How Hot Is A Kiln For Wood . Usually, you need anywhere between five to eight kiln schedules to complete the process. Usually, wood mills use bricks and concrete structures. Conventional dry kilns commonly use initial drying temperatures, when the lumber is more than 50 percent mc, from 100 to 130. It has different types and components such as a sealed chamber, insulation, heat source, and ventilation. Kiln drying your own wood at home can be a great way to sustainably harvest the materials around you, and dry it fast enough to build furniture with. Kiln drying, especially in a steam kiln,. However, you may need more cycles depending on the species, moisture content, and size of the timber. If furniture is made with wood that is too. The temperature you should run your wood kiln depends on what type of wood you are curing and what the desired outcome is. A typical kiln consists of the following.

from anthologywoods.com

A typical kiln consists of the following. Usually, wood mills use bricks and concrete structures. Kiln drying, especially in a steam kiln,. It has different types and components such as a sealed chamber, insulation, heat source, and ventilation. The temperature you should run your wood kiln depends on what type of wood you are curing and what the desired outcome is. Conventional dry kilns commonly use initial drying temperatures, when the lumber is more than 50 percent mc, from 100 to 130. Usually, you need anywhere between five to eight kiln schedules to complete the process. If furniture is made with wood that is too. Kiln drying your own wood at home can be a great way to sustainably harvest the materials around you, and dry it fast enough to build furniture with. However, you may need more cycles depending on the species, moisture content, and size of the timber.

Kiln Drying Reclaimed Wood A Key Step to Quality — ANTHOLOGY WOODS

How Hot Is A Kiln For Wood Usually, you need anywhere between five to eight kiln schedules to complete the process. Kiln drying, especially in a steam kiln,. It has different types and components such as a sealed chamber, insulation, heat source, and ventilation. Kiln drying your own wood at home can be a great way to sustainably harvest the materials around you, and dry it fast enough to build furniture with. The temperature you should run your wood kiln depends on what type of wood you are curing and what the desired outcome is. Usually, wood mills use bricks and concrete structures. However, you may need more cycles depending on the species, moisture content, and size of the timber. A typical kiln consists of the following. If furniture is made with wood that is too. Conventional dry kilns commonly use initial drying temperatures, when the lumber is more than 50 percent mc, from 100 to 130. Usually, you need anywhere between five to eight kiln schedules to complete the process.

From www.youtube.com

What is a Wood Kiln and How Does it Work? YouTube How Hot Is A Kiln For Wood Kiln drying, especially in a steam kiln,. A typical kiln consists of the following. Usually, wood mills use bricks and concrete structures. The temperature you should run your wood kiln depends on what type of wood you are curing and what the desired outcome is. It has different types and components such as a sealed chamber, insulation, heat source, and. How Hot Is A Kiln For Wood.

From wikiblog70.blogspot.com

Diy Lumber Kiln / How To Kiln Dry Wood Wood Drying Kiln Guide Kiln How Hot Is A Kiln For Wood Kiln drying, especially in a steam kiln,. Usually, you need anywhere between five to eight kiln schedules to complete the process. A typical kiln consists of the following. If furniture is made with wood that is too. The temperature you should run your wood kiln depends on what type of wood you are curing and what the desired outcome is.. How Hot Is A Kiln For Wood.

From www.woodfireceramic.com

How to build a wood fired ceramic kiln wood Fire Ceramic How Hot Is A Kiln For Wood It has different types and components such as a sealed chamber, insulation, heat source, and ventilation. Conventional dry kilns commonly use initial drying temperatures, when the lumber is more than 50 percent mc, from 100 to 130. Usually, you need anywhere between five to eight kiln schedules to complete the process. The temperature you should run your wood kiln depends. How Hot Is A Kiln For Wood.

From www.youtube.com

Ultimate DIY Electric Kiln Guide The Heating Elements (part 2) YouTube How Hot Is A Kiln For Wood It has different types and components such as a sealed chamber, insulation, heat source, and ventilation. A typical kiln consists of the following. However, you may need more cycles depending on the species, moisture content, and size of the timber. The temperature you should run your wood kiln depends on what type of wood you are curing and what the. How Hot Is A Kiln For Wood.

From www.tuscarorawoodmidwest.com

Why Kiln Dry Wood? Tuscarora Wood Midwest How Hot Is A Kiln For Wood Conventional dry kilns commonly use initial drying temperatures, when the lumber is more than 50 percent mc, from 100 to 130. Kiln drying your own wood at home can be a great way to sustainably harvest the materials around you, and dry it fast enough to build furniture with. Usually, wood mills use bricks and concrete structures. A typical kiln. How Hot Is A Kiln For Wood.

From www.youtube.com

Wood Technology Kiln Seasoning Timber YouTube How Hot Is A Kiln For Wood Usually, you need anywhere between five to eight kiln schedules to complete the process. The temperature you should run your wood kiln depends on what type of wood you are curing and what the desired outcome is. It has different types and components such as a sealed chamber, insulation, heat source, and ventilation. Usually, wood mills use bricks and concrete. How Hot Is A Kiln For Wood.

From www.youtube.com

Time To Load My New Wood Fired Kiln YouTube How Hot Is A Kiln For Wood Conventional dry kilns commonly use initial drying temperatures, when the lumber is more than 50 percent mc, from 100 to 130. If furniture is made with wood that is too. Usually, you need anywhere between five to eight kiln schedules to complete the process. However, you may need more cycles depending on the species, moisture content, and size of the. How Hot Is A Kiln For Wood.

From buildersvilla.com

How to build a wood fired kiln Builders Villa How Hot Is A Kiln For Wood It has different types and components such as a sealed chamber, insulation, heat source, and ventilation. If furniture is made with wood that is too. Usually, wood mills use bricks and concrete structures. However, you may need more cycles depending on the species, moisture content, and size of the timber. The temperature you should run your wood kiln depends on. How Hot Is A Kiln For Wood.

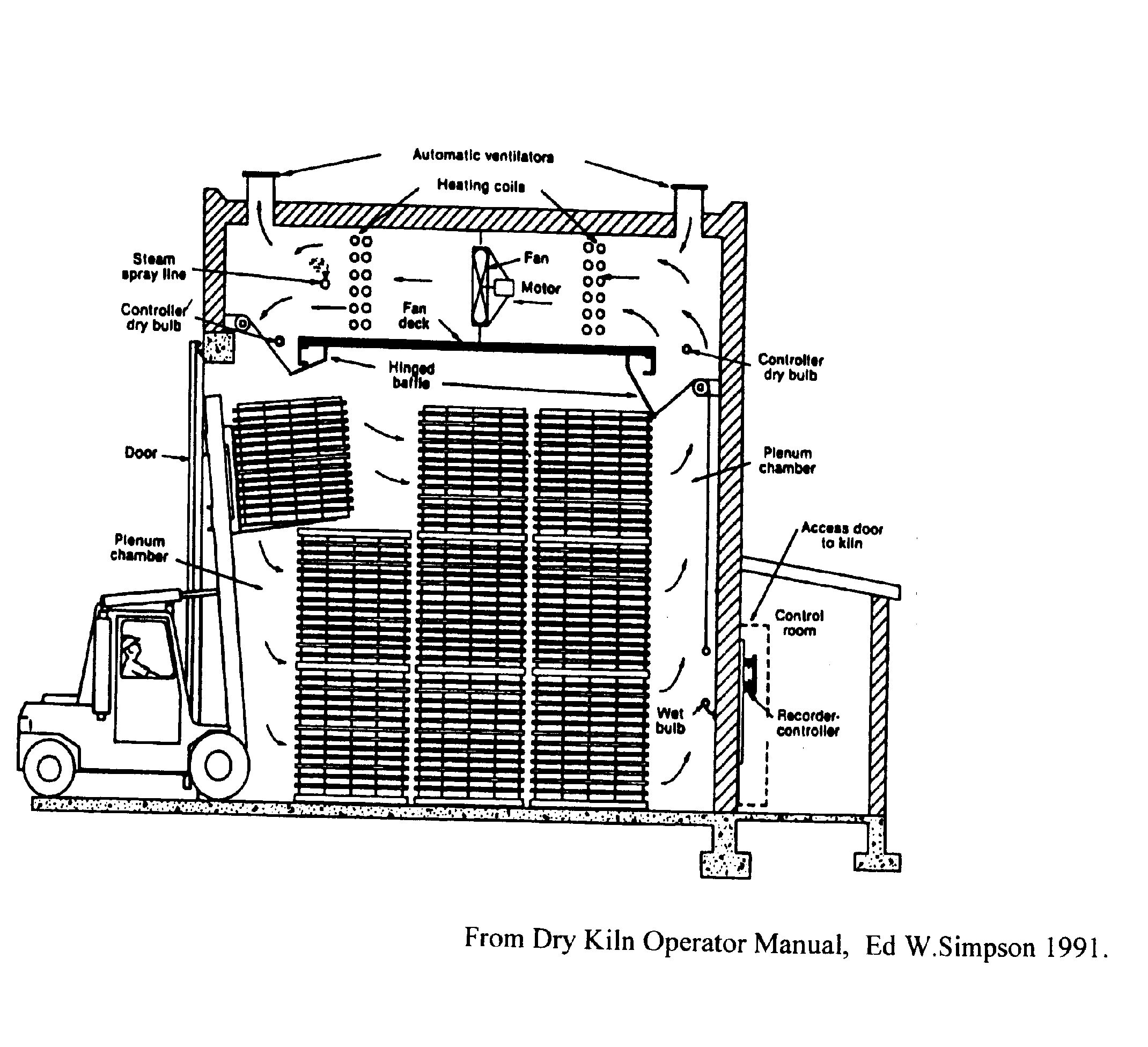

From www.researchgate.net

Basic components of kiln lumber drying Download Scientific Diagram How Hot Is A Kiln For Wood A typical kiln consists of the following. The temperature you should run your wood kiln depends on what type of wood you are curing and what the desired outcome is. If furniture is made with wood that is too. However, you may need more cycles depending on the species, moisture content, and size of the timber. Kiln drying your own. How Hot Is A Kiln For Wood.

From www.slideserve.com

PPT Seasoning of Timber PowerPoint Presentation ID3027749 How Hot Is A Kiln For Wood Conventional dry kilns commonly use initial drying temperatures, when the lumber is more than 50 percent mc, from 100 to 130. The temperature you should run your wood kiln depends on what type of wood you are curing and what the desired outcome is. Usually, you need anywhere between five to eight kiln schedules to complete the process. It has. How Hot Is A Kiln For Wood.

From www.youtube.com

Why & How To Build a Wood Kiln YouTube How Hot Is A Kiln For Wood The temperature you should run your wood kiln depends on what type of wood you are curing and what the desired outcome is. Usually, wood mills use bricks and concrete structures. Conventional dry kilns commonly use initial drying temperatures, when the lumber is more than 50 percent mc, from 100 to 130. Kiln drying, especially in a steam kiln,. Kiln. How Hot Is A Kiln For Wood.

From circuitengineeclair.z21.web.core.windows.net

Wood Kiln Plans And Diagrams How Hot Is A Kiln For Wood However, you may need more cycles depending on the species, moisture content, and size of the timber. If furniture is made with wood that is too. A typical kiln consists of the following. The temperature you should run your wood kiln depends on what type of wood you are curing and what the desired outcome is. Usually, wood mills use. How Hot Is A Kiln For Wood.

From www.youtube.com

DIY Wood Kiln, Building a Simple Wood Kiln for Drying Timber, Michigan How Hot Is A Kiln For Wood Usually, you need anywhere between five to eight kiln schedules to complete the process. Usually, wood mills use bricks and concrete structures. Kiln drying your own wood at home can be a great way to sustainably harvest the materials around you, and dry it fast enough to build furniture with. Kiln drying, especially in a steam kiln,. It has different. How Hot Is A Kiln For Wood.

From www.youtube.com

Logosol Sauno Wood Drying Kiln How to build and set up YouTube How Hot Is A Kiln For Wood A typical kiln consists of the following. It has different types and components such as a sealed chamber, insulation, heat source, and ventilation. The temperature you should run your wood kiln depends on what type of wood you are curing and what the desired outcome is. Usually, wood mills use bricks and concrete structures. However, you may need more cycles. How Hot Is A Kiln For Wood.

From opopots.blogspot.com

Peter's Pottery How the wood fired kiln works! How Hot Is A Kiln For Wood If furniture is made with wood that is too. Usually, you need anywhere between five to eight kiln schedules to complete the process. However, you may need more cycles depending on the species, moisture content, and size of the timber. The temperature you should run your wood kiln depends on what type of wood you are curing and what the. How Hot Is A Kiln For Wood.

From www.cozilogs.co.uk

How Does the Kiln Drying of Wood Process Work? How Hot Is A Kiln For Wood Usually, you need anywhere between five to eight kiln schedules to complete the process. However, you may need more cycles depending on the species, moisture content, and size of the timber. The temperature you should run your wood kiln depends on what type of wood you are curing and what the desired outcome is. If furniture is made with wood. How Hot Is A Kiln For Wood.

From www.youtube.com

Kiln Drying Wood Made Easy With This! YouTube How Hot Is A Kiln For Wood However, you may need more cycles depending on the species, moisture content, and size of the timber. If furniture is made with wood that is too. Conventional dry kilns commonly use initial drying temperatures, when the lumber is more than 50 percent mc, from 100 to 130. Usually, you need anywhere between five to eight kiln schedules to complete the. How Hot Is A Kiln For Wood.

From www.youtube.com

Simple DIY Wood Drying Kiln YouTube How Hot Is A Kiln For Wood Usually, you need anywhere between five to eight kiln schedules to complete the process. Usually, wood mills use bricks and concrete structures. Conventional dry kilns commonly use initial drying temperatures, when the lumber is more than 50 percent mc, from 100 to 130. A typical kiln consists of the following. The temperature you should run your wood kiln depends on. How Hot Is A Kiln For Wood.

From www.bhlumberandland.com

Top Ways To Kiln Dry Wood How Hot Is A Kiln For Wood Kiln drying, especially in a steam kiln,. If furniture is made with wood that is too. Kiln drying your own wood at home can be a great way to sustainably harvest the materials around you, and dry it fast enough to build furniture with. Conventional dry kilns commonly use initial drying temperatures, when the lumber is more than 50 percent. How Hot Is A Kiln For Wood.

From imagetou.com

How To Build Wood Drying Kiln Image to u How Hot Is A Kiln For Wood Usually, you need anywhere between five to eight kiln schedules to complete the process. A typical kiln consists of the following. Usually, wood mills use bricks and concrete structures. If furniture is made with wood that is too. However, you may need more cycles depending on the species, moisture content, and size of the timber. The temperature you should run. How Hot Is A Kiln For Wood.

From anthologywoods.com

Kiln Drying Reclaimed Wood A Key Step to Quality — ANTHOLOGY WOODS How Hot Is A Kiln For Wood Usually, you need anywhere between five to eight kiln schedules to complete the process. Kiln drying your own wood at home can be a great way to sustainably harvest the materials around you, and dry it fast enough to build furniture with. If furniture is made with wood that is too. The temperature you should run your wood kiln depends. How Hot Is A Kiln For Wood.

From s3-us-west-1.amazonaws.com

Woodwork How To Build Wood Fired Kiln PDF Plans How Hot Is A Kiln For Wood Kiln drying your own wood at home can be a great way to sustainably harvest the materials around you, and dry it fast enough to build furniture with. However, you may need more cycles depending on the species, moisture content, and size of the timber. Usually, you need anywhere between five to eight kiln schedules to complete the process. A. How Hot Is A Kiln For Wood.

From woodworking-1.blogspot.com

Wood Drying Kiln Plans WOODWORKING How Hot Is A Kiln For Wood Kiln drying your own wood at home can be a great way to sustainably harvest the materials around you, and dry it fast enough to build furniture with. Usually, you need anywhere between five to eight kiln schedules to complete the process. Conventional dry kilns commonly use initial drying temperatures, when the lumber is more than 50 percent mc, from. How Hot Is A Kiln For Wood.

From www.britannica.com

Wood Treatments, Structure, Properties Britannica How Hot Is A Kiln For Wood Conventional dry kilns commonly use initial drying temperatures, when the lumber is more than 50 percent mc, from 100 to 130. The temperature you should run your wood kiln depends on what type of wood you are curing and what the desired outcome is. A typical kiln consists of the following. Kiln drying your own wood at home can be. How Hot Is A Kiln For Wood.

From www.homesteadpottery.com

Our Wood Fired Kiln Homestead Pottery How Hot Is A Kiln For Wood However, you may need more cycles depending on the species, moisture content, and size of the timber. Kiln drying, especially in a steam kiln,. Usually, you need anywhere between five to eight kiln schedules to complete the process. Kiln drying your own wood at home can be a great way to sustainably harvest the materials around you, and dry it. How Hot Is A Kiln For Wood.

From woodhoohoo.blogspot.com

How Does A Wood Kiln Work Woodhoohoo How Hot Is A Kiln For Wood However, you may need more cycles depending on the species, moisture content, and size of the timber. A typical kiln consists of the following. The temperature you should run your wood kiln depends on what type of wood you are curing and what the desired outcome is. Kiln drying your own wood at home can be a great way to. How Hot Is A Kiln For Wood.

From www.alamy.com

Wood drying kiln hires stock photography and images Alamy How Hot Is A Kiln For Wood The temperature you should run your wood kiln depends on what type of wood you are curing and what the desired outcome is. Usually, you need anywhere between five to eight kiln schedules to complete the process. A typical kiln consists of the following. However, you may need more cycles depending on the species, moisture content, and size of the. How Hot Is A Kiln For Wood.

From www.gardentoolexpert.com

How To Kiln Dry Wood In An Oven Step By Step Method Garden Tool How Hot Is A Kiln For Wood Kiln drying your own wood at home can be a great way to sustainably harvest the materials around you, and dry it fast enough to build furniture with. The temperature you should run your wood kiln depends on what type of wood you are curing and what the desired outcome is. However, you may need more cycles depending on the. How Hot Is A Kiln For Wood.

From www.mcilvain.com

Kiln Drying wood should be a slow and steady process How Hot Is A Kiln For Wood Conventional dry kilns commonly use initial drying temperatures, when the lumber is more than 50 percent mc, from 100 to 130. Usually, you need anywhere between five to eight kiln schedules to complete the process. Kiln drying your own wood at home can be a great way to sustainably harvest the materials around you, and dry it fast enough to. How Hot Is A Kiln For Wood.

From www.aheidemanart.com

How do kilns work and why are they different? How Hot Is A Kiln For Wood Usually, wood mills use bricks and concrete structures. Kiln drying, especially in a steam kiln,. However, you may need more cycles depending on the species, moisture content, and size of the timber. A typical kiln consists of the following. Usually, you need anywhere between five to eight kiln schedules to complete the process. It has different types and components such. How Hot Is A Kiln For Wood.

From www.craftcouncil.org

Kilns That Build Community American Craft Council How Hot Is A Kiln For Wood Kiln drying, especially in a steam kiln,. It has different types and components such as a sealed chamber, insulation, heat source, and ventilation. If furniture is made with wood that is too. However, you may need more cycles depending on the species, moisture content, and size of the timber. Kiln drying your own wood at home can be a great. How Hot Is A Kiln For Wood.

From timberlinemag.com

WoodMizer Kiln Kits Provide Affordable, Profitable Lumber Drying How Hot Is A Kiln For Wood A typical kiln consists of the following. However, you may need more cycles depending on the species, moisture content, and size of the timber. Usually, wood mills use bricks and concrete structures. Usually, you need anywhere between five to eight kiln schedules to complete the process. Kiln drying, especially in a steam kiln,. Kiln drying your own wood at home. How Hot Is A Kiln For Wood.

From www.drykilns.com

Continuous Kilns American Wood Dryers, Inc. How Hot Is A Kiln For Wood It has different types and components such as a sealed chamber, insulation, heat source, and ventilation. Usually, wood mills use bricks and concrete structures. Usually, you need anywhere between five to eight kiln schedules to complete the process. A typical kiln consists of the following. However, you may need more cycles depending on the species, moisture content, and size of. How Hot Is A Kiln For Wood.

From woodworkpdfplans.web.fc2.com

Diy Wood Kiln Plans Free PDF Download How Hot Is A Kiln For Wood Usually, you need anywhere between five to eight kiln schedules to complete the process. The temperature you should run your wood kiln depends on what type of wood you are curing and what the desired outcome is. Usually, wood mills use bricks and concrete structures. However, you may need more cycles depending on the species, moisture content, and size of. How Hot Is A Kiln For Wood.

From woodarchivist.com

DIY Wood Drying Kiln • WoodArchivist How Hot Is A Kiln For Wood If furniture is made with wood that is too. However, you may need more cycles depending on the species, moisture content, and size of the timber. A typical kiln consists of the following. It has different types and components such as a sealed chamber, insulation, heat source, and ventilation. Conventional dry kilns commonly use initial drying temperatures, when the lumber. How Hot Is A Kiln For Wood.