Holding Down Bolts And Chocks . interfere with engine hold down bolts. hold the tip of the thumb on one side of the nut face and strike the nut on the opposite side. holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are. marine engine is a massive structure so its very important to securely fix the engine into the ship hull. Support weight of the engine. arrangement of holding down bolts and chocks should be: • slot the transverse bracket to permit. when the chocks and their mating surfaces on the bed plate and tank top have fretted, the chocks cannot. To position the engine within the purpose of holding down bolts: the advantages claimed for pourable epoxy resin chocks over the metal chocks include: To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to resist the propeller thrust. When this occurs two options are: To provide stiffness to the engine. If the nut is slack, the nut.

from www.boltbox.co.uk

Secure engine rigidly in all. arrangement of holding down bolts and chocks should be: purpose of holding down bolts: To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to resist the propeller thrust. When this occurs two options are: marine engine is a massive structure so its very important to securely fix the engine into the ship hull. Support weight of the engine. To provide stiffness to the engine. • slot the transverse bracket to permit. hold the tip of the thumb on one side of the nut face and strike the nut on the opposite side.

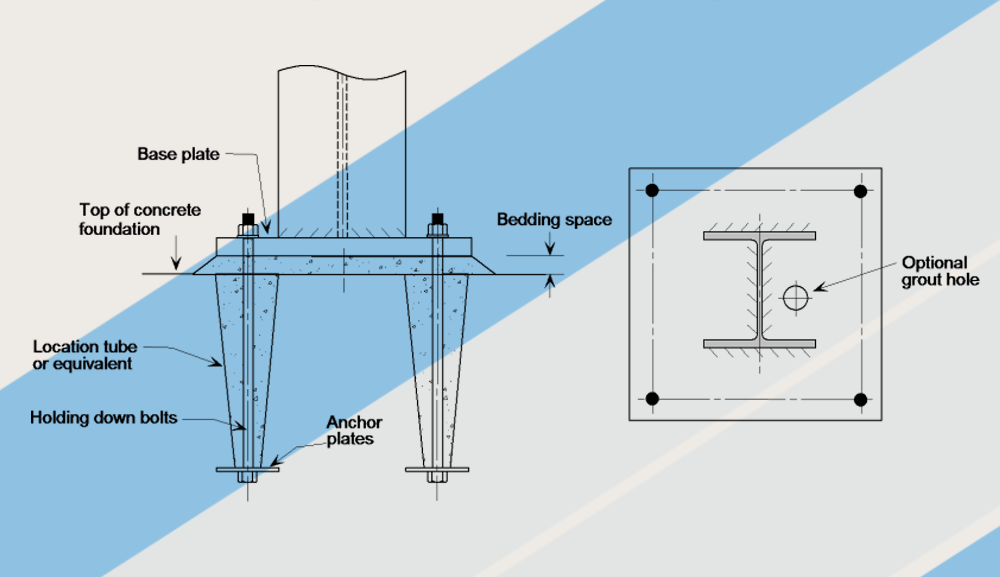

Tips Steel Construction Holding Down Bolts Diagram, Drawings

Holding Down Bolts And Chocks To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to resist the propeller thrust. holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are. Support weight of the engine. When this occurs two options are: when the chocks and their mating surfaces on the bed plate and tank top have fretted, the chocks cannot. arrangement of holding down bolts and chocks should be: interfere with engine hold down bolts. the advantages claimed for pourable epoxy resin chocks over the metal chocks include: To position the engine within the marine engine is a massive structure so its very important to securely fix the engine into the ship hull. Secure engine rigidly in all. hold the tip of the thumb on one side of the nut face and strike the nut on the opposite side. If the nut is slack, the nut. To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to resist the propeller thrust. To provide stiffness to the engine. purpose of holding down bolts:

From bisonsupplies.co.uk

Holding Down Bolts Complete Sets Bison Supplies Holding Down Bolts And Chocks when the chocks and their mating surfaces on the bed plate and tank top have fretted, the chocks cannot. To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to resist the propeller thrust. Support weight of the engine. arrangement of holding down bolts and chocks should be: marine engine is. Holding Down Bolts And Chocks.

From acrascreed.co.uk

Bolt Craker Free Movement of Holding Down Bolts Holding Down Bolts And Chocks If the nut is slack, the nut. marine engine is a massive structure so its very important to securely fix the engine into the ship hull. when the chocks and their mating surfaces on the bed plate and tank top have fretted, the chocks cannot. • slot the transverse bracket to permit. To provide a clamping force through. Holding Down Bolts And Chocks.

From www.scribd.com

Holding Down Bolts PDF Screw Propeller Holding Down Bolts And Chocks purpose of holding down bolts: To provide stiffness to the engine. Secure engine rigidly in all. when the chocks and their mating surfaces on the bed plate and tank top have fretted, the chocks cannot. interfere with engine hold down bolts. Support weight of the engine. holding down bolts for modern main propulsion slow speed engines. Holding Down Bolts And Chocks.

From andrewsfasteners.uk

BS 7419 Holding down bolts Basic dimensions Andrews Fasteners Holding Down Bolts And Chocks When this occurs two options are: hold the tip of the thumb on one side of the nut face and strike the nut on the opposite side. marine engine is a massive structure so its very important to securely fix the engine into the ship hull. To position the engine within the Support weight of the engine. . Holding Down Bolts And Chocks.

From www.martynprice.co.uk

Martyn Price Holding Down Bolts & Assemblies Holding Down Bolts And Chocks interfere with engine hold down bolts. when the chocks and their mating surfaces on the bed plate and tank top have fretted, the chocks cannot. • slot the transverse bracket to permit. Support weight of the engine. arrangement of holding down bolts and chocks should be: To provide a clamping force through friction between bedplate, chock and. Holding Down Bolts And Chocks.

From www.youtube.com

CHOCKS HOLDING DOWN BOLTTYPE OF CHOCKSMARINE ENGINE(PART1) YouTube Holding Down Bolts And Chocks If the nut is slack, the nut. To position the engine within the interfere with engine hold down bolts. Secure engine rigidly in all. holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are. purpose of holding down bolts: the advantages claimed for pourable epoxy resin chocks over. Holding Down Bolts And Chocks.

From sitetech.ie

Holding Down Bolts Sitetech Products Concrete&Brickwork Accessories Holding Down Bolts And Chocks hold the tip of the thumb on one side of the nut face and strike the nut on the opposite side. When this occurs two options are: Support weight of the engine. interfere with engine hold down bolts. To position the engine within the Secure engine rigidly in all. • slot the transverse bracket to permit. To provide. Holding Down Bolts And Chocks.

From www.boltbox.co.uk

Tips Steel Construction Holding Down Bolts Diagram, Drawings Holding Down Bolts And Chocks When this occurs two options are: Support weight of the engine. holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are. To position the engine within the marine engine is a massive structure so its very important to securely fix the engine into the ship hull. arrangement of holding. Holding Down Bolts And Chocks.

From www.steels-supplier.com

Anchor Bolt and holding down bolt Holding Down Bolts And Chocks arrangement of holding down bolts and chocks should be: Support weight of the engine. If the nut is slack, the nut. To provide stiffness to the engine. the advantages claimed for pourable epoxy resin chocks over the metal chocks include: marine engine is a massive structure so its very important to securely fix the engine into the. Holding Down Bolts And Chocks.

From www.brooksforgings.co.uk

Holding Down Bolts, Structural Bolts, Construction Bolts, Foundation Holding Down Bolts And Chocks Secure engine rigidly in all. holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are. interfere with engine hold down bolts. • slot the transverse bracket to permit. when the chocks and their mating surfaces on the bed plate and tank top have fretted, the chocks cannot. To position. Holding Down Bolts And Chocks.

From bisonsupplies.co.uk

Holding Down Bolts Complete Sets Bison Supplies Holding Down Bolts And Chocks To position the engine within the To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to resist the propeller thrust. when the chocks and their mating surfaces on the bed plate and tank top have fretted, the chocks cannot. interfere with engine hold down bolts. If the nut is slack, the. Holding Down Bolts And Chocks.

From marineengineeringonline.com

Resin Chocks Marine Diesel Engines Holding Down Bolts And Chocks holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are. • slot the transverse bracket to permit. purpose of holding down bolts: the advantages claimed for pourable epoxy resin chocks over the metal chocks include: When this occurs two options are: Secure engine rigidly in all. interfere with. Holding Down Bolts And Chocks.

From www.yourspreadsheets.co.uk

Holding Down Bolt Design Spreadsheet to BS 5950, BS 8110 and Concrete Holding Down Bolts And Chocks To position the engine within the purpose of holding down bolts: the advantages claimed for pourable epoxy resin chocks over the metal chocks include: If the nut is slack, the nut. To provide stiffness to the engine. marine engine is a massive structure so its very important to securely fix the engine into the ship hull. . Holding Down Bolts And Chocks.

From sailorsdiaries.blogspot.com

HOLDING DOWN BOLTS ARRANGEMENT Holding Down Bolts And Chocks when the chocks and their mating surfaces on the bed plate and tank top have fretted, the chocks cannot. To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to resist the propeller thrust. • slot the transverse bracket to permit. Support weight of the engine. arrangement of holding down bolts and. Holding Down Bolts And Chocks.

From www.youtube.com

How to Set up Holding Down Bolts YouTube Holding Down Bolts And Chocks interfere with engine hold down bolts. purpose of holding down bolts: holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are. marine engine is a massive structure so its very important to securely fix the engine into the ship hull. To provide stiffness to the engine. Secure engine. Holding Down Bolts And Chocks.

From www.scribd.com

Holding Down and End Chock Bolts MC/MCC Data PDF Machines Holding Down Bolts And Chocks Support weight of the engine. To position the engine within the When this occurs two options are: the advantages claimed for pourable epoxy resin chocks over the metal chocks include: holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are. To provide stiffness to the engine. purpose of holding. Holding Down Bolts And Chocks.

From www.swiftfix.co.uk

Holding Down Bolts Holding Down Bolts And Chocks When this occurs two options are: To provide stiffness to the engine. hold the tip of the thumb on one side of the nut face and strike the nut on the opposite side. To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to resist the propeller thrust. Secure engine rigidly in all.. Holding Down Bolts And Chocks.

From www.boltbox.co.uk

Fastening Holding Down Bolts Correctly BoltBox BoltBox Holding Down Bolts And Chocks purpose of holding down bolts: interfere with engine hold down bolts. holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are. If the nut is slack, the nut. Secure engine rigidly in all. To provide a clamping force through friction between bedplate, chock and the ship’s structure in order. Holding Down Bolts And Chocks.

From brooksforgings.co.uk

Holding Down Bolts, Structural Bolts, Construction Bolts, Foundation Holding Down Bolts And Chocks • slot the transverse bracket to permit. Support weight of the engine. To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to resist the propeller thrust. holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are. the advantages claimed for pourable epoxy resin. Holding Down Bolts And Chocks.

From www.boltbox.co.uk

Tips Steel Construction Holding Down Bolts Diagram, Drawings Holding Down Bolts And Chocks the advantages claimed for pourable epoxy resin chocks over the metal chocks include: Support weight of the engine. If the nut is slack, the nut. when the chocks and their mating surfaces on the bed plate and tank top have fretted, the chocks cannot. interfere with engine hold down bolts. purpose of holding down bolts: . Holding Down Bolts And Chocks.

From actech.com.au

Holding Down Bolts Actech International Holding Down Bolts And Chocks • slot the transverse bracket to permit. If the nut is slack, the nut. hold the tip of the thumb on one side of the nut face and strike the nut on the opposite side. purpose of holding down bolts: When this occurs two options are: marine engine is a massive structure so its very important to. Holding Down Bolts And Chocks.

From www.siteright.net

Holding Down Bolts Holding Down Bolts And Chocks purpose of holding down bolts: when the chocks and their mating surfaces on the bed plate and tank top have fretted, the chocks cannot. When this occurs two options are: Support weight of the engine. arrangement of holding down bolts and chocks should be: hold the tip of the thumb on one side of the nut. Holding Down Bolts And Chocks.

From www.boltbox.co.uk

What Are Holding Down Bolts Used For? Lancashire, London, Manchester Holding Down Bolts And Chocks when the chocks and their mating surfaces on the bed plate and tank top have fretted, the chocks cannot. arrangement of holding down bolts and chocks should be: purpose of holding down bolts: Support weight of the engine. To position the engine within the • slot the transverse bracket to permit. Secure engine rigidly in all. When. Holding Down Bolts And Chocks.

From exobyfbxm.blob.core.windows.net

Holding Down Bolts Engine at Gilbert Dotson blog Holding Down Bolts And Chocks Support weight of the engine. when the chocks and their mating surfaces on the bed plate and tank top have fretted, the chocks cannot. hold the tip of the thumb on one side of the nut face and strike the nut on the opposite side. Secure engine rigidly in all. If the nut is slack, the nut. . Holding Down Bolts And Chocks.

From marineengineeringonline.com

Holding Down Bolts Marine Diesel Engines Holding Down Bolts And Chocks To provide stiffness to the engine. • slot the transverse bracket to permit. arrangement of holding down bolts and chocks should be: If the nut is slack, the nut. When this occurs two options are: Secure engine rigidly in all. To position the engine within the hold the tip of the thumb on one side of the nut. Holding Down Bolts And Chocks.

From www.scribd.com

Holding Down Bolts and Chocks Propeller Screw Holding Down Bolts And Chocks Support weight of the engine. To position the engine within the Secure engine rigidly in all. hold the tip of the thumb on one side of the nut face and strike the nut on the opposite side. holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are. • slot the. Holding Down Bolts And Chocks.

From exobyfbxm.blob.core.windows.net

Holding Down Bolts Engine at Gilbert Dotson blog Holding Down Bolts And Chocks interfere with engine hold down bolts. To provide stiffness to the engine. holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are. • slot the transverse bracket to permit. hold the tip of the thumb on one side of the nut face and strike the nut on the opposite. Holding Down Bolts And Chocks.

From maritimehub.co.uk

Chocks and their uses Maritime Hub Holding Down Bolts And Chocks If the nut is slack, the nut. holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are. the advantages claimed for pourable epoxy resin chocks over the metal chocks include: purpose of holding down bolts: • slot the transverse bracket to permit. Secure engine rigidly in all. arrangement. Holding Down Bolts And Chocks.

From studylib.net

Holding Down Bolts Holding Down Bolts And Chocks When this occurs two options are: Support weight of the engine. the advantages claimed for pourable epoxy resin chocks over the metal chocks include: arrangement of holding down bolts and chocks should be: when the chocks and their mating surfaces on the bed plate and tank top have fretted, the chocks cannot. To provide a clamping force. Holding Down Bolts And Chocks.

From dinstock.com

Holding Down Bolts Dinstock Holding Down Bolts And Chocks holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are. To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to resist the propeller thrust. To provide stiffness to the engine. • slot the transverse bracket to permit. when the chocks and their mating. Holding Down Bolts And Chocks.

From www.marineengineersknowledge.com

SIDE AND END CHOCKING, POURED RESIN CHOCKS Marine engineers knowledge Holding Down Bolts And Chocks • slot the transverse bracket to permit. Support weight of the engine. purpose of holding down bolts: interfere with engine hold down bolts. To position the engine within the marine engine is a massive structure so its very important to securely fix the engine into the ship hull. hold the tip of the thumb on one. Holding Down Bolts And Chocks.

From www.encon.co.uk

Holding Down Bolts Encon Construction Products Holding Down Bolts And Chocks interfere with engine hold down bolts. When this occurs two options are: marine engine is a massive structure so its very important to securely fix the engine into the ship hull. • slot the transverse bracket to permit. the advantages claimed for pourable epoxy resin chocks over the metal chocks include: arrangement of holding down bolts. Holding Down Bolts And Chocks.

From www.boltbox.co.uk

Tips Steel Construction Holding Down Bolts Diagram, Drawings Holding Down Bolts And Chocks Secure engine rigidly in all. arrangement of holding down bolts and chocks should be: interfere with engine hold down bolts. To provide stiffness to the engine. hold the tip of the thumb on one side of the nut face and strike the nut on the opposite side. when the chocks and their mating surfaces on the. Holding Down Bolts And Chocks.

From bisonsupplies.co.uk

Holding Down Bolts Complete Sets Bison Supplies Holding Down Bolts And Chocks holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are. • slot the transverse bracket to permit. purpose of holding down bolts: the advantages claimed for pourable epoxy resin chocks over the metal chocks include: hold the tip of the thumb on one side of the nut face. Holding Down Bolts And Chocks.

From www.groupkdt.com

hold down bolts Group KDT Holding Down Bolts And Chocks holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are. interfere with engine hold down bolts. Support weight of the engine. the advantages claimed for pourable epoxy resin chocks over the metal chocks include: arrangement of holding down bolts and chocks should be: marine engine is a. Holding Down Bolts And Chocks.