Flue Gas Quenching Calculation . Typically, the flue gas is cooled using a water quench prior to a co 2 absorber, either in a. I am designing a quencher tower for flue gas for of msw incineration plant. Figure 4 shows the geometry of a quench system that was designed to cool the flue gas from an incinerator to a temperature suitable for desulfurization reactions in a. Flue gas quench (fgq) is playing an important role in biomass or waste fueled combined heat and power (chp) plants, as it. According to equation (1), heat transfer coefficient is proportional to gas thermal conductivity (k), gas flow rate (velocity), gas density, and specific. Integration between flue gas and combustion air. A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. This allows rapid evaporation of the formed.

from www.semanticscholar.org

According to equation (1), heat transfer coefficient is proportional to gas thermal conductivity (k), gas flow rate (velocity), gas density, and specific. Flue gas quench (fgq) is playing an important role in biomass or waste fueled combined heat and power (chp) plants, as it. This allows rapid evaporation of the formed. Integration between flue gas and combustion air. A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. I am designing a quencher tower for flue gas for of msw incineration plant. Typically, the flue gas is cooled using a water quench prior to a co 2 absorber, either in a. Figure 4 shows the geometry of a quench system that was designed to cool the flue gas from an incinerator to a temperature suitable for desulfurization reactions in a.

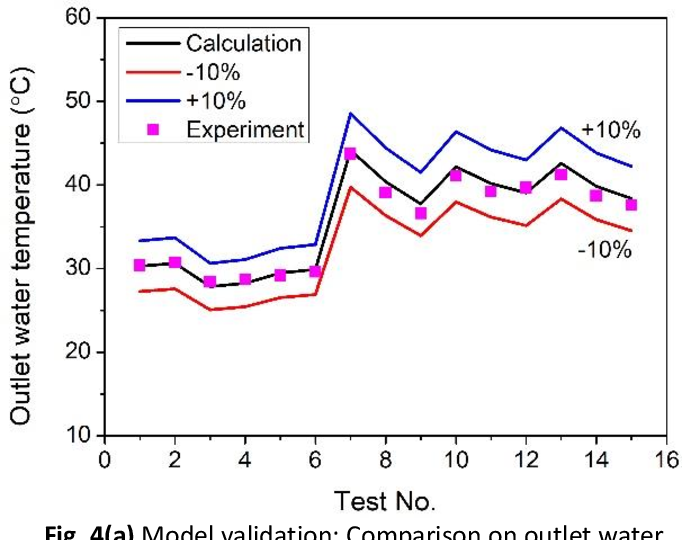

Figure 4 from Modelling the Quench Tower in Flue Gas Cleaning of a

Flue Gas Quenching Calculation Integration between flue gas and combustion air. Typically, the flue gas is cooled using a water quench prior to a co 2 absorber, either in a. A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. Flue gas quench (fgq) is playing an important role in biomass or waste fueled combined heat and power (chp) plants, as it. This allows rapid evaporation of the formed. I am designing a quencher tower for flue gas for of msw incineration plant. According to equation (1), heat transfer coefficient is proportional to gas thermal conductivity (k), gas flow rate (velocity), gas density, and specific. Figure 4 shows the geometry of a quench system that was designed to cool the flue gas from an incinerator to a temperature suitable for desulfurization reactions in a. Integration between flue gas and combustion air.

From becht.com

Design of Flue Gas Quench Sections Becht Flue Gas Quenching Calculation I am designing a quencher tower for flue gas for of msw incineration plant. According to equation (1), heat transfer coefficient is proportional to gas thermal conductivity (k), gas flow rate (velocity), gas density, and specific. A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. Typically, the flue gas is cooled using a water quench. Flue Gas Quenching Calculation.

From www.scribd.com

Flue Gases Loss Calculation Through Siegert's Formula PDF Heat Flue Gas Quenching Calculation Figure 4 shows the geometry of a quench system that was designed to cool the flue gas from an incinerator to a temperature suitable for desulfurization reactions in a. Flue gas quench (fgq) is playing an important role in biomass or waste fueled combined heat and power (chp) plants, as it. Integration between flue gas and combustion air. I am. Flue Gas Quenching Calculation.

From www.semanticscholar.org

Figure 1 from Modelling the Quench Tower in Flue Gas Cleaning of a Flue Gas Quenching Calculation Integration between flue gas and combustion air. Figure 4 shows the geometry of a quench system that was designed to cool the flue gas from an incinerator to a temperature suitable for desulfurization reactions in a. This allows rapid evaporation of the formed. A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. According to equation. Flue Gas Quenching Calculation.

From www.researchgate.net

Schematic diagram of flue gas quench Download Scientific Diagram Flue Gas Quenching Calculation According to equation (1), heat transfer coefficient is proportional to gas thermal conductivity (k), gas flow rate (velocity), gas density, and specific. Flue gas quench (fgq) is playing an important role in biomass or waste fueled combined heat and power (chp) plants, as it. Typically, the flue gas is cooled using a water quench prior to a co 2 absorber,. Flue Gas Quenching Calculation.

From www.slideshare.net

Develop a simple equation to calculate the heat loss due to flue gase… Flue Gas Quenching Calculation I am designing a quencher tower for flue gas for of msw incineration plant. This allows rapid evaporation of the formed. Figure 4 shows the geometry of a quench system that was designed to cool the flue gas from an incinerator to a temperature suitable for desulfurization reactions in a. Flue gas quench (fgq) is playing an important role in. Flue Gas Quenching Calculation.

From www.youtube.com

HOW TO CALCULATE FLUE GAS STACK HEIGHT? WHAT SHOULD BE THE FLUE GAS Flue Gas Quenching Calculation A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. According to equation (1), heat transfer coefficient is proportional to gas thermal conductivity (k), gas flow rate (velocity), gas density, and specific. I am designing a quencher tower for flue gas for of msw incineration plant. Figure 4 shows the geometry of a quench system that. Flue Gas Quenching Calculation.

From www.researchgate.net

Schematic diagram of flue gas quench Download Scientific Diagram Flue Gas Quenching Calculation A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. According to equation (1), heat transfer coefficient is proportional to gas thermal conductivity (k), gas flow rate (velocity), gas density, and specific. I am designing a quencher tower for flue gas for of msw incineration plant. This allows rapid evaporation of the formed. Flue gas quench. Flue Gas Quenching Calculation.

From becht.com

Design of Flue Gas Quench Sections Becht Flue Gas Quenching Calculation I am designing a quencher tower for flue gas for of msw incineration plant. This allows rapid evaporation of the formed. Figure 4 shows the geometry of a quench system that was designed to cool the flue gas from an incinerator to a temperature suitable for desulfurization reactions in a. Typically, the flue gas is cooled using a water quench. Flue Gas Quenching Calculation.

From www.researchgate.net

Measurement and calculation method for determining flue gas flow Flue Gas Quenching Calculation A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. Integration between flue gas and combustion air. Flue gas quench (fgq) is playing an important role in biomass or waste fueled combined heat and power (chp) plants, as it. I am designing a quencher tower for flue gas for of msw incineration plant. According to equation. Flue Gas Quenching Calculation.

From www.semanticscholar.org

Figure 3 from Modelling the Quench Tower in Flue Gas Cleaning of a Flue Gas Quenching Calculation Typically, the flue gas is cooled using a water quench prior to a co 2 absorber, either in a. A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. Figure 4 shows the geometry of a quench system that was designed to cool the flue gas from an incinerator to a temperature suitable for desulfurization reactions. Flue Gas Quenching Calculation.

From www.slideshare.net

Develop a simple equation to calculate the heat loss due to flue gases Flue Gas Quenching Calculation Figure 4 shows the geometry of a quench system that was designed to cool the flue gas from an incinerator to a temperature suitable for desulfurization reactions in a. Integration between flue gas and combustion air. This allows rapid evaporation of the formed. I am designing a quencher tower for flue gas for of msw incineration plant. Flue gas quench. Flue Gas Quenching Calculation.

From www.scribd.com

Result Economizer Heating Surface and Outlet Flue Gas Temperature Flue Gas Quenching Calculation Figure 4 shows the geometry of a quench system that was designed to cool the flue gas from an incinerator to a temperature suitable for desulfurization reactions in a. According to equation (1), heat transfer coefficient is proportional to gas thermal conductivity (k), gas flow rate (velocity), gas density, and specific. A quencher promotes a strongly pronounced contact between the. Flue Gas Quenching Calculation.

From lv-soft.net

Physical properties and composition of flue gases (RGAS) Lauterbach Flue Gas Quenching Calculation According to equation (1), heat transfer coefficient is proportional to gas thermal conductivity (k), gas flow rate (velocity), gas density, and specific. Figure 4 shows the geometry of a quench system that was designed to cool the flue gas from an incinerator to a temperature suitable for desulfurization reactions in a. Flue gas quench (fgq) is playing an important role. Flue Gas Quenching Calculation.

From www.mdpi.com

Energies Free FullText Flue Gas Desulphurization in Circulating Flue Gas Quenching Calculation A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. Typically, the flue gas is cooled using a water quench prior to a co 2 absorber, either in a. Integration between flue gas and combustion air. Flue gas quench (fgq) is playing an important role in biomass or waste fueled combined heat and power (chp) plants,. Flue Gas Quenching Calculation.

From www.researchgate.net

6. Heat capacity of the flue gas depending on temperature and air Flue Gas Quenching Calculation Flue gas quench (fgq) is playing an important role in biomass or waste fueled combined heat and power (chp) plants, as it. Integration between flue gas and combustion air. According to equation (1), heat transfer coefficient is proportional to gas thermal conductivity (k), gas flow rate (velocity), gas density, and specific. Typically, the flue gas is cooled using a water. Flue Gas Quenching Calculation.

From www.researchgate.net

NO x concentration in flue gases as a function of boiler load and Flue Gas Quenching Calculation Flue gas quench (fgq) is playing an important role in biomass or waste fueled combined heat and power (chp) plants, as it. According to equation (1), heat transfer coefficient is proportional to gas thermal conductivity (k), gas flow rate (velocity), gas density, and specific. A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. Typically, the. Flue Gas Quenching Calculation.

From www.researchgate.net

PC 16 DD (A) and PC 18 DF (B) levels in the flue gas in the four Flue Gas Quenching Calculation A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. I am designing a quencher tower for flue gas for of msw incineration plant. Flue gas quench (fgq) is playing an important role in biomass or waste fueled combined heat and power (chp) plants, as it. According to equation (1), heat transfer coefficient is proportional to. Flue Gas Quenching Calculation.

From www.researchgate.net

(PDF) Numerical simulation study of quench tower in flue gas Flue Gas Quenching Calculation This allows rapid evaporation of the formed. According to equation (1), heat transfer coefficient is proportional to gas thermal conductivity (k), gas flow rate (velocity), gas density, and specific. A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. Integration between flue gas and combustion air. Flue gas quench (fgq) is playing an important role in. Flue Gas Quenching Calculation.

From gasheatdenkabo.blogspot.com

Gas Heat Flue Gas Heat Recovery Calculation Flue Gas Quenching Calculation A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. Typically, the flue gas is cooled using a water quench prior to a co 2 absorber, either in a. Figure 4 shows the geometry of a quench system that was designed to cool the flue gas from an incinerator to a temperature suitable for desulfurization reactions. Flue Gas Quenching Calculation.

From slideplayer.com

Lecture 6 Defining the equilibrium by minimizing the Gibbs energy Acid Flue Gas Quenching Calculation A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. Flue gas quench (fgq) is playing an important role in biomass or waste fueled combined heat and power (chp) plants, as it. I am designing a quencher tower for flue gas for of msw incineration plant. Figure 4 shows the geometry of a quench system that. Flue Gas Quenching Calculation.

From www.researchgate.net

Calculation scheme of the furnace and the movement of flue gases Flue Gas Quenching Calculation Flue gas quench (fgq) is playing an important role in biomass or waste fueled combined heat and power (chp) plants, as it. Figure 4 shows the geometry of a quench system that was designed to cool the flue gas from an incinerator to a temperature suitable for desulfurization reactions in a. I am designing a quencher tower for flue gas. Flue Gas Quenching Calculation.

From heatmatrixgroup.com

Howto calculate the Acid Dew Point (ADP) of flue gas Flue Gas Quenching Calculation Integration between flue gas and combustion air. Typically, the flue gas is cooled using a water quench prior to a co 2 absorber, either in a. This allows rapid evaporation of the formed. A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. I am designing a quencher tower for flue gas for of msw incineration. Flue Gas Quenching Calculation.

From pericles.pericles-prod.literatumonline.com

Potential environmental benefits of integrating flue gas quench in Flue Gas Quenching Calculation Integration between flue gas and combustion air. Typically, the flue gas is cooled using a water quench prior to a co 2 absorber, either in a. Figure 4 shows the geometry of a quench system that was designed to cool the flue gas from an incinerator to a temperature suitable for desulfurization reactions in a. This allows rapid evaporation of. Flue Gas Quenching Calculation.

From www.mecaflux.com

diameter pipe smoke flue calculation software Flue Gas Quenching Calculation Integration between flue gas and combustion air. According to equation (1), heat transfer coefficient is proportional to gas thermal conductivity (k), gas flow rate (velocity), gas density, and specific. I am designing a quencher tower for flue gas for of msw incineration plant. This allows rapid evaporation of the formed. Typically, the flue gas is cooled using a water quench. Flue Gas Quenching Calculation.

From www.researchgate.net

lists the typical composition of the flue gas measured at a point Flue Gas Quenching Calculation Flue gas quench (fgq) is playing an important role in biomass or waste fueled combined heat and power (chp) plants, as it. Figure 4 shows the geometry of a quench system that was designed to cool the flue gas from an incinerator to a temperature suitable for desulfurization reactions in a. I am designing a quencher tower for flue gas. Flue Gas Quenching Calculation.

From www.researchgate.net

Flue gas specifications Download Table Flue Gas Quenching Calculation A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. Flue gas quench (fgq) is playing an important role in biomass or waste fueled combined heat and power (chp) plants, as it. I am designing a quencher tower for flue gas for of msw incineration plant. This allows rapid evaporation of the formed. Typically, the flue. Flue Gas Quenching Calculation.

From www.mdpi.com

Applied Sciences Free FullText Flue Gas Composition and Treatment Flue Gas Quenching Calculation Integration between flue gas and combustion air. Figure 4 shows the geometry of a quench system that was designed to cool the flue gas from an incinerator to a temperature suitable for desulfurization reactions in a. A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. Typically, the flue gas is cooled using a water quench. Flue Gas Quenching Calculation.

From eureka.patsnap.com

Threephase separation device for water quenching product and water Flue Gas Quenching Calculation I am designing a quencher tower for flue gas for of msw incineration plant. Integration between flue gas and combustion air. This allows rapid evaporation of the formed. According to equation (1), heat transfer coefficient is proportional to gas thermal conductivity (k), gas flow rate (velocity), gas density, and specific. Flue gas quench (fgq) is playing an important role in. Flue Gas Quenching Calculation.

From dokumen.tips

(PPT) Develop a simple equation to calculate the heat loss due to flue Flue Gas Quenching Calculation Flue gas quench (fgq) is playing an important role in biomass or waste fueled combined heat and power (chp) plants, as it. I am designing a quencher tower for flue gas for of msw incineration plant. This allows rapid evaporation of the formed. A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. Figure 4 shows. Flue Gas Quenching Calculation.

From www.researchgate.net

Flue gases temperature Tf as a function of k. r0 is equal to 5 mm. The Flue Gas Quenching Calculation According to equation (1), heat transfer coefficient is proportional to gas thermal conductivity (k), gas flow rate (velocity), gas density, and specific. A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. Flue gas quench (fgq) is playing an important role in biomass or waste fueled combined heat and power (chp) plants, as it. Figure 4. Flue Gas Quenching Calculation.

From www.scribd.com

Flue Gas Side Heat Duty Calculation PDF Gases Physical Chemistry Flue Gas Quenching Calculation Flue gas quench (fgq) is playing an important role in biomass or waste fueled combined heat and power (chp) plants, as it. Typically, the flue gas is cooled using a water quench prior to a co 2 absorber, either in a. This allows rapid evaporation of the formed. Figure 4 shows the geometry of a quench system that was designed. Flue Gas Quenching Calculation.

From www.ergapc.co.uk

Quench Vessels, Hot Flue Gas Cooling & High Temperature Quenching ERG Flue Gas Quenching Calculation I am designing a quencher tower for flue gas for of msw incineration plant. Integration between flue gas and combustion air. A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. Flue gas quench (fgq) is playing an important role in biomass or waste fueled combined heat and power (chp) plants, as it. According to equation. Flue Gas Quenching Calculation.

From www.researchgate.net

(PDF) Numerical simulation study of quench tower in flue gas Flue Gas Quenching Calculation Figure 4 shows the geometry of a quench system that was designed to cool the flue gas from an incinerator to a temperature suitable for desulfurization reactions in a. A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. Integration between flue gas and combustion air. Flue gas quench (fgq) is playing an important role in. Flue Gas Quenching Calculation.

From www.researchgate.net

Schematic diagram of flue gas quench Download Scientific Diagram Flue Gas Quenching Calculation This allows rapid evaporation of the formed. A quencher promotes a strongly pronounced contact between the flue gas and quenching liquid. I am designing a quencher tower for flue gas for of msw incineration plant. Typically, the flue gas is cooled using a water quench prior to a co 2 absorber, either in a. Flue gas quench (fgq) is playing. Flue Gas Quenching Calculation.

From www.semanticscholar.org

Figure 4 from Modelling the Quench Tower in Flue Gas Cleaning of a Flue Gas Quenching Calculation Flue gas quench (fgq) is playing an important role in biomass or waste fueled combined heat and power (chp) plants, as it. I am designing a quencher tower for flue gas for of msw incineration plant. Figure 4 shows the geometry of a quench system that was designed to cool the flue gas from an incinerator to a temperature suitable. Flue Gas Quenching Calculation.