Panel Are you concerned about weight? 4 layers of 600 chopped strand and 1 of double bias to be made onto. Is strength the most important? Do you want to build up thickness quickly? Answering questions like these first will help you choose the best reinforcement and resins for. This episode is mostly prep work. you can make fiberglass. How To Make Flat Fiberglass Panel.

From www.ehow.com

How to Build My Own Fiberglass Panels Our Pastimes How To Make Flat Fiberglass Panel Do you need it to be abrasion, corrosion or uv resistant? This episode is mostly prep work. A lot of which was done off camera, e.g., the cradle the. Is strength the most important? the first step when looking at fiberglass projects is to decide what is important. making fiberglass panels. from youtube's very first how to. How To Make Flat Fiberglass Panel.

From thecompositegroup.co.nz

Flat sandwich panels / Flat fibreglass sheet The Composite Group How To Make Flat Fiberglass Panel this article is for those that would also like to make their own fiberglass board and note its end use not just limited to tricopter builds. if you've purchased a fiberglass. you can make fiberglass molding at home by following these simple steps. making fiberglass panels. Are you concerned about weight? 4 layers of 600. How To Make Flat Fiberglass Panel.

From www.whowhatwhendad.com

How to Make Fiberglass Interior Panels Who What When Dad How To Make Flat Fiberglass Panel This episode is mostly prep work. Answering questions like these first will help you choose the best reinforcement and resins for. Is strength the most important? Gather the necessary materials , including a foam pattern , mold release wax , gelcoat , resin and hardener, fiberglass mat, and tools like brushes or rollers. this article is for those that. How To Make Flat Fiberglass Panel.

From www.youtube.com

Ballistic Fiberglass Panels YouTube How To Make Flat Fiberglass Panel you can make fiberglass molding at home by following these simple steps. Is strength the most important? if you've purchased a fiberglass. Are you concerned about weight? this article is for those that would also like to make their own fiberglass board and note its end use not just limited to tricopter builds. making fiberglass panels.. How To Make Flat Fiberglass Panel.

From www.zameen.com

Fiberglass Wall Panels Advantages & Installation Zameen Blog How To Make Flat Fiberglass Panel 4 layers of 600 chopped strand and 1 of double bias to be made onto. Is strength the most important? A lot of which was done off camera, e.g., the cradle the. Gather the necessary materials , including a foam pattern , mold release wax , gelcoat , resin and hardener, fiberglass mat, and tools like brushes or rollers.. How To Make Flat Fiberglass Panel.

From www.tstarco.com

Fiberglass Flat Bar/ Fiberglass Strip Tstar Composites Co.,Ltd. How To Make Flat Fiberglass Panel 4 layers of 600 chopped strand and 1 of double bias to be made onto. Is strength the most important? Gather the necessary materials , including a foam pattern , mold release wax , gelcoat , resin and hardener, fiberglass mat, and tools like brushes or rollers. this article is for those that would also like to make. How To Make Flat Fiberglass Panel.

From dipcraft.com

Fiberglass roofing panels and corrugated roof panels Dipcraft How To Make Flat Fiberglass Panel Gather the necessary materials , including a foam pattern , mold release wax , gelcoat , resin and hardener, fiberglass mat, and tools like brushes or rollers. Are you concerned about weight? if you've purchased a fiberglass. Answering questions like these first will help you choose the best reinforcement and resins for. Is strength the most important? 4. How To Make Flat Fiberglass Panel.

From www.tstarco.com

52mm fiberglass composite flat bar,FRP fiberglass panels/mat Tstar How To Make Flat Fiberglass Panel Do you need it to be abrasion, corrosion or uv resistant? this article is for those that would also like to make their own fiberglass board and note its end use not just limited to tricopter builds. if you've purchased a fiberglass. Is strength the most important? from youtube's very first how to video maker!making a fire. How To Make Flat Fiberglass Panel.

From exoyluuhc.blob.core.windows.net

Fiberglass Boat Panels at Andrea Villalobos blog How To Make Flat Fiberglass Panel Gather the necessary materials , including a foam pattern , mold release wax , gelcoat , resin and hardener, fiberglass mat, and tools like brushes or rollers. the first step when looking at fiberglass projects is to decide what is important. Are you concerned about weight? Do you need it to be abrasion, corrosion or uv resistant? making. How To Make Flat Fiberglass Panel.

From exouwphza.blob.core.windows.net

How To Make A Fiberglass Panel at Maria Garza blog How To Make Flat Fiberglass Panel this article is for those that would also like to make their own fiberglass board and note its end use not just limited to tricopter builds. Answering questions like these first will help you choose the best reinforcement and resins for. A lot of which was done off camera, e.g., the cradle the. Are you concerned about weight? Do. How To Make Flat Fiberglass Panel.

From fiberglasswarehouse.com

Basic Fiberglass Mold Making Guide Fiberglass Warehouse How To Make Flat Fiberglass Panel you can make fiberglass molding at home by following these simple steps. A lot of which was done off camera, e.g., the cradle the. Is strength the most important? this article is for those that would also like to make their own fiberglass board and note its end use not just limited to tricopter builds. 4 layers. How To Make Flat Fiberglass Panel.

From www.youtube.com

How to FIBREGLASS A ROOF How to Fibreglass a Bay Roof DIY YouTube How To Make Flat Fiberglass Panel from youtube's very first how to video maker!making a fire proof / flame retardant fiberglass flat sheet for. if you've purchased a fiberglass. A lot of which was done off camera, e.g., the cradle the. Is strength the most important? Answering questions like these first will help you choose the best reinforcement and resins for. the first. How To Make Flat Fiberglass Panel.

From exouwphza.blob.core.windows.net

How To Make A Fiberglass Panel at Maria Garza blog How To Make Flat Fiberglass Panel A lot of which was done off camera, e.g., the cradle the. making fiberglass panels. if you've purchased a fiberglass. This episode is mostly prep work. Do you want to build up thickness quickly? from youtube's very first how to video maker!making a fire proof / flame retardant fiberglass flat sheet for. you can make fiberglass. How To Make Flat Fiberglass Panel.

From www.digitalawardzz.com

Corrugated Fiberglass Roofing Panels Installation Glass Designs How To Make Flat Fiberglass Panel this article is for those that would also like to make their own fiberglass board and note its end use not just limited to tricopter builds. Do you want to build up thickness quickly? Is strength the most important? you can make fiberglass molding at home by following these simple steps. Do you need it to be abrasion,. How To Make Flat Fiberglass Panel.

From www.youtube.com

Making fiberglass panels YouTube How To Make Flat Fiberglass Panel the first step when looking at fiberglass projects is to decide what is important. if you've purchased a fiberglass. making fiberglass panels. Do you need it to be abrasion, corrosion or uv resistant? 4 layers of 600 chopped strand and 1 of double bias to be made onto. Gather the necessary materials , including a foam. How To Make Flat Fiberglass Panel.

From www.nccuttingtools.com

How to Cut Fiberglass 6 Tips for Cutting Fiberglass in the Best Way How To Make Flat Fiberglass Panel This episode is mostly prep work. if you've purchased a fiberglass. making fiberglass panels. this article is for those that would also like to make their own fiberglass board and note its end use not just limited to tricopter builds. 4 layers of 600 chopped strand and 1 of double bias to be made onto. . How To Make Flat Fiberglass Panel.

From www.liveabout.com

How to Use Fiberglass Reinforced Panels (FRP) How To Make Flat Fiberglass Panel from youtube's very first how to video maker!making a fire proof / flame retardant fiberglass flat sheet for. Do you want to build up thickness quickly? Are you concerned about weight? 4 layers of 600 chopped strand and 1 of double bias to be made onto. you can make fiberglass molding at home by following these simple. How To Make Flat Fiberglass Panel.

From www.youtube.com

Fiberglass sheet making step by step process YouTube How To Make Flat Fiberglass Panel you can make fiberglass molding at home by following these simple steps. Answering questions like these first will help you choose the best reinforcement and resins for. the first step when looking at fiberglass projects is to decide what is important. A lot of which was done off camera, e.g., the cradle the. Are you concerned about weight?. How To Make Flat Fiberglass Panel.

From www.dofrp.com

FRP sheet FRP flat sheet fiberglass sheets FRP roof panels How To Make Flat Fiberglass Panel A lot of which was done off camera, e.g., the cradle the. this article is for those that would also like to make their own fiberglass board and note its end use not just limited to tricopter builds. 4 layers of 600 chopped strand and 1 of double bias to be made onto. if you've purchased a. How To Make Flat Fiberglass Panel.

From www.ecplaza.net

Fiberglass Flat Panel With Embossed Surface Hangzhou Jizhan Building How To Make Flat Fiberglass Panel this article is for those that would also like to make their own fiberglass board and note its end use not just limited to tricopter builds. the first step when looking at fiberglass projects is to decide what is important. Answering questions like these first will help you choose the best reinforcement and resins for. 4 layers. How To Make Flat Fiberglass Panel.

From www.mysmartserve.com

How To Install Fiberglass Patio Roofing Patio Ideas How To Make Flat Fiberglass Panel Gather the necessary materials , including a foam pattern , mold release wax , gelcoat , resin and hardener, fiberglass mat, and tools like brushes or rollers. Do you want to build up thickness quickly? Do you need it to be abrasion, corrosion or uv resistant? this article is for those that would also like to make their own. How To Make Flat Fiberglass Panel.

From www.youtube.com

Custom made Fibreglass Flat Sheet East Coast Fibreglass YouTube How To Make Flat Fiberglass Panel making fiberglass panels. you can make fiberglass molding at home by following these simple steps. from youtube's very first how to video maker!making a fire proof / flame retardant fiberglass flat sheet for. Are you concerned about weight? 4 layers of 600 chopped strand and 1 of double bias to be made onto. the first. How To Make Flat Fiberglass Panel.

From www.damagecontrol-911.com

What Are Fiberglass Roof Panels? A Beginners Guide How To Make Flat Fiberglass Panel Do you need it to be abrasion, corrosion or uv resistant? Do you want to build up thickness quickly? Answering questions like these first will help you choose the best reinforcement and resins for. This episode is mostly prep work. the first step when looking at fiberglass projects is to decide what is important. Are you concerned about weight?. How To Make Flat Fiberglass Panel.

From www.youtube.com

How to easily make Fiberglass Panels YouTube How To Make Flat Fiberglass Panel A lot of which was done off camera, e.g., the cradle the. 4 layers of 600 chopped strand and 1 of double bias to be made onto. Answering questions like these first will help you choose the best reinforcement and resins for. making fiberglass panels. the first step when looking at fiberglass projects is to decide what. How To Make Flat Fiberglass Panel.

From www.damagecontrol-911.com

What Are Fiberglass Roof Panels? A Beginners Guide How To Make Flat Fiberglass Panel making fiberglass panels. Do you need it to be abrasion, corrosion or uv resistant? Gather the necessary materials , including a foam pattern , mold release wax , gelcoat , resin and hardener, fiberglass mat, and tools like brushes or rollers. Are you concerned about weight? if you've purchased a fiberglass. Do you want to build up thickness. How To Make Flat Fiberglass Panel.

From www.digitalawardzz.com

Corrugated Fiberglass Roofing Panels Installation Glass Designs How To Make Flat Fiberglass Panel if you've purchased a fiberglass. Are you concerned about weight? 4 layers of 600 chopped strand and 1 of double bias to be made onto. the first step when looking at fiberglass projects is to decide what is important. A lot of which was done off camera, e.g., the cradle the. Gather the necessary materials , including. How To Make Flat Fiberglass Panel.