Condensing Steam . — steam condensers are critical components in both power generation and industrial processes, serving the primary function of condensing exhaust steam from a steam turbine into water. The heat released when condensing steam can be. a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an external. During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. Condensation can be done by removing heat from exhaust steam using circulating cooling water. Heat transfer when steam condensates. — condensing steam in a closed system reduces its volume, creates a vacuum, and lowers the outlet pressure at. steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. the condenser acts as a heat exchanger where exchange of heat occurs between steam and cold circulating water. By converting steam to liquid form, condensers help maintain low turbine back pressure and facilitate the reuse of water, thereby enhancing the overall efficiency.

from www.watco-group.co

Condensation can be done by removing heat from exhaust steam using circulating cooling water. steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. — steam condensers are critical components in both power generation and industrial processes, serving the primary function of condensing exhaust steam from a steam turbine into water. the condenser acts as a heat exchanger where exchange of heat occurs between steam and cold circulating water. — condensing steam in a closed system reduces its volume, creates a vacuum, and lowers the outlet pressure at. During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. The heat released when condensing steam can be. a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an external. Heat transfer when steam condensates. By converting steam to liquid form, condensers help maintain low turbine back pressure and facilitate the reuse of water, thereby enhancing the overall efficiency.

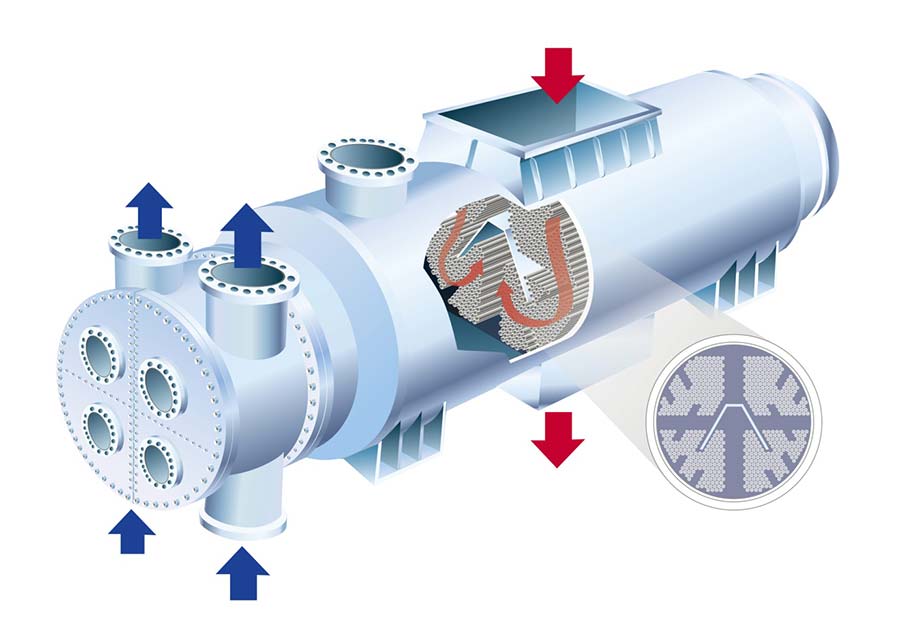

Surface Condenser in Thermal Power Plant Watco Group

Condensing Steam the condenser acts as a heat exchanger where exchange of heat occurs between steam and cold circulating water. the condenser acts as a heat exchanger where exchange of heat occurs between steam and cold circulating water. Condensation can be done by removing heat from exhaust steam using circulating cooling water. By converting steam to liquid form, condensers help maintain low turbine back pressure and facilitate the reuse of water, thereby enhancing the overall efficiency. — steam condensers are critical components in both power generation and industrial processes, serving the primary function of condensing exhaust steam from a steam turbine into water. During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. — condensing steam in a closed system reduces its volume, creates a vacuum, and lowers the outlet pressure at. Heat transfer when steam condensates. steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an external. The heat released when condensing steam can be.

From www.watco-group.co

Surface Condenser in Thermal Power Plant Watco Group Condensing Steam the condenser acts as a heat exchanger where exchange of heat occurs between steam and cold circulating water. steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. The heat released when condensing steam can be. — condensing steam in a closed system reduces its volume, creates. Condensing Steam.

From www.slideserve.com

PPT Design &Types of Steam Turbines PowerPoint Presentation ID5327050 Condensing Steam Condensation can be done by removing heat from exhaust steam using circulating cooling water. By converting steam to liquid form, condensers help maintain low turbine back pressure and facilitate the reuse of water, thereby enhancing the overall efficiency. — steam condensers are critical components in both power generation and industrial processes, serving the primary function of condensing exhaust steam. Condensing Steam.

From www.youtube.com

Operation Animation SR Steam Condensing Heat Exchanger YouTube Condensing Steam By converting steam to liquid form, condensers help maintain low turbine back pressure and facilitate the reuse of water, thereby enhancing the overall efficiency. — condensing steam in a closed system reduces its volume, creates a vacuum, and lowers the outlet pressure at. During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent. Condensing Steam.

From www.mechanicalbooster.com

What is Steam Condenser Complete Explanation Mechanical Booster Condensing Steam steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. By converting steam to liquid form, condensers help maintain low turbine back pressure and facilitate the reuse of water, thereby enhancing the overall efficiency. a condensing steam turbine is provided with a vacuum device at its exit (the. Condensing Steam.

From jetflowtechnologies.com

Steam Condenser Manufacturer Surface Condenser manufacturer Condensing Steam During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an external. Heat transfer when steam condensates. The heat released when condensing steam can be. —. Condensing Steam.

From mechanicaljungle.com

What Is Steam Condenser? Steam Condenser Working Principle of Steam Condensing Steam Condensation can be done by removing heat from exhaust steam using circulating cooling water. By converting steam to liquid form, condensers help maintain low turbine back pressure and facilitate the reuse of water, thereby enhancing the overall efficiency. — steam condensers are critical components in both power generation and industrial processes, serving the primary function of condensing exhaust steam. Condensing Steam.

From electricala2z.com

Combined Heat and Power Plants Steam, Gas, Micro Turbine, Fuel Cell Condensing Steam — condensing steam in a closed system reduces its volume, creates a vacuum, and lowers the outlet pressure at. a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an external. During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat. Condensing Steam.

From mechanicaljungle.com

What Is Steam Condenser? Steam Condenser Working Principle of Steam Condensing Steam a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an external. — condensing steam in a closed system reduces its volume, creates a vacuum, and lowers the outlet pressure at. By converting steam to liquid form, condensers help maintain low turbine back pressure and facilitate the reuse. Condensing Steam.

From mechanicaljungle.com

What Is Steam Condenser? Steam Condenser Working Principle of Steam Condensing Steam The heat released when condensing steam can be. Heat transfer when steam condensates. the condenser acts as a heat exchanger where exchange of heat occurs between steam and cold circulating water. During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. Condensation can be done by removing. Condensing Steam.

From www.researchgate.net

20MW, 15 stages, condensing steam turbine with dismounted rotor [13 Condensing Steam Condensation can be done by removing heat from exhaust steam using circulating cooling water. During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. By converting steam to liquid form, condensers help maintain low turbine back pressure and facilitate the reuse of water, thereby enhancing the overall efficiency.. Condensing Steam.

From www.youtube.com

Steam Condenser YouTube Condensing Steam Heat transfer when steam condensates. a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an external. the condenser acts as a heat exchanger where exchange of heat occurs between steam and cold circulating water. — steam condensers are critical components in both power generation and industrial. Condensing Steam.

From farad.gr

Steam Condensers Farad S.A. Condensing Steam Heat transfer when steam condensates. During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. The heat released when condensing steam can be. a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an external. Condensation can. Condensing Steam.

From savree.com

Surface Condenser Explained saVRee Condensing Steam By converting steam to liquid form, condensers help maintain low turbine back pressure and facilitate the reuse of water, thereby enhancing the overall efficiency. — steam condensers are critical components in both power generation and industrial processes, serving the primary function of condensing exhaust steam from a steam turbine into water. the condenser acts as a heat exchanger. Condensing Steam.

From www.theengineerspost.com

Steam Condenser Types, Working Principle, Advantages [PDF] Condensing Steam By converting steam to liquid form, condensers help maintain low turbine back pressure and facilitate the reuse of water, thereby enhancing the overall efficiency. Condensation can be done by removing heat from exhaust steam using circulating cooling water. a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an. Condensing Steam.

From www.cnboilers.net

Automatic WNS Series Oil Gas Fired Condensing Steam Boiler Condensing Steam Condensation can be done by removing heat from exhaust steam using circulating cooling water. — steam condensers are critical components in both power generation and industrial processes, serving the primary function of condensing exhaust steam from a steam turbine into water. — condensing steam in a closed system reduces its volume, creates a vacuum, and lowers the outlet. Condensing Steam.

From www.researchgate.net

Thermodynamic system diagram of condensing steam turbine. Download Condensing Steam — steam condensers are critical components in both power generation and industrial processes, serving the primary function of condensing exhaust steam from a steam turbine into water. — condensing steam in a closed system reduces its volume, creates a vacuum, and lowers the outlet pressure at. By converting steam to liquid form, condensers help maintain low turbine back. Condensing Steam.

From www.linquip.com

Steam Condenser Basics, Parts, Advantages, and Disadvantages Condensing Steam — steam condensers are critical components in both power generation and industrial processes, serving the primary function of condensing exhaust steam from a steam turbine into water. steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. the condenser acts as a heat exchanger where exchange of. Condensing Steam.

From dizz.com

Steam Condenser Definition, Functions, Working Principle, 7 Types Condensing Steam a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an external. Condensation can be done by removing heat from exhaust steam using circulating cooling water. — condensing steam in a closed system reduces its volume, creates a vacuum, and lowers the outlet pressure at. the condenser. Condensing Steam.

From www.theengineerspost.com

Steam Condenser Types, Working Principle, Advantages [PDF] Condensing Steam a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an external. the condenser acts as a heat exchanger where exchange of heat occurs between steam and cold circulating water. During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as. Condensing Steam.

From mechanicaljungle.com

What Is Steam Condenser? Steam Condenser Working Principle of Steam Condensing Steam a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an external. Heat transfer when steam condensates. — steam condensers are critical components in both power generation and industrial processes, serving the primary function of condensing exhaust steam from a steam turbine into water. — condensing steam. Condensing Steam.

From www.oshima.com.tw

Condensing Steam Excellence Cuttingedge garment solutions for your Condensing Steam — steam condensers are critical components in both power generation and industrial processes, serving the primary function of condensing exhaust steam from a steam turbine into water. a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an external. — condensing steam in a closed system reduces. Condensing Steam.

From mechanicaljungle.com

What Is Steam Condenser? Steam Condenser Working Principle of Steam Condensing Steam During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. The heat released when condensing steam can be. a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an external. the condenser acts as a heat. Condensing Steam.

From www.jetflowtechnologies.com

Steam Condensing System Manufacturer Steam Condenser manufacturer Condensing Steam a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an external. By converting steam to liquid form, condensers help maintain low turbine back pressure and facilitate the reuse of water, thereby enhancing the overall efficiency. — condensing steam in a closed system reduces its volume, creates a. Condensing Steam.

From www.jetflowtechnologies.com

Steam Condensing System Manufacturer Steam Condenser manufacturer Condensing Steam Heat transfer when steam condensates. — condensing steam in a closed system reduces its volume, creates a vacuum, and lowers the outlet pressure at. Condensation can be done by removing heat from exhaust steam using circulating cooling water. — steam condensers are critical components in both power generation and industrial processes, serving the primary function of condensing exhaust. Condensing Steam.

From www.slideserve.com

PPT Steam Condenser I PowerPoint Presentation, free download ID5340720 Condensing Steam — steam condensers are critical components in both power generation and industrial processes, serving the primary function of condensing exhaust steam from a steam turbine into water. Condensation can be done by removing heat from exhaust steam using circulating cooling water. Heat transfer when steam condensates. the condenser acts as a heat exchanger where exchange of heat occurs. Condensing Steam.

From www.theengineerspost.com

Steam Condenser Types, Working Principle, Advantages [PDF] Condensing Steam Condensation can be done by removing heat from exhaust steam using circulating cooling water. — condensing steam in a closed system reduces its volume, creates a vacuum, and lowers the outlet pressure at. a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an external. the condenser. Condensing Steam.

From www.steamturbo.net

Double Extraction Condensing Steam Turbine Condensing Steam Condensation can be done by removing heat from exhaust steam using circulating cooling water. — steam condensers are critical components in both power generation and industrial processes, serving the primary function of condensing exhaust steam from a steam turbine into water. Heat transfer when steam condensates. steam condensers are devices in which the exhaust steam from the steam. Condensing Steam.

From www.ge.com

Condenser GE Steam Power Condensing Steam The heat released when condensing steam can be. a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an external. — condensing steam in a closed system reduces its volume, creates a vacuum, and lowers the outlet pressure at. Heat transfer when steam condensates. Condensation can be done. Condensing Steam.

From www.watco-group.co

Surface Condenser in Thermal Power Plant Watco Group Condensing Steam the condenser acts as a heat exchanger where exchange of heat occurs between steam and cold circulating water. — steam condensers are critical components in both power generation and industrial processes, serving the primary function of condensing exhaust steam from a steam turbine into water. Heat transfer when steam condensates. Condensation can be done by removing heat from. Condensing Steam.

From www.jetflowtechnologies.com

Steam Condenser Manufacturer Surface Condenser manufacturer Condensing Steam — steam condensers are critical components in both power generation and industrial processes, serving the primary function of condensing exhaust steam from a steam turbine into water. steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. By converting steam to liquid form, condensers help maintain low turbine. Condensing Steam.

From www.nuclear-power.com

Condensing Steam Turbine Characteristics Condensing Steam The heat released when condensing steam can be. During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an external. Condensation can be done by removing heat. Condensing Steam.

From mepacademy.com

Steam Heating System Basics MEP Academy Condensing Steam the condenser acts as a heat exchanger where exchange of heat occurs between steam and cold circulating water. Heat transfer when steam condensates. a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an external. — condensing steam in a closed system reduces its volume, creates a. Condensing Steam.

From www.engineeringchoice.com

What Is Steam Condenser? Parts, Working, And Types Condensing Steam The heat released when condensing steam can be. a condensing steam turbine is provided with a vacuum device at its exit (the condenser) where the forced flow of an external. — condensing steam in a closed system reduces its volume, creates a vacuum, and lowers the outlet pressure at. — steam condensers are critical components in both. Condensing Steam.

From www.theengineerspost.com

Steam Condenser Types, Working Principle, Advantages [PDF] Condensing Steam steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. — steam condensers are critical components in both power generation and industrial processes, serving the primary function of condensing exhaust steam from a steam turbine into water. the condenser acts as a heat exchanger where exchange of. Condensing Steam.

From www.yxboiler-factory.com

Buying Condensing Steam Boiler For Your Industry Is It Worth It Condensing Steam Condensation can be done by removing heat from exhaust steam using circulating cooling water. The heat released when condensing steam can be. By converting steam to liquid form, condensers help maintain low turbine back pressure and facilitate the reuse of water, thereby enhancing the overall efficiency. During condensation, the working substance (steam) changes its phase from vapour to liquid and. Condensing Steam.