Hot Plate Welding Design Guidelines . Once you have an initial design, you should have a hot plate welding expert like extol check it and. The 0.030 material displacement per side includes 0.015. Hot plate welding joint designs: A weld rib or bead on each component is brought into contact with the. The process of hot plate welding uses a heated platen to melt the joining surfaces of the two halves of a thermoplastic part. Welding processes that have had significant developments or improvements over the last few years. The part halves are brought into contact with a precisely heated platen. A flat weld plane normal to the direction of pressure is ideal. Hot plate welding is widely used for the most challenging materials and large part assembly with high strength and hermetic requirements. Typical total material displacement is 0.060. Minimize welding angles as much as possible (max recommended 30 degrees);

from www.assemblymag.com

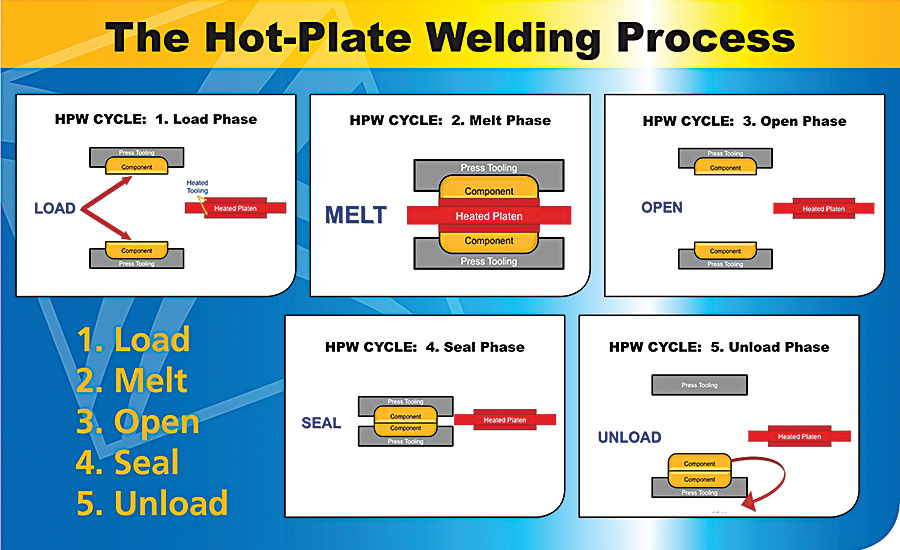

Hot plate welding joint designs: The process of hot plate welding uses a heated platen to melt the joining surfaces of the two halves of a thermoplastic part. Once you have an initial design, you should have a hot plate welding expert like extol check it and. Hot plate welding is widely used for the most challenging materials and large part assembly with high strength and hermetic requirements. A flat weld plane normal to the direction of pressure is ideal. Minimize welding angles as much as possible (max recommended 30 degrees); The part halves are brought into contact with a precisely heated platen. The 0.030 material displacement per side includes 0.015. Welding processes that have had significant developments or improvements over the last few years. A weld rib or bead on each component is brought into contact with the.

HotPlate Welding vs. Infrared Welding for Plastics Assembly 201510

Hot Plate Welding Design Guidelines Once you have an initial design, you should have a hot plate welding expert like extol check it and. Hot plate welding is widely used for the most challenging materials and large part assembly with high strength and hermetic requirements. Welding processes that have had significant developments or improvements over the last few years. A weld rib or bead on each component is brought into contact with the. A flat weld plane normal to the direction of pressure is ideal. Hot plate welding joint designs: Minimize welding angles as much as possible (max recommended 30 degrees); The process of hot plate welding uses a heated platen to melt the joining surfaces of the two halves of a thermoplastic part. The part halves are brought into contact with a precisely heated platen. The 0.030 material displacement per side includes 0.015. Typical total material displacement is 0.060. Once you have an initial design, you should have a hot plate welding expert like extol check it and.

From www.dizo-global.com

The Ultimate Guide to Using Hot Plate Welding Machines for Glove Boxes Hot Plate Welding Design Guidelines A weld rib or bead on each component is brought into contact with the. A flat weld plane normal to the direction of pressure is ideal. Hot plate welding is widely used for the most challenging materials and large part assembly with high strength and hermetic requirements. Welding processes that have had significant developments or improvements over the last few. Hot Plate Welding Design Guidelines.

From vimalsonic.com

How hot plate plastic welding machine works ? VIMALS SONIC Hot Plate Welding Design Guidelines The process of hot plate welding uses a heated platen to melt the joining surfaces of the two halves of a thermoplastic part. The 0.030 material displacement per side includes 0.015. Minimize welding angles as much as possible (max recommended 30 degrees); Once you have an initial design, you should have a hot plate welding expert like extol check it. Hot Plate Welding Design Guidelines.

From www.youtube.com

열판용착(Hot plate welding) YouTube Hot Plate Welding Design Guidelines Once you have an initial design, you should have a hot plate welding expert like extol check it and. Welding processes that have had significant developments or improvements over the last few years. Hot plate welding is widely used for the most challenging materials and large part assembly with high strength and hermetic requirements. The 0.030 material displacement per side. Hot Plate Welding Design Guidelines.

From www.youtube.com

HotPlate Welding PP with Teflon coating (500 F) vs Chromium coating Hot Plate Welding Design Guidelines Minimize welding angles as much as possible (max recommended 30 degrees); Hot plate welding joint designs: Hot plate welding is widely used for the most challenging materials and large part assembly with high strength and hermetic requirements. A weld rib or bead on each component is brought into contact with the. Typical total material displacement is 0.060. The part halves. Hot Plate Welding Design Guidelines.

From www.vimalgroup.co.in

Hot Plate Welding Hot Plate Welding Design Guidelines Minimize welding angles as much as possible (max recommended 30 degrees); A flat weld plane normal to the direction of pressure is ideal. Hot plate welding is widely used for the most challenging materials and large part assembly with high strength and hermetic requirements. A weld rib or bead on each component is brought into contact with the. The process. Hot Plate Welding Design Guidelines.

From www.global-plastics.com

Hot Plate Welding Hot Plate Welding Design Guidelines The process of hot plate welding uses a heated platen to melt the joining surfaces of the two halves of a thermoplastic part. Once you have an initial design, you should have a hot plate welding expert like extol check it and. A weld rib or bead on each component is brought into contact with the. Hot plate welding is. Hot Plate Welding Design Guidelines.

From www.youtube.com

HotPlate Welding Precise, High Speed YouTube Hot Plate Welding Design Guidelines Once you have an initial design, you should have a hot plate welding expert like extol check it and. The part halves are brought into contact with a precisely heated platen. A flat weld plane normal to the direction of pressure is ideal. Minimize welding angles as much as possible (max recommended 30 degrees); A weld rib or bead on. Hot Plate Welding Design Guidelines.

From www.extolinc.com

HotPlate Welding For Strong, Sealed Parts EXTOL, INC. Hot Plate Welding Design Guidelines Minimize welding angles as much as possible (max recommended 30 degrees); Once you have an initial design, you should have a hot plate welding expert like extol check it and. The 0.030 material displacement per side includes 0.015. A flat weld plane normal to the direction of pressure is ideal. Typical total material displacement is 0.060. Welding processes that have. Hot Plate Welding Design Guidelines.

From www.extolinc.com

HotPlate Welding Design Guidelines EXTOL, INC. Hot Plate Welding Design Guidelines A weld rib or bead on each component is brought into contact with the. Minimize welding angles as much as possible (max recommended 30 degrees); Hot plate welding joint designs: The process of hot plate welding uses a heated platen to melt the joining surfaces of the two halves of a thermoplastic part. The part halves are brought into contact. Hot Plate Welding Design Guidelines.

From dizosonics.com

PP auto carbon canister box hot plate welding machine Hot Plate Welding Design Guidelines The part halves are brought into contact with a precisely heated platen. Welding processes that have had significant developments or improvements over the last few years. Once you have an initial design, you should have a hot plate welding expert like extol check it and. Minimize welding angles as much as possible (max recommended 30 degrees); Hot plate welding is. Hot Plate Welding Design Guidelines.

From www.ibortech.com

Hot Platen WeldingIbortech Machinery Technology Hot Plate Welding Design Guidelines The 0.030 material displacement per side includes 0.015. Welding processes that have had significant developments or improvements over the last few years. Hot plate welding joint designs: Hot plate welding is widely used for the most challenging materials and large part assembly with high strength and hermetic requirements. Typical total material displacement is 0.060. A weld rib or bead on. Hot Plate Welding Design Guidelines.

From www.bielomatik.com

Hotplate welding by bielomatik Hot Plate Welding Design Guidelines A weld rib or bead on each component is brought into contact with the. The part halves are brought into contact with a precisely heated platen. A flat weld plane normal to the direction of pressure is ideal. Hot plate welding joint designs: The process of hot plate welding uses a heated platen to melt the joining surfaces of the. Hot Plate Welding Design Guidelines.

From www.ibortech.com

Hot Platen WeldingIbortech Machinery Technology Hot Plate Welding Design Guidelines The process of hot plate welding uses a heated platen to melt the joining surfaces of the two halves of a thermoplastic part. The part halves are brought into contact with a precisely heated platen. Hot plate welding is widely used for the most challenging materials and large part assembly with high strength and hermetic requirements. A flat weld plane. Hot Plate Welding Design Guidelines.

From www.extolinc.com

HotPlate Welding Design Guidelines EXTOL, INC. Hot Plate Welding Design Guidelines A flat weld plane normal to the direction of pressure is ideal. Hot plate welding is widely used for the most challenging materials and large part assembly with high strength and hermetic requirements. Once you have an initial design, you should have a hot plate welding expert like extol check it and. Hot plate welding joint designs: A weld rib. Hot Plate Welding Design Guidelines.

From www.assemblymag.com

HotPlate Welding vs. Infrared Welding for Plastics Assembly 201510 Hot Plate Welding Design Guidelines Hot plate welding joint designs: Minimize welding angles as much as possible (max recommended 30 degrees); A weld rib or bead on each component is brought into contact with the. The part halves are brought into contact with a precisely heated platen. A flat weld plane normal to the direction of pressure is ideal. Welding processes that have had significant. Hot Plate Welding Design Guidelines.

From www.mdpi.com

Materials Free FullText On the HotPlate Welding of Reactively Hot Plate Welding Design Guidelines Once you have an initial design, you should have a hot plate welding expert like extol check it and. Minimize welding angles as much as possible (max recommended 30 degrees); The process of hot plate welding uses a heated platen to melt the joining surfaces of the two halves of a thermoplastic part. The part halves are brought into contact. Hot Plate Welding Design Guidelines.

From sonictech.urr.kr

Hot Plate Welding SONICTECH Hot Plate Welding Design Guidelines Welding processes that have had significant developments or improvements over the last few years. A weld rib or bead on each component is brought into contact with the. Typical total material displacement is 0.060. Once you have an initial design, you should have a hot plate welding expert like extol check it and. Hot plate welding joint designs: The 0.030. Hot Plate Welding Design Guidelines.

From www.youtube.com

EPE Hot Welding Machine Foam Hot Plate Welding Machine Automatic Hot Plate Welding Design Guidelines A flat weld plane normal to the direction of pressure is ideal. A weld rib or bead on each component is brought into contact with the. The process of hot plate welding uses a heated platen to melt the joining surfaces of the two halves of a thermoplastic part. The part halves are brought into contact with a precisely heated. Hot Plate Welding Design Guidelines.

From www.extolinc.com

HotPlate Welding For Strong, Sealed Parts EXTOL, INC. Hot Plate Welding Design Guidelines The part halves are brought into contact with a precisely heated platen. Typical total material displacement is 0.060. Welding processes that have had significant developments or improvements over the last few years. The 0.030 material displacement per side includes 0.015. The process of hot plate welding uses a heated platen to melt the joining surfaces of the two halves of. Hot Plate Welding Design Guidelines.

From www.heatstaking.com

Hot Plate Welding Hot Plate Welding Design Guidelines Typical total material displacement is 0.060. The process of hot plate welding uses a heated platen to melt the joining surfaces of the two halves of a thermoplastic part. The part halves are brought into contact with a precisely heated platen. A weld rib or bead on each component is brought into contact with the. Once you have an initial. Hot Plate Welding Design Guidelines.

From bteplastics.com

Hot Plate Welding Services Custom Plastic Welded Parts Hot Plate Welding Design Guidelines Hot plate welding joint designs: Once you have an initial design, you should have a hot plate welding expert like extol check it and. Hot plate welding is widely used for the most challenging materials and large part assembly with high strength and hermetic requirements. The 0.030 material displacement per side includes 0.015. Typical total material displacement is 0.060. Welding. Hot Plate Welding Design Guidelines.

From preview.bnpmedia.com

Hot Plate Welding Hot Plate Welding Design Guidelines Once you have an initial design, you should have a hot plate welding expert like extol check it and. A flat weld plane normal to the direction of pressure is ideal. The 0.030 material displacement per side includes 0.015. Hot plate welding is widely used for the most challenging materials and large part assembly with high strength and hermetic requirements.. Hot Plate Welding Design Guidelines.

From hotplateweldingmachine.com

Home Chinese Leading Manufacturer of Hot Plate Welding Machine Hot Plate Welding Design Guidelines A weld rib or bead on each component is brought into contact with the. Hot plate welding is widely used for the most challenging materials and large part assembly with high strength and hermetic requirements. Welding processes that have had significant developments or improvements over the last few years. The part halves are brought into contact with a precisely heated. Hot Plate Welding Design Guidelines.

From steelexplained.com

Steel Connections Design Guidelines Hot Plate Welding Design Guidelines The 0.030 material displacement per side includes 0.015. Once you have an initial design, you should have a hot plate welding expert like extol check it and. Typical total material displacement is 0.060. Hot plate welding joint designs: The part halves are brought into contact with a precisely heated platen. The process of hot plate welding uses a heated platen. Hot Plate Welding Design Guidelines.

From www.heatstaking.com

Home Plastic Assembly Systems Hot Plate Welding Design Guidelines Once you have an initial design, you should have a hot plate welding expert like extol check it and. The 0.030 material displacement per side includes 0.015. Welding processes that have had significant developments or improvements over the last few years. Minimize welding angles as much as possible (max recommended 30 degrees); The process of hot plate welding uses a. Hot Plate Welding Design Guidelines.

From www.extolinc.com

Laser Welding Design Guidelines EXTOL, INC. Hot Plate Welding Design Guidelines A weld rib or bead on each component is brought into contact with the. Hot plate welding is widely used for the most challenging materials and large part assembly with high strength and hermetic requirements. Hot plate welding joint designs: Once you have an initial design, you should have a hot plate welding expert like extol check it and. Minimize. Hot Plate Welding Design Guidelines.

From www.aminaappliances.in

Electrical Earthing Methods And Types Of Earthing Grounding, 40 OFF Hot Plate Welding Design Guidelines A weld rib or bead on each component is brought into contact with the. Once you have an initial design, you should have a hot plate welding expert like extol check it and. A flat weld plane normal to the direction of pressure is ideal. The process of hot plate welding uses a heated platen to melt the joining surfaces. Hot Plate Welding Design Guidelines.

From www.researchgate.net

Schematic view of hot plate welding equipment and some of the process Hot Plate Welding Design Guidelines The part halves are brought into contact with a precisely heated platen. A flat weld plane normal to the direction of pressure is ideal. Hot plate welding is widely used for the most challenging materials and large part assembly with high strength and hermetic requirements. Welding processes that have had significant developments or improvements over the last few years. Typical. Hot Plate Welding Design Guidelines.

From digitaledition.assemblymag.com

Hot Plate Welding Hot Plate Welding Design Guidelines Minimize welding angles as much as possible (max recommended 30 degrees); A weld rib or bead on each component is brought into contact with the. The part halves are brought into contact with a precisely heated platen. Hot plate welding is widely used for the most challenging materials and large part assembly with high strength and hermetic requirements. Typical total. Hot Plate Welding Design Guidelines.

From www.semanticscholar.org

Figure 1 from Process Analysis of the Hot Plate Welding of Drive Belts Hot Plate Welding Design Guidelines Once you have an initial design, you should have a hot plate welding expert like extol check it and. The part halves are brought into contact with a precisely heated platen. Typical total material displacement is 0.060. Minimize welding angles as much as possible (max recommended 30 degrees); A weld rib or bead on each component is brought into contact. Hot Plate Welding Design Guidelines.

From www.pinterest.com

EPE Hot Plate Welding Machine Foam Inserts Laminating Machine Hot Plate Welding Design Guidelines The process of hot plate welding uses a heated platen to melt the joining surfaces of the two halves of a thermoplastic part. A weld rib or bead on each component is brought into contact with the. The 0.030 material displacement per side includes 0.015. The part halves are brought into contact with a precisely heated platen. Hot plate welding. Hot Plate Welding Design Guidelines.

From www.assemblymag.com

HotPlate Welding vs. Infrared Welding for Plastics Assembly 201510 Hot Plate Welding Design Guidelines A flat weld plane normal to the direction of pressure is ideal. The part halves are brought into contact with a precisely heated platen. The 0.030 material displacement per side includes 0.015. Once you have an initial design, you should have a hot plate welding expert like extol check it and. The process of hot plate welding uses a heated. Hot Plate Welding Design Guidelines.

From www.youtube.com

HotPlate Welding a 3D Printed Bottle YouTube Hot Plate Welding Design Guidelines Typical total material displacement is 0.060. A flat weld plane normal to the direction of pressure is ideal. Once you have an initial design, you should have a hot plate welding expert like extol check it and. Welding processes that have had significant developments or improvements over the last few years. The part halves are brought into contact with a. Hot Plate Welding Design Guidelines.

From plasticsmoulds.blogspot.com

Plastics Knowledge Hot Plate Welding Hot Plate Welding Design Guidelines The process of hot plate welding uses a heated platen to melt the joining surfaces of the two halves of a thermoplastic part. Hot plate welding is widely used for the most challenging materials and large part assembly with high strength and hermetic requirements. Hot plate welding joint designs: Minimize welding angles as much as possible (max recommended 30 degrees);. Hot Plate Welding Design Guidelines.

From www.bielomatik.com

Hotplate welding by bielomatik Hot Plate Welding Design Guidelines A weld rib or bead on each component is brought into contact with the. The part halves are brought into contact with a precisely heated platen. Hot plate welding is widely used for the most challenging materials and large part assembly with high strength and hermetic requirements. Once you have an initial design, you should have a hot plate welding. Hot Plate Welding Design Guidelines.