Actuator Valve Wiring Diagram . Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). Adjust the open and close of the valve using the zero (4ma) and span (20ma) pots on the controller board. Install actuator after ignition switch. Fluid power actuators process control actuators. With actuator in place on valve, ensure proper flange mating and valve actuator orientation. Learn how to read and understand rotork valve actuator wiring diagrams, including electrical symbols, connections, and functionality. 1 wires from all actuators are tied together and tied to the negative leg of the control signal. Use a number 30 (.1285) drill bit to drill a hole. Learn how to read and understand electric actuator wiring diagrams.

from www.176iot.com

Install actuator after ignition switch. Fluid power actuators process control actuators. Adjust the open and close of the valve using the zero (4ma) and span (20ma) pots on the controller board. Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). Use a number 30 (.1285) drill bit to drill a hole. With actuator in place on valve, ensure proper flange mating and valve actuator orientation. Learn how to read and understand rotork valve actuator wiring diagrams, including electrical symbols, connections, and functionality. Learn how to read and understand electric actuator wiring diagrams. 1 wires from all actuators are tied together and tied to the negative leg of the control signal.

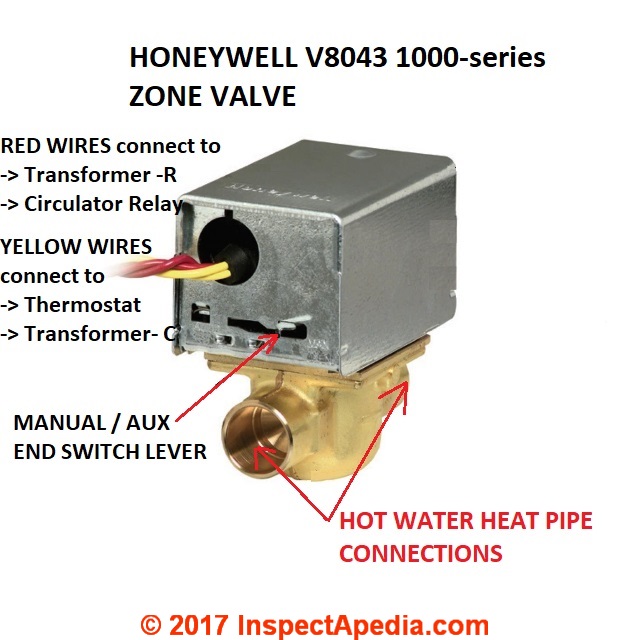

Honeywell V8043e Zone Valve Wiring Diagram IOT Wiring Diagram

Actuator Valve Wiring Diagram Use a number 30 (.1285) drill bit to drill a hole. Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). Adjust the open and close of the valve using the zero (4ma) and span (20ma) pots on the controller board. Learn how to read and understand electric actuator wiring diagrams. Install actuator after ignition switch. Fluid power actuators process control actuators. 1 wires from all actuators are tied together and tied to the negative leg of the control signal. Use a number 30 (.1285) drill bit to drill a hole. Learn how to read and understand rotork valve actuator wiring diagrams, including electrical symbols, connections, and functionality. With actuator in place on valve, ensure proper flange mating and valve actuator orientation.

From armourvalve.com

Electric Actuator and Valve Gearbox Armour Valve Actuator Valve Wiring Diagram Fluid power actuators process control actuators. Learn how to read and understand electric actuator wiring diagrams. Adjust the open and close of the valve using the zero (4ma) and span (20ma) pots on the controller board. 1 wires from all actuators are tied together and tied to the negative leg of the control signal. With actuator in place on valve,. Actuator Valve Wiring Diagram.

From wiringschemas.blogspot.com

12v Linear Actuator Wiring Diagram Wiring Diagram Schemas Actuator Valve Wiring Diagram 1 wires from all actuators are tied together and tied to the negative leg of the control signal. Learn how to read and understand electric actuator wiring diagrams. With actuator in place on valve, ensure proper flange mating and valve actuator orientation. Learn how to read and understand rotork valve actuator wiring diagrams, including electrical symbols, connections, and functionality. Install. Actuator Valve Wiring Diagram.

From circuitmanualostermann.z19.web.core.windows.net

Valve Actuator Wiring Diagram Actuator Valve Wiring Diagram Install actuator after ignition switch. 1 wires from all actuators are tied together and tied to the negative leg of the control signal. Fluid power actuators process control actuators. Learn how to read and understand electric actuator wiring diagrams. Adjust the open and close of the valve using the zero (4ma) and span (20ma) pots on the controller board. Use. Actuator Valve Wiring Diagram.

From www.got2bwireless.com

Honeywell Actuator Wiring Diagram Database Actuator Valve Wiring Diagram Learn how to read and understand rotork valve actuator wiring diagrams, including electrical symbols, connections, and functionality. Install actuator after ignition switch. Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). Fluid power actuators process control actuators. With. Actuator Valve Wiring Diagram.

From www.proactuator.com

How to Wire AUMA Actuators Diagram ProActuator Actuator Valve Wiring Diagram Install actuator after ignition switch. With actuator in place on valve, ensure proper flange mating and valve actuator orientation. Fluid power actuators process control actuators. Use a number 30 (.1285) drill bit to drill a hole. Learn how to read and understand rotork valve actuator wiring diagrams, including electrical symbols, connections, and functionality. Adjust the open and close of the. Actuator Valve Wiring Diagram.

From rawanology.blogspot.com

Volt Actuator Wiring Diagram rawanology Actuator Valve Wiring Diagram Install actuator after ignition switch. Adjust the open and close of the valve using the zero (4ma) and span (20ma) pots on the controller board. Learn how to read and understand electric actuator wiring diagrams. Fluid power actuators process control actuators. With actuator in place on valve, ensure proper flange mating and valve actuator orientation. 1 wires from all actuators. Actuator Valve Wiring Diagram.

From schematron.org

Jandy Valve Actuator Wiring Diagram Wiring Diagram Pictures Actuator Valve Wiring Diagram Learn how to read and understand electric actuator wiring diagrams. 1 wires from all actuators are tied together and tied to the negative leg of the control signal. Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). Adjust. Actuator Valve Wiring Diagram.

From color370.blogspot.com

Honeywell 3 Port Valve Wiring Diagram, Way Three Way Valve Schematic Actuator Valve Wiring Diagram Adjust the open and close of the valve using the zero (4ma) and span (20ma) pots on the controller board. Learn how to read and understand rotork valve actuator wiring diagrams, including electrical symbols, connections, and functionality. With actuator in place on valve, ensure proper flange mating and valve actuator orientation. Learn how to read and understand electric actuator wiring. Actuator Valve Wiring Diagram.

From www.youtube.com

How do Pneumatic actuators Valves WorkPneumatic Actuators Valves Types Actuator Valve Wiring Diagram With actuator in place on valve, ensure proper flange mating and valve actuator orientation. Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). Adjust the open and close of the valve using the zero (4ma) and span (20ma). Actuator Valve Wiring Diagram.

From www.mdpi.com

Actuators Free FullText Design, Implementation and Evaluation of a Actuator Valve Wiring Diagram Learn how to read and understand electric actuator wiring diagrams. Install actuator after ignition switch. With actuator in place on valve, ensure proper flange mating and valve actuator orientation. Use a number 30 (.1285) drill bit to drill a hole. 1 wires from all actuators are tied together and tied to the negative leg of the control signal. Adjust the. Actuator Valve Wiring Diagram.

From www.youtube.com

Rotork Actuator Drawing Rotork Actuator Wiring Diagram Rotork Actuator Valve Wiring Diagram 1 wires from all actuators are tied together and tied to the negative leg of the control signal. Learn how to read and understand rotork valve actuator wiring diagrams, including electrical symbols, connections, and functionality. Learn how to read and understand electric actuator wiring diagrams. Install actuator after ignition switch. Fluid power actuators process control actuators. Adjust the open and. Actuator Valve Wiring Diagram.

From guidemanualmanganites.z21.web.core.windows.net

Rcel Electric Actuator Wiring Diagram Actuator Valve Wiring Diagram Learn how to read and understand electric actuator wiring diagrams. Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). Fluid power actuators process control actuators. Learn how to read and understand rotork valve actuator wiring diagrams, including electrical. Actuator Valve Wiring Diagram.

From www.176iot.com

Honeywell V8043e Zone Valve Wiring Diagram IOT Wiring Diagram Actuator Valve Wiring Diagram 1 wires from all actuators are tied together and tied to the negative leg of the control signal. Learn how to read and understand rotork valve actuator wiring diagrams, including electrical symbols, connections, and functionality. Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors. Actuator Valve Wiring Diagram.

From schematicdatawinkel.z19.web.core.windows.net

Electric Actuator Valve Wiring Diagram Actuator Valve Wiring Diagram Fluid power actuators process control actuators. Install actuator after ignition switch. Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). 1 wires from all actuators are tied together and tied to the negative leg of the control signal.. Actuator Valve Wiring Diagram.

From diagramweb.net

12v Linear Actuator Wiring Diagram Actuator Valve Wiring Diagram Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). Adjust the open and close of the valve using the zero (4ma) and span (20ma) pots on the controller board. Learn how to read and understand electric actuator wiring. Actuator Valve Wiring Diagram.

From wittlemwlody.blogspot.com

Electric Valve Actuator Wiring Diagram wittlemwlody Actuator Valve Wiring Diagram Learn how to read and understand rotork valve actuator wiring diagrams, including electrical symbols, connections, and functionality. 1 wires from all actuators are tied together and tied to the negative leg of the control signal. Fluid power actuators process control actuators. Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and. Actuator Valve Wiring Diagram.

From www.researchgate.net

Schematic of the electrohydraulic valve actuation system. Download Actuator Valve Wiring Diagram Learn how to read and understand electric actuator wiring diagrams. Learn how to read and understand rotork valve actuator wiring diagrams, including electrical symbols, connections, and functionality. 1 wires from all actuators are tied together and tied to the negative leg of the control signal. Install actuator after ignition switch. With actuator in place on valve, ensure proper flange mating. Actuator Valve Wiring Diagram.

From zen-fab.blogspot.com

Auma Valve Actuator Wiring Diagram Zen Fab Actuator Valve Wiring Diagram Learn how to read and understand rotork valve actuator wiring diagrams, including electrical symbols, connections, and functionality. Learn how to read and understand electric actuator wiring diagrams. Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). Adjust the. Actuator Valve Wiring Diagram.

From schematicgesindetq.z4.web.core.windows.net

Wiring Zone Valves Diagram Actuator Valve Wiring Diagram Use a number 30 (.1285) drill bit to drill a hole. Learn how to read and understand rotork valve actuator wiring diagrams, including electrical symbols, connections, and functionality. Learn how to read and understand electric actuator wiring diagrams. Fluid power actuators process control actuators. Install actuator after ignition switch. Adjust the open and close of the valve using the zero. Actuator Valve Wiring Diagram.

From forum.arduino.cc

Conecting Arduino with 5 Wires Electric Ball Valve CWX15Q Brass 36V Actuator Valve Wiring Diagram Adjust the open and close of the valve using the zero (4ma) and span (20ma) pots on the controller board. Fluid power actuators process control actuators. Learn how to read and understand electric actuator wiring diagrams. Use a number 30 (.1285) drill bit to drill a hole. With actuator in place on valve, ensure proper flange mating and valve actuator. Actuator Valve Wiring Diagram.

From wittlemwlody.blogspot.com

Electric Valve Actuator Wiring Diagram wittlemwlody Actuator Valve Wiring Diagram With actuator in place on valve, ensure proper flange mating and valve actuator orientation. Fluid power actuators process control actuators. Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). Learn how to read and understand rotork valve actuator. Actuator Valve Wiring Diagram.

From www.chanish.org

Rotork Actuator Wiring Diagram Actuator Valve Wiring Diagram Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). Learn how to read and understand electric actuator wiring diagrams. Learn how to read and understand rotork valve actuator wiring diagrams, including electrical symbols, connections, and functionality. Fluid power. Actuator Valve Wiring Diagram.

From copaintx.blogspot.com

Tb2001 Actuator Wiring Diagram Copaint Actuator Valve Wiring Diagram Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). Fluid power actuators process control actuators. Use a number 30 (.1285) drill bit to drill a hole. 1 wires from all actuators are tied together and tied to the. Actuator Valve Wiring Diagram.

From missastuces3eschematic.z4.web.core.windows.net

Honeywell Motorized Zone Valve Wiring Diagram Actuator Valve Wiring Diagram Install actuator after ignition switch. Fluid power actuators process control actuators. 1 wires from all actuators are tied together and tied to the negative leg of the control signal. Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter).. Actuator Valve Wiring Diagram.

From wiringdiagram.2bitboer.com

Bernard Actuator Wiring Diagram Wiring Diagram Actuator Valve Wiring Diagram Adjust the open and close of the valve using the zero (4ma) and span (20ma) pots on the controller board. 1 wires from all actuators are tied together and tied to the negative leg of the control signal. Install actuator after ignition switch. Fluid power actuators process control actuators. Use a number 30 (.1285) drill bit to drill a hole.. Actuator Valve Wiring Diagram.

From guidemanualsidcup.z21.web.core.windows.net

Honeywell Motorized Valve Wiring Diagrams Actuator Valve Wiring Diagram Use a number 30 (.1285) drill bit to drill a hole. Learn how to read and understand rotork valve actuator wiring diagrams, including electrical symbols, connections, and functionality. Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). Adjust. Actuator Valve Wiring Diagram.

From rawanology.blogspot.com

Volt Actuator Wiring Diagram rawanology Actuator Valve Wiring Diagram With actuator in place on valve, ensure proper flange mating and valve actuator orientation. Fluid power actuators process control actuators. 1 wires from all actuators are tied together and tied to the negative leg of the control signal. Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices. Actuator Valve Wiring Diagram.

From schematicfixlankier.z21.web.core.windows.net

Blend Door Actuator Diagram Actuator Valve Wiring Diagram Install actuator after ignition switch. 1 wires from all actuators are tied together and tied to the negative leg of the control signal. Learn how to read and understand electric actuator wiring diagrams. Learn how to read and understand rotork valve actuator wiring diagrams, including electrical symbols, connections, and functionality. Use a number 30 (.1285) drill bit to drill a. Actuator Valve Wiring Diagram.

From www.mtd-actuator.com

Precise 3way valve actuator for food and beverage industry MTD Actuator Valve Wiring Diagram Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). Install actuator after ignition switch. With actuator in place on valve, ensure proper flange mating and valve actuator orientation. Fluid power actuators process control actuators. Use a number 30. Actuator Valve Wiring Diagram.

From www.got2bwireless.com

Actuator Wiring Diagram For Your Needs Actuator Valve Wiring Diagram 1 wires from all actuators are tied together and tied to the negative leg of the control signal. Fluid power actuators process control actuators. Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). Use a number 30 (.1285). Actuator Valve Wiring Diagram.

From wiring.hpricorpcom.com

Honeywell Actuator Valve Wiring Diagram Wiring Diagram and Schematic Actuator Valve Wiring Diagram With actuator in place on valve, ensure proper flange mating and valve actuator orientation. 1 wires from all actuators are tied together and tied to the negative leg of the control signal. Use a number 30 (.1285) drill bit to drill a hole. Learn how to read and understand rotork valve actuator wiring diagrams, including electrical symbols, connections, and functionality.. Actuator Valve Wiring Diagram.

From manual.imagenes4k.com

Siemens 3 Port Valve Wiring Diagram Ansul Wiring Diagram Siemens Actuator Valve Wiring Diagram 1 wires from all actuators are tied together and tied to the negative leg of the control signal. Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). Learn how to read and understand electric actuator wiring diagrams. Adjust. Actuator Valve Wiring Diagram.

From techschems.com

Everything You Need to Know About Wiring a Honeywell Actuator Valve Actuator Valve Wiring Diagram Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). Install actuator after ignition switch. Learn how to read and understand electric actuator wiring diagrams. Learn how to read and understand rotork valve actuator wiring diagrams, including electrical symbols,. Actuator Valve Wiring Diagram.

From wiringdiagram.2bitboer.com

White Rodgers Zone Valve Wiring Schematic Wiring Diagram Actuator Valve Wiring Diagram Use a number 30 (.1285) drill bit to drill a hole. Install actuator after ignition switch. Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). With actuator in place on valve, ensure proper flange mating and valve actuator. Actuator Valve Wiring Diagram.

From motorwiringdiagram.blogspot.com

Electric Valve Actuator Wiring Diagram Motor Wiring Diagram Actuator Valve Wiring Diagram Learn how to read and understand electric actuator wiring diagrams. With actuator in place on valve, ensure proper flange mating and valve actuator orientation. Follow the manufacturer’s wiring diagram meticulously to ensure proper connection of power supply, control signals, torque limit switches and any feedback devices (e.g., position sensors like limit switches and position transmitter). Install actuator after ignition switch.. Actuator Valve Wiring Diagram.