Wire Cut Edm Working Principle . This common principle is applied to all three types of edm: The process is particularly well suited for. The wire edm process involves using a brass wire with a current and high voltage that passes through the workpiece. Wire edm machining is a kind of technological method of spark discharge cutting and forming the machined workpiece for the metal electrode wire that is damaged. Previously, ge used as many as 27 different operations, many. The basic principle behind wire edm cutting is the flame formation between the wire and the workpiece, resulting in controlled strain. General electric uses 36 wire edm machines to cut steam turbine bucket roots. While the workpiece remains fixed, the cut is guided. Ultimate wire edm guide that explains the working principle, type of material. What is edm wire cutting machine and how it works? Wire electrical discharge machining (wire edm) is a precise and versatile manufacturing process that utilizes a thin, continuously moving wire.

from tylercasteel.blogspot.com

Previously, ge used as many as 27 different operations, many. The process is particularly well suited for. Ultimate wire edm guide that explains the working principle, type of material. Wire edm machining is a kind of technological method of spark discharge cutting and forming the machined workpiece for the metal electrode wire that is damaged. The wire edm process involves using a brass wire with a current and high voltage that passes through the workpiece. This common principle is applied to all three types of edm: Wire electrical discharge machining (wire edm) is a precise and versatile manufacturing process that utilizes a thin, continuously moving wire. General electric uses 36 wire edm machines to cut steam turbine bucket roots. While the workpiece remains fixed, the cut is guided. What is edm wire cutting machine and how it works?

wire edm machine working principle Tyler Casteel

Wire Cut Edm Working Principle Previously, ge used as many as 27 different operations, many. The wire edm process involves using a brass wire with a current and high voltage that passes through the workpiece. This common principle is applied to all three types of edm: Ultimate wire edm guide that explains the working principle, type of material. General electric uses 36 wire edm machines to cut steam turbine bucket roots. Wire edm machining is a kind of technological method of spark discharge cutting and forming the machined workpiece for the metal electrode wire that is damaged. The basic principle behind wire edm cutting is the flame formation between the wire and the workpiece, resulting in controlled strain. What is edm wire cutting machine and how it works? The process is particularly well suited for. Previously, ge used as many as 27 different operations, many. Wire electrical discharge machining (wire edm) is a precise and versatile manufacturing process that utilizes a thin, continuously moving wire. While the workpiece remains fixed, the cut is guided.

From finemetalworking.com

Wire EDM. Guide to EDM Wirecut Machine, Process & Uses Fine MetalWorking Wire Cut Edm Working Principle The process is particularly well suited for. The basic principle behind wire edm cutting is the flame formation between the wire and the workpiece, resulting in controlled strain. What is edm wire cutting machine and how it works? The wire edm process involves using a brass wire with a current and high voltage that passes through the workpiece. General electric. Wire Cut Edm Working Principle.

From huldakelso.blogspot.com

wire edm machine how it works Hulda Kelso Wire Cut Edm Working Principle Wire electrical discharge machining (wire edm) is a precise and versatile manufacturing process that utilizes a thin, continuously moving wire. General electric uses 36 wire edm machines to cut steam turbine bucket roots. While the workpiece remains fixed, the cut is guided. This common principle is applied to all three types of edm: The basic principle behind wire edm cutting. Wire Cut Edm Working Principle.

From www.team-mfg.com

Understanding Wire EDM Cutting Mechanism and Diverse Applications Wire Cut Edm Working Principle Ultimate wire edm guide that explains the working principle, type of material. Previously, ge used as many as 27 different operations, many. Wire edm machining is a kind of technological method of spark discharge cutting and forming the machined workpiece for the metal electrode wire that is damaged. This common principle is applied to all three types of edm: While. Wire Cut Edm Working Principle.

From plasticsmoulds.blogspot.com

Plastics Knowledge Wire Cutting EDM Wire Cut Edm Working Principle Ultimate wire edm guide that explains the working principle, type of material. Wire electrical discharge machining (wire edm) is a precise and versatile manufacturing process that utilizes a thin, continuously moving wire. The wire edm process involves using a brass wire with a current and high voltage that passes through the workpiece. Wire edm machining is a kind of technological. Wire Cut Edm Working Principle.

From www.researchgate.net

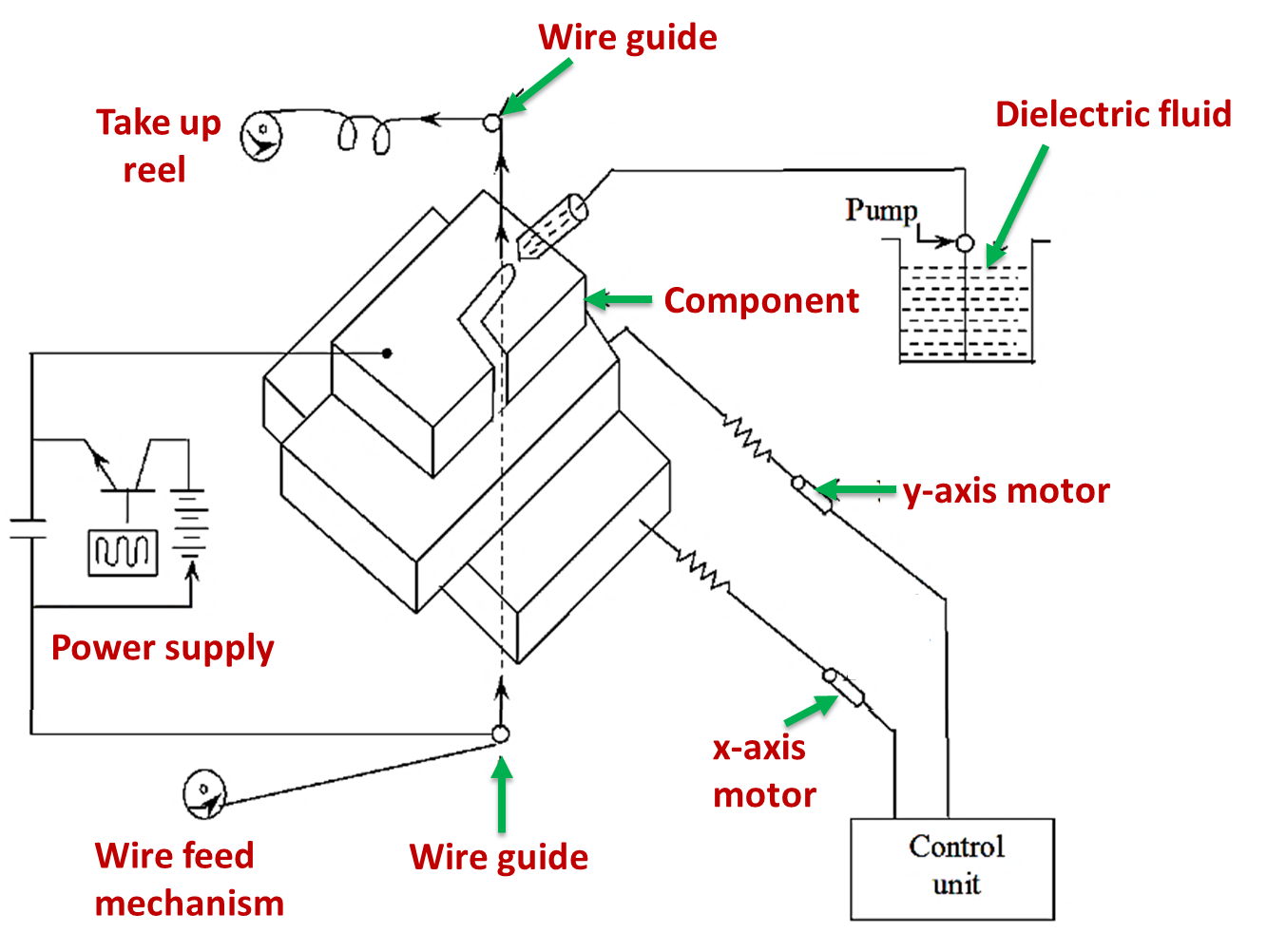

Schematic working principle of wire EDM Download Scientific Diagram Wire Cut Edm Working Principle Wire electrical discharge machining (wire edm) is a precise and versatile manufacturing process that utilizes a thin, continuously moving wire. While the workpiece remains fixed, the cut is guided. General electric uses 36 wire edm machines to cut steam turbine bucket roots. Ultimate wire edm guide that explains the working principle, type of material. The process is particularly well suited. Wire Cut Edm Working Principle.

From armidatimm.blogspot.com

wire edm machine working principle Armida Timm Wire Cut Edm Working Principle This common principle is applied to all three types of edm: The basic principle behind wire edm cutting is the flame formation between the wire and the workpiece, resulting in controlled strain. General electric uses 36 wire edm machines to cut steam turbine bucket roots. Wire electrical discharge machining (wire edm) is a precise and versatile manufacturing process that utilizes. Wire Cut Edm Working Principle.

From truffe2100momon.blogspot.com

wire edm machine is an electro process Heidy Leblanc Wire Cut Edm Working Principle Wire edm machining is a kind of technological method of spark discharge cutting and forming the machined workpiece for the metal electrode wire that is damaged. What is edm wire cutting machine and how it works? While the workpiece remains fixed, the cut is guided. The process is particularly well suited for. Wire electrical discharge machining (wire edm) is a. Wire Cut Edm Working Principle.

From alenaoden.blogspot.com

wire edm machine working principle Alena Oden Wire Cut Edm Working Principle General electric uses 36 wire edm machines to cut steam turbine bucket roots. While the workpiece remains fixed, the cut is guided. Previously, ge used as many as 27 different operations, many. This common principle is applied to all three types of edm: The wire edm process involves using a brass wire with a current and high voltage that passes. Wire Cut Edm Working Principle.

From sodicom.net

iGroove WireCut EDM wireelectrode rotation Wire Cut Edm Working Principle The basic principle behind wire edm cutting is the flame formation between the wire and the workpiece, resulting in controlled strain. While the workpiece remains fixed, the cut is guided. Ultimate wire edm guide that explains the working principle, type of material. This common principle is applied to all three types of edm: General electric uses 36 wire edm machines. Wire Cut Edm Working Principle.

From www.researchgate.net

Schematic working principle of wire EDM Download Scientific Diagram Wire Cut Edm Working Principle The wire edm process involves using a brass wire with a current and high voltage that passes through the workpiece. The basic principle behind wire edm cutting is the flame formation between the wire and the workpiece, resulting in controlled strain. Ultimate wire edm guide that explains the working principle, type of material. What is edm wire cutting machine and. Wire Cut Edm Working Principle.

From tylercasteel.blogspot.com

wire edm machine working principle Tyler Casteel Wire Cut Edm Working Principle The basic principle behind wire edm cutting is the flame formation between the wire and the workpiece, resulting in controlled strain. What is edm wire cutting machine and how it works? Ultimate wire edm guide that explains the working principle, type of material. While the workpiece remains fixed, the cut is guided. The wire edm process involves using a brass. Wire Cut Edm Working Principle.

From www.iqsdirectory.com

EDM Machining Components, Types, Applications, and Advantages Wire Cut Edm Working Principle This common principle is applied to all three types of edm: What is edm wire cutting machine and how it works? General electric uses 36 wire edm machines to cut steam turbine bucket roots. The process is particularly well suited for. Previously, ge used as many as 27 different operations, many. The basic principle behind wire edm cutting is the. Wire Cut Edm Working Principle.

From alenaoden.blogspot.com

wire edm machine working principle Alena Oden Wire Cut Edm Working Principle What is edm wire cutting machine and how it works? Wire edm machining is a kind of technological method of spark discharge cutting and forming the machined workpiece for the metal electrode wire that is damaged. The process is particularly well suited for. The wire edm process involves using a brass wire with a current and high voltage that passes. Wire Cut Edm Working Principle.

From www.sl-machining.com

EDM Wire cutting Wire Cut Edm Working Principle Ultimate wire edm guide that explains the working principle, type of material. The wire edm process involves using a brass wire with a current and high voltage that passes through the workpiece. The process is particularly well suited for. What is edm wire cutting machine and how it works? Wire edm machining is a kind of technological method of spark. Wire Cut Edm Working Principle.

From huldakelso.blogspot.com

wire edm machine how it works Hulda Kelso Wire Cut Edm Working Principle Ultimate wire edm guide that explains the working principle, type of material. Previously, ge used as many as 27 different operations, many. The basic principle behind wire edm cutting is the flame formation between the wire and the workpiece, resulting in controlled strain. Wire electrical discharge machining (wire edm) is a precise and versatile manufacturing process that utilizes a thin,. Wire Cut Edm Working Principle.

From www.researchgate.net

Schema of Wire EDM principle Download Scientific Diagram Wire Cut Edm Working Principle The basic principle behind wire edm cutting is the flame formation between the wire and the workpiece, resulting in controlled strain. General electric uses 36 wire edm machines to cut steam turbine bucket roots. Wire edm machining is a kind of technological method of spark discharge cutting and forming the machined workpiece for the metal electrode wire that is damaged.. Wire Cut Edm Working Principle.

From www.iqsdirectory.com

Wire EDM Components, Types, Applications, and Advantages Wire Cut Edm Working Principle The basic principle behind wire edm cutting is the flame formation between the wire and the workpiece, resulting in controlled strain. This common principle is applied to all three types of edm: What is edm wire cutting machine and how it works? While the workpiece remains fixed, the cut is guided. The process is particularly well suited for. Ultimate wire. Wire Cut Edm Working Principle.

From dokumen.tips

(PDF) LAB 6 EDM WIRE CUTportal.unimap.edu.my/portal/page/portal30 Wire Cut Edm Working Principle Previously, ge used as many as 27 different operations, many. Wire edm machining is a kind of technological method of spark discharge cutting and forming the machined workpiece for the metal electrode wire that is damaged. The basic principle behind wire edm cutting is the flame formation between the wire and the workpiece, resulting in controlled strain. General electric uses. Wire Cut Edm Working Principle.

From www.autodesk.com

What is Computer Aided Manufacturing (CAM)? Fusion 360 Blog Wire Cut Edm Working Principle Wire edm machining is a kind of technological method of spark discharge cutting and forming the machined workpiece for the metal electrode wire that is damaged. What is edm wire cutting machine and how it works? Ultimate wire edm guide that explains the working principle, type of material. The basic principle behind wire edm cutting is the flame formation between. Wire Cut Edm Working Principle.

From www.youtube.com

Electrical Discharge Machining wire EDM working principle, animation Wire Cut Edm Working Principle What is edm wire cutting machine and how it works? Ultimate wire edm guide that explains the working principle, type of material. The wire edm process involves using a brass wire with a current and high voltage that passes through the workpiece. Previously, ge used as many as 27 different operations, many. This common principle is applied to all three. Wire Cut Edm Working Principle.

From alenaoden.blogspot.com

wire edm machine working principle Alena Oden Wire Cut Edm Working Principle This common principle is applied to all three types of edm: The wire edm process involves using a brass wire with a current and high voltage that passes through the workpiece. What is edm wire cutting machine and how it works? The basic principle behind wire edm cutting is the flame formation between the wire and the workpiece, resulting in. Wire Cut Edm Working Principle.

From tylercasteel.blogspot.com

wire edm machine working principle Tyler Casteel Wire Cut Edm Working Principle Wire electrical discharge machining (wire edm) is a precise and versatile manufacturing process that utilizes a thin, continuously moving wire. The wire edm process involves using a brass wire with a current and high voltage that passes through the workpiece. What is edm wire cutting machine and how it works? Ultimate wire edm guide that explains the working principle, type. Wire Cut Edm Working Principle.

From udljac.blogspot.com

wire edm machine how it works Breanne Markham Wire Cut Edm Working Principle The basic principle behind wire edm cutting is the flame formation between the wire and the workpiece, resulting in controlled strain. While the workpiece remains fixed, the cut is guided. Wire edm machining is a kind of technological method of spark discharge cutting and forming the machined workpiece for the metal electrode wire that is damaged. The process is particularly. Wire Cut Edm Working Principle.

From mechanicalinventions.blogspot.com

Electrical Discharge Machining (EDM) Principles Mechanical Engineering Wire Cut Edm Working Principle While the workpiece remains fixed, the cut is guided. Wire electrical discharge machining (wire edm) is a precise and versatile manufacturing process that utilizes a thin, continuously moving wire. Wire edm machining is a kind of technological method of spark discharge cutting and forming the machined workpiece for the metal electrode wire that is damaged. This common principle is applied. Wire Cut Edm Working Principle.

From chanayala.blogspot.com

wire edm machine working principle Chan Ayala Wire Cut Edm Working Principle This common principle is applied to all three types of edm: Wire electrical discharge machining (wire edm) is a precise and versatile manufacturing process that utilizes a thin, continuously moving wire. The basic principle behind wire edm cutting is the flame formation between the wire and the workpiece, resulting in controlled strain. Previously, ge used as many as 27 different. Wire Cut Edm Working Principle.

From www.youtube.com

What is Wire EDM? Wire EDM Machining Process Explained YouTube Wire Cut Edm Working Principle The basic principle behind wire edm cutting is the flame formation between the wire and the workpiece, resulting in controlled strain. This common principle is applied to all three types of edm: General electric uses 36 wire edm machines to cut steam turbine bucket roots. The wire edm process involves using a brass wire with a current and high voltage. Wire Cut Edm Working Principle.

From www.youtube.com

Wire EDM Basics Continuing Education YouTube Wire Cut Edm Working Principle The process is particularly well suited for. Previously, ge used as many as 27 different operations, many. General electric uses 36 wire edm machines to cut steam turbine bucket roots. Ultimate wire edm guide that explains the working principle, type of material. The wire edm process involves using a brass wire with a current and high voltage that passes through. Wire Cut Edm Working Principle.

From prototype-shortrun.com

How Wire EDM Services Are Used to Create Intricate Parts Wire Cut Edm Working Principle While the workpiece remains fixed, the cut is guided. General electric uses 36 wire edm machines to cut steam turbine bucket roots. The wire edm process involves using a brass wire with a current and high voltage that passes through the workpiece. This common principle is applied to all three types of edm: Wire edm machining is a kind of. Wire Cut Edm Working Principle.

From www.researchgate.net

Detail diagram of the wirecut EDM method and its responses Download Wire Cut Edm Working Principle Previously, ge used as many as 27 different operations, many. General electric uses 36 wire edm machines to cut steam turbine bucket roots. What is edm wire cutting machine and how it works? The basic principle behind wire edm cutting is the flame formation between the wire and the workpiece, resulting in controlled strain. Wire edm machining is a kind. Wire Cut Edm Working Principle.

From cfedm.net

cnc edm wire cutting machine working principle wire edm,cnc edm wire Wire Cut Edm Working Principle What is edm wire cutting machine and how it works? The process is particularly well suited for. Ultimate wire edm guide that explains the working principle, type of material. This common principle is applied to all three types of edm: Wire electrical discharge machining (wire edm) is a precise and versatile manufacturing process that utilizes a thin, continuously moving wire.. Wire Cut Edm Working Principle.

From www.iqsdirectory.com

Sinker EDM Components, Types, Applications, and Advantages Wire Cut Edm Working Principle General electric uses 36 wire edm machines to cut steam turbine bucket roots. The basic principle behind wire edm cutting is the flame formation between the wire and the workpiece, resulting in controlled strain. Previously, ge used as many as 27 different operations, many. While the workpiece remains fixed, the cut is guided. What is edm wire cutting machine and. Wire Cut Edm Working Principle.

From lynnapinckney.blogspot.com

wire edm machine working principle Lynna Pinckney Wire Cut Edm Working Principle Wire electrical discharge machining (wire edm) is a precise and versatile manufacturing process that utilizes a thin, continuously moving wire. While the workpiece remains fixed, the cut is guided. Ultimate wire edm guide that explains the working principle, type of material. The process is particularly well suited for. The wire edm process involves using a brass wire with a current. Wire Cut Edm Working Principle.

From wiringdiagramrods.z19.web.core.windows.net

Working Principle Of Wire Edm Wire Cut Edm Working Principle This common principle is applied to all three types of edm: General electric uses 36 wire edm machines to cut steam turbine bucket roots. What is edm wire cutting machine and how it works? Ultimate wire edm guide that explains the working principle, type of material. Wire edm machining is a kind of technological method of spark discharge cutting and. Wire Cut Edm Working Principle.

From www.iqsdirectory.com

Wire EDM Components, Types, Applications, and Advantages Wire Cut Edm Working Principle Ultimate wire edm guide that explains the working principle, type of material. The wire edm process involves using a brass wire with a current and high voltage that passes through the workpiece. The process is particularly well suited for. What is edm wire cutting machine and how it works? The basic principle behind wire edm cutting is the flame formation. Wire Cut Edm Working Principle.

From finemetalworking.com

Wire EDM. Guide to EDM Wirecut Machine, Process & Uses Fine MetalWorking Wire Cut Edm Working Principle The basic principle behind wire edm cutting is the flame formation between the wire and the workpiece, resulting in controlled strain. Wire electrical discharge machining (wire edm) is a precise and versatile manufacturing process that utilizes a thin, continuously moving wire. Previously, ge used as many as 27 different operations, many. While the workpiece remains fixed, the cut is guided.. Wire Cut Edm Working Principle.