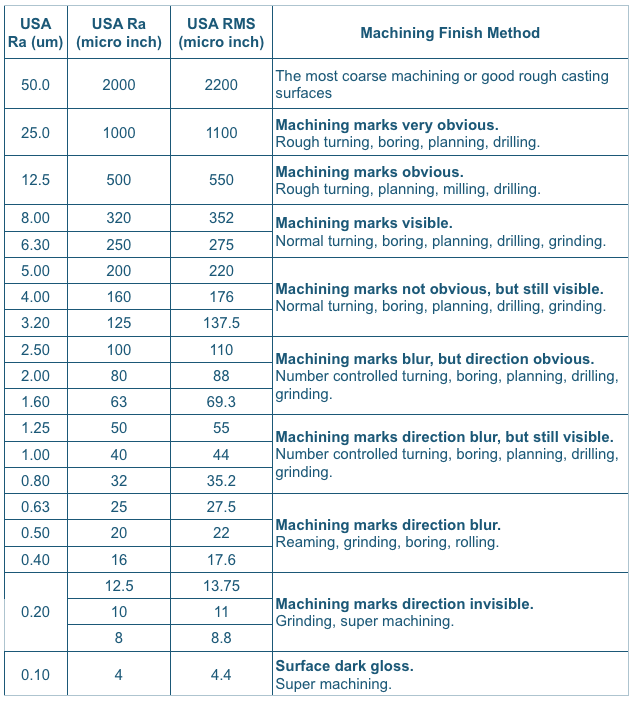

Surface Finish 32 Rms . The typical surface roughness is 32 micro inches or a surface finish of 32. Ra and rms are both representations of surface roughness, but each is calculated differently. Surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Ra is calculated as the roughness average of a. A standard #4 finish has an ra of about 0.8 µm (32 µin), while a #4 dairy or sanitary finish has a roughness average between 0.3 µm (12 µin) and 0.4 µm (16 µin). Additionally, manufacturers can use the surface finish conversion chart to compare. Metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. In addition to physical properties like strength, ductility or toughness. The following charts and tables convert surface finish or roughness between selected industry standard units.

from www.nextgentooling.com

In addition to physical properties like strength, ductility or toughness. Metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. The typical surface roughness is 32 micro inches or a surface finish of 32. A standard #4 finish has an ra of about 0.8 µm (32 µin), while a #4 dairy or sanitary finish has a roughness average between 0.3 µm (12 µin) and 0.4 µm (16 µin). Ra and rms are both representations of surface roughness, but each is calculated differently. Ra is calculated as the roughness average of a. Additionally, manufacturers can use the surface finish conversion chart to compare. The following charts and tables convert surface finish or roughness between selected industry standard units. Surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve.

Understanding Surface Finish RMS vs Ra NEXT GENERATION TOOLING

Surface Finish 32 Rms A standard #4 finish has an ra of about 0.8 µm (32 µin), while a #4 dairy or sanitary finish has a roughness average between 0.3 µm (12 µin) and 0.4 µm (16 µin). Ra and rms are both representations of surface roughness, but each is calculated differently. Surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. The typical surface roughness is 32 micro inches or a surface finish of 32. In addition to physical properties like strength, ductility or toughness. Metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. Ra is calculated as the roughness average of a. The following charts and tables convert surface finish or roughness between selected industry standard units. A standard #4 finish has an ra of about 0.8 µm (32 µin), while a #4 dairy or sanitary finish has a roughness average between 0.3 µm (12 µin) and 0.4 µm (16 µin). Additionally, manufacturers can use the surface finish conversion chart to compare.

From www.iron-foundry.com

Machining surface finish chart, conversion, comparator, method, degree Surface Finish 32 Rms Metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. A standard #4 finish has an ra of about 0.8 µm (32 µin), while a #4 dairy or sanitary finish has a roughness average between 0.3 µm (12 µin) and 0.4 µm (16 µin). Ra and rms are both representations of surface roughness,. Surface Finish 32 Rms.

From mavink.com

Iso Surface Finish Chart Surface Finish 32 Rms The following charts and tables convert surface finish or roughness between selected industry standard units. Additionally, manufacturers can use the surface finish conversion chart to compare. Metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. Ra is calculated as the roughness average of a. A standard #4 finish has an ra of. Surface Finish 32 Rms.

From mavink.com

Surface Roughness Symbols And Meanings Surface Finish 32 Rms Surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. The following charts and tables convert surface finish or roughness between selected industry standard units. In addition to physical properties like strength, ductility or toughness. The typical surface roughness is 32 micro inches. Surface Finish 32 Rms.

From mavink.com

Rms Surface Roughness Chart Surface Finish 32 Rms The typical surface roughness is 32 micro inches or a surface finish of 32. Ra and rms are both representations of surface roughness, but each is calculated differently. The following charts and tables convert surface finish or roughness between selected industry standard units. Surface finish chart by machining technology in the chart below, you can find the lowest surface roughness. Surface Finish 32 Rms.

From mavink.com

Rms Surface Roughness Chart Surface Finish 32 Rms Ra is calculated as the roughness average of a. Ra and rms are both representations of surface roughness, but each is calculated differently. The typical surface roughness is 32 micro inches or a surface finish of 32. The following charts and tables convert surface finish or roughness between selected industry standard units. In addition to physical properties like strength, ductility. Surface Finish 32 Rms.

From mungfali.com

Ra Roughness Chart Surface Finish 32 Rms A standard #4 finish has an ra of about 0.8 µm (32 µin), while a #4 dairy or sanitary finish has a roughness average between 0.3 µm (12 µin) and 0.4 µm (16 µin). The typical surface roughness is 32 micro inches or a surface finish of 32. The following charts and tables convert surface finish or roughness between selected. Surface Finish 32 Rms.

From www.reddit.com

Getting a 32 rms finish on this OD 6.00" ID 4.00" LONG 90.00" Tube Surface Finish 32 Rms Additionally, manufacturers can use the surface finish conversion chart to compare. Ra is calculated as the roughness average of a. In addition to physical properties like strength, ductility or toughness. Ra and rms are both representations of surface roughness, but each is calculated differently. The following charts and tables convert surface finish or roughness between selected industry standard units. Surface. Surface Finish 32 Rms.

From learningzonebgaertner.z13.web.core.windows.net

Machined Surface Finish Rms Surface Finish 32 Rms In addition to physical properties like strength, ductility or toughness. The typical surface roughness is 32 micro inches or a surface finish of 32. Surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Ra is calculated as the roughness average of a.. Surface Finish 32 Rms.

From mungfali.com

RMS Surface Finish Chart Surface Finish 32 Rms In addition to physical properties like strength, ductility or toughness. Additionally, manufacturers can use the surface finish conversion chart to compare. Metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. Surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the. Surface Finish 32 Rms.

From xometry.eu

Selecting right surface roughness for CNC machining Xometry Europe Surface Finish 32 Rms Metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. Additionally, manufacturers can use the surface finish conversion chart to compare. In addition to physical properties like strength, ductility or toughness. Ra and rms are both representations of surface roughness, but each is calculated differently. Surface finish chart by machining technology in the. Surface Finish 32 Rms.

From isabellesharpe.z21.web.core.windows.net

16 Rms Surface Finish Chart Surface Finish 32 Rms In addition to physical properties like strength, ductility or toughness. Ra and rms are both representations of surface roughness, but each is calculated differently. Additionally, manufacturers can use the surface finish conversion chart to compare. The typical surface roughness is 32 micro inches or a surface finish of 32. A standard #4 finish has an ra of about 0.8 µm. Surface Finish 32 Rms.

From freyabartlett.z13.web.core.windows.net

Rms Surface Finish Meaning Surface Finish 32 Rms Metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. Ra is calculated as the roughness average of a. A standard #4 finish has an ra of about 0.8 µm (32 µin), while a #4 dairy or sanitary finish has a roughness average between 0.3 µm (12 µin) and 0.4 µm (16 µin).. Surface Finish 32 Rms.

From torku.clinica180grados.es

Gallery of 32 rms finish chart complete surface finish chart rms Surface Finish 32 Rms The typical surface roughness is 32 micro inches or a surface finish of 32. Ra is calculated as the roughness average of a. A standard #4 finish has an ra of about 0.8 µm (32 µin), while a #4 dairy or sanitary finish has a roughness average between 0.3 µm (12 µin) and 0.4 µm (16 µin). Surface finish chart. Surface Finish 32 Rms.

From www.researchgate.net

A specimen for textural roughness. The peaktovalley height Rz ranges Surface Finish 32 Rms The typical surface roughness is 32 micro inches or a surface finish of 32. A standard #4 finish has an ra of about 0.8 µm (32 µin), while a #4 dairy or sanitary finish has a roughness average between 0.3 µm (12 µin) and 0.4 µm (16 µin). Ra and rms are both representations of surface roughness, but each is. Surface Finish 32 Rms.

From michmet.com

Average Roughness basics Michigan Metrology Surface Finish 32 Rms The typical surface roughness is 32 micro inches or a surface finish of 32. Ra and rms are both representations of surface roughness, but each is calculated differently. Additionally, manufacturers can use the surface finish conversion chart to compare. Metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. The following charts and. Surface Finish 32 Rms.

From oliverrandall.z13.web.core.windows.net

Rms Surface Roughness Chart Surface Finish 32 Rms In addition to physical properties like strength, ductility or toughness. Surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. Ra and rms are both representations. Surface Finish 32 Rms.

From gahess.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Finish 32 Rms Surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. In addition to physical properties like strength, ductility or toughness. A standard #4 finish has an ra of about 0.8 µm (32 µin), while a #4 dairy or sanitary finish has a roughness. Surface Finish 32 Rms.

From moseys.com

Machining Surface Finish Chart & Specifications Moseys Production Surface Finish 32 Rms In addition to physical properties like strength, ductility or toughness. Metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. The typical surface roughness is 32 micro inches or a surface finish of 32. Additionally, manufacturers can use the surface finish conversion chart to compare. Ra and rms are both representations of surface. Surface Finish 32 Rms.

From mavink.com

Engineering Surface Finish Symbols Surface Finish 32 Rms In addition to physical properties like strength, ductility or toughness. Surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Ra is calculated as the roughness average of a. The typical surface roughness is 32 micro inches or a surface finish of 32.. Surface Finish 32 Rms.

From engineersedge.com

Surface Roughness Conversion Chart Tables Surface Finish 32 Rms The typical surface roughness is 32 micro inches or a surface finish of 32. A standard #4 finish has an ra of about 0.8 µm (32 µin), while a #4 dairy or sanitary finish has a roughness average between 0.3 µm (12 µin) and 0.4 µm (16 µin). Additionally, manufacturers can use the surface finish conversion chart to compare. Surface. Surface Finish 32 Rms.

From www.nextgentooling.com

Understanding Surface Finish RMS vs Ra NEXT GENERATION TOOLING Surface Finish 32 Rms A standard #4 finish has an ra of about 0.8 µm (32 µin), while a #4 dairy or sanitary finish has a roughness average between 0.3 µm (12 µin) and 0.4 µm (16 µin). Ra and rms are both representations of surface roughness, but each is calculated differently. Metal surface finish charts are a reference tool used for assuring quality. Surface Finish 32 Rms.

From mavink.com

Rms Surface Finish Chart Surface Finish 32 Rms Ra is calculated as the roughness average of a. The typical surface roughness is 32 micro inches or a surface finish of 32. In addition to physical properties like strength, ductility or toughness. Metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. The following charts and tables convert surface finish or roughness. Surface Finish 32 Rms.

From at-machining.com

Surface Finish Chart A Guide to Understanding Surface Finishing Chart Surface Finish 32 Rms Surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. In addition to physical properties like strength, ductility or toughness. Ra is calculated as the roughness. Surface Finish 32 Rms.

From www.pinterest.com

AscastRMSScale.jpg (1632×1224) Surface Finish 32 Rms In addition to physical properties like strength, ductility or toughness. The typical surface roughness is 32 micro inches or a surface finish of 32. Ra and rms are both representations of surface roughness, but each is calculated differently. Surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the. Surface Finish 32 Rms.

From cafecentralmugron.fr

Surface Finish Chart A Guide To Understanding Surface Surface Finish 32 Rms Metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. Additionally, manufacturers can use the surface finish conversion chart to compare. The typical surface roughness is 32 micro inches or a surface finish of 32. A standard #4 finish has an ra of about 0.8 µm (32 µin), while a #4 dairy or. Surface Finish 32 Rms.

From www.youtube.com

Visual Inpection of Surface Roughness YouTube Surface Finish 32 Rms Additionally, manufacturers can use the surface finish conversion chart to compare. The following charts and tables convert surface finish or roughness between selected industry standard units. Ra is calculated as the roughness average of a. In addition to physical properties like strength, ductility or toughness. A standard #4 finish has an ra of about 0.8 µm (32 µin), while a. Surface Finish 32 Rms.

From mungfali.com

Surface Finish Roughness Chart Surface Finish 32 Rms The following charts and tables convert surface finish or roughness between selected industry standard units. Ra and rms are both representations of surface roughness, but each is calculated differently. Surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Metal surface finish charts. Surface Finish 32 Rms.

From torku.clinica180grados.es

Gallery of 32 rms finish chart complete surface finish chart rms Surface Finish 32 Rms In addition to physical properties like strength, ductility or toughness. The typical surface roughness is 32 micro inches or a surface finish of 32. Ra is calculated as the roughness average of a. Ra and rms are both representations of surface roughness, but each is calculated differently. Additionally, manufacturers can use the surface finish conversion chart to compare. Surface finish. Surface Finish 32 Rms.

From www.engineeringchoice.com

What is Surface Finish? Units, Symbols & Chart Surface Finish 32 Rms The following charts and tables convert surface finish or roughness between selected industry standard units. In addition to physical properties like strength, ductility or toughness. Ra is calculated as the roughness average of a. The typical surface roughness is 32 micro inches or a surface finish of 32. Surface finish chart by machining technology in the chart below, you can. Surface Finish 32 Rms.

From mavink.com

Rms Surface Finish Chart Surface Finish 32 Rms Additionally, manufacturers can use the surface finish conversion chart to compare. The typical surface roughness is 32 micro inches or a surface finish of 32. In addition to physical properties like strength, ductility or toughness. Metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. The following charts and tables convert surface finish. Surface Finish 32 Rms.

From mavink.com

Rms Surface Finish Chart Surface Finish 32 Rms In addition to physical properties like strength, ductility or toughness. Additionally, manufacturers can use the surface finish conversion chart to compare. Ra and rms are both representations of surface roughness, but each is calculated differently. Metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. Surface finish chart by machining technology in the. Surface Finish 32 Rms.

From cafecentralmugron.fr

Surface Finish Chart A Guide To Understanding Surface Surface Finish 32 Rms The typical surface roughness is 32 micro inches or a surface finish of 32. Surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Ra is calculated as the roughness average of a. Metal surface finish charts are a reference tool used for. Surface Finish 32 Rms.

From mungfali.com

Surface Finish Roughness Chart Surface Finish 32 Rms Metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. The typical surface roughness is 32 micro inches or a surface finish of 32. Ra is calculated as the roughness average of a. The following charts and tables convert surface finish or roughness between selected industry standard units. A standard #4 finish has. Surface Finish 32 Rms.

From edmontonrealestateinvestmentblog.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Finish 32 Rms In addition to physical properties like strength, ductility or toughness. Surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. A standard #4 finish has an ra of about 0.8 µm (32 µin), while a #4 dairy or sanitary finish has a roughness. Surface Finish 32 Rms.

From mavink.com

Rms Surface Roughness Chart Surface Finish 32 Rms Surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. A standard #4 finish has an ra of about 0.8 µm (32 µin), while a #4 dairy or sanitary finish has a roughness average between 0.3 µm (12 µin) and 0.4 µm (16. Surface Finish 32 Rms.