Water Level Gauge Boiler . boilers operating up to 400 psi are required to have one gage glass in service at all times. methods of detecting water level in steam boilers. the gauge glass device, which has stood the test of time, is used on the vast majority of boilers and is usually arranged to give a. On applications operating above 400 psi, the gage. electronic gauging system for steam drum water level measurement. the steam boiler sight glass or water level gauge allows the building owner or maintenance person to monitor the. the american society of mechanical engineers (asme) international boiler and pressure vessel code (bpvc) outlines several. The application of level controls and alarms, plus an overview of different level. one critical variable that directly affects the safety and efficiency of a boiler is the water level.

from mavink.com

electronic gauging system for steam drum water level measurement. boilers operating up to 400 psi are required to have one gage glass in service at all times. The application of level controls and alarms, plus an overview of different level. the steam boiler sight glass or water level gauge allows the building owner or maintenance person to monitor the. On applications operating above 400 psi, the gage. one critical variable that directly affects the safety and efficiency of a boiler is the water level. methods of detecting water level in steam boilers. the american society of mechanical engineers (asme) international boiler and pressure vessel code (bpvc) outlines several. the gauge glass device, which has stood the test of time, is used on the vast majority of boilers and is usually arranged to give a.

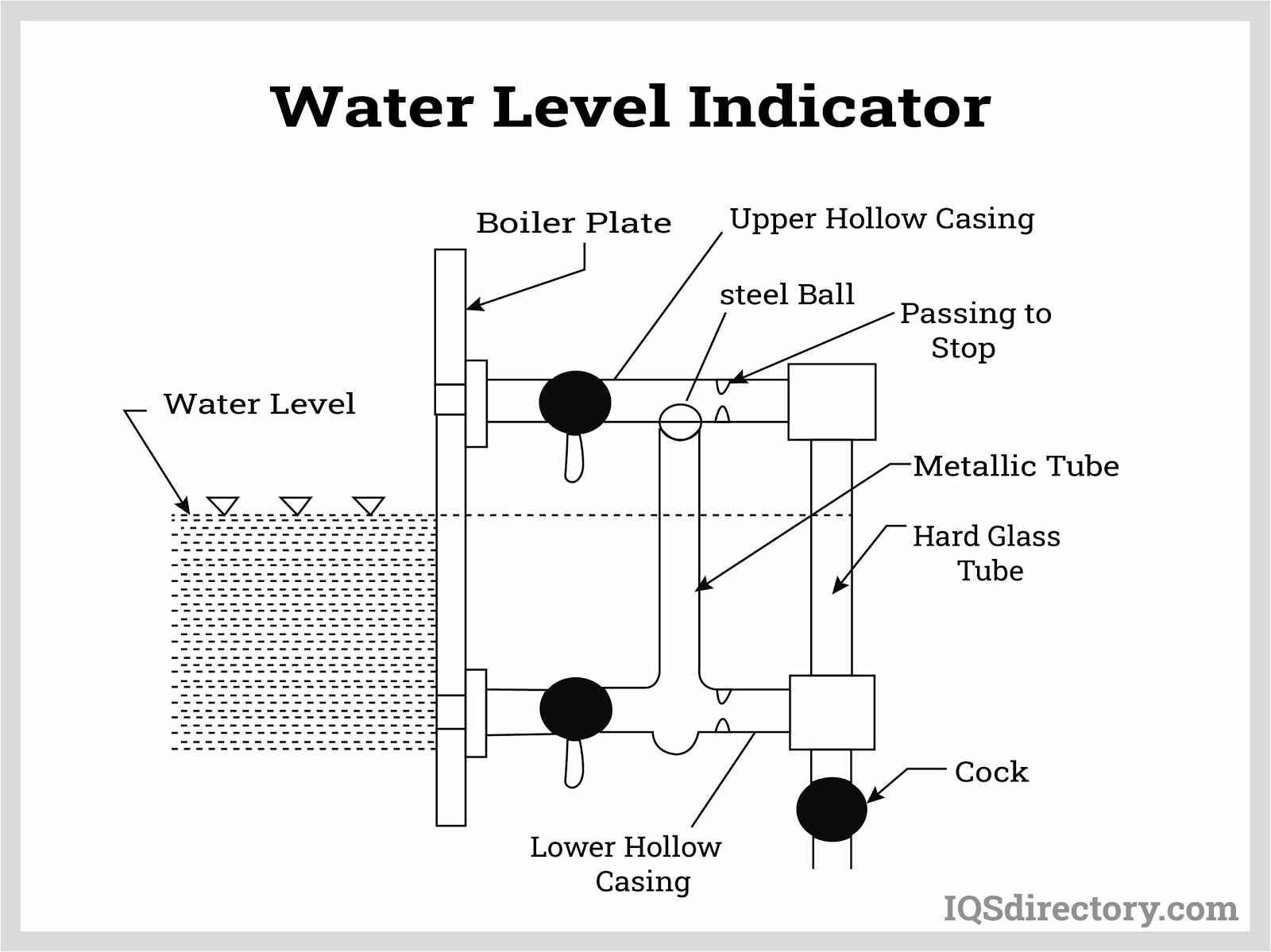

Water Level Indicator Gauge

Water Level Gauge Boiler one critical variable that directly affects the safety and efficiency of a boiler is the water level. The application of level controls and alarms, plus an overview of different level. methods of detecting water level in steam boilers. boilers operating up to 400 psi are required to have one gage glass in service at all times. the steam boiler sight glass or water level gauge allows the building owner or maintenance person to monitor the. one critical variable that directly affects the safety and efficiency of a boiler is the water level. On applications operating above 400 psi, the gage. the american society of mechanical engineers (asme) international boiler and pressure vessel code (bpvc) outlines several. the gauge glass device, which has stood the test of time, is used on the vast majority of boilers and is usually arranged to give a. electronic gauging system for steam drum water level measurement.

From www.alibaba.com

Steam Boiler Water Measuring Level Gauge With Alarm Level Switch Buy Water Level Gauge Boiler electronic gauging system for steam drum water level measurement. On applications operating above 400 psi, the gage. the american society of mechanical engineers (asme) international boiler and pressure vessel code (bpvc) outlines several. the gauge glass device, which has stood the test of time, is used on the vast majority of boilers and is usually arranged to. Water Level Gauge Boiler.

From inspectapedia.com

Steam Boiler Sight Glass How to use the sight gauge to set the water Water Level Gauge Boiler electronic gauging system for steam drum water level measurement. The application of level controls and alarms, plus an overview of different level. On applications operating above 400 psi, the gage. methods of detecting water level in steam boilers. the steam boiler sight glass or water level gauge allows the building owner or maintenance person to monitor the.. Water Level Gauge Boiler.

From learnmech.com

Water Level Indicator Boiler Mounting and Accessories Water Level Gauge Boiler boilers operating up to 400 psi are required to have one gage glass in service at all times. The application of level controls and alarms, plus an overview of different level. On applications operating above 400 psi, the gage. the gauge glass device, which has stood the test of time, is used on the vast majority of boilers. Water Level Gauge Boiler.

From www.youtube.com

Water Level Indicator (Basics, Structure, Working & Location in Boiler Water Level Gauge Boiler the american society of mechanical engineers (asme) international boiler and pressure vessel code (bpvc) outlines several. the steam boiler sight glass or water level gauge allows the building owner or maintenance person to monitor the. one critical variable that directly affects the safety and efficiency of a boiler is the water level. the gauge glass device,. Water Level Gauge Boiler.

From bestrode.com.my

Replacement boiler water level gauge at plywood mill Bestrode Sdn Bhd Water Level Gauge Boiler the american society of mechanical engineers (asme) international boiler and pressure vessel code (bpvc) outlines several. one critical variable that directly affects the safety and efficiency of a boiler is the water level. boilers operating up to 400 psi are required to have one gage glass in service at all times. methods of detecting water level. Water Level Gauge Boiler.

From levelmeters.com

B69H super high pressure water level gauge for boiler level gauge Water Level Gauge Boiler boilers operating up to 400 psi are required to have one gage glass in service at all times. On applications operating above 400 psi, the gage. the gauge glass device, which has stood the test of time, is used on the vast majority of boilers and is usually arranged to give a. electronic gauging system for steam. Water Level Gauge Boiler.

From u-ideal.en.made-in-china.com

High Temperature High Pressure Type Two Color Sight Glass Level Gauge Water Level Gauge Boiler On applications operating above 400 psi, the gage. the american society of mechanical engineers (asme) international boiler and pressure vessel code (bpvc) outlines several. boilers operating up to 400 psi are required to have one gage glass in service at all times. the gauge glass device, which has stood the test of time, is used on the. Water Level Gauge Boiler.

From www.magneticlevel-gauge.com

Boiler Water Level Gauge Stainless Steel Side Mount Glass Level Gauge Water Level Gauge Boiler boilers operating up to 400 psi are required to have one gage glass in service at all times. electronic gauging system for steam drum water level measurement. one critical variable that directly affects the safety and efficiency of a boiler is the water level. The application of level controls and alarms, plus an overview of different level.. Water Level Gauge Boiler.

From www.powermag.com

boiler level measurement Archives Water Level Gauge Boiler boilers operating up to 400 psi are required to have one gage glass in service at all times. the gauge glass device, which has stood the test of time, is used on the vast majority of boilers and is usually arranged to give a. The application of level controls and alarms, plus an overview of different level. . Water Level Gauge Boiler.

From marineprogress.com

Marine Boilers (introduction and Operational guide) Marine Progress Water Level Gauge Boiler electronic gauging system for steam drum water level measurement. methods of detecting water level in steam boilers. On applications operating above 400 psi, the gage. the gauge glass device, which has stood the test of time, is used on the vast majority of boilers and is usually arranged to give a. The application of level controls and. Water Level Gauge Boiler.

From u-ideal.en.made-in-china.com

Glass Level Gauges Continuous Reading and Illuminator Boiler Water Water Level Gauge Boiler the steam boiler sight glass or water level gauge allows the building owner or maintenance person to monitor the. methods of detecting water level in steam boilers. The application of level controls and alarms, plus an overview of different level. one critical variable that directly affects the safety and efficiency of a boiler is the water level.. Water Level Gauge Boiler.

From www.alamy.com

Boiler water level or sight glass and pressure gauge Head Wrightson Water Level Gauge Boiler On applications operating above 400 psi, the gage. the american society of mechanical engineers (asme) international boiler and pressure vessel code (bpvc) outlines several. The application of level controls and alarms, plus an overview of different level. electronic gauging system for steam drum water level measurement. boilers operating up to 400 psi are required to have one. Water Level Gauge Boiler.

From www.alibaba.com

B49x Double/two Color Water Level Gauge Red And Green Display High Water Level Gauge Boiler electronic gauging system for steam drum water level measurement. the steam boiler sight glass or water level gauge allows the building owner or maintenance person to monitor the. On applications operating above 400 psi, the gage. the american society of mechanical engineers (asme) international boiler and pressure vessel code (bpvc) outlines several. the gauge glass device,. Water Level Gauge Boiler.

From mitraboiler.com

JUAL LEVEL GAUGE BOILER KLINGER R25D GELAS PENDUGA BOILER Water Level Gauge Boiler the american society of mechanical engineers (asme) international boiler and pressure vessel code (bpvc) outlines several. The application of level controls and alarms, plus an overview of different level. the steam boiler sight glass or water level gauge allows the building owner or maintenance person to monitor the. boilers operating up to 400 psi are required to. Water Level Gauge Boiler.

From www.jinbomarine.com

ULB3G Type Boiler Level Gauge, Buy Marine Level Gauge from China Water Level Gauge Boiler The application of level controls and alarms, plus an overview of different level. boilers operating up to 400 psi are required to have one gage glass in service at all times. On applications operating above 400 psi, the gage. the gauge glass device, which has stood the test of time, is used on the vast majority of boilers. Water Level Gauge Boiler.

From u-ideal.en.made-in-china.com

China Boiler BiColor Water Level Indicator Tank Level Gauge (B49H Water Level Gauge Boiler one critical variable that directly affects the safety and efficiency of a boiler is the water level. methods of detecting water level in steam boilers. the american society of mechanical engineers (asme) international boiler and pressure vessel code (bpvc) outlines several. boilers operating up to 400 psi are required to have one gage glass in service. Water Level Gauge Boiler.

From www.alibaba.com

Steam Boiler Water Measuring Level Gauge With Alarm Level Switch Buy Water Level Gauge Boiler electronic gauging system for steam drum water level measurement. The application of level controls and alarms, plus an overview of different level. boilers operating up to 400 psi are required to have one gage glass in service at all times. methods of detecting water level in steam boilers. the american society of mechanical engineers (asme) international. Water Level Gauge Boiler.

From www.esmagazine.com

Code Requirements Monitoring Boiler Water Levels Engineered Systems Water Level Gauge Boiler one critical variable that directly affects the safety and efficiency of a boiler is the water level. On applications operating above 400 psi, the gage. boilers operating up to 400 psi are required to have one gage glass in service at all times. electronic gauging system for steam drum water level measurement. The application of level controls. Water Level Gauge Boiler.

From ceojjcph.blob.core.windows.net

Water Level Gauge In Boiler at Mitchell Blevins blog Water Level Gauge Boiler the gauge glass device, which has stood the test of time, is used on the vast majority of boilers and is usually arranged to give a. methods of detecting water level in steam boilers. boilers operating up to 400 psi are required to have one gage glass in service at all times. The application of level controls. Water Level Gauge Boiler.

From ceojjcph.blob.core.windows.net

Water Level Gauge In Boiler at Mitchell Blevins blog Water Level Gauge Boiler one critical variable that directly affects the safety and efficiency of a boiler is the water level. the gauge glass device, which has stood the test of time, is used on the vast majority of boilers and is usually arranged to give a. The application of level controls and alarms, plus an overview of different level. On applications. Water Level Gauge Boiler.

From www.exportersindia.com

Round Reflex boiler water level gauge glass, Color Transparent at Rs Water Level Gauge Boiler the gauge glass device, which has stood the test of time, is used on the vast majority of boilers and is usually arranged to give a. one critical variable that directly affects the safety and efficiency of a boiler is the water level. electronic gauging system for steam drum water level measurement. methods of detecting water. Water Level Gauge Boiler.

From www.lazada.com.ph

Boiler Liquid Level Gauge Water Level Gauge Copper Joint Glass Tube Water Level Gauge Boiler the american society of mechanical engineers (asme) international boiler and pressure vessel code (bpvc) outlines several. On applications operating above 400 psi, the gage. one critical variable that directly affects the safety and efficiency of a boiler is the water level. the gauge glass device, which has stood the test of time, is used on the vast. Water Level Gauge Boiler.

From bestrode.com.my

Replacement boiler water level gauge at plywood mill Bestrode Sdn Bhd Water Level Gauge Boiler the american society of mechanical engineers (asme) international boiler and pressure vessel code (bpvc) outlines several. electronic gauging system for steam drum water level measurement. the steam boiler sight glass or water level gauge allows the building owner or maintenance person to monitor the. The application of level controls and alarms, plus an overview of different level.. Water Level Gauge Boiler.

From www.alibaba.com

Reflex Sight Glass Boiler Water Level Gauge Buy Boiler Water Level Water Level Gauge Boiler the gauge glass device, which has stood the test of time, is used on the vast majority of boilers and is usually arranged to give a. boilers operating up to 400 psi are required to have one gage glass in service at all times. electronic gauging system for steam drum water level measurement. On applications operating above. Water Level Gauge Boiler.

From inspectapedia.com

Steam Boiler Sight Glass How to use the sight gauge to set the water Water Level Gauge Boiler the american society of mechanical engineers (asme) international boiler and pressure vessel code (bpvc) outlines several. the gauge glass device, which has stood the test of time, is used on the vast majority of boilers and is usually arranged to give a. boilers operating up to 400 psi are required to have one gage glass in service. Water Level Gauge Boiler.

From shopnwim.us

Reflex Water Level Gauge Assembly NWIM Boiler Parts & Equipment Water Level Gauge Boiler electronic gauging system for steam drum water level measurement. the american society of mechanical engineers (asme) international boiler and pressure vessel code (bpvc) outlines several. On applications operating above 400 psi, the gage. one critical variable that directly affects the safety and efficiency of a boiler is the water level. methods of detecting water level in. Water Level Gauge Boiler.

From www.youtube.com

Boiler [Part 2], Water Level Indicator (Gauge Glass) YouTube Water Level Gauge Boiler the american society of mechanical engineers (asme) international boiler and pressure vessel code (bpvc) outlines several. the gauge glass device, which has stood the test of time, is used on the vast majority of boilers and is usually arranged to give a. electronic gauging system for steam drum water level measurement. The application of level controls and. Water Level Gauge Boiler.

From www.boilersupplies.com

Economy Gauge EG150150 Heavy Pattern Bronze Water Gauges Water Level Gauge Boiler On applications operating above 400 psi, the gage. one critical variable that directly affects the safety and efficiency of a boiler is the water level. electronic gauging system for steam drum water level measurement. The application of level controls and alarms, plus an overview of different level. the steam boiler sight glass or water level gauge allows. Water Level Gauge Boiler.

From www.alibaba.com

Water Level Gauge Valve Brass Boiler Water Level Gauge Buy Tubular Water Level Gauge Boiler methods of detecting water level in steam boilers. the american society of mechanical engineers (asme) international boiler and pressure vessel code (bpvc) outlines several. electronic gauging system for steam drum water level measurement. boilers operating up to 400 psi are required to have one gage glass in service at all times. The application of level controls. Water Level Gauge Boiler.

From www.alibaba.com

Steam Boiler Water Measuring Level Gauge With Alarm Level Switch Buy Water Level Gauge Boiler On applications operating above 400 psi, the gage. the american society of mechanical engineers (asme) international boiler and pressure vessel code (bpvc) outlines several. boilers operating up to 400 psi are required to have one gage glass in service at all times. one critical variable that directly affects the safety and efficiency of a boiler is the. Water Level Gauge Boiler.

From u-ideal.en.made-in-china.com

Side Mounted Boiler Water Fuel Level Float Level Gauge Water Level Gauge Boiler the american society of mechanical engineers (asme) international boiler and pressure vessel code (bpvc) outlines several. one critical variable that directly affects the safety and efficiency of a boiler is the water level. On applications operating above 400 psi, the gage. The application of level controls and alarms, plus an overview of different level. electronic gauging system. Water Level Gauge Boiler.

From www.boilersupplies.com

Liquid Level Sight Gauges & Water Gauges Boiler Supplies Water Level Gauge Boiler one critical variable that directly affects the safety and efficiency of a boiler is the water level. The application of level controls and alarms, plus an overview of different level. boilers operating up to 400 psi are required to have one gage glass in service at all times. the gauge glass device, which has stood the test. Water Level Gauge Boiler.

From www.durcon-vice.com.br

Two Color Water Level Gauge for Hign Pressure Boilers Durcon Vice Water Level Gauge Boiler electronic gauging system for steam drum water level measurement. boilers operating up to 400 psi are required to have one gage glass in service at all times. one critical variable that directly affects the safety and efficiency of a boiler is the water level. methods of detecting water level in steam boilers. the gauge glass. Water Level Gauge Boiler.

From mavink.com

Water Level Indicator Gauge Water Level Gauge Boiler methods of detecting water level in steam boilers. one critical variable that directly affects the safety and efficiency of a boiler is the water level. electronic gauging system for steam drum water level measurement. boilers operating up to 400 psi are required to have one gage glass in service at all times. the steam boiler. Water Level Gauge Boiler.

From ceojjcph.blob.core.windows.net

Water Level Gauge In Boiler at Mitchell Blevins blog Water Level Gauge Boiler boilers operating up to 400 psi are required to have one gage glass in service at all times. one critical variable that directly affects the safety and efficiency of a boiler is the water level. the gauge glass device, which has stood the test of time, is used on the vast majority of boilers and is usually. Water Level Gauge Boiler.