Cutting Tool Having Zero Rake . Now if sum of wedge angle and clearance angle becomes equal to 90° on a particular plane, then rake angle becomes zero. Similarly, when sum of wedge angle and clearance angle is more than 90° on a particular plane, rake angle becomes negative. Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here. The recommended rake angle depends on the tool material, the material to be cut, and the speed and depth of cutting. There are three types of rake angles: Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. Rake angle may have positive, negative or even zero value, as elaborated in the following section. It explains classification of rake angles with diagram and their examples,. Positive, zero or neutral, and negative. A tool has a positive rake when the face of the cutting. Rake surface of the cutting tool is the only chip flowing surface and orientation of this rake surface is indicated by rake angles. There are three different types of rake angles, positive rake angle, negative rake angle, and zero rake angle. Governs direction of chip flow. Negative rake offers stronger tool tip and thus enhanced tool life. Thus rake angle is crucial factor to judge machining action.

from www.mdpi.com

There are three types of rake angles: Positive, zero or neutral, and negative. Negative rake offers stronger tool tip and thus enhanced tool life. The recommended rake angle depends on the tool material, the material to be cut, and the speed and depth of cutting. Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here. Rake surface of the cutting tool is the only chip flowing surface and orientation of this rake surface is indicated by rake angles. Now if sum of wedge angle and clearance angle becomes equal to 90° on a particular plane, then rake angle becomes zero. Similarly, when sum of wedge angle and clearance angle is more than 90° on a particular plane, rake angle becomes negative. There are three different types of rake angles, positive rake angle, negative rake angle, and zero rake angle.

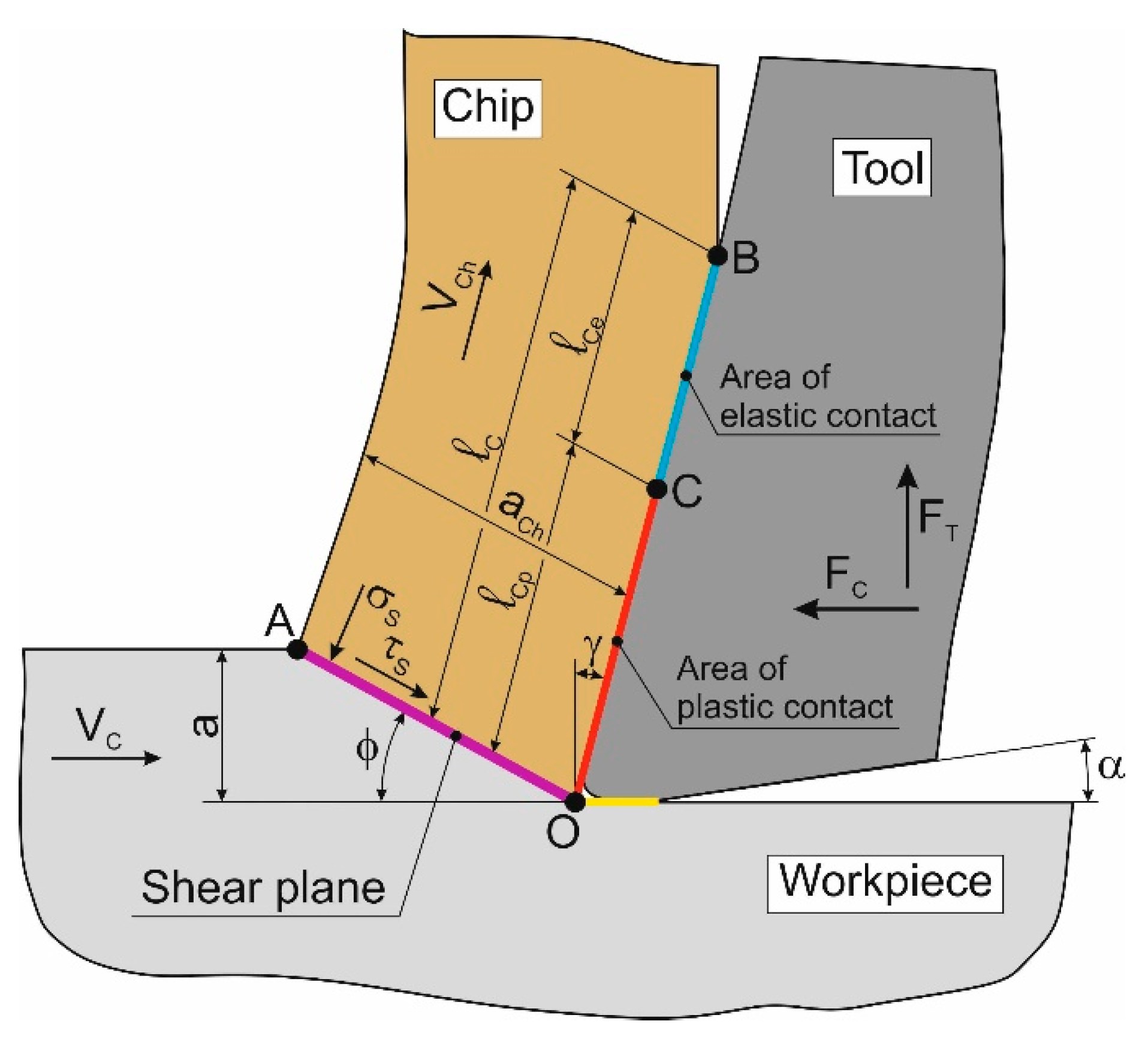

JMMP Free FullText Determination of the Shear Angle in the

Cutting Tool Having Zero Rake It explains classification of rake angles with diagram and their examples,. Thus rake angle is crucial factor to judge machining action. Similarly, when sum of wedge angle and clearance angle is more than 90° on a particular plane, rake angle becomes negative. Rake surface of the cutting tool is the only chip flowing surface and orientation of this rake surface is indicated by rake angles. Governs direction of chip flow. It explains classification of rake angles with diagram and their examples,. Now if sum of wedge angle and clearance angle becomes equal to 90° on a particular plane, then rake angle becomes zero. The recommended rake angle depends on the tool material, the material to be cut, and the speed and depth of cutting. There are three types of rake angles: Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here. A tool has a positive rake when the face of the cutting. Positive, zero or neutral, and negative. Rake angle may have positive, negative or even zero value, as elaborated in the following section. There are three different types of rake angles, positive rake angle, negative rake angle, and zero rake angle. Negative rake offers stronger tool tip and thus enhanced tool life. Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane.

From www.mechanicalbooster.com

Single Point Cutting Tool Geometry, Angles, Nomenclature and Signature Cutting Tool Having Zero Rake Negative rake offers stronger tool tip and thus enhanced tool life. There are three types of rake angles: Rake surface of the cutting tool is the only chip flowing surface and orientation of this rake surface is indicated by rake angles. Similarly, when sum of wedge angle and clearance angle is more than 90° on a particular plane, rake angle. Cutting Tool Having Zero Rake.

From www.pacific.edu

Parameters Affecting Mechanical and Thermal Responses in Bone Drilling Cutting Tool Having Zero Rake There are three different types of rake angles, positive rake angle, negative rake angle, and zero rake angle. Thus rake angle is crucial factor to judge machining action. Positive, zero or neutral, and negative. Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. Rake angle may have positive, negative or even zero value, as elaborated. Cutting Tool Having Zero Rake.

From slideshare.net

Mechanics of metal cutting Cutting Tool Having Zero Rake A tool has a positive rake when the face of the cutting. Negative rake offers stronger tool tip and thus enhanced tool life. Governs direction of chip flow. There are three types of rake angles: There are three different types of rake angles, positive rake angle, negative rake angle, and zero rake angle. It explains classification of rake angles with. Cutting Tool Having Zero Rake.

From www.minaprem.com

Concept of Positive Rake, Negative Rake and Zero Rake Angle Cutting Tool Having Zero Rake Now if sum of wedge angle and clearance angle becomes equal to 90° on a particular plane, then rake angle becomes zero. Positive, zero or neutral, and negative. Thus rake angle is crucial factor to judge machining action. Similarly, when sum of wedge angle and clearance angle is more than 90° on a particular plane, rake angle becomes negative. Concept. Cutting Tool Having Zero Rake.

From www.mech4study.com

Single Point Cutting Tool Nomenclature, Angle,Geometry and Signature Cutting Tool Having Zero Rake Similarly, when sum of wedge angle and clearance angle is more than 90° on a particular plane, rake angle becomes negative. The recommended rake angle depends on the tool material, the material to be cut, and the speed and depth of cutting. Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. It explains classification of. Cutting Tool Having Zero Rake.

From www.themachinedesign.com

Single Point Cutting Tool Nomenclature, Geometry The Machine Design Cutting Tool Having Zero Rake Now if sum of wedge angle and clearance angle becomes equal to 90° on a particular plane, then rake angle becomes zero. Similarly, when sum of wedge angle and clearance angle is more than 90° on a particular plane, rake angle becomes negative. Governs direction of chip flow. Positive, zero or neutral, and negative. Concept of positive rake angle, negative. Cutting Tool Having Zero Rake.

From www.mechanicalbooster.com

Single Point Cutting Tool Geometry, Angles, Nomenclature and Signature Cutting Tool Having Zero Rake A tool has a positive rake when the face of the cutting. Governs direction of chip flow. Positive, zero or neutral, and negative. Now if sum of wedge angle and clearance angle becomes equal to 90° on a particular plane, then rake angle becomes zero. Thus rake angle is crucial factor to judge machining action. It explains classification of rake. Cutting Tool Having Zero Rake.

From www.slideserve.com

PPT Traditional Machining PowerPoint Presentation, free download ID Cutting Tool Having Zero Rake A tool has a positive rake when the face of the cutting. Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. Similarly, when sum of wedge angle and clearance angle is more than 90° on a particular plane, rake angle becomes negative. Now if sum of wedge angle and clearance angle becomes equal to 90°. Cutting Tool Having Zero Rake.

From www.minaprem.com

Why brittle materials are machined with tools having negative rake? Cutting Tool Having Zero Rake Similarly, when sum of wedge angle and clearance angle is more than 90° on a particular plane, rake angle becomes negative. Rake surface of the cutting tool is the only chip flowing surface and orientation of this rake surface is indicated by rake angles. Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool. Cutting Tool Having Zero Rake.

From learnmechanical.com

Single Point Cutting Tool Definition, Types, Geometry, Nomenclature Cutting Tool Having Zero Rake Thus rake angle is crucial factor to judge machining action. Rake surface of the cutting tool is the only chip flowing surface and orientation of this rake surface is indicated by rake angles. Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here. Similarly, when sum of wedge angle and clearance. Cutting Tool Having Zero Rake.

From sharkind.com

Positive Rake Zero Angle Tool Holder Bits 407, 408, 409 or 060 Cutting Tool Having Zero Rake Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. Similarly, when sum of wedge angle and clearance angle is more than 90° on a particular plane, rake angle becomes negative. Negative rake offers stronger tool tip and thus enhanced tool life. Now if sum of wedge angle and clearance angle becomes equal to 90° on. Cutting Tool Having Zero Rake.

From www.youtube.com

Single Point Cutting Tool Nomenclature, Tool Signature, Side Rake Cutting Tool Having Zero Rake A tool has a positive rake when the face of the cutting. Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. Thus rake angle is crucial factor to judge machining action. Negative rake offers stronger tool tip and thus enhanced tool life. Governs direction of chip flow. There are three types of rake angles: Similarly,. Cutting Tool Having Zero Rake.

From onesitegroup.com

Circular Saw Blade 216/30mm 48 Tooth Zero Rake OneSite Group Cutting Tool Having Zero Rake The recommended rake angle depends on the tool material, the material to be cut, and the speed and depth of cutting. Positive, zero or neutral, and negative. Rake surface of the cutting tool is the only chip flowing surface and orientation of this rake surface is indicated by rake angles. There are three different types of rake angles, positive rake. Cutting Tool Having Zero Rake.

From www.minaprem.com

What is Rake Surface of Cutting Tool? Machining Principles Cutting Tool Having Zero Rake It explains classification of rake angles with diagram and their examples,. Similarly, when sum of wedge angle and clearance angle is more than 90° on a particular plane, rake angle becomes negative. Thus rake angle is crucial factor to judge machining action. Rake angle may have positive, negative or even zero value, as elaborated in the following section. Negative rake. Cutting Tool Having Zero Rake.

From www.minaprem.com

Name of the angle between face and flank of single point cutting tool Cutting Tool Having Zero Rake There are three different types of rake angles, positive rake angle, negative rake angle, and zero rake angle. Positive, zero or neutral, and negative. Thus rake angle is crucial factor to judge machining action. A tool has a positive rake when the face of the cutting. The recommended rake angle depends on the tool material, the material to be cut,. Cutting Tool Having Zero Rake.

From www.youtube.com

Tool Nomenclature of Single Point Cutting Tool ENGINEERING STUDY Cutting Tool Having Zero Rake There are three types of rake angles: Rake surface of the cutting tool is the only chip flowing surface and orientation of this rake surface is indicated by rake angles. Governs direction of chip flow. Positive, zero or neutral, and negative. Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here.. Cutting Tool Having Zero Rake.

From www.mdpi.com

JMMP Free FullText Determination of the Shear Angle in the Cutting Tool Having Zero Rake Negative rake offers stronger tool tip and thus enhanced tool life. There are three different types of rake angles, positive rake angle, negative rake angle, and zero rake angle. Similarly, when sum of wedge angle and clearance angle is more than 90° on a particular plane, rake angle becomes negative. The recommended rake angle depends on the tool material, the. Cutting Tool Having Zero Rake.

From www.youtube.com

Differences between Positive Rake Angle and Negative Rake Angle Cutting Tool Having Zero Rake It explains classification of rake angles with diagram and their examples,. Positive, zero or neutral, and negative. Rake surface of the cutting tool is the only chip flowing surface and orientation of this rake surface is indicated by rake angles. Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here. A. Cutting Tool Having Zero Rake.

From www.youtube.com

DIY CNC homing, auto tool zero, and milling aluminium YouTube Cutting Tool Having Zero Rake Now if sum of wedge angle and clearance angle becomes equal to 90° on a particular plane, then rake angle becomes zero. A tool has a positive rake when the face of the cutting. Similarly, when sum of wedge angle and clearance angle is more than 90° on a particular plane, rake angle becomes negative. There are three different types. Cutting Tool Having Zero Rake.

From www.youtube.com

Lathe Cutting Tool Angle l Positive Rake Angle, Negative Rake Angle l Cutting Tool Having Zero Rake A tool has a positive rake when the face of the cutting. Rake surface of the cutting tool is the only chip flowing surface and orientation of this rake surface is indicated by rake angles. Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. Positive, zero or neutral, and negative. Governs direction of chip flow.. Cutting Tool Having Zero Rake.

From www.minaprem.com

What is Rake Surface of Cutting Tool? Machining Principles Cutting Tool Having Zero Rake A tool has a positive rake when the face of the cutting. Governs direction of chip flow. Negative rake offers stronger tool tip and thus enhanced tool life. The recommended rake angle depends on the tool material, the material to be cut, and the speed and depth of cutting. Concept of positive rake angle, negative rake angle and zero rake. Cutting Tool Having Zero Rake.

From www.themachinedesign.com

Single Point Cutting Tool Nomenclature, Geometry The Machine Design Cutting Tool Having Zero Rake There are three types of rake angles: A tool has a positive rake when the face of the cutting. There are three different types of rake angles, positive rake angle, negative rake angle, and zero rake angle. Similarly, when sum of wedge angle and clearance angle is more than 90° on a particular plane, rake angle becomes negative. It explains. Cutting Tool Having Zero Rake.

From www.mmc-carbide.com

Rake Angle Technical Info / Cutting Formula MITSUBISHI MATERIALS Cutting Tool Having Zero Rake Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here. Rake angle may have positive, negative or even zero value, as elaborated in the following section. Rake surface of the cutting tool is the only chip flowing surface and orientation of this rake surface is indicated by rake angles. Cutting edge. Cutting Tool Having Zero Rake.

From www.manomano.co.uk

Kennedy No.57C 8mm Diameter HSS Boring Tool Zero Rake Cutting Tool Having Zero Rake There are three types of rake angles: It explains classification of rake angles with diagram and their examples,. Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. Now if sum of wedge angle and clearance angle becomes equal to 90° on a particular plane, then rake angle becomes zero. A tool has a positive rake. Cutting Tool Having Zero Rake.

From www.chegg.com

Solved In a machining operation that approximates orthogonal Cutting Tool Having Zero Rake Now if sum of wedge angle and clearance angle becomes equal to 90° on a particular plane, then rake angle becomes zero. A tool has a positive rake when the face of the cutting. Rake surface of the cutting tool is the only chip flowing surface and orientation of this rake surface is indicated by rake angles. Governs direction of. Cutting Tool Having Zero Rake.

From www.minaprem.com

Concept of Positive Rake, Negative Rake and Zero Rake Angle Cutting Tool Having Zero Rake A tool has a positive rake when the face of the cutting. It explains classification of rake angles with diagram and their examples,. Rake surface of the cutting tool is the only chip flowing surface and orientation of this rake surface is indicated by rake angles. Now if sum of wedge angle and clearance angle becomes equal to 90° on. Cutting Tool Having Zero Rake.

From www.youtube.com

FE Simulation of Machining with Zero tool rake angle YouTube Cutting Tool Having Zero Rake Positive, zero or neutral, and negative. Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here. Rake surface of the cutting tool is the only chip flowing surface and orientation of this rake surface is indicated by rake angles. There are three different types of rake angles, positive rake angle, negative. Cutting Tool Having Zero Rake.

From dizz.com

Rake Angle Definition, Importance, and Types (Positive, Negative, Zero Cutting Tool Having Zero Rake There are three different types of rake angles, positive rake angle, negative rake angle, and zero rake angle. A tool has a positive rake when the face of the cutting. Negative rake offers stronger tool tip and thus enhanced tool life. There are three types of rake angles: Positive, zero or neutral, and negative. It explains classification of rake angles. Cutting Tool Having Zero Rake.

From www.hobby-machinist.com

What end mill for brass? Copper? Page 2 The HobbyMachinist Cutting Tool Having Zero Rake Governs direction of chip flow. There are three different types of rake angles, positive rake angle, negative rake angle, and zero rake angle. Cutting edge at an angle(λ) to normal to velocity vector in the cutting plane. Rake surface of the cutting tool is the only chip flowing surface and orientation of this rake surface is indicated by rake angles.. Cutting Tool Having Zero Rake.

From www.youtube.com

Grinding a Positive Rake Turning Tool to cut the Inside Corner Feature Cutting Tool Having Zero Rake A tool has a positive rake when the face of the cutting. Negative rake offers stronger tool tip and thus enhanced tool life. Rake angle may have positive, negative or even zero value, as elaborated in the following section. Rake surface of the cutting tool is the only chip flowing surface and orientation of this rake surface is indicated by. Cutting Tool Having Zero Rake.

From www.youtube.com

Single point cutting tool Side rake angle End relief Angle Cutting Tool Having Zero Rake Rake angle may have positive, negative or even zero value, as elaborated in the following section. Negative rake offers stronger tool tip and thus enhanced tool life. Similarly, when sum of wedge angle and clearance angle is more than 90° on a particular plane, rake angle becomes negative. There are three different types of rake angles, positive rake angle, negative. Cutting Tool Having Zero Rake.

From www.minaprem.com

Coefficient of friction from cutting force and thrust force for zero Cutting Tool Having Zero Rake The recommended rake angle depends on the tool material, the material to be cut, and the speed and depth of cutting. Rake surface of the cutting tool is the only chip flowing surface and orientation of this rake surface is indicated by rake angles. Similarly, when sum of wedge angle and clearance angle is more than 90° on a particular. Cutting Tool Having Zero Rake.

From www.minaprem.com

What is Rake Surface of Cutting Tool? Machining Principles Cutting Tool Having Zero Rake It explains classification of rake angles with diagram and their examples,. Thus rake angle is crucial factor to judge machining action. A tool has a positive rake when the face of the cutting. The recommended rake angle depends on the tool material, the material to be cut, and the speed and depth of cutting. Similarly, when sum of wedge angle. Cutting Tool Having Zero Rake.

From www.aircraftwindshieldstore.com

11/64" (.172") Drill Cutting Tool Having Zero Rake Rake angle may have positive, negative or even zero value, as elaborated in the following section. The recommended rake angle depends on the tool material, the material to be cut, and the speed and depth of cutting. It explains classification of rake angles with diagram and their examples,. Thus rake angle is crucial factor to judge machining action. Negative rake. Cutting Tool Having Zero Rake.

From www.numerade.com

SOLVED 'In an orthogonal cutting operation; the cutting tool has rake Cutting Tool Having Zero Rake Similarly, when sum of wedge angle and clearance angle is more than 90° on a particular plane, rake angle becomes negative. It explains classification of rake angles with diagram and their examples,. The recommended rake angle depends on the tool material, the material to be cut, and the speed and depth of cutting. Concept of positive rake angle, negative rake. Cutting Tool Having Zero Rake.