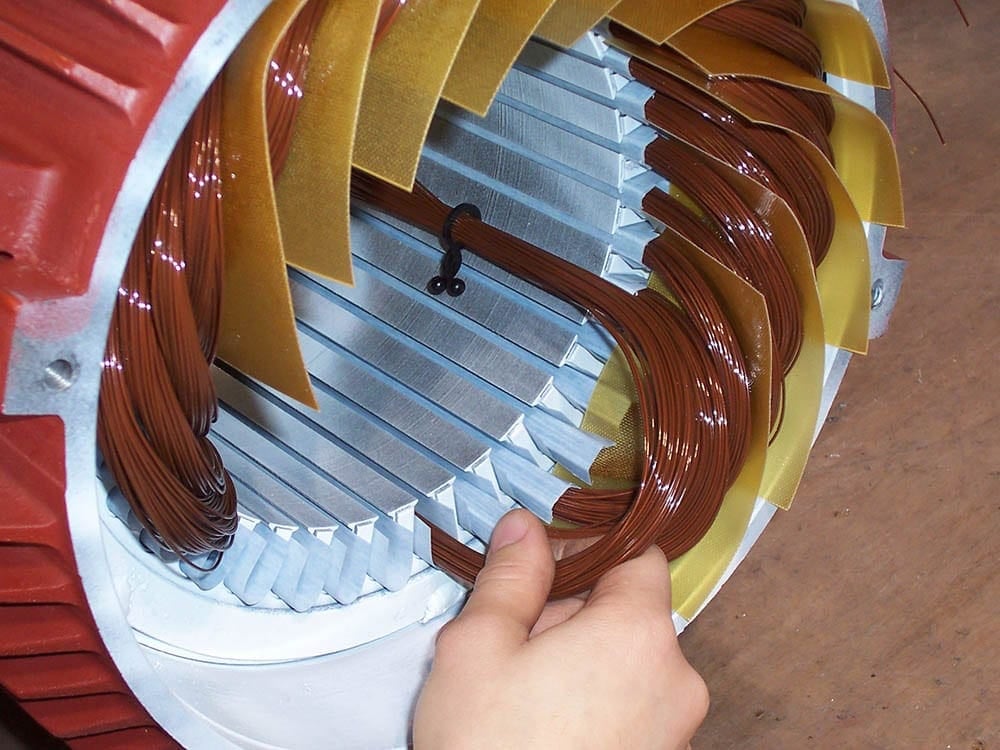

Stator Insulation Winding . Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or epoxy, followed by baking (curing),. And test motor stator windings to ensure good quality. The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an oven. Withstand 120 v ac test voltage; The guide is presented from the point of view of the entire winding system including. There are four types of varnishing methods that we will describe below:

from electrical-engineering-portal.com

Withstand 120 v ac test voltage; Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or epoxy, followed by baking (curing),. And test motor stator windings to ensure good quality. Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an oven. The guide is presented from the point of view of the entire winding system including. There are four types of varnishing methods that we will describe below: The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and.

Troubleshooting the most typical winding problems of three phase

Stator Insulation Winding Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or epoxy, followed by baking (curing),. Withstand 120 v ac test voltage; And test motor stator windings to ensure good quality. Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or epoxy, followed by baking (curing),. There are four types of varnishing methods that we will describe below: The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an oven. The guide is presented from the point of view of the entire winding system including.

From vangokelin.blogspot.com

Stator Windings Can Best Be Described as Stator Insulation Winding The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. Withstand 120 v ac test voltage; And test motor stator windings to ensure good quality. The guide is presented from the point of view of the entire winding system including. Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or. Stator Insulation Winding.

From 1-1how.blogspot.com

1.3.3FormWound Stators—Roebel Bar Type, 1.4STATOR WINDING Stator Insulation Winding And test motor stator windings to ensure good quality. Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or epoxy, followed by baking (curing),. Withstand 120 v ac test voltage; The guide is presented from the point of view of the entire winding system including. The stator winding process involves precision in crafting coils around the stator,. Stator Insulation Winding.

From www.mdpi.com

Applied Sciences Free FullText Synthesis and Diagnostics of Stator Insulation Winding And test motor stator windings to ensure good quality. Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an oven. The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. There are four types of varnishing methods that. Stator Insulation Winding.

From szjiarun.en.made-in-china.com

Wound & Insulation Layer Electric Motor Rotor Stator, Copper Winding Stator Insulation Winding Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an oven. Withstand 120 v ac test voltage; And test motor stator windings to ensure good quality. The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. Wound stator. Stator Insulation Winding.

From mungfali.com

Motor Stator Winding Diagram Stator Insulation Winding Withstand 120 v ac test voltage; Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an oven. There are four types of varnishing methods that we will describe below: The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency. Stator Insulation Winding.

From www.researchgate.net

Insulation system of stator winding. Download Scientific Diagram Stator Insulation Winding The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or epoxy, followed by baking (curing),. Withstand 120 v ac test voltage; And test motor stator windings to ensure good quality. There are four types of varnishing methods that we will. Stator Insulation Winding.

From www.aawva.com

Typical Failures in ThreePhase Stator Windings — Alexandria Armature Works Stator Insulation Winding The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. And test motor stator windings to ensure good quality. Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or epoxy, followed by baking (curing),. There are four types of varnishing methods that we will describe below: Withstand 120 v ac. Stator Insulation Winding.

From thegundcompany.com

Motor Applications The Gund Company Stator Insulation Winding And test motor stator windings to ensure good quality. The guide is presented from the point of view of the entire winding system including. There are four types of varnishing methods that we will describe below: Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or epoxy, followed by baking (curing),. Dip and bake is a standard. Stator Insulation Winding.

From webmotor.org

What Is A Motor Stator Winding Stator Insulation Winding Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an oven. And test motor stator windings to ensure good quality. The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. There are four types of varnishing methods that. Stator Insulation Winding.

From powertechlabs.com

STATOR WINDING INSULATION LAB Powertech Labs Stator Insulation Winding Withstand 120 v ac test voltage; Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or epoxy, followed by baking (curing),. The guide is presented from the point of view of the entire winding system including. There are four types of varnishing methods that we will describe below: The stator winding process involves precision in crafting coils. Stator Insulation Winding.

From www.researchgate.net

Degradation of stator winding insulation due to operation under Stator Insulation Winding The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. And test motor stator windings to ensure good quality. Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an oven. Withstand 120 v ac test voltage; There are. Stator Insulation Winding.

From salesdpti-nide.en.made-in-china.com

Semi Automatic Electric Motor Stator Coil Winding Insulation Wedge Stator Insulation Winding And test motor stator windings to ensure good quality. Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or epoxy, followed by baking (curing),. The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. Dip and bake is a standard varnishing technique where the motor windings are dipped into a. Stator Insulation Winding.

From electrical-engineering-portal.com

Troubleshooting the most typical winding problems of three phase Stator Insulation Winding Withstand 120 v ac test voltage; There are four types of varnishing methods that we will describe below: And test motor stator windings to ensure good quality. Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or epoxy, followed by baking (curing),. The guide is presented from the point of view of the entire winding system including.. Stator Insulation Winding.

From guanfeirotor.en.made-in-china.com

Wound & Insulation Layer Electric Motor Rotor Stator, Copper Winding Stator Insulation Winding And test motor stator windings to ensure good quality. The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. There are four types of varnishing methods that we will describe below: Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or epoxy, followed by baking (curing),. Withstand 120 v ac. Stator Insulation Winding.

From www.powertechlabs.com

STATOR WINDING INSULATION LAB — Powertech Labs Stator Insulation Winding Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an oven. There are four types of varnishing methods that we will describe below: Withstand 120 v ac test voltage; The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency. Stator Insulation Winding.

From www.researchgate.net

16Typical insulation damage leading to interturn short circuit of the Stator Insulation Winding The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. There are four types of varnishing methods that we will describe below: Withstand 120 v ac test voltage; The guide is presented from the point of view of the entire winding system including. Dip and bake is a standard varnishing technique where the. Stator Insulation Winding.

From www.researchgate.net

6 Phase insulation in a partiallywound lowvoltage stator [14 Stator Insulation Winding Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an oven. And test motor stator windings to ensure good quality. The guide is presented from the point of view of the entire winding system including. Wound stator •by simple impregnation in a recommended insulating varnish,. Stator Insulation Winding.

From motor-machines.en.hisupplier.com

insulation material armature rotor and stator insulation paper for Stator Insulation Winding The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an oven. There are four types of varnishing methods that we will describe below: Withstand 120 v ac test. Stator Insulation Winding.

From www.dukeelectric.com

3phase stator winding failure [With examples] Duke Electric Stator Insulation Winding And test motor stator windings to ensure good quality. Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an oven. Withstand 120 v ac test voltage; The guide is presented from the point of view of the entire winding system including. The stator winding process. Stator Insulation Winding.

From www.youtube.com

How to analyse expected lifetime of the stator winding insulation YouTube Stator Insulation Winding The guide is presented from the point of view of the entire winding system including. Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an oven. Withstand 120 v ac test voltage; Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or. Stator Insulation Winding.

From www.semanticscholar.org

Figure 7 from Case studies of stator winding turn insulation failures Stator Insulation Winding There are four types of varnishing methods that we will describe below: And test motor stator windings to ensure good quality. The guide is presented from the point of view of the entire winding system including. Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in. Stator Insulation Winding.

From vangokelin.blogspot.com

Stator Windings Can Best Be Described as Stator Insulation Winding Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an oven. There are four types of varnishing methods that we will describe below: Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or epoxy, followed by baking (curing),. The guide is presented. Stator Insulation Winding.

From www.semanticscholar.org

Figure 1 from Case studies of stator winding turn insulation failures Stator Insulation Winding Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or epoxy, followed by baking (curing),. The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an. Stator Insulation Winding.

From www.aawva.com

Typical Failures in ThreePhase Stator Windings — Alexandria Armature Works Stator Insulation Winding And test motor stator windings to ensure good quality. The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. There are four types of varnishing methods that we will describe below: Withstand 120 v ac test voltage; Dip and bake is a standard varnishing technique where the motor windings are dipped into a. Stator Insulation Winding.

From www.backlack.com

motor stator and rotor coil winding manufacturer Stator Insulation Winding Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an oven. Withstand 120 v ac test voltage; And test motor stator windings to ensure good quality. The guide is presented from the point of view of the entire winding system including. There are four types. Stator Insulation Winding.

From www.youtube.com

Pump Electric Motor Stator Slot Insulation Machine YouTube Stator Insulation Winding The guide is presented from the point of view of the entire winding system including. Withstand 120 v ac test voltage; Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an oven. There are four types of varnishing methods that we will describe below: The. Stator Insulation Winding.

From electricalgang.com

What Is Motor Winding? Types of Motor Winding Stator Insulation Winding Withstand 120 v ac test voltage; The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an oven. Wound stator •by simple impregnation in a recommended insulating varnish, normally. Stator Insulation Winding.

From www.researchgate.net

An illustration of stator bar insulation arrangement. Download Stator Insulation Winding And test motor stator windings to ensure good quality. Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an oven. Withstand 120 v ac test voltage; The guide is presented from the point of view of the entire winding system including. Wound stator •by simple. Stator Insulation Winding.

From www.aawva.com

Typical Failures in ThreePhase Stator Windings — Alexandria Armature Works Stator Insulation Winding There are four types of varnishing methods that we will describe below: The guide is presented from the point of view of the entire winding system including. And test motor stator windings to ensure good quality. Withstand 120 v ac test voltage; Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or epoxy, followed by baking (curing),.. Stator Insulation Winding.

From www.dukeelectric.com

3phase stator winding failure [With examples] Duke Electric Stator Insulation Winding Withstand 120 v ac test voltage; And test motor stator windings to ensure good quality. The guide is presented from the point of view of the entire winding system including. Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or epoxy, followed by baking (curing),. There are four types of varnishing methods that we will describe below:. Stator Insulation Winding.

From www.dukeelectric.com

3phase stator winding failure [With examples] Duke Electric Stator Insulation Winding The guide is presented from the point of view of the entire winding system including. Withstand 120 v ac test voltage; And test motor stator windings to ensure good quality. The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or. Stator Insulation Winding.

From www.globalspec.com

Motor Winding Calculations GlobalSpec Stator Insulation Winding The guide is presented from the point of view of the entire winding system including. There are four types of varnishing methods that we will describe below: The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. Withstand 120 v ac test voltage; And test motor stator windings to ensure good quality. Dip. Stator Insulation Winding.

From www.gulfelectroquip.com

Stator Upgrade Gulf Electroquip Stator Insulation Winding There are four types of varnishing methods that we will describe below: Withstand 120 v ac test voltage; And test motor stator windings to ensure good quality. The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. Wound stator •by simple impregnation in a recommended insulating varnish, normally synthetic or epoxy, followed by. Stator Insulation Winding.

From gm-volt.com

Aluminum Windings Stator Insulation Winding Dip and bake is a standard varnishing technique where the motor windings are dipped into a varnish tank and then set to cure in an oven. And test motor stator windings to ensure good quality. The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. There are four types of varnishing methods that. Stator Insulation Winding.

From dreisilker.com

4 Types of Motor Winding Insulation Methods Dreisilker Electric Motors Stator Insulation Winding There are four types of varnishing methods that we will describe below: The guide is presented from the point of view of the entire winding system including. Withstand 120 v ac test voltage; And test motor stator windings to ensure good quality. The stator winding process involves precision in crafting coils around the stator, enhancing the motor’s efficiency and. Dip. Stator Insulation Winding.