Axle Adjustment Procedure . The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). Lubricate the wheel bearing with clean lubricant of the same type used in the. Wheel bearing adjustment step 1. “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a guide to any supplier that would develop systems for setting wheel. When the races come closer together, the balls come in contact with the outer races. It represents the combined input. It represents the combined input of manufacturers of wheel end components. Adjustment recommendation was developed by tmc’s wheel end task force.

from www.hunter.com

Wheel bearing adjustment step 1. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). Lubricate the wheel bearing with clean lubricant of the same type used in the. It represents the combined input. When the races come closer together, the balls come in contact with the outer races. Adjustment recommendation was developed by tmc’s wheel end task force. It represents the combined input of manufacturers of wheel end components. “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a guide to any supplier that would develop systems for setting wheel.

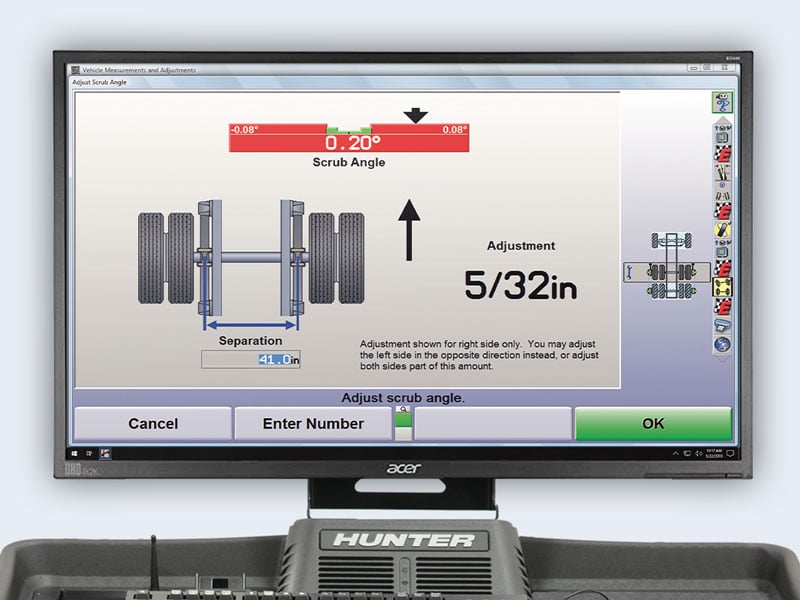

HeavyDuty Alignment Machine Hunter Engineering Company®

Axle Adjustment Procedure When the races come closer together, the balls come in contact with the outer races. Wheel bearing adjustment step 1. It represents the combined input. When the races come closer together, the balls come in contact with the outer races. Lubricate the wheel bearing with clean lubricant of the same type used in the. Adjustment recommendation was developed by tmc’s wheel end task force. It represents the combined input of manufacturers of wheel end components. “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a guide to any supplier that would develop systems for setting wheel. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm).

From www.autozone.com

Repair Guides Rear Axle Fullfloating Axle Rear Wheel Bearings Axle Adjustment Procedure It represents the combined input. Wheel bearing adjustment step 1. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). When the races come closer together, the balls come in contact with the outer races. Lubricate the wheel bearing with clean lubricant of the same type used. Axle Adjustment Procedure.

From www.youtube.com

105 2009 flh primary repair chain conversion axle adjustment fix 96ci Axle Adjustment Procedure Wheel bearing adjustment step 1. Lubricate the wheel bearing with clean lubricant of the same type used in the. It represents the combined input of manufacturers of wheel end components. When the races come closer together, the balls come in contact with the outer races. It represents the combined input. Adjustment recommendation was developed by tmc’s wheel end task force.. Axle Adjustment Procedure.

From motorgearrevs.com

AxleAdjustmentBlock Motorcycle Gear Reviews Axle Adjustment Procedure It represents the combined input of manufacturers of wheel end components. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). Lubricate the wheel bearing with clean lubricant of the same type used in the. “sae’s recommended procedure, j2535, provides target and maximum preload settings for class. Axle Adjustment Procedure.

From www.youtube.com

Horizontal Axle Adjustment YouTube Axle Adjustment Procedure Adjustment recommendation was developed by tmc’s wheel end task force. Wheel bearing adjustment step 1. It represents the combined input of manufacturers of wheel end components. When the races come closer together, the balls come in contact with the outer races. “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a. Axle Adjustment Procedure.

From www.youtube.com

Doonan® Slide Axle Adjustment Procedure Drop Deck Trailers YouTube Axle Adjustment Procedure Adjustment recommendation was developed by tmc’s wheel end task force. It represents the combined input. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). Wheel bearing adjustment step 1. “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles. Axle Adjustment Procedure.

From www.justanswer.com

Chevy 3500 Axle Nut Torque Q&A on GM Procedure & Specs JustAnswer Axle Adjustment Procedure Wheel bearing adjustment step 1. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). Adjustment recommendation was developed by tmc’s wheel end task force. Lubricate the wheel bearing with clean lubricant of the same type used in the. It represents the combined input. When the races. Axle Adjustment Procedure.

From www.youtube.com

Kubota BX Front Axle Adjustment YouTube Axle Adjustment Procedure It represents the combined input of manufacturers of wheel end components. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). Lubricate the wheel bearing with clean lubricant of the same type used in the. It represents the combined input. Wheel bearing adjustment step 1. When the. Axle Adjustment Procedure.

From www.youtube.com

Tips and Tricks for Thru Axle Rear Wheel Removal (Step by Step in 4K Axle Adjustment Procedure It represents the combined input. When the races come closer together, the balls come in contact with the outer races. Lubricate the wheel bearing with clean lubricant of the same type used in the. “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a guide to any supplier that would develop. Axle Adjustment Procedure.

From www.youtube.com

RV Trailer Axle Straightning and Alignment YouTube Axle Adjustment Procedure The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). When the races come closer together, the balls come in contact with the outer races. “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a guide to any. Axle Adjustment Procedure.

From www.autozone.com

Repair Guides Rear Axle Identification Axle Adjustment Procedure Lubricate the wheel bearing with clean lubricant of the same type used in the. When the races come closer together, the balls come in contact with the outer races. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). It represents the combined input of manufacturers of. Axle Adjustment Procedure.

From www.hunter.com

HeavyDuty Alignment Machine Hunter Engineering Company® Axle Adjustment Procedure The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). Wheel bearing adjustment step 1. “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a guide to any supplier that would develop systems for setting wheel. When the. Axle Adjustment Procedure.

From www.youtube.com

Motus Tech Tips Chain & Axle Adjustment YouTube Axle Adjustment Procedure Wheel bearing adjustment step 1. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). Adjustment recommendation was developed by tmc’s wheel end task force. When the races come closer together, the balls come in contact with the outer races. Lubricate the wheel bearing with clean lubricant. Axle Adjustment Procedure.

From www.youtube.com

Installing an Eaton advantage clutch YouTube Axle Adjustment Procedure Wheel bearing adjustment step 1. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). It represents the combined input. It represents the combined input of manufacturers of wheel end components. When the races come closer together, the balls come in contact with the outer races. “sae’s. Axle Adjustment Procedure.

From jtsjunkyard.blogspot.com

the cynical gearhead 8 3/4 rearend rebuild Part III Axle Adjustment Procedure It represents the combined input of manufacturers of wheel end components. Wheel bearing adjustment step 1. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a guide to. Axle Adjustment Procedure.

From www.youtube.com

Jeep TJ Rear Axle Clunking!? + Wheel Bearing Diagnosis and Hand Brake Axle Adjustment Procedure The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). It represents the combined input of manufacturers of wheel end components. Lubricate the wheel bearing with clean lubricant of the same type used in the. When the races come closer together, the balls come in contact with. Axle Adjustment Procedure.

From www.autozone.com

Repair Guides Rear Axle Axle Shaft, Bearing And Seal Axle Adjustment Procedure The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a guide to any supplier that would develop systems for setting wheel. It represents the combined input. Adjustment recommendation. Axle Adjustment Procedure.

From site.petitrc.com

Team Associated Axle Height Adjustment Reference Chart by Ray Munday Axle Adjustment Procedure “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a guide to any supplier that would develop systems for setting wheel. Adjustment recommendation was developed by tmc’s wheel end task force. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025. Axle Adjustment Procedure.

From www.youtube.com

Motorcycle Chain Maintenance Slack and axle adjustment YouTube Axle Adjustment Procedure It represents the combined input of manufacturers of wheel end components. It represents the combined input. Wheel bearing adjustment step 1. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). Lubricate the wheel bearing with clean lubricant of the same type used in the. “sae’s recommended. Axle Adjustment Procedure.

From www.youtube.com

Truck Alignment Axle Adjustment YouTube Axle Adjustment Procedure Adjustment recommendation was developed by tmc’s wheel end task force. It represents the combined input. It represents the combined input of manufacturers of wheel end components. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). Lubricate the wheel bearing with clean lubricant of the same type. Axle Adjustment Procedure.

From www.jeepfan.com

Installing Camber Adjustment Shims Dana 30 and Dana 44 Front Axle Axle Adjustment Procedure “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a guide to any supplier that would develop systems for setting wheel. It represents the combined input. Lubricate the wheel bearing with clean lubricant of the same type used in the. The goal of this recommended procedure is to achieve a verifiable. Axle Adjustment Procedure.

From manualzz.com

Click here to view Stemco's bearing adjustment procedure Axle Adjustment Procedure Adjustment recommendation was developed by tmc’s wheel end task force. “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a guide to any supplier that would develop systems for setting wheel. It represents the combined input of manufacturers of wheel end components. Lubricate the wheel bearing with clean lubricant of the. Axle Adjustment Procedure.

From www.youtube.com

Part 2 How To Replace Rear Axle Bearings and Seals for the Jeep Grand Axle Adjustment Procedure Adjustment recommendation was developed by tmc’s wheel end task force. It represents the combined input. Wheel bearing adjustment step 1. It represents the combined input of manufacturers of wheel end components. “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a guide to any supplier that would develop systems for setting. Axle Adjustment Procedure.

From www.dieselworldmag.com

11.5 AAM Rear Axle Best Aftermarket Products Diesel World Axle Adjustment Procedure “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a guide to any supplier that would develop systems for setting wheel. When the races come closer together, the balls come in contact with the outer races. Wheel bearing adjustment step 1. Adjustment recommendation was developed by tmc’s wheel end task force.. Axle Adjustment Procedure.

From www.jbmcamp.com

BALANCE AXLE ADJUSTMENT KIT JAGUAR/LAND ROVER 2.0D JBM Axle Adjustment Procedure It represents the combined input. Adjustment recommendation was developed by tmc’s wheel end task force. Wheel bearing adjustment step 1. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). It represents the combined input of manufacturers of wheel end components. When the races come closer together,. Axle Adjustment Procedure.

From www.jeepfan.com

Installing Camber Adjustment Shims Dana 30 and Dana 44 Front Axle Axle Adjustment Procedure Lubricate the wheel bearing with clean lubricant of the same type used in the. It represents the combined input of manufacturers of wheel end components. Adjustment recommendation was developed by tmc’s wheel end task force. When the races come closer together, the balls come in contact with the outer races. The goal of this recommended procedure is to achieve a. Axle Adjustment Procedure.

From postureinfohub.com

How To Raise A Trailer Height? PostureInfoHub Axle Adjustment Procedure Wheel bearing adjustment step 1. It represents the combined input. “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a guide to any supplier that would develop systems for setting wheel. When the races come closer together, the balls come in contact with the outer races. Adjustment recommendation was developed by. Axle Adjustment Procedure.

From www.youtube.com

How To Align Your Trailer Axles with Lippert Correct Track YouTube Axle Adjustment Procedure It represents the combined input of manufacturers of wheel end components. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). It represents the combined input. When the races come closer together, the balls come in contact with the outer races. Adjustment recommendation was developed by tmc’s. Axle Adjustment Procedure.

From www.designjudges.com

A Guide To FSAE Axles — Axle Adjustment Procedure Wheel bearing adjustment step 1. Lubricate the wheel bearing with clean lubricant of the same type used in the. “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a guide to any supplier that would develop systems for setting wheel. The goal of this recommended procedure is to achieve a verifiable. Axle Adjustment Procedure.

From www.scribd.com

Adjustment Procedure For Heavy Duty Right Angle Drive Output Shaft Axle Adjustment Procedure It represents the combined input. Wheel bearing adjustment step 1. It represents the combined input of manufacturers of wheel end components. When the races come closer together, the balls come in contact with the outer races. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). “sae’s. Axle Adjustment Procedure.

From www.jeepfan.com

Dana 30 and Dana 44 Front Axle Toe Adjustment Axle Adjustment Procedure It represents the combined input of manufacturers of wheel end components. “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a guide to any supplier that would develop systems for setting wheel. Adjustment recommendation was developed by tmc’s wheel end task force. It represents the combined input. Lubricate the wheel bearing. Axle Adjustment Procedure.

From www.youtube.com

Beam Alignment, Wheelend Adjustment Ingersoll Axles YouTube Axle Adjustment Procedure It represents the combined input of manufacturers of wheel end components. Adjustment recommendation was developed by tmc’s wheel end task force. “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a guide to any supplier that would develop systems for setting wheel. Lubricate the wheel bearing with clean lubricant of the. Axle Adjustment Procedure.

From www.web.imperialclub.info

New Features for 1964 Rear Axle Axle Adjustment Procedure It represents the combined input. When the races come closer together, the balls come in contact with the outer races. Wheel bearing adjustment step 1. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). Adjustment recommendation was developed by tmc’s wheel end task force. Lubricate the. Axle Adjustment Procedure.

From www.nostalgiatech.co.uk

Rear Axle Overhaul Axle Adjustment Procedure The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). When the races come closer together, the balls come in contact with the outer races. Adjustment recommendation was developed by tmc’s wheel end task force. “sae’s recommended procedure, j2535, provides target and maximum preload settings for class. Axle Adjustment Procedure.

From www.youtube.com

Trailer Axle Bearing Adjustment Trick YouTube Axle Adjustment Procedure The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). It represents the combined input. Adjustment recommendation was developed by tmc’s wheel end task force. “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a guide to any. Axle Adjustment Procedure.

From bicycles.stackexchange.com

rear wheel Axle installation spacer placement / usage Bicycles Axle Adjustment Procedure Lubricate the wheel bearing with clean lubricant of the same type used in the. Adjustment recommendation was developed by tmc’s wheel end task force. “sae’s recommended procedure, j2535, provides target and maximum preload settings for class 8 tractor and trailer axles as a guide to any supplier that would develop systems for setting wheel. It represents the combined input of. Axle Adjustment Procedure.