Brazing Carbide Inserts . Carbide brazing is a specialized joining process that utilizes a filler metal (brazing alloy) to create a strong, permanent bond. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for. When it comes to cutting tool selection, machinists have three basic choices: Brazing tungsten carbide is a very easy and reliable process if a few simple steps are taken but the steps are not necessarily obvious or. Let’s look at key factors that play a role in successful carbide brazing: Learn about the key factors that impact the brazing process and how to achieve strong and durable joints. Coefficient of thermal expansion, joint design, carbide composition, filler metal selection, flux/atmosphere, fixturing and heating. Discover the essential tips and techniques for brazing cemented carbide. This international standard specifies the dimensions of carbide tips for turning tools intended to be fixed on the shanks of tools by. Induction heating is the recommended preheating method for any pcd brazing process as it ensures safety, manufacturing efficiency and.

from www.radyne.com

Coefficient of thermal expansion, joint design, carbide composition, filler metal selection, flux/atmosphere, fixturing and heating. Discover the essential tips and techniques for brazing cemented carbide. This international standard specifies the dimensions of carbide tips for turning tools intended to be fixed on the shanks of tools by. Carbide brazing is a specialized joining process that utilizes a filler metal (brazing alloy) to create a strong, permanent bond. Induction heating is the recommended preheating method for any pcd brazing process as it ensures safety, manufacturing efficiency and. Let’s look at key factors that play a role in successful carbide brazing: Learn about the key factors that impact the brazing process and how to achieve strong and durable joints. Brazing tungsten carbide is a very easy and reliable process if a few simple steps are taken but the steps are not necessarily obvious or. When it comes to cutting tool selection, machinists have three basic choices: This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for.

Induction Carbide Brazing Blog Radyne Corporation

Brazing Carbide Inserts Discover the essential tips and techniques for brazing cemented carbide. Learn about the key factors that impact the brazing process and how to achieve strong and durable joints. When it comes to cutting tool selection, machinists have three basic choices: Carbide brazing is a specialized joining process that utilizes a filler metal (brazing alloy) to create a strong, permanent bond. Coefficient of thermal expansion, joint design, carbide composition, filler metal selection, flux/atmosphere, fixturing and heating. Let’s look at key factors that play a role in successful carbide brazing: Brazing tungsten carbide is a very easy and reliable process if a few simple steps are taken but the steps are not necessarily obvious or. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for. Induction heating is the recommended preheating method for any pcd brazing process as it ensures safety, manufacturing efficiency and. Discover the essential tips and techniques for brazing cemented carbide. This international standard specifies the dimensions of carbide tips for turning tools intended to be fixed on the shanks of tools by.

From www.tungstencarbide-alloy.com

Bush Hammer Roller Brazing Carbide Inserts / Round Carbide Inserts Tips Brazing Carbide Inserts Learn about the key factors that impact the brazing process and how to achieve strong and durable joints. Let’s look at key factors that play a role in successful carbide brazing: Brazing tungsten carbide is a very easy and reliable process if a few simple steps are taken but the steps are not necessarily obvious or. When it comes to. Brazing Carbide Inserts.

From www.youtube.com

Brazing a Carbide to Steel YouTube Brazing Carbide Inserts This international standard specifies the dimensions of carbide tips for turning tools intended to be fixed on the shanks of tools by. Induction heating is the recommended preheating method for any pcd brazing process as it ensures safety, manufacturing efficiency and. Let’s look at key factors that play a role in successful carbide brazing: Coefficient of thermal expansion, joint design,. Brazing Carbide Inserts.

From www.tongyicarbide.com

tungsten carbide inserts, tungsten carbide CNC inserts,carbide blade Brazing Carbide Inserts When it comes to cutting tool selection, machinists have three basic choices: Brazing tungsten carbide is a very easy and reliable process if a few simple steps are taken but the steps are not necessarily obvious or. Learn about the key factors that impact the brazing process and how to achieve strong and durable joints. This article will explain why. Brazing Carbide Inserts.

From www.cdcarbide.com

Tungsten Carbide Brazing Inserts Brazing Carbide Inserts Brazing tungsten carbide is a very easy and reliable process if a few simple steps are taken but the steps are not necessarily obvious or. Discover the essential tips and techniques for brazing cemented carbide. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for. Let’s look at key factors that. Brazing Carbide Inserts.

From www.youtube.com

Induction Brazing three carbide inserts into a tool housing YouTube Brazing Carbide Inserts Induction heating is the recommended preheating method for any pcd brazing process as it ensures safety, manufacturing efficiency and. This international standard specifies the dimensions of carbide tips for turning tools intended to be fixed on the shanks of tools by. Brazing tungsten carbide is a very easy and reliable process if a few simple steps are taken but the. Brazing Carbide Inserts.

From www.cdcarbide.com

Tungsten Carbide Brazing Inserts Brazing Carbide Inserts Let’s look at key factors that play a role in successful carbide brazing: Brazing tungsten carbide is a very easy and reliable process if a few simple steps are taken but the steps are not necessarily obvious or. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for. Carbide brazing is. Brazing Carbide Inserts.

From www.jwecarbide.com

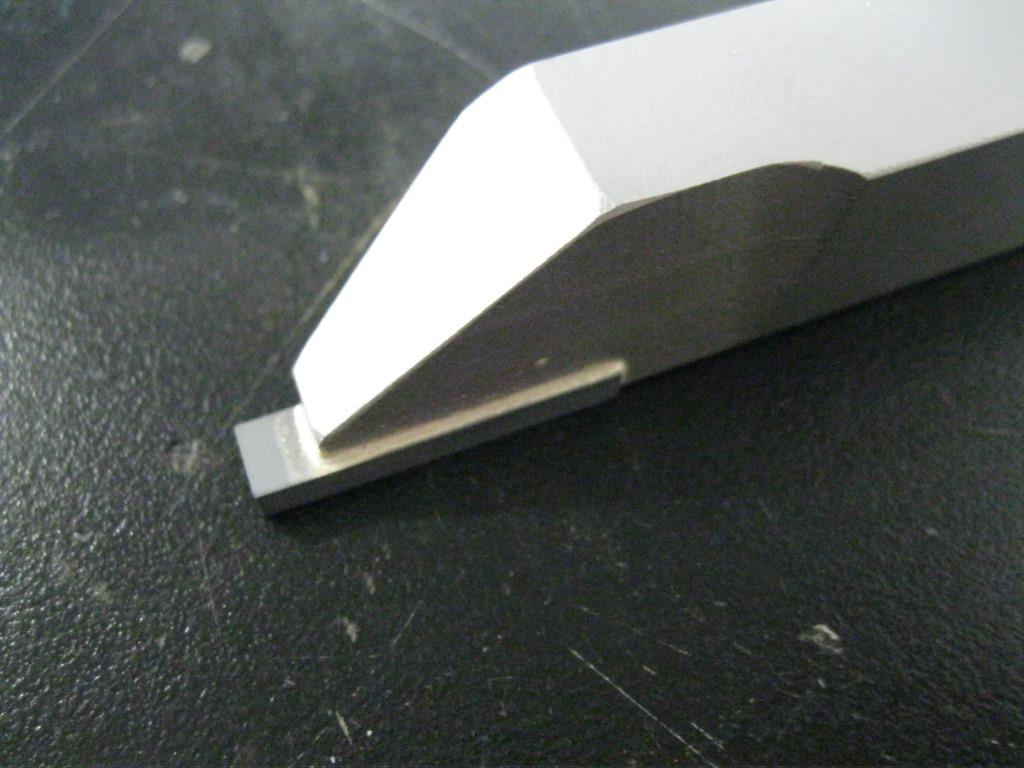

Brazing L15mm Tungsten Carbide Insert For Periphery Turning Tools Brazing Carbide Inserts This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for. Carbide brazing is a specialized joining process that utilizes a filler metal (brazing alloy) to create a strong, permanent bond. Let’s look at key factors that play a role in successful carbide brazing: Coefficient of thermal expansion, joint design, carbide composition,. Brazing Carbide Inserts.

From jdcarbide.en.made-in-china.com

Cemented Carbide Brazing Short Inserts China Silver Brazing Rods and Brazing Carbide Inserts Brazing tungsten carbide is a very easy and reliable process if a few simple steps are taken but the steps are not necessarily obvious or. Coefficient of thermal expansion, joint design, carbide composition, filler metal selection, flux/atmosphere, fixturing and heating. When it comes to cutting tool selection, machinists have three basic choices: This international standard specifies the dimensions of carbide. Brazing Carbide Inserts.

From www.upcarbide.com

YG8 C122 tungsten carbide brazing insert Brazing Carbide Inserts Learn about the key factors that impact the brazing process and how to achieve strong and durable joints. Carbide brazing is a specialized joining process that utilizes a filler metal (brazing alloy) to create a strong, permanent bond. When it comes to cutting tool selection, machinists have three basic choices: This international standard specifies the dimensions of carbide tips for. Brazing Carbide Inserts.

From www.carbidecomponents.com

Tungsten Carbide Brazed Inserts Brazing Carbide Inserts Coefficient of thermal expansion, joint design, carbide composition, filler metal selection, flux/atmosphere, fixturing and heating. This international standard specifies the dimensions of carbide tips for turning tools intended to be fixed on the shanks of tools by. Let’s look at key factors that play a role in successful carbide brazing: Induction heating is the recommended preheating method for any pcd. Brazing Carbide Inserts.

From www.tungstencarbide-alloy.com

SNMG120408R,Brazing Carbide Teeth Inserts , Square Lathe Carbide Brazing Carbide Inserts Carbide brazing is a specialized joining process that utilizes a filler metal (brazing alloy) to create a strong, permanent bond. Induction heating is the recommended preheating method for any pcd brazing process as it ensures safety, manufacturing efficiency and. When it comes to cutting tool selection, machinists have three basic choices: Brazing tungsten carbide is a very easy and reliable. Brazing Carbide Inserts.

From www.carbidecomponents.com

B40 coarse grain size cemented carbide brazing tips, tile, inserts Brazing Carbide Inserts Discover the essential tips and techniques for brazing cemented carbide. Let’s look at key factors that play a role in successful carbide brazing: When it comes to cutting tool selection, machinists have three basic choices: Learn about the key factors that impact the brazing process and how to achieve strong and durable joints. Brazing tungsten carbide is a very easy. Brazing Carbide Inserts.

From www.cdcarbide.com

tungsten carbide brazing cutting tips inserts for mining Brazing Carbide Inserts This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for. Induction heating is the recommended preheating method for any pcd brazing process as it ensures safety, manufacturing efficiency and. This international standard specifies the dimensions of carbide tips for turning tools intended to be fixed on the shanks of tools by.. Brazing Carbide Inserts.

From www.cdcarbide.com

tungsten carbide brazing cutting tips inserts for mining Brazing Carbide Inserts This international standard specifies the dimensions of carbide tips for turning tools intended to be fixed on the shanks of tools by. Carbide brazing is a specialized joining process that utilizes a filler metal (brazing alloy) to create a strong, permanent bond. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice. Brazing Carbide Inserts.

From www.carbidestrips.com

Cutting Tools Custom Tungsten Carbide , Brazing Carbide Inserts Easy Brazing Carbide Inserts Let’s look at key factors that play a role in successful carbide brazing: This international standard specifies the dimensions of carbide tips for turning tools intended to be fixed on the shanks of tools by. Induction heating is the recommended preheating method for any pcd brazing process as it ensures safety, manufacturing efficiency and. This article will explain why the. Brazing Carbide Inserts.

From www.tungstencarbide-tools.com

F Cemented Carbide Brazing Carbide Inserts WC Cobalt High Strength Brazing Carbide Inserts Brazing tungsten carbide is a very easy and reliable process if a few simple steps are taken but the steps are not necessarily obvious or. Induction heating is the recommended preheating method for any pcd brazing process as it ensures safety, manufacturing efficiency and. Coefficient of thermal expansion, joint design, carbide composition, filler metal selection, flux/atmosphere, fixturing and heating. This. Brazing Carbide Inserts.

From www.youtube.com

Brazing Carbide Tip on Boring Bar YouTube Brazing Carbide Inserts Carbide brazing is a specialized joining process that utilizes a filler metal (brazing alloy) to create a strong, permanent bond. Let’s look at key factors that play a role in successful carbide brazing: Induction heating is the recommended preheating method for any pcd brazing process as it ensures safety, manufacturing efficiency and. When it comes to cutting tool selection, machinists. Brazing Carbide Inserts.

From www.ambrell.com

Improving Steel Cutting Bit Quality with DiamondCarbide Inserts Brazing Carbide Inserts This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for. When it comes to cutting tool selection, machinists have three basic choices: Carbide brazing is a specialized joining process that utilizes a filler metal (brazing alloy) to create a strong, permanent bond. Induction heating is the recommended preheating method for any. Brazing Carbide Inserts.

From www.youtube.com

Induction Brazing Carbide to Steel on a Form Tool YouTube Brazing Carbide Inserts This international standard specifies the dimensions of carbide tips for turning tools intended to be fixed on the shanks of tools by. Carbide brazing is a specialized joining process that utilizes a filler metal (brazing alloy) to create a strong, permanent bond. Coefficient of thermal expansion, joint design, carbide composition, filler metal selection, flux/atmosphere, fixturing and heating. Learn about the. Brazing Carbide Inserts.

From www.cdcarbide.com

Tungsten Carbide Brazing Inserts Brazing Carbide Inserts This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for. Learn about the key factors that impact the brazing process and how to achieve strong and durable joints. Let’s look at key factors that play a role in successful carbide brazing: Brazing tungsten carbide is a very easy and reliable process. Brazing Carbide Inserts.

From www.alibaba.com

Pcd Body Tungsten Carbide Brazing Brazed Inserts Braze En 19 Material Brazing Carbide Inserts Coefficient of thermal expansion, joint design, carbide composition, filler metal selection, flux/atmosphere, fixturing and heating. This international standard specifies the dimensions of carbide tips for turning tools intended to be fixed on the shanks of tools by. Let’s look at key factors that play a role in successful carbide brazing: Discover the essential tips and techniques for brazing cemented carbide.. Brazing Carbide Inserts.

From www.cdcarbide.com

Tungsten Carbide Brazing Inserts Brazing Carbide Inserts This international standard specifies the dimensions of carbide tips for turning tools intended to be fixed on the shanks of tools by. Learn about the key factors that impact the brazing process and how to achieve strong and durable joints. Discover the essential tips and techniques for brazing cemented carbide. Let’s look at key factors that play a role in. Brazing Carbide Inserts.

From www.indiamart.com

Yg Brazing Insert Yg6 Carbide Tips, For Industrial at Rs 60/piece in Brazing Carbide Inserts Carbide brazing is a specialized joining process that utilizes a filler metal (brazing alloy) to create a strong, permanent bond. Let’s look at key factors that play a role in successful carbide brazing: Discover the essential tips and techniques for brazing cemented carbide. Learn about the key factors that impact the brazing process and how to achieve strong and durable. Brazing Carbide Inserts.

From www.tongyicarbide.com

Brazing inserts carbide inserts,carbide inserts, brazing inserts Brazing Carbide Inserts Induction heating is the recommended preheating method for any pcd brazing process as it ensures safety, manufacturing efficiency and. Carbide brazing is a specialized joining process that utilizes a filler metal (brazing alloy) to create a strong, permanent bond. Discover the essential tips and techniques for brazing cemented carbide. Let’s look at key factors that play a role in successful. Brazing Carbide Inserts.

From www.jwecarbide.com

Brazing L15mm Tungsten Carbide Insert For Periphery Turning Tools Brazing Carbide Inserts Induction heating is the recommended preheating method for any pcd brazing process as it ensures safety, manufacturing efficiency and. This international standard specifies the dimensions of carbide tips for turning tools intended to be fixed on the shanks of tools by. When it comes to cutting tool selection, machinists have three basic choices: Discover the essential tips and techniques for. Brazing Carbide Inserts.

From www.cdcarbide.com

tungsten carbide brazing cutting tips inserts for mining Brazing Carbide Inserts This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for. Let’s look at key factors that play a role in successful carbide brazing: Learn about the key factors that impact the brazing process and how to achieve strong and durable joints. Brazing tungsten carbide is a very easy and reliable process. Brazing Carbide Inserts.

From www.ambrell.com

Induction Braze Carbide Inserts to Prevent Defects in Tool Tips Brazing Carbide Inserts Induction heating is the recommended preheating method for any pcd brazing process as it ensures safety, manufacturing efficiency and. Discover the essential tips and techniques for brazing cemented carbide. When it comes to cutting tool selection, machinists have three basic choices: Coefficient of thermal expansion, joint design, carbide composition, filler metal selection, flux/atmosphere, fixturing and heating. Let’s look at key. Brazing Carbide Inserts.

From www.pcdblank.com

PCD Carbide Inserts Tools Vacuum Brazing Service 800 Degree High Brazing Carbide Inserts This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for. When it comes to cutting tool selection, machinists have three basic choices: Let’s look at key factors that play a role in successful carbide brazing: Brazing tungsten carbide is a very easy and reliable process if a few simple steps are. Brazing Carbide Inserts.

From rivictory.en.made-in-china.com

Tungsten Carbide Tipped Tool Welding Insert Carbide Brazing Tips Brazing Carbide Inserts Brazing tungsten carbide is a very easy and reliable process if a few simple steps are taken but the steps are not necessarily obvious or. Discover the essential tips and techniques for brazing cemented carbide. Learn about the key factors that impact the brazing process and how to achieve strong and durable joints. Induction heating is the recommended preheating method. Brazing Carbide Inserts.

From www.artofit.org

Induction brazing carbide Artofit Brazing Carbide Inserts Brazing tungsten carbide is a very easy and reliable process if a few simple steps are taken but the steps are not necessarily obvious or. This international standard specifies the dimensions of carbide tips for turning tools intended to be fixed on the shanks of tools by. This article will explain why the middle choice— indexable turning, milling, and drilling. Brazing Carbide Inserts.

From www.youtube.com

Induction Brazing Carbide Tool Inserts & Induction welding equipment Brazing Carbide Inserts Discover the essential tips and techniques for brazing cemented carbide. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for. Carbide brazing is a specialized joining process that utilizes a filler metal (brazing alloy) to create a strong, permanent bond. Induction heating is the recommended preheating method for any pcd brazing. Brazing Carbide Inserts.

From www.cdcarbide.com

Tungsten Carbide Brazing Inserts Brazing Carbide Inserts Induction heating is the recommended preheating method for any pcd brazing process as it ensures safety, manufacturing efficiency and. Carbide brazing is a specialized joining process that utilizes a filler metal (brazing alloy) to create a strong, permanent bond. Discover the essential tips and techniques for brazing cemented carbide. When it comes to cutting tool selection, machinists have three basic. Brazing Carbide Inserts.

From www.radyne.com

Induction Carbide Brazing Blog Radyne Corporation Brazing Carbide Inserts Coefficient of thermal expansion, joint design, carbide composition, filler metal selection, flux/atmosphere, fixturing and heating. This international standard specifies the dimensions of carbide tips for turning tools intended to be fixed on the shanks of tools by. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for. Let’s look at key. Brazing Carbide Inserts.

From www.cdcarbide.com

Tungsten Carbide Brazing Inserts Brazing Carbide Inserts Let’s look at key factors that play a role in successful carbide brazing: When it comes to cutting tool selection, machinists have three basic choices: Carbide brazing is a specialized joining process that utilizes a filler metal (brazing alloy) to create a strong, permanent bond. Induction heating is the recommended preheating method for any pcd brazing process as it ensures. Brazing Carbide Inserts.

From zzbetter.en.made-in-china.com

C Type Cemented Carbide Brazing Inserts, Carbide Soldering Tips China Brazing Carbide Inserts This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for. Let’s look at key factors that play a role in successful carbide brazing: When it comes to cutting tool selection, machinists have three basic choices: Brazing tungsten carbide is a very easy and reliable process if a few simple steps are. Brazing Carbide Inserts.