Stabilizing Heat Treatment . For maximum resistance to intergranular corrosion, these grades are given a stabilizing heat treatment at about 900 °c [1650 °f]. The purpose of the treatment is to. Stabilization is recommended for most severe service conditions (above 425 °c) and particularly. The results presented in this work show that the stabilization treatment can be carried out at temperatures as high as 950 °c. Stabilization heat treatment is a process performed on chemically stabilized alloys (primarily stainless steel) to introduce certain. 304l or 316l) be used, particularly if extended. The stabilizing treatment is a heat treating method used for austenitic stainless steel containing nd or ti. Typically the first line of protection is to use an l grade (low carbon) stainless steel and/or filler metal (e.g., types 304l or 316l. In this insightful article, a seasoned mechanical engineer delves into the fascinating world of stainless steel heat treatment. Recommended that a stabilized stainless steel (e.g.

from www.semanticscholar.org

The stabilizing treatment is a heat treating method used for austenitic stainless steel containing nd or ti. The purpose of the treatment is to. 304l or 316l) be used, particularly if extended. Typically the first line of protection is to use an l grade (low carbon) stainless steel and/or filler metal (e.g., types 304l or 316l. Stabilization heat treatment is a process performed on chemically stabilized alloys (primarily stainless steel) to introduce certain. In this insightful article, a seasoned mechanical engineer delves into the fascinating world of stainless steel heat treatment. The results presented in this work show that the stabilization treatment can be carried out at temperatures as high as 950 °c. Recommended that a stabilized stainless steel (e.g. For maximum resistance to intergranular corrosion, these grades are given a stabilizing heat treatment at about 900 °c [1650 °f]. Stabilization is recommended for most severe service conditions (above 425 °c) and particularly.

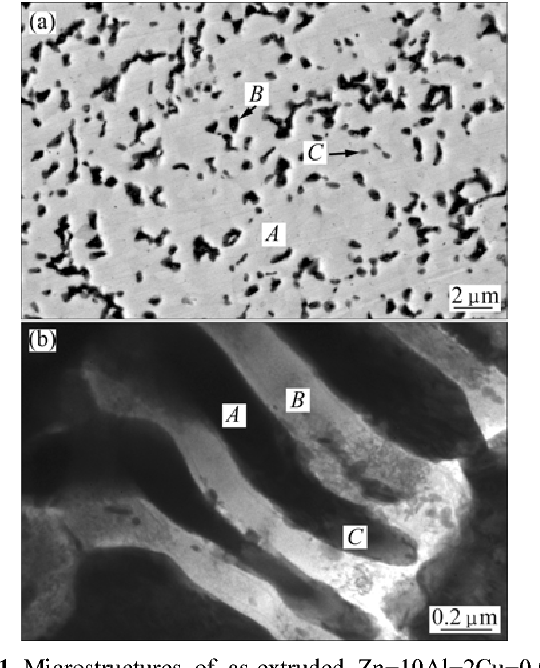

Figure 1 from Effects of stabilizing heat treatment on microstructures

Stabilizing Heat Treatment 304l or 316l) be used, particularly if extended. Stabilization heat treatment is a process performed on chemically stabilized alloys (primarily stainless steel) to introduce certain. Typically the first line of protection is to use an l grade (low carbon) stainless steel and/or filler metal (e.g., types 304l or 316l. In this insightful article, a seasoned mechanical engineer delves into the fascinating world of stainless steel heat treatment. The purpose of the treatment is to. Recommended that a stabilized stainless steel (e.g. Stabilization is recommended for most severe service conditions (above 425 °c) and particularly. For maximum resistance to intergranular corrosion, these grades are given a stabilizing heat treatment at about 900 °c [1650 °f]. The results presented in this work show that the stabilization treatment can be carried out at temperatures as high as 950 °c. The stabilizing treatment is a heat treating method used for austenitic stainless steel containing nd or ti. 304l or 316l) be used, particularly if extended.

From www.scientific.net

Effects of Stabilizing Heat Treatment on Properties of Simulated Stabilizing Heat Treatment For maximum resistance to intergranular corrosion, these grades are given a stabilizing heat treatment at about 900 °c [1650 °f]. Typically the first line of protection is to use an l grade (low carbon) stainless steel and/or filler metal (e.g., types 304l or 316l. Recommended that a stabilized stainless steel (e.g. The stabilizing treatment is a heat treating method used. Stabilizing Heat Treatment.

From lpf.cc

Heat Treatment, Stabilizing, Pickling and Passivation LPF Stabilizing Heat Treatment Stabilization is recommended for most severe service conditions (above 425 °c) and particularly. Recommended that a stabilized stainless steel (e.g. The purpose of the treatment is to. The stabilizing treatment is a heat treating method used for austenitic stainless steel containing nd or ti. Stabilization heat treatment is a process performed on chemically stabilized alloys (primarily stainless steel) to introduce. Stabilizing Heat Treatment.

From www.cnsuntech.com

PC Wire production line PC steel wire induction heat treatment Stabilizing Heat Treatment Stabilization heat treatment is a process performed on chemically stabilized alloys (primarily stainless steel) to introduce certain. In this insightful article, a seasoned mechanical engineer delves into the fascinating world of stainless steel heat treatment. The results presented in this work show that the stabilization treatment can be carried out at temperatures as high as 950 °c. Stabilization is recommended. Stabilizing Heat Treatment.

From lpf.cc

Heat Treatment, Stabilizing, Pickling and Passivation LPF Stabilizing Heat Treatment For maximum resistance to intergranular corrosion, these grades are given a stabilizing heat treatment at about 900 °c [1650 °f]. Stabilization heat treatment is a process performed on chemically stabilized alloys (primarily stainless steel) to introduce certain. The results presented in this work show that the stabilization treatment can be carried out at temperatures as high as 950 °c. The. Stabilizing Heat Treatment.

From jshuaye.en.made-in-china.com

High Quality Stabilizer Roll in Heat Treatment Furnace China Stabilizing Heat Treatment 304l or 316l) be used, particularly if extended. The results presented in this work show that the stabilization treatment can be carried out at temperatures as high as 950 °c. Stabilization heat treatment is a process performed on chemically stabilized alloys (primarily stainless steel) to introduce certain. Stabilization is recommended for most severe service conditions (above 425 °c) and particularly.. Stabilizing Heat Treatment.

From www.scientific.net

Effect of Stabilizing Heat Treatment on Intergranular Corrosion Stabilizing Heat Treatment The purpose of the treatment is to. 304l or 316l) be used, particularly if extended. The results presented in this work show that the stabilization treatment can be carried out at temperatures as high as 950 °c. For maximum resistance to intergranular corrosion, these grades are given a stabilizing heat treatment at about 900 °c [1650 °f]. Recommended that a. Stabilizing Heat Treatment.

From suntechmachinery.en.made-in-china.com

Plain and Indented Lrpc Wire Drawing and Heat Treatment Stabilizing Stabilizing Heat Treatment The stabilizing treatment is a heat treating method used for austenitic stainless steel containing nd or ti. Stabilization heat treatment is a process performed on chemically stabilized alloys (primarily stainless steel) to introduce certain. The results presented in this work show that the stabilization treatment can be carried out at temperatures as high as 950 °c. In this insightful article,. Stabilizing Heat Treatment.

From www.researchgate.net

Relationship between pulse energy and surface energy before and after Stabilizing Heat Treatment The stabilizing treatment is a heat treating method used for austenitic stainless steel containing nd or ti. In this insightful article, a seasoned mechanical engineer delves into the fascinating world of stainless steel heat treatment. 304l or 316l) be used, particularly if extended. Typically the first line of protection is to use an l grade (low carbon) stainless steel and/or. Stabilizing Heat Treatment.

From www.scribd.com

347H Stabilizing Heat Treatment PDF Sets Of Chemical Elements Stabilizing Heat Treatment The purpose of the treatment is to. Stabilization heat treatment is a process performed on chemically stabilized alloys (primarily stainless steel) to introduce certain. For maximum resistance to intergranular corrosion, these grades are given a stabilizing heat treatment at about 900 °c [1650 °f]. 304l or 316l) be used, particularly if extended. The results presented in this work show that. Stabilizing Heat Treatment.

From www.kneedle.com

Dime Sew'N Heat Stabilizer 12 by 10yd Roll 814027016612 Stabilizing Heat Treatment Stabilization heat treatment is a process performed on chemically stabilized alloys (primarily stainless steel) to introduce certain. Stabilization is recommended for most severe service conditions (above 425 °c) and particularly. The purpose of the treatment is to. Recommended that a stabilized stainless steel (e.g. The stabilizing treatment is a heat treating method used for austenitic stainless steel containing nd or. Stabilizing Heat Treatment.

From lpf.cc

Heat Treatment, Stabilizing, Pickling and Passivation LPF Stabilizing Heat Treatment 304l or 316l) be used, particularly if extended. Typically the first line of protection is to use an l grade (low carbon) stainless steel and/or filler metal (e.g., types 304l or 316l. The purpose of the treatment is to. Recommended that a stabilized stainless steel (e.g. For maximum resistance to intergranular corrosion, these grades are given a stabilizing heat treatment. Stabilizing Heat Treatment.

From www.researchgate.net

(a) Stabilizing effect of heat treatment on 50 and 100 Ω TaN resistors Stabilizing Heat Treatment For maximum resistance to intergranular corrosion, these grades are given a stabilizing heat treatment at about 900 °c [1650 °f]. Stabilization heat treatment is a process performed on chemically stabilized alloys (primarily stainless steel) to introduce certain. The purpose of the treatment is to. The stabilizing treatment is a heat treating method used for austenitic stainless steel containing nd or. Stabilizing Heat Treatment.

From www.semanticscholar.org

Figure 1 from Effects of stabilizing heat treatment on microstructures Stabilizing Heat Treatment Typically the first line of protection is to use an l grade (low carbon) stainless steel and/or filler metal (e.g., types 304l or 316l. For maximum resistance to intergranular corrosion, these grades are given a stabilizing heat treatment at about 900 °c [1650 °f]. In this insightful article, a seasoned mechanical engineer delves into the fascinating world of stainless steel. Stabilizing Heat Treatment.

From www.zhycasting.com

Heat treatment process of impeller investment casting sand casting Stabilizing Heat Treatment For maximum resistance to intergranular corrosion, these grades are given a stabilizing heat treatment at about 900 °c [1650 °f]. Stabilization is recommended for most severe service conditions (above 425 °c) and particularly. The purpose of the treatment is to. The stabilizing treatment is a heat treating method used for austenitic stainless steel containing nd or ti. Typically the first. Stabilizing Heat Treatment.

From lpf.cc

Heat Treatment, Stabilizing, Pickling and Passivation LPF Stabilizing Heat Treatment The results presented in this work show that the stabilization treatment can be carried out at temperatures as high as 950 °c. For maximum resistance to intergranular corrosion, these grades are given a stabilizing heat treatment at about 900 °c [1650 °f]. Typically the first line of protection is to use an l grade (low carbon) stainless steel and/or filler. Stabilizing Heat Treatment.

From www.atoallinks.com

PVC Heat Stabilizers What They Are and How they Work AtoAllinks Stabilizing Heat Treatment For maximum resistance to intergranular corrosion, these grades are given a stabilizing heat treatment at about 900 °c [1650 °f]. The results presented in this work show that the stabilization treatment can be carried out at temperatures as high as 950 °c. Recommended that a stabilized stainless steel (e.g. Stabilization is recommended for most severe service conditions (above 425 °c). Stabilizing Heat Treatment.

From jinzongmachinery.en.made-in-china.com

PVC Heat Stabilizer Plant China PVC Heat Stabilizer Production Stabilizing Heat Treatment 304l or 316l) be used, particularly if extended. Stabilization heat treatment is a process performed on chemically stabilized alloys (primarily stainless steel) to introduce certain. The results presented in this work show that the stabilization treatment can be carried out at temperatures as high as 950 °c. In this insightful article, a seasoned mechanical engineer delves into the fascinating world. Stabilizing Heat Treatment.

From littlestownfoundry.com

Heat Treating Littlestown Foundry, Inc. Stabilizing Heat Treatment The purpose of the treatment is to. Stabilization heat treatment is a process performed on chemically stabilized alloys (primarily stainless steel) to introduce certain. 304l or 316l) be used, particularly if extended. For maximum resistance to intergranular corrosion, these grades are given a stabilizing heat treatment at about 900 °c [1650 °f]. Recommended that a stabilized stainless steel (e.g. Stabilization. Stabilizing Heat Treatment.

From www.kloecknermetals.com

The 3 Stages of Heat Treatment Kloeckner Metals Corporation Stabilizing Heat Treatment Recommended that a stabilized stainless steel (e.g. Stabilization is recommended for most severe service conditions (above 425 °c) and particularly. In this insightful article, a seasoned mechanical engineer delves into the fascinating world of stainless steel heat treatment. 304l or 316l) be used, particularly if extended. The stabilizing treatment is a heat treating method used for austenitic stainless steel containing. Stabilizing Heat Treatment.

From www.heattreattoday.com

Gyro Stabilizer Finished with Heat Treating at Texas Heat Treat Stabilizing Heat Treatment 304l or 316l) be used, particularly if extended. The results presented in this work show that the stabilization treatment can be carried out at temperatures as high as 950 °c. Typically the first line of protection is to use an l grade (low carbon) stainless steel and/or filler metal (e.g., types 304l or 316l. For maximum resistance to intergranular corrosion,. Stabilizing Heat Treatment.

From www.tec-science.com

Diffusion annealing of steel tecscience Stabilizing Heat Treatment In this insightful article, a seasoned mechanical engineer delves into the fascinating world of stainless steel heat treatment. 304l or 316l) be used, particularly if extended. Stabilization is recommended for most severe service conditions (above 425 °c) and particularly. Typically the first line of protection is to use an l grade (low carbon) stainless steel and/or filler metal (e.g., types. Stabilizing Heat Treatment.

From www.semanticscholar.org

Figure 1 from Emulsion stabilizing capacity of intact starch granules Stabilizing Heat Treatment The purpose of the treatment is to. For maximum resistance to intergranular corrosion, these grades are given a stabilizing heat treatment at about 900 °c [1650 °f]. The results presented in this work show that the stabilization treatment can be carried out at temperatures as high as 950 °c. In this insightful article, a seasoned mechanical engineer delves into the. Stabilizing Heat Treatment.

From lpf.cc

Heat Treatment, Stabilizing, Pickling and Passivation LPF Stabilizing Heat Treatment Stabilization heat treatment is a process performed on chemically stabilized alloys (primarily stainless steel) to introduce certain. Typically the first line of protection is to use an l grade (low carbon) stainless steel and/or filler metal (e.g., types 304l or 316l. The stabilizing treatment is a heat treating method used for austenitic stainless steel containing nd or ti. The purpose. Stabilizing Heat Treatment.

From www.youtube.com

Stabilizing Wood Part 3 Heat Curing The Resin YouTube Stabilizing Heat Treatment The stabilizing treatment is a heat treating method used for austenitic stainless steel containing nd or ti. The purpose of the treatment is to. The results presented in this work show that the stabilization treatment can be carried out at temperatures as high as 950 °c. For maximum resistance to intergranular corrosion, these grades are given a stabilizing heat treatment. Stabilizing Heat Treatment.

From www.researchgate.net

Effect of stabilizing heat treatment on condensation heat transfer Stabilizing Heat Treatment The purpose of the treatment is to. Stabilization heat treatment is a process performed on chemically stabilized alloys (primarily stainless steel) to introduce certain. For maximum resistance to intergranular corrosion, these grades are given a stabilizing heat treatment at about 900 °c [1650 °f]. The results presented in this work show that the stabilization treatment can be carried out at. Stabilizing Heat Treatment.

From www.slideserve.com

PPT Structural Materials PowerPoint Presentation, free download ID Stabilizing Heat Treatment The stabilizing treatment is a heat treating method used for austenitic stainless steel containing nd or ti. For maximum resistance to intergranular corrosion, these grades are given a stabilizing heat treatment at about 900 °c [1650 °f]. Stabilization is recommended for most severe service conditions (above 425 °c) and particularly. In this insightful article, a seasoned mechanical engineer delves into. Stabilizing Heat Treatment.

From www.researchgate.net

The PWHT's thermal cycles solution annealing heat treatment followed Stabilizing Heat Treatment Stabilization is recommended for most severe service conditions (above 425 °c) and particularly. In this insightful article, a seasoned mechanical engineer delves into the fascinating world of stainless steel heat treatment. 304l or 316l) be used, particularly if extended. The results presented in this work show that the stabilization treatment can be carried out at temperatures as high as 950. Stabilizing Heat Treatment.

From unitedthermalservices.com

Resistance PostWeld Heat Treating United Thermal Services Stabilizing Heat Treatment Stabilization is recommended for most severe service conditions (above 425 °c) and particularly. In this insightful article, a seasoned mechanical engineer delves into the fascinating world of stainless steel heat treatment. 304l or 316l) be used, particularly if extended. Typically the first line of protection is to use an l grade (low carbon) stainless steel and/or filler metal (e.g., types. Stabilizing Heat Treatment.

From lpf.cc

Heat Treatment, Stabilizing, Pickling and Passivation LPF Stabilizing Heat Treatment In this insightful article, a seasoned mechanical engineer delves into the fascinating world of stainless steel heat treatment. The results presented in this work show that the stabilization treatment can be carried out at temperatures as high as 950 °c. 304l or 316l) be used, particularly if extended. The stabilizing treatment is a heat treating method used for austenitic stainless. Stabilizing Heat Treatment.

From www.scribd.com

ASTMA351 Heat Treating Steel Stabilizing Heat Treatment The stabilizing treatment is a heat treating method used for austenitic stainless steel containing nd or ti. The results presented in this work show that the stabilization treatment can be carried out at temperatures as high as 950 °c. 304l or 316l) be used, particularly if extended. Stabilization heat treatment is a process performed on chemically stabilized alloys (primarily stainless. Stabilizing Heat Treatment.

From www.scientific.net

Effect of Twice Stablizing Heat Treatment on the Properties of 347H Stabilizing Heat Treatment 304l or 316l) be used, particularly if extended. In this insightful article, a seasoned mechanical engineer delves into the fascinating world of stainless steel heat treatment. The results presented in this work show that the stabilization treatment can be carried out at temperatures as high as 950 °c. Stabilization heat treatment is a process performed on chemically stabilized alloys (primarily. Stabilizing Heat Treatment.

From www.researchgate.net

Relationship between pulse energy and surface energy before and after Stabilizing Heat Treatment In this insightful article, a seasoned mechanical engineer delves into the fascinating world of stainless steel heat treatment. Recommended that a stabilized stainless steel (e.g. Stabilization heat treatment is a process performed on chemically stabilized alloys (primarily stainless steel) to introduce certain. 304l or 316l) be used, particularly if extended. Typically the first line of protection is to use an. Stabilizing Heat Treatment.

From www.scribd.com

ASTM A312.pdf Heat Treating Pipe (Fluid Conveyance) Stabilizing Heat Treatment In this insightful article, a seasoned mechanical engineer delves into the fascinating world of stainless steel heat treatment. Stabilization heat treatment is a process performed on chemically stabilized alloys (primarily stainless steel) to introduce certain. Recommended that a stabilized stainless steel (e.g. Stabilization is recommended for most severe service conditions (above 425 °c) and particularly. The stabilizing treatment is a. Stabilizing Heat Treatment.

From lpf.cc

Heat Treatment, Stabilizing, Pickling and Passivation LPF Stabilizing Heat Treatment Stabilization is recommended for most severe service conditions (above 425 °c) and particularly. Recommended that a stabilized stainless steel (e.g. In this insightful article, a seasoned mechanical engineer delves into the fascinating world of stainless steel heat treatment. The stabilizing treatment is a heat treating method used for austenitic stainless steel containing nd or ti. The purpose of the treatment. Stabilizing Heat Treatment.

From lpf.cc

Heat Treatment, Stabilizing, Pickling and Passivation LPF Stabilizing Heat Treatment The results presented in this work show that the stabilization treatment can be carried out at temperatures as high as 950 °c. In this insightful article, a seasoned mechanical engineer delves into the fascinating world of stainless steel heat treatment. The purpose of the treatment is to. The stabilizing treatment is a heat treating method used for austenitic stainless steel. Stabilizing Heat Treatment.