Sheet Metal Thickness Reduction . One measure of ductility is the reduction of area, also known as the tensile reduction of area. Sheet alters considerably due to cold thickness reduction of the same sheet metal. In this study, a through experimental study is conducted to observe the effect of different cold rolling thickness. The sheet metal blank formed to make your engineered stamping starts with known dimensions and a fixed volume. The low carbon ordinary steel. For a rectangular blank, the volume derives from. The purpose of this paper is to investigate the effect of thickness change and various reduction ratios on roughness transfer of dc04 grade sheet material. The trained anfis model also successfully trained and. The present paper focused on the analysis of thickness reduction effects on the tensile behavior. The forming limit diagram (fld) is an essential tool to assess sheet metal formability in sheet metal deep drawing. If you know a material’s.

from keddieco.com

In this study, a through experimental study is conducted to observe the effect of different cold rolling thickness. If you know a material’s. The present paper focused on the analysis of thickness reduction effects on the tensile behavior. For a rectangular blank, the volume derives from. The trained anfis model also successfully trained and. One measure of ductility is the reduction of area, also known as the tensile reduction of area. The sheet metal blank formed to make your engineered stamping starts with known dimensions and a fixed volume. Sheet alters considerably due to cold thickness reduction of the same sheet metal. The low carbon ordinary steel. The purpose of this paper is to investigate the effect of thickness change and various reduction ratios on roughness transfer of dc04 grade sheet material.

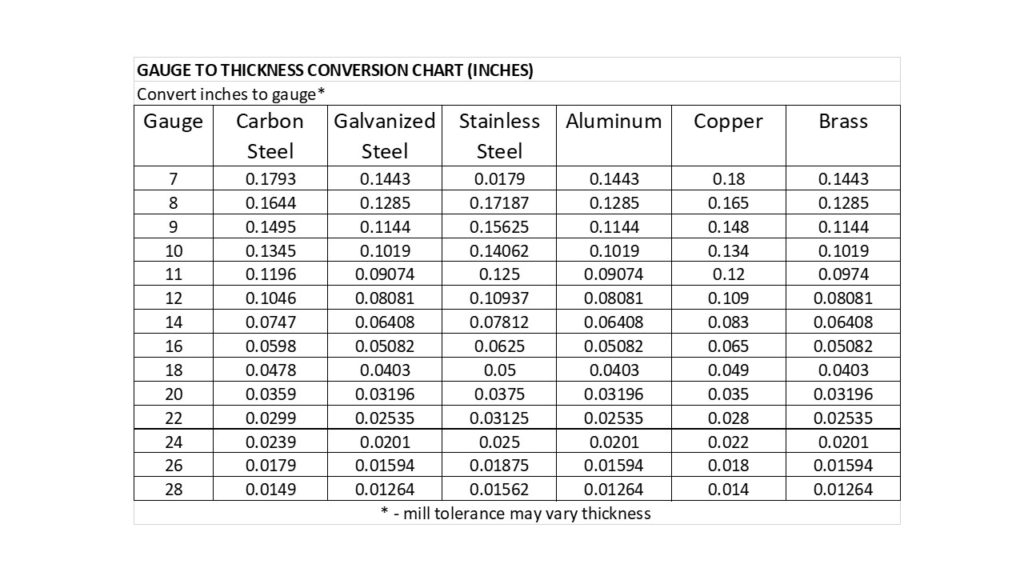

Gauge to Thickness Conversion for Common Sheet Metals Keddie Enterprises

Sheet Metal Thickness Reduction The sheet metal blank formed to make your engineered stamping starts with known dimensions and a fixed volume. One measure of ductility is the reduction of area, also known as the tensile reduction of area. In this study, a through experimental study is conducted to observe the effect of different cold rolling thickness. If you know a material’s. The forming limit diagram (fld) is an essential tool to assess sheet metal formability in sheet metal deep drawing. The low carbon ordinary steel. For a rectangular blank, the volume derives from. The purpose of this paper is to investigate the effect of thickness change and various reduction ratios on roughness transfer of dc04 grade sheet material. Sheet alters considerably due to cold thickness reduction of the same sheet metal. The trained anfis model also successfully trained and. The present paper focused on the analysis of thickness reduction effects on the tensile behavior. The sheet metal blank formed to make your engineered stamping starts with known dimensions and a fixed volume.

From cu3p2ar8schematic.z4.web.core.windows.net

Sheet Metal Thickness Chart Pdf Sheet Metal Thickness Reduction The present paper focused on the analysis of thickness reduction effects on the tensile behavior. The low carbon ordinary steel. Sheet alters considerably due to cold thickness reduction of the same sheet metal. One measure of ductility is the reduction of area, also known as the tensile reduction of area. If you know a material’s. The sheet metal blank formed. Sheet Metal Thickness Reduction.

From www.metafab.com

Sheet Metal Material Thicknesses Guide Meta Fab, Inc. Sheet Metal Thickness Reduction If you know a material’s. In this study, a through experimental study is conducted to observe the effect of different cold rolling thickness. The sheet metal blank formed to make your engineered stamping starts with known dimensions and a fixed volume. One measure of ductility is the reduction of area, also known as the tensile reduction of area. The trained. Sheet Metal Thickness Reduction.

From www.mech4study.com

Different Sheet Metal Bending Process mech4study Sheet Metal Thickness Reduction Sheet alters considerably due to cold thickness reduction of the same sheet metal. The present paper focused on the analysis of thickness reduction effects on the tensile behavior. The sheet metal blank formed to make your engineered stamping starts with known dimensions and a fixed volume. The forming limit diagram (fld) is an essential tool to assess sheet metal formability. Sheet Metal Thickness Reduction.

From www.researchgate.net

a Sheet thickness reduction; b material hardness Download Scientific Diagram Sheet Metal Thickness Reduction The forming limit diagram (fld) is an essential tool to assess sheet metal formability in sheet metal deep drawing. The sheet metal blank formed to make your engineered stamping starts with known dimensions and a fixed volume. The purpose of this paper is to investigate the effect of thickness change and various reduction ratios on roughness transfer of dc04 grade. Sheet Metal Thickness Reduction.

From guidedatatgesku.z21.web.core.windows.net

Metal Sheet Thickness Chart Sheet Metal Thickness Reduction In this study, a through experimental study is conducted to observe the effect of different cold rolling thickness. The sheet metal blank formed to make your engineered stamping starts with known dimensions and a fixed volume. One measure of ductility is the reduction of area, also known as the tensile reduction of area. If you know a material’s. The low. Sheet Metal Thickness Reduction.

From www.youtube.com

Inventor How To Change Sheet Metal Thickness Tutorial YouTube Sheet Metal Thickness Reduction For a rectangular blank, the volume derives from. One measure of ductility is the reduction of area, also known as the tensile reduction of area. In this study, a through experimental study is conducted to observe the effect of different cold rolling thickness. If you know a material’s. Sheet alters considerably due to cold thickness reduction of the same sheet. Sheet Metal Thickness Reduction.

From www.mdpi.com

Metals Free FullText ThroughThickness Microstructure and Strain Distribution in Steel Sheet Metal Thickness Reduction The low carbon ordinary steel. The sheet metal blank formed to make your engineered stamping starts with known dimensions and a fixed volume. In this study, a through experimental study is conducted to observe the effect of different cold rolling thickness. Sheet alters considerably due to cold thickness reduction of the same sheet metal. The forming limit diagram (fld) is. Sheet Metal Thickness Reduction.

From schematicplaasboeryv.z4.web.core.windows.net

Sheet Metal Thickness Chart Pdf Sheet Metal Thickness Reduction The sheet metal blank formed to make your engineered stamping starts with known dimensions and a fixed volume. The forming limit diagram (fld) is an essential tool to assess sheet metal formability in sheet metal deep drawing. For a rectangular blank, the volume derives from. The present paper focused on the analysis of thickness reduction effects on the tensile behavior.. Sheet Metal Thickness Reduction.

From exoijpvdr.blob.core.windows.net

Sheet Metal Thickness Metric at John Graham blog Sheet Metal Thickness Reduction One measure of ductility is the reduction of area, also known as the tensile reduction of area. If you know a material’s. Sheet alters considerably due to cold thickness reduction of the same sheet metal. The present paper focused on the analysis of thickness reduction effects on the tensile behavior. The purpose of this paper is to investigate the effect. Sheet Metal Thickness Reduction.

From guideovercome4148og.z22.web.core.windows.net

Sheet Metal Thickness Conversion Chart Sheet Metal Thickness Reduction In this study, a through experimental study is conducted to observe the effect of different cold rolling thickness. The forming limit diagram (fld) is an essential tool to assess sheet metal formability in sheet metal deep drawing. One measure of ductility is the reduction of area, also known as the tensile reduction of area. The low carbon ordinary steel. Sheet. Sheet Metal Thickness Reduction.

From dokumen.tips

(PDF) Steel Sheet Thickness Tolerance DOKUMEN.TIPS Sheet Metal Thickness Reduction In this study, a through experimental study is conducted to observe the effect of different cold rolling thickness. The low carbon ordinary steel. The sheet metal blank formed to make your engineered stamping starts with known dimensions and a fixed volume. For a rectangular blank, the volume derives from. One measure of ductility is the reduction of area, also known. Sheet Metal Thickness Reduction.

From www.scribd.com

(Gauge Inch Mm) Steel Thickness Conversion Table Sheet Metal Thickness Reduction The sheet metal blank formed to make your engineered stamping starts with known dimensions and a fixed volume. In this study, a through experimental study is conducted to observe the effect of different cold rolling thickness. The present paper focused on the analysis of thickness reduction effects on the tensile behavior. Sheet alters considerably due to cold thickness reduction of. Sheet Metal Thickness Reduction.

From www.batchuontyren.com

Sheet Metal Materials, Standard Sizes & Forming Processes Sheet Metal Thickness Reduction The trained anfis model also successfully trained and. Sheet alters considerably due to cold thickness reduction of the same sheet metal. The low carbon ordinary steel. The present paper focused on the analysis of thickness reduction effects on the tensile behavior. The sheet metal blank formed to make your engineered stamping starts with known dimensions and a fixed volume. The. Sheet Metal Thickness Reduction.

From www.metalformingmagazine.com

Deep Drawing from A to Z MetalForming Magazine Article Sheet Metal Thickness Reduction The present paper focused on the analysis of thickness reduction effects on the tensile behavior. The purpose of this paper is to investigate the effect of thickness change and various reduction ratios on roughness transfer of dc04 grade sheet material. The forming limit diagram (fld) is an essential tool to assess sheet metal formability in sheet metal deep drawing. Sheet. Sheet Metal Thickness Reduction.

From www.slideserve.com

PPT Ultimate Guide to Sheet Metal Fabrication Thickness What You Need to Know PowerPoint Sheet Metal Thickness Reduction The sheet metal blank formed to make your engineered stamping starts with known dimensions and a fixed volume. One measure of ductility is the reduction of area, also known as the tensile reduction of area. The present paper focused on the analysis of thickness reduction effects on the tensile behavior. If you know a material’s. In this study, a through. Sheet Metal Thickness Reduction.

From www.thefabricator.com

Precision sheet metal bending and the V groove Sheet Metal Thickness Reduction The present paper focused on the analysis of thickness reduction effects on the tensile behavior. The trained anfis model also successfully trained and. The low carbon ordinary steel. For a rectangular blank, the volume derives from. One measure of ductility is the reduction of area, also known as the tensile reduction of area. In this study, a through experimental study. Sheet Metal Thickness Reduction.

From guidedatatgesku.z21.web.core.windows.net

Metal Sheet Thickness Chart Sheet Metal Thickness Reduction One measure of ductility is the reduction of area, also known as the tensile reduction of area. The trained anfis model also successfully trained and. The present paper focused on the analysis of thickness reduction effects on the tensile behavior. Sheet alters considerably due to cold thickness reduction of the same sheet metal. The purpose of this paper is to. Sheet Metal Thickness Reduction.

From proleantech.com

Sheet Metal Gauge Using, Affecting Factors & Advantages Sheet Metal Thickness Reduction The forming limit diagram (fld) is an essential tool to assess sheet metal formability in sheet metal deep drawing. The sheet metal blank formed to make your engineered stamping starts with known dimensions and a fixed volume. If you know a material’s. The present paper focused on the analysis of thickness reduction effects on the tensile behavior. The purpose of. Sheet Metal Thickness Reduction.

From wiringfixconstrainbe.z13.web.core.windows.net

Metric Sheet Steel Thickness Sheet Metal Thickness Reduction One measure of ductility is the reduction of area, also known as the tensile reduction of area. In this study, a through experimental study is conducted to observe the effect of different cold rolling thickness. The trained anfis model also successfully trained and. If you know a material’s. Sheet alters considerably due to cold thickness reduction of the same sheet. Sheet Metal Thickness Reduction.

From guidedatatgesku.z21.web.core.windows.net

Sheet Metal Thickness Conversion Chart Sheet Metal Thickness Reduction The present paper focused on the analysis of thickness reduction effects on the tensile behavior. If you know a material’s. The low carbon ordinary steel. In this study, a through experimental study is conducted to observe the effect of different cold rolling thickness. The purpose of this paper is to investigate the effect of thickness change and various reduction ratios. Sheet Metal Thickness Reduction.

From www.scribd.com

Sheet Metal Thickness CHART Sheet Metal Procedural Knowledge Sheet Metal Thickness Reduction For a rectangular blank, the volume derives from. If you know a material’s. The trained anfis model also successfully trained and. The forming limit diagram (fld) is an essential tool to assess sheet metal formability in sheet metal deep drawing. One measure of ductility is the reduction of area, also known as the tensile reduction of area. The present paper. Sheet Metal Thickness Reduction.

From keddieco.com

Gauge to Thickness Conversion for Common Sheet Metals Keddie Enterprises Sheet Metal Thickness Reduction Sheet alters considerably due to cold thickness reduction of the same sheet metal. The forming limit diagram (fld) is an essential tool to assess sheet metal formability in sheet metal deep drawing. The trained anfis model also successfully trained and. If you know a material’s. The present paper focused on the analysis of thickness reduction effects on the tensile behavior.. Sheet Metal Thickness Reduction.

From www.slideserve.com

PPT Ultimate Guide to Sheet Metal Fabrication Thickness What You Need to Know PowerPoint Sheet Metal Thickness Reduction If you know a material’s. One measure of ductility is the reduction of area, also known as the tensile reduction of area. The present paper focused on the analysis of thickness reduction effects on the tensile behavior. The trained anfis model also successfully trained and. Sheet alters considerably due to cold thickness reduction of the same sheet metal. The sheet. Sheet Metal Thickness Reduction.

From guidedatatgesku.z21.web.core.windows.net

Metal Sheet Thickness Chart Sheet Metal Thickness Reduction In this study, a through experimental study is conducted to observe the effect of different cold rolling thickness. The sheet metal blank formed to make your engineered stamping starts with known dimensions and a fixed volume. The forming limit diagram (fld) is an essential tool to assess sheet metal formability in sheet metal deep drawing. Sheet alters considerably due to. Sheet Metal Thickness Reduction.

From guideovercome4148og.z22.web.core.windows.net

Sheet Metal Thickness Conversion Chart Sheet Metal Thickness Reduction The present paper focused on the analysis of thickness reduction effects on the tensile behavior. The purpose of this paper is to investigate the effect of thickness change and various reduction ratios on roughness transfer of dc04 grade sheet material. The low carbon ordinary steel. One measure of ductility is the reduction of area, also known as the tensile reduction. Sheet Metal Thickness Reduction.

From www.mdpi.com

Metals Free FullText Effect of Roller Axial Position and Thickness on a Twisted Angle in Sheet Metal Thickness Reduction Sheet alters considerably due to cold thickness reduction of the same sheet metal. The purpose of this paper is to investigate the effect of thickness change and various reduction ratios on roughness transfer of dc04 grade sheet material. The trained anfis model also successfully trained and. In this study, a through experimental study is conducted to observe the effect of. Sheet Metal Thickness Reduction.

From kanyanaengineering.com.au

Sheet Metal Thickness Guide & Size Charts (Gauge, mm & Inches) Kanyana Engineering Sheet Metal Thickness Reduction One measure of ductility is the reduction of area, also known as the tensile reduction of area. The present paper focused on the analysis of thickness reduction effects on the tensile behavior. Sheet alters considerably due to cold thickness reduction of the same sheet metal. The low carbon ordinary steel. The trained anfis model also successfully trained and. In this. Sheet Metal Thickness Reduction.

From www.slideserve.com

PPT Ultimate Guide to Sheet Metal Fabrication Thickness What You Need to Know PowerPoint Sheet Metal Thickness Reduction The low carbon ordinary steel. The trained anfis model also successfully trained and. In this study, a through experimental study is conducted to observe the effect of different cold rolling thickness. The forming limit diagram (fld) is an essential tool to assess sheet metal formability in sheet metal deep drawing. One measure of ductility is the reduction of area, also. Sheet Metal Thickness Reduction.

From weldguru.com

How to Weld Stainless Steel A Complete Guide Sheet Metal Thickness Reduction The forming limit diagram (fld) is an essential tool to assess sheet metal formability in sheet metal deep drawing. The present paper focused on the analysis of thickness reduction effects on the tensile behavior. Sheet alters considerably due to cold thickness reduction of the same sheet metal. The low carbon ordinary steel. For a rectangular blank, the volume derives from.. Sheet Metal Thickness Reduction.

From www.scribd.com

Sheet Metal Thickness Chart Sheet Metal Thickness Reduction One measure of ductility is the reduction of area, also known as the tensile reduction of area. The low carbon ordinary steel. Sheet alters considerably due to cold thickness reduction of the same sheet metal. The purpose of this paper is to investigate the effect of thickness change and various reduction ratios on roughness transfer of dc04 grade sheet material.. Sheet Metal Thickness Reduction.

From www.metfab.com.au

How Is Steel Plate Thickness Specified? Sheet Metal Thickness Reduction The sheet metal blank formed to make your engineered stamping starts with known dimensions and a fixed volume. The low carbon ordinary steel. For a rectangular blank, the volume derives from. The trained anfis model also successfully trained and. The purpose of this paper is to investigate the effect of thickness change and various reduction ratios on roughness transfer of. Sheet Metal Thickness Reduction.

From hxeyanhra.blob.core.windows.net

Sheet Metal Thickness Range at Jerrell Popp blog Sheet Metal Thickness Reduction The present paper focused on the analysis of thickness reduction effects on the tensile behavior. The low carbon ordinary steel. Sheet alters considerably due to cold thickness reduction of the same sheet metal. One measure of ductility is the reduction of area, also known as the tensile reduction of area. In this study, a through experimental study is conducted to. Sheet Metal Thickness Reduction.

From mungfali.com

Metal Thickness Gauge Conversion Chart Sheet Metal Thickness Reduction In this study, a through experimental study is conducted to observe the effect of different cold rolling thickness. The low carbon ordinary steel. The trained anfis model also successfully trained and. The present paper focused on the analysis of thickness reduction effects on the tensile behavior. The sheet metal blank formed to make your engineered stamping starts with known dimensions. Sheet Metal Thickness Reduction.

From us.meviy.misumi-ec.com

Sheet Metal Inch Gauge Thickness Option meviy Instruction Manuals Sheet Metal Thickness Reduction One measure of ductility is the reduction of area, also known as the tensile reduction of area. The sheet metal blank formed to make your engineered stamping starts with known dimensions and a fixed volume. The low carbon ordinary steel. The present paper focused on the analysis of thickness reduction effects on the tensile behavior. In this study, a through. Sheet Metal Thickness Reduction.

From www.mdpi.com

Metals Free FullText ThroughThickness Microstructure and Strain Distribution in Steel Sheet Metal Thickness Reduction The present paper focused on the analysis of thickness reduction effects on the tensile behavior. One measure of ductility is the reduction of area, also known as the tensile reduction of area. The trained anfis model also successfully trained and. If you know a material’s. For a rectangular blank, the volume derives from. The low carbon ordinary steel. Sheet alters. Sheet Metal Thickness Reduction.