Spot Drill Vs Chamfer Mill . However, if you’re working on a hole you will be using a drill or spot drill typically with a solid stainless steel or carbide body. chamfer mill for spotting & countersinking. For general chamfering and nc spot drilling.2. Spotting drill, drill, flat bottom counterbore, and countersink. If not, are there other ways to. chamfering best practices. Though chamfering can be done with a hand tool, it would be a primitive choice. In fact, some use up to four different tools to machine a perfect hole: They can also be used for chamfering,. spot drills are essential for enhancing the precision of secondary drilling operations. Your best bet is to chamfer your edges with a chamfer mill. for reference i use an everede nc indexable spot drill for spotting and a helical flute chamfer mill for chamfering. can i use a chamfer mill to chamfer, countersink, and spot drill? the spot drill's chamfer will be.

from www.youtube.com

the spot drill's chamfer will be. chamfer mill for spotting & countersinking. for reference i use an everede nc indexable spot drill for spotting and a helical flute chamfer mill for chamfering. can i use a chamfer mill to chamfer, countersink, and spot drill? They can also be used for chamfering,. Spotting drill, drill, flat bottom counterbore, and countersink. spot drills are essential for enhancing the precision of secondary drilling operations. In fact, some use up to four different tools to machine a perfect hole: Though chamfering can be done with a hand tool, it would be a primitive choice. For general chamfering and nc spot drilling.2.

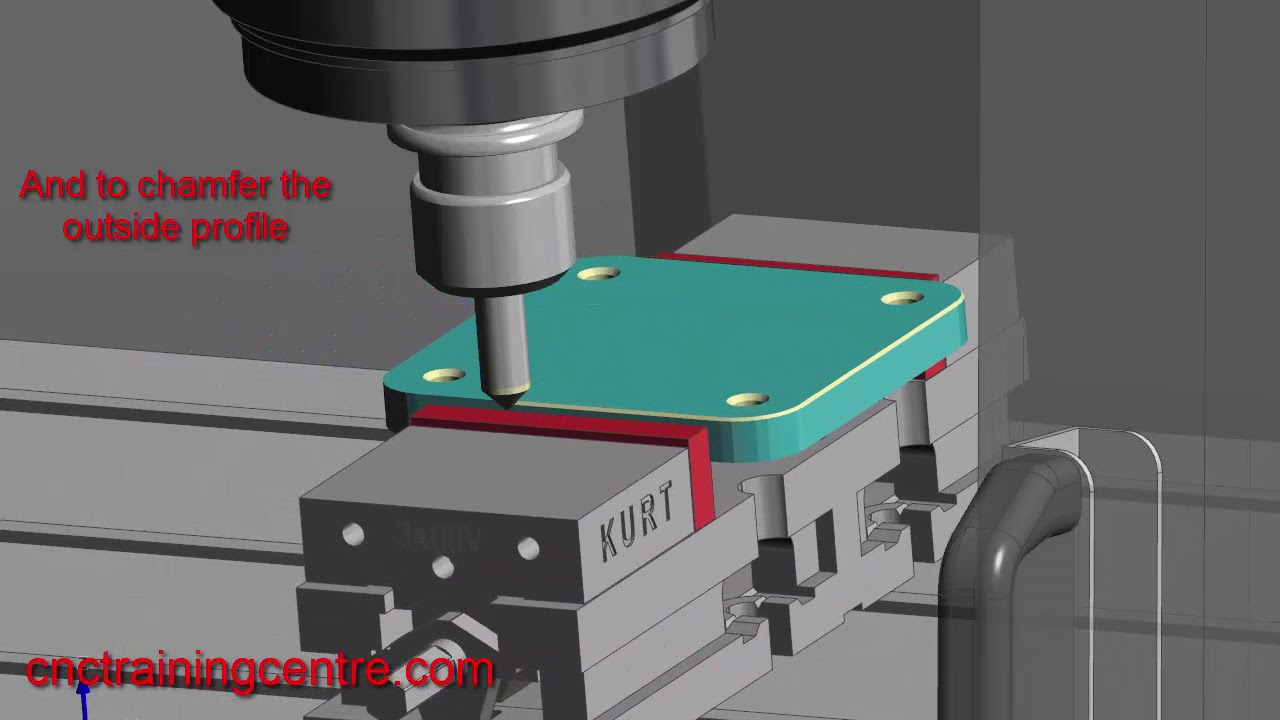

Using a spot drill to chamfer the outside of a part YouTube

Spot Drill Vs Chamfer Mill If not, are there other ways to. spot drills are essential for enhancing the precision of secondary drilling operations. can i use a chamfer mill to chamfer, countersink, and spot drill? chamfer mill for spotting & countersinking. In fact, some use up to four different tools to machine a perfect hole: Spotting drill, drill, flat bottom counterbore, and countersink. They can also be used for chamfering,. Though chamfering can be done with a hand tool, it would be a primitive choice. However, if you’re working on a hole you will be using a drill or spot drill typically with a solid stainless steel or carbide body. For general chamfering and nc spot drilling.2. chamfering best practices. the spot drill's chamfer will be. If not, are there other ways to. for reference i use an everede nc indexable spot drill for spotting and a helical flute chamfer mill for chamfering. Your best bet is to chamfer your edges with a chamfer mill.

From www.amazon.com

Maifix Chamfer Ticoated point Drill 3MM 90 Degree Tungsten Spot Drill Vs Chamfer Mill For general chamfering and nc spot drilling.2. for reference i use an everede nc indexable spot drill for spotting and a helical flute chamfer mill for chamfering. can i use a chamfer mill to chamfer, countersink, and spot drill? They can also be used for chamfering,. Spotting drill, drill, flat bottom counterbore, and countersink. chamfer mill for. Spot Drill Vs Chamfer Mill.

From hxehjvfmy.blob.core.windows.net

Chamfer Mill Vs Countersink at Latasha Henson blog Spot Drill Vs Chamfer Mill Your best bet is to chamfer your edges with a chamfer mill. the spot drill's chamfer will be. For general chamfering and nc spot drilling.2. can i use a chamfer mill to chamfer, countersink, and spot drill? chamfer mill for spotting & countersinking. chamfering best practices. In fact, some use up to four different tools to. Spot Drill Vs Chamfer Mill.

From ru.zipy.co.il

Купить Алиэкспресс 90 Degrees Chamfer Mill Drill HSS Spot Drill 3/4/5 Spot Drill Vs Chamfer Mill Your best bet is to chamfer your edges with a chamfer mill. In fact, some use up to four different tools to machine a perfect hole: Though chamfering can be done with a hand tool, it would be a primitive choice. Spotting drill, drill, flat bottom counterbore, and countersink. the spot drill's chamfer will be. chamfering best practices.. Spot Drill Vs Chamfer Mill.

From hxehjvfmy.blob.core.windows.net

Chamfer Mill Vs Countersink at Latasha Henson blog Spot Drill Vs Chamfer Mill the spot drill's chamfer will be. Spotting drill, drill, flat bottom counterbore, and countersink. chamfer mill for spotting & countersinking. For general chamfering and nc spot drilling.2. can i use a chamfer mill to chamfer, countersink, and spot drill? If not, are there other ways to. Though chamfering can be done with a hand tool, it would. Spot Drill Vs Chamfer Mill.

From museumhead.com

Milling Tools for use with Speed Tiger NC Spot Drill Tool SPEED TIGER Spot Drill Vs Chamfer Mill However, if you’re working on a hole you will be using a drill or spot drill typically with a solid stainless steel or carbide body. If not, are there other ways to. For general chamfering and nc spot drilling.2. Though chamfering can be done with a hand tool, it would be a primitive choice. They can also be used for. Spot Drill Vs Chamfer Mill.

From www.youtube.com

Using a spot drill to chamfer the outside of a part YouTube Spot Drill Vs Chamfer Mill chamfering best practices. For general chamfering and nc spot drilling.2. the spot drill's chamfer will be. Your best bet is to chamfer your edges with a chamfer mill. However, if you’re working on a hole you will be using a drill or spot drill typically with a solid stainless steel or carbide body. In fact, some use up. Spot Drill Vs Chamfer Mill.

From www.aliexpress.com

Carbide Spot Drill Bit 60 90 120 Degree CNC Drilling Guide Tool Spot Drill Vs Chamfer Mill chamfering best practices. Though chamfering can be done with a hand tool, it would be a primitive choice. However, if you’re working on a hole you will be using a drill or spot drill typically with a solid stainless steel or carbide body. If not, are there other ways to. Your best bet is to chamfer your edges with. Spot Drill Vs Chamfer Mill.

From rinaldi-tools.com

Chamfer Mill HF45...SPMG... Spot Drill Vs Chamfer Mill Spotting drill, drill, flat bottom counterbore, and countersink. However, if you’re working on a hole you will be using a drill or spot drill typically with a solid stainless steel or carbide body. Your best bet is to chamfer your edges with a chamfer mill. If not, are there other ways to. the spot drill's chamfer will be. They. Spot Drill Vs Chamfer Mill.

From www.cut-tools.com.tw

Spot Drill Milling Cutters Y.T. / YT / YIH TROUN Spot Drill Vs Chamfer Mill for reference i use an everede nc indexable spot drill for spotting and a helical flute chamfer mill for chamfering. They can also be used for chamfering,. the spot drill's chamfer will be. Your best bet is to chamfer your edges with a chamfer mill. spot drills are essential for enhancing the precision of secondary drilling operations.. Spot Drill Vs Chamfer Mill.

From www.brownesales.com

The Nine 9 NC Drilling, Spotting, Engraving, Chamfering, Facing and Spot Drill Vs Chamfer Mill If not, are there other ways to. for reference i use an everede nc indexable spot drill for spotting and a helical flute chamfer mill for chamfering. They can also be used for chamfering,. Spotting drill, drill, flat bottom counterbore, and countersink. chamfering best practices. Though chamfering can be done with a hand tool, it would be a. Spot Drill Vs Chamfer Mill.

From alexnld.com

Drillpro 90 Degree Chamfer End Mill 3 Flute 212mm Carbide CNC Spot Drill Vs Chamfer Mill chamfer mill for spotting & countersinking. for reference i use an everede nc indexable spot drill for spotting and a helical flute chamfer mill for chamfering. Though chamfering can be done with a hand tool, it would be a primitive choice. Spotting drill, drill, flat bottom counterbore, and countersink. the spot drill's chamfer will be. spot. Spot Drill Vs Chamfer Mill.

From xmkktool.en.made-in-china.com

Carbide Centering Drill Spot 60/ 90 Degree Solid Tungsten Chamfering Spot Drill Vs Chamfer Mill the spot drill's chamfer will be. For general chamfering and nc spot drilling.2. In fact, some use up to four different tools to machine a perfect hole: Though chamfering can be done with a hand tool, it would be a primitive choice. Your best bet is to chamfer your edges with a chamfer mill. spot drills are essential. Spot Drill Vs Chamfer Mill.

From www.amazon.com

Maifix Chamfer Point Drill 3MM 90 Degree Tungsten Carbide Spot Drill Vs Chamfer Mill If not, are there other ways to. can i use a chamfer mill to chamfer, countersink, and spot drill? Spotting drill, drill, flat bottom counterbore, and countersink. For general chamfering and nc spot drilling.2. chamfering best practices. the spot drill's chamfer will be. for reference i use an everede nc indexable spot drill for spotting and. Spot Drill Vs Chamfer Mill.

From jimmore.en.taiwantrade.com

90° NC Spot Drill with carbide insert_suit spotting, engraving Spot Drill Vs Chamfer Mill Spotting drill, drill, flat bottom counterbore, and countersink. spot drills are essential for enhancing the precision of secondary drilling operations. the spot drill's chamfer will be. Your best bet is to chamfer your edges with a chamfer mill. for reference i use an everede nc indexable spot drill for spotting and a helical flute chamfer mill for. Spot Drill Vs Chamfer Mill.

From nine9.jic-tools.com.tw

Combined Spotting and Chamfering 145 + 90 degree, dia 10, 16 and 25mm Spot Drill Vs Chamfer Mill Your best bet is to chamfer your edges with a chamfer mill. the spot drill's chamfer will be. spot drills are essential for enhancing the precision of secondary drilling operations. chamfering best practices. chamfer mill for spotting & countersinking. for reference i use an everede nc indexable spot drill for spotting and a helical flute. Spot Drill Vs Chamfer Mill.

From www.harveyperformance.com

The Multiple Uses of a Chamfer Mill In The Loupe Machinist Blog Spot Drill Vs Chamfer Mill If not, are there other ways to. In fact, some use up to four different tools to machine a perfect hole: Spotting drill, drill, flat bottom counterbore, and countersink. chamfering best practices. Your best bet is to chamfer your edges with a chamfer mill. chamfer mill for spotting & countersinking. for reference i use an everede nc. Spot Drill Vs Chamfer Mill.

From www.youtube.com

SE12 Spot Drill & Chamfer Mill YouTube Spot Drill Vs Chamfer Mill However, if you’re working on a hole you will be using a drill or spot drill typically with a solid stainless steel or carbide body. They can also be used for chamfering,. the spot drill's chamfer will be. Though chamfering can be done with a hand tool, it would be a primitive choice. If not, are there other ways. Spot Drill Vs Chamfer Mill.

From gbu-taganskij.ru

Spot Drilling The First Step To Precision Drilling In The, 54 OFF Spot Drill Vs Chamfer Mill Though chamfering can be done with a hand tool, it would be a primitive choice. chamfer mill for spotting & countersinking. They can also be used for chamfering,. For general chamfering and nc spot drilling.2. spot drills are essential for enhancing the precision of secondary drilling operations. chamfering best practices. for reference i use an everede. Spot Drill Vs Chamfer Mill.

From www.casascomobili.it

Maifix Chamfer Point Drill 5MM 90 Degree Tungsten Carbide Steel Spot Spot Drill Vs Chamfer Mill They can also be used for chamfering,. Your best bet is to chamfer your edges with a chamfer mill. spot drills are essential for enhancing the precision of secondary drilling operations. for reference i use an everede nc indexable spot drill for spotting and a helical flute chamfer mill for chamfering. chamfering best practices. can i. Spot Drill Vs Chamfer Mill.

From www.practicalmachinist.com

Understanding Chamfer and Chamfer Mills Practical Machinist Spot Drill Vs Chamfer Mill the spot drill's chamfer will be. chamfer mill for spotting & countersinking. For general chamfering and nc spot drilling.2. Spotting drill, drill, flat bottom counterbore, and countersink. spot drills are essential for enhancing the precision of secondary drilling operations. Your best bet is to chamfer your edges with a chamfer mill. They can also be used for. Spot Drill Vs Chamfer Mill.

From www.alibaba.com

Hss Spotting Drill Nc Spot Drill High Speed Steel Milling Cutter Bits Spot Drill Vs Chamfer Mill Your best bet is to chamfer your edges with a chamfer mill. for reference i use an everede nc indexable spot drill for spotting and a helical flute chamfer mill for chamfering. can i use a chamfer mill to chamfer, countersink, and spot drill? However, if you’re working on a hole you will be using a drill or. Spot Drill Vs Chamfer Mill.

From blog.tormach.com

When to Use a Spot Drill Spot Drill Vs Chamfer Mill chamfer mill for spotting & countersinking. Your best bet is to chamfer your edges with a chamfer mill. spot drills are essential for enhancing the precision of secondary drilling operations. chamfering best practices. can i use a chamfer mill to chamfer, countersink, and spot drill? In fact, some use up to four different tools to machine. Spot Drill Vs Chamfer Mill.

From museumhead.com

Milling Tools for use with Speed Tiger NC Spot Drill Tool SPEED TIGER Spot Drill Vs Chamfer Mill the spot drill's chamfer will be. Your best bet is to chamfer your edges with a chamfer mill. If not, are there other ways to. spot drills are essential for enhancing the precision of secondary drilling operations. chamfer mill for spotting & countersinking. Though chamfering can be done with a hand tool, it would be a primitive. Spot Drill Vs Chamfer Mill.

From www.casascomobili.it

Maifix Chamfer Point Drill 5MM 90 Degree Tungsten Carbide Steel Spot Spot Drill Vs Chamfer Mill can i use a chamfer mill to chamfer, countersink, and spot drill? For general chamfering and nc spot drilling.2. spot drills are essential for enhancing the precision of secondary drilling operations. the spot drill's chamfer will be. chamfer mill for spotting & countersinking. In fact, some use up to four different tools to machine a perfect. Spot Drill Vs Chamfer Mill.

From www.tpqtools.co.th

MultiPro Spot Drill & Chamfer Mill tpqtools Spot Drill Vs Chamfer Mill the spot drill's chamfer will be. chamfer mill for spotting & countersinking. If not, are there other ways to. Though chamfering can be done with a hand tool, it would be a primitive choice. However, if you’re working on a hole you will be using a drill or spot drill typically with a solid stainless steel or carbide. Spot Drill Vs Chamfer Mill.

From www.aliexpress.com

XCAN 90 Degrees Chamfer Mill Drill HSS Spot Drill 3/4/5/6/8/10/12mm Spot Drill Vs Chamfer Mill chamfer mill for spotting & countersinking. the spot drill's chamfer will be. They can also be used for chamfering,. However, if you’re working on a hole you will be using a drill or spot drill typically with a solid stainless steel or carbide body. Your best bet is to chamfer your edges with a chamfer mill. For general. Spot Drill Vs Chamfer Mill.

From www.manufacturingguide.com

Chamfer milling Find suppliers, processes & material Spot Drill Vs Chamfer Mill for reference i use an everede nc indexable spot drill for spotting and a helical flute chamfer mill for chamfering. spot drills are essential for enhancing the precision of secondary drilling operations. Your best bet is to chamfer your edges with a chamfer mill. In fact, some use up to four different tools to machine a perfect hole:. Spot Drill Vs Chamfer Mill.

From www.youtube.com

Check Out Our New Chamfer Mills on Haas Automation Spot Drill Vs Chamfer Mill However, if you’re working on a hole you will be using a drill or spot drill typically with a solid stainless steel or carbide body. the spot drill's chamfer will be. Your best bet is to chamfer your edges with a chamfer mill. For general chamfering and nc spot drilling.2. If not, are there other ways to. spot. Spot Drill Vs Chamfer Mill.

From www.aliexpress.com

Store Home Products Feedback Spot Drill Vs Chamfer Mill can i use a chamfer mill to chamfer, countersink, and spot drill? the spot drill's chamfer will be. Though chamfering can be done with a hand tool, it would be a primitive choice. chamfer mill for spotting & countersinking. In fact, some use up to four different tools to machine a perfect hole: They can also be. Spot Drill Vs Chamfer Mill.

From www.carbidetoolsource.com

1/8" (.125") 2 Flute 60 degree Carbide Chamfer Mill / Spot Drill 5Pack Spot Drill Vs Chamfer Mill can i use a chamfer mill to chamfer, countersink, and spot drill? Though chamfering can be done with a hand tool, it would be a primitive choice. the spot drill's chamfer will be. spot drills are essential for enhancing the precision of secondary drilling operations. For general chamfering and nc spot drilling.2. They can also be used. Spot Drill Vs Chamfer Mill.

From www.aliexpress.com

1pcs chamfering 10mm carbide chamfering milling cutter Chamfer D10*75L Spot Drill Vs Chamfer Mill spot drills are essential for enhancing the precision of secondary drilling operations. If not, are there other ways to. They can also be used for chamfering,. Spotting drill, drill, flat bottom counterbore, and countersink. In fact, some use up to four different tools to machine a perfect hole: can i use a chamfer mill to chamfer, countersink, and. Spot Drill Vs Chamfer Mill.

From www.harveyperformance.com

The Multiple Uses of a Chamfer Mill In The Loupe Machinist Blog Spot Drill Vs Chamfer Mill chamfer mill for spotting & countersinking. Though chamfering can be done with a hand tool, it would be a primitive choice. Your best bet is to chamfer your edges with a chamfer mill. spot drills are essential for enhancing the precision of secondary drilling operations. the spot drill's chamfer will be. For general chamfering and nc spot. Spot Drill Vs Chamfer Mill.

From www.harveyperformance.com

Spot Drilling The First Step to Precision Drilling In The Loupe Spot Drill Vs Chamfer Mill Spotting drill, drill, flat bottom counterbore, and countersink. for reference i use an everede nc indexable spot drill for spotting and a helical flute chamfer mill for chamfering. spot drills are essential for enhancing the precision of secondary drilling operations. If not, are there other ways to. can i use a chamfer mill to chamfer, countersink, and. Spot Drill Vs Chamfer Mill.

From www.carbidetoolsource.com

Chamfer Mills — Spot Drill Vs Chamfer Mill spot drills are essential for enhancing the precision of secondary drilling operations. Your best bet is to chamfer your edges with a chamfer mill. chamfer mill for spotting & countersinking. For general chamfering and nc spot drilling.2. the spot drill's chamfer will be. In fact, some use up to four different tools to machine a perfect hole:. Spot Drill Vs Chamfer Mill.

From www.harveyperformance.com

Spot Drilling The First Step to Precision Drilling In The Loupe Spot Drill Vs Chamfer Mill the spot drill's chamfer will be. chamfering best practices. for reference i use an everede nc indexable spot drill for spotting and a helical flute chamfer mill for chamfering. can i use a chamfer mill to chamfer, countersink, and spot drill? chamfer mill for spotting & countersinking. Your best bet is to chamfer your edges. Spot Drill Vs Chamfer Mill.