Line Balancing Ratio . what is line balancing? learn how to balance your manufacturing line for optimal performance and efficiency. Conversely, any deviations from this. line balancing is leveling the workload across all processes in a cell or value stream to remove bottlenecks and excess capacity. A constraint slows the process down and. line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a manufacturing line. a perfectly balanced production line achieves a takt time ratio of 1:1, meaning the actual takt time equals the planned takt time. Line balancing is a production strategy and efficiency optimization exercise that can be used to identify optimal production. Discover different methods such as kilbridge and wester,. The primary objective of line balancing is to optimize the production process by ensuring that each workstation operates at an efficient pace. the line balance rate (lbr) is a metric that quantifies how well a production line is balanced. line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time.

from www.allaboutlean.com

A constraint slows the process down and. what is line balancing? the line balance rate (lbr) is a metric that quantifies how well a production line is balanced. learn how to balance your manufacturing line for optimal performance and efficiency. Line balancing is a production strategy and efficiency optimization exercise that can be used to identify optimal production. Discover different methods such as kilbridge and wester,. a perfectly balanced production line achieves a takt time ratio of 1:1, meaning the actual takt time equals the planned takt time. line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time. Conversely, any deviations from this. line balancing is leveling the workload across all processes in a cell or value stream to remove bottlenecks and excess capacity.

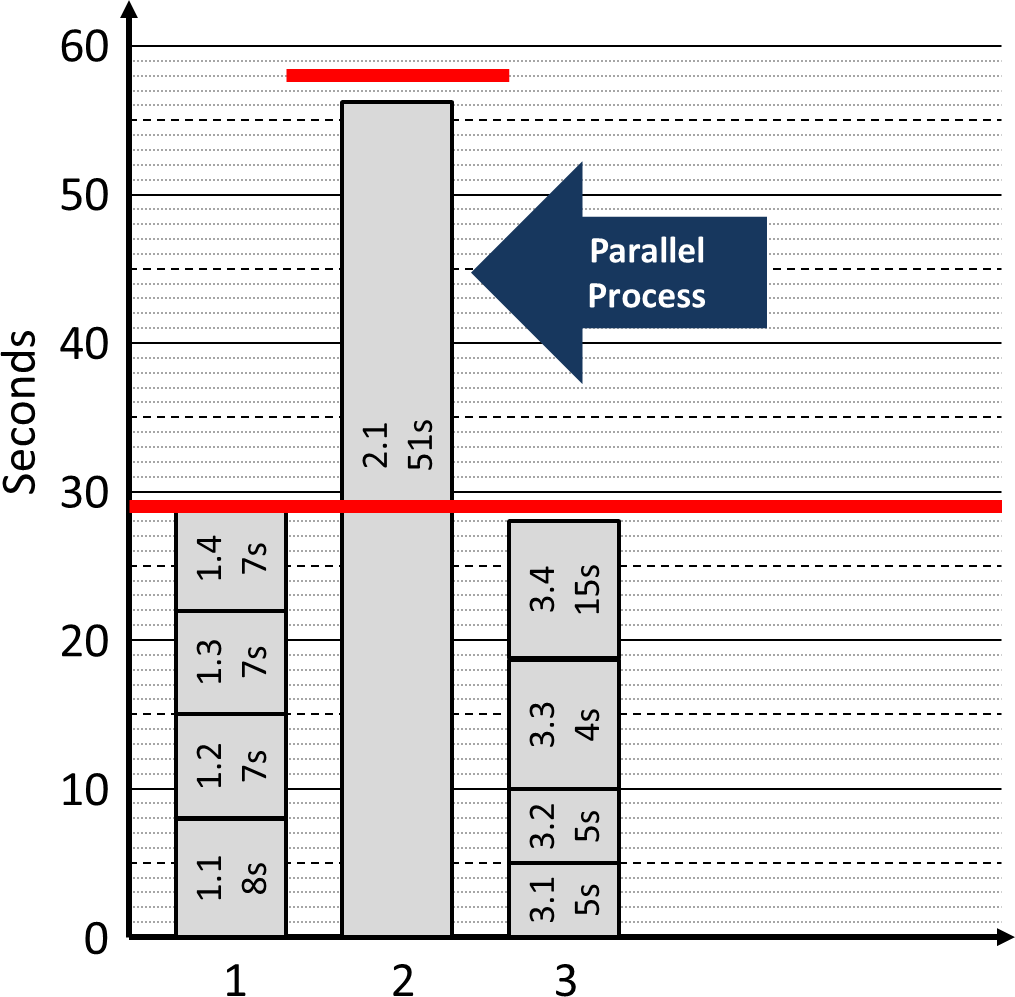

Line Balancing Part 6 Tips and Tricks for Balancing

Line Balancing Ratio A constraint slows the process down and. Discover different methods such as kilbridge and wester,. Conversely, any deviations from this. what is line balancing? A constraint slows the process down and. learn how to balance your manufacturing line for optimal performance and efficiency. line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a manufacturing line. line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time. The primary objective of line balancing is to optimize the production process by ensuring that each workstation operates at an efficient pace. the line balance rate (lbr) is a metric that quantifies how well a production line is balanced. line balancing is leveling the workload across all processes in a cell or value stream to remove bottlenecks and excess capacity. a perfectly balanced production line achieves a takt time ratio of 1:1, meaning the actual takt time equals the planned takt time. Line balancing is a production strategy and efficiency optimization exercise that can be used to identify optimal production.

From www.youtube.com

Line Of Balance Examples 3 3 YouTube Line Balancing Ratio learn how to balance your manufacturing line for optimal performance and efficiency. A constraint slows the process down and. line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time. Discover different methods such as kilbridge and wester,. a perfectly balanced production line achieves a takt. Line Balancing Ratio.

From mungfali.com

Line Balancing Diagram Line Balancing Ratio learn how to balance your manufacturing line for optimal performance and efficiency. what is line balancing? a perfectly balanced production line achieves a takt time ratio of 1:1, meaning the actual takt time equals the planned takt time. A constraint slows the process down and. line balancing in production management refers to the process of distributing. Line Balancing Ratio.

From corningdata.com

What is Production Line Balancing? Corning Data Line Balancing Ratio a perfectly balanced production line achieves a takt time ratio of 1:1, meaning the actual takt time equals the planned takt time. line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a manufacturing line. Conversely, any deviations from this. learn how to balance. Line Balancing Ratio.

From ordnur.com

Example of Line Balancing of TShirt ORDNUR Line Balancing Ratio a perfectly balanced production line achieves a takt time ratio of 1:1, meaning the actual takt time equals the planned takt time. the line balance rate (lbr) is a metric that quantifies how well a production line is balanced. A constraint slows the process down and. what is line balancing? The primary objective of line balancing is. Line Balancing Ratio.

From www.youtube.com

What is Line Balancing YouTube Line Balancing Ratio line balancing is leveling the workload across all processes in a cell or value stream to remove bottlenecks and excess capacity. learn how to balance your manufacturing line for optimal performance and efficiency. line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a. Line Balancing Ratio.

From www.allaboutlean.com

Line Balancing Large Gaps Line Balancing Ratio line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time. a perfectly balanced production line achieves a takt time ratio of 1:1, meaning the actual takt time equals the planned takt time. The primary objective of line balancing is to optimize the production process by ensuring. Line Balancing Ratio.

From www.onlineclothingstudy.com

Line Balancing Tool Based on Operator Skill Matrix Line Balancing Ratio Discover different methods such as kilbridge and wester,. Line balancing is a production strategy and efficiency optimization exercise that can be used to identify optimal production. Conversely, any deviations from this. A constraint slows the process down and. line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt. Line Balancing Ratio.

From www.youtube.com

𝐋𝐢𝐧𝐞 𝐁𝐚𝐥𝐚𝐧𝐜𝐢𝐧𝐠 Production Line Balancing ? Assembly Line Balancing Line Balancing Ratio line balancing is leveling the workload across all processes in a cell or value stream to remove bottlenecks and excess capacity. Line balancing is a production strategy and efficiency optimization exercise that can be used to identify optimal production. Discover different methods such as kilbridge and wester,. line balancing in production management refers to the process of distributing. Line Balancing Ratio.

From www.tetrahedron.in

Line Balancing in Manufacturing Training Tetrahedron Line Balancing Ratio the line balance rate (lbr) is a metric that quantifies how well a production line is balanced. learn how to balance your manufacturing line for optimal performance and efficiency. The primary objective of line balancing is to optimize the production process by ensuring that each workstation operates at an efficient pace. Conversely, any deviations from this. Discover different. Line Balancing Ratio.

From www.allaboutlean.com

Line Balancing Part 6 Tips and Tricks for Balancing Line Balancing Ratio line balancing is leveling the workload across all processes in a cell or value stream to remove bottlenecks and excess capacity. learn how to balance your manufacturing line for optimal performance and efficiency. A constraint slows the process down and. line balancing is a production strategy that involves balancing operator and machine time to match the production. Line Balancing Ratio.

From ppt-online.org

Facility Layout презентация онлайн Line Balancing Ratio a perfectly balanced production line achieves a takt time ratio of 1:1, meaning the actual takt time equals the planned takt time. line balancing is leveling the workload across all processes in a cell or value stream to remove bottlenecks and excess capacity. A constraint slows the process down and. Discover different methods such as kilbridge and wester,.. Line Balancing Ratio.

From mungfali.com

Line Balancing Formula Line Balancing Ratio Conversely, any deviations from this. learn how to balance your manufacturing line for optimal performance and efficiency. the line balance rate (lbr) is a metric that quantifies how well a production line is balanced. line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within. Line Balancing Ratio.

From www.allaboutlean.com

Line Balancing Part 6 Tips and Tricks for Balancing Line Balancing Ratio line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time. what is line balancing? The primary objective of line balancing is to optimize the production process by ensuring that each workstation operates at an efficient pace. Conversely, any deviations from this. line balancing is leveling. Line Balancing Ratio.

From www.youtube.com

How to Change Line Balancing Chart Views YouTube Line Balancing Ratio the line balance rate (lbr) is a metric that quantifies how well a production line is balanced. Conversely, any deviations from this. line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time. A constraint slows the process down and. Line balancing is a production strategy and. Line Balancing Ratio.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Line Balancing Ratio a perfectly balanced production line achieves a takt time ratio of 1:1, meaning the actual takt time equals the planned takt time. line balancing is leveling the workload across all processes in a cell or value stream to remove bottlenecks and excess capacity. what is line balancing? Conversely, any deviations from this. the line balance rate. Line Balancing Ratio.

From pt.slideshare.net

assembly line balancing Line Balancing Ratio Line balancing is a production strategy and efficiency optimization exercise that can be used to identify optimal production. a perfectly balanced production line achieves a takt time ratio of 1:1, meaning the actual takt time equals the planned takt time. A constraint slows the process down and. line balancing in production management refers to the process of distributing. Line Balancing Ratio.

From www.youtube.com

Line Balancing Example YouTube Line Balancing Ratio the line balance rate (lbr) is a metric that quantifies how well a production line is balanced. line balancing is leveling the workload across all processes in a cell or value stream to remove bottlenecks and excess capacity. Line balancing is a production strategy and efficiency optimization exercise that can be used to identify optimal production. learn. Line Balancing Ratio.

From www.scribd.com

Line Balance Ratio (LBR) Lean Manufacturing Explained LME PDF Line Balancing Ratio A constraint slows the process down and. Line balancing is a production strategy and efficiency optimization exercise that can be used to identify optimal production. what is line balancing? Conversely, any deviations from this. line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time. The primary. Line Balancing Ratio.

From www.slideserve.com

PPT Assembly Line Balance PowerPoint Presentation, free download ID Line Balancing Ratio what is line balancing? a perfectly balanced production line achieves a takt time ratio of 1:1, meaning the actual takt time equals the planned takt time. A constraint slows the process down and. line balancing is leveling the workload across all processes in a cell or value stream to remove bottlenecks and excess capacity. line balancing. Line Balancing Ratio.

From collectionperformance.com

Maximizing Efficiency A Guide to Line Balancing in Production Line Balancing Ratio learn how to balance your manufacturing line for optimal performance and efficiency. a perfectly balanced production line achieves a takt time ratio of 1:1, meaning the actual takt time equals the planned takt time. the line balance rate (lbr) is a metric that quantifies how well a production line is balanced. line balancing is a production. Line Balancing Ratio.

From www.slideserve.com

PPT Line Balancing in Operations Management PowerPoint Presentation Line Balancing Ratio the line balance rate (lbr) is a metric that quantifies how well a production line is balanced. Conversely, any deviations from this. The primary objective of line balancing is to optimize the production process by ensuring that each workstation operates at an efficient pace. line balancing in production management refers to the process of distributing work tasks and. Line Balancing Ratio.

From www.youtube.com

Ranked Positional Weight for Line Balancing Manual Assembly Line Line Balancing Ratio learn how to balance your manufacturing line for optimal performance and efficiency. The primary objective of line balancing is to optimize the production process by ensuring that each workstation operates at an efficient pace. a perfectly balanced production line achieves a takt time ratio of 1:1, meaning the actual takt time equals the planned takt time. line. Line Balancing Ratio.

From studiousguy.com

Operations Management StudiousGuy Line Balancing Ratio line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a manufacturing line. Line balancing is a production strategy and efficiency optimization exercise that can be used to identify optimal production. the line balance rate (lbr) is a metric that quantifies how well a production. Line Balancing Ratio.

From www.youtube.com

Line Of Balance Introduction 1 3 YouTube Line Balancing Ratio learn how to balance your manufacturing line for optimal performance and efficiency. line balancing is leveling the workload across all processes in a cell or value stream to remove bottlenecks and excess capacity. the line balance rate (lbr) is a metric that quantifies how well a production line is balanced. Line balancing is a production strategy and. Line Balancing Ratio.

From www.financestrategists.com

Balance Sheet Ratios Explanation With Examples Formula Line Balancing Ratio the line balance rate (lbr) is a metric that quantifies how well a production line is balanced. what is line balancing? line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time. line balancing is leveling the workload across all processes in a cell or. Line Balancing Ratio.

From www.youtube.com

How to calculate Line Efficiency line balancing lean manufacturing Line Balancing Ratio Line balancing is a production strategy and efficiency optimization exercise that can be used to identify optimal production. learn how to balance your manufacturing line for optimal performance and efficiency. A constraint slows the process down and. a perfectly balanced production line achieves a takt time ratio of 1:1, meaning the actual takt time equals the planned takt. Line Balancing Ratio.

From engineeringwithmanagement.com

Improve operational performance with line balancing Line Balancing Ratio a perfectly balanced production line achieves a takt time ratio of 1:1, meaning the actual takt time equals the planned takt time. Conversely, any deviations from this. line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a manufacturing line. what is line balancing?. Line Balancing Ratio.

From www.youtube.com

How to calculate line balancing ratio YouTube Line Balancing Ratio the line balance rate (lbr) is a metric that quantifies how well a production line is balanced. what is line balancing? A constraint slows the process down and. learn how to balance your manufacturing line for optimal performance and efficiency. Conversely, any deviations from this. The primary objective of line balancing is to optimize the production process. Line Balancing Ratio.

From www.slideserve.com

PPT Line Balancing in Operations Management PowerPoint Presentation Line Balancing Ratio Line balancing is a production strategy and efficiency optimization exercise that can be used to identify optimal production. a perfectly balanced production line achieves a takt time ratio of 1:1, meaning the actual takt time equals the planned takt time. line balancing is a production strategy that involves balancing operator and machine time to match the production rate. Line Balancing Ratio.

From www.patriotsoftware.com

Balance Sheet Ratios Types of Ratios, Examples, & More Line Balancing Ratio The primary objective of line balancing is to optimize the production process by ensuring that each workstation operates at an efficient pace. a perfectly balanced production line achieves a takt time ratio of 1:1, meaning the actual takt time equals the planned takt time. Conversely, any deviations from this. what is line balancing? A constraint slows the process. Line Balancing Ratio.

From www.smlease.com

What is production Line Balancing and How to implement it? Line Balancing Ratio line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time. a perfectly balanced production line achieves a takt time ratio of 1:1, meaning the actual takt time equals the planned takt time. what is line balancing? line balancing is leveling the workload across all. Line Balancing Ratio.

From www.allaboutlean.com

Line Balancing in Excel Line Balancing Ratio the line balance rate (lbr) is a metric that quantifies how well a production line is balanced. A constraint slows the process down and. line balancing is leveling the workload across all processes in a cell or value stream to remove bottlenecks and excess capacity. line balancing is a production strategy that involves balancing operator and machine. Line Balancing Ratio.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Line Balancing Ratio the line balance rate (lbr) is a metric that quantifies how well a production line is balanced. line balancing is leveling the workload across all processes in a cell or value stream to remove bottlenecks and excess capacity. a perfectly balanced production line achieves a takt time ratio of 1:1, meaning the actual takt time equals the. Line Balancing Ratio.

From www.qualitydigest.com

The Line Balance Rate Quality Digest Line Balancing Ratio Line balancing is a production strategy and efficiency optimization exercise that can be used to identify optimal production. the line balance rate (lbr) is a metric that quantifies how well a production line is balanced. The primary objective of line balancing is to optimize the production process by ensuring that each workstation operates at an efficient pace. Discover different. Line Balancing Ratio.

From zh.scribd.com

Examples Line Balancing Applied Mathematics Mathematics Line Balancing Ratio Discover different methods such as kilbridge and wester,. Line balancing is a production strategy and efficiency optimization exercise that can be used to identify optimal production. learn how to balance your manufacturing line for optimal performance and efficiency. The primary objective of line balancing is to optimize the production process by ensuring that each workstation operates at an efficient. Line Balancing Ratio.