Copper Plate Bend Radius . Finding the minimum bend radius for steel or aluminum plate requires a little research. In steel between 0.5 and 0.8 in. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). Use xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects If the plate thickness is less than 6mm, the bending radius. A simple and rough method to determine the bending radius is: Navigate your projects seamlessly with our comprehensive 90° bend radius chart. Learn how to bend metal and about bending steel plate and aluminum. It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Learn about them to avoid issues during your design process.

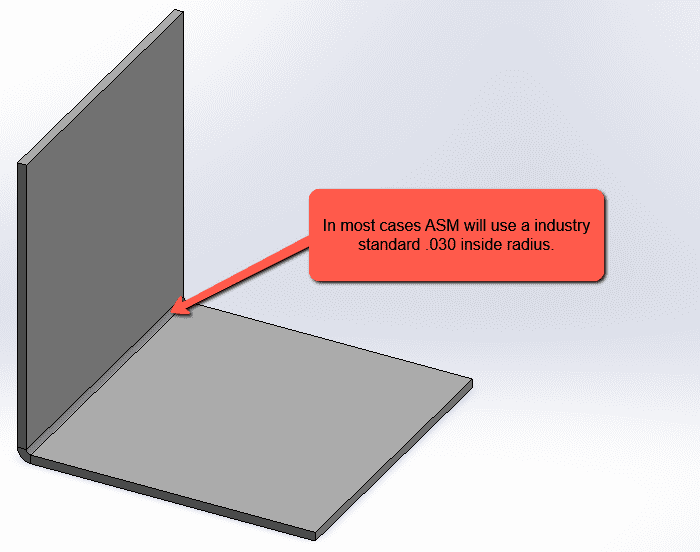

from www.approvedsheetmetal.com

Learn how to bend metal and about bending steel plate and aluminum. A simple and rough method to determine the bending radius is: If the plate thickness is less than 6mm, the bending radius. In steel between 0.5 and 0.8 in. Learn about them to avoid issues during your design process. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). Navigate your projects seamlessly with our comprehensive 90° bend radius chart. Use xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects Finding the minimum bend radius for steel or aluminum plate requires a little research. It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii.

Sheet Metal Bend Radius Best Practices (Updated for 2024) ASM

Copper Plate Bend Radius A simple and rough method to determine the bending radius is: If the plate thickness is less than 6mm, the bending radius. Use xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects Navigate your projects seamlessly with our comprehensive 90° bend radius chart. Learn how to bend metal and about bending steel plate and aluminum. In steel between 0.5 and 0.8 in. Learn about them to avoid issues during your design process. It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Finding the minimum bend radius for steel or aluminum plate requires a little research. A simple and rough method to determine the bending radius is: Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1).

From www.youtube.com

SolidWorks Tutorial Sheet Metal Part Design Bend Allowance YouTube Copper Plate Bend Radius A simple and rough method to determine the bending radius is: If the plate thickness is less than 6mm, the bending radius. Use xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects Learn about them to avoid issues during your design process. Navigate your projects seamlessly with. Copper Plate Bend Radius.

From mavink.com

Sheet Metal Minimum Bend Radius Chart Copper Plate Bend Radius It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Learn about them to avoid issues during your design process. Finding the minimum bend radius for steel or aluminum plate requires a little research. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the. Copper Plate Bend Radius.

From www.hippobender.com

How To Design Pipe Bend Radius? Hippo Machinery Copper Plate Bend Radius In steel between 0.5 and 0.8 in. Use xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects Learn about them to avoid issues during your design process. If the plate thickness is less than 6mm, the bending radius. Thick, grade 350 and 400 may have a minimum. Copper Plate Bend Radius.

From mavink.com

Standard Pipe Bend Radius Chart Copper Plate Bend Radius Learn how to bend metal and about bending steel plate and aluminum. Learn about them to avoid issues during your design process. Finding the minimum bend radius for steel or aluminum plate requires a little research. It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Navigate your projects. Copper Plate Bend Radius.

From www.thefabricator.com

Predicting an airformed sheet metal inside bend radius Copper Plate Bend Radius If the plate thickness is less than 6mm, the bending radius. Learn how to bend metal and about bending steel plate and aluminum. Use xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects A simple and rough method to determine the bending radius is: Learn about them. Copper Plate Bend Radius.

From www.thefabricator.com

Minimum inside sheet metal bend radius vs what's Copper Plate Bend Radius Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn about them to avoid issues during your. Copper Plate Bend Radius.

From www.youtube.com

Making a Radius Bending Fixture for Sheetmetal YouTube Copper Plate Bend Radius A simple and rough method to determine the bending radius is: If the plate thickness is less than 6mm, the bending radius. Finding the minimum bend radius for steel or aluminum plate requires a little research. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may. Copper Plate Bend Radius.

From nomghost.weebly.com

Copper tube bending radius chart nomghost Copper Plate Bend Radius Navigate your projects seamlessly with our comprehensive 90° bend radius chart. In steel between 0.5 and 0.8 in. Learn about them to avoid issues during your design process. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times. Copper Plate Bend Radius.

From fractory.com

Sheet Metal Bending Design Tips, Bend Allowance, K Factor Fractory Copper Plate Bend Radius Finding the minimum bend radius for steel or aluminum plate requires a little research. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). Learn about them to avoid issues during your. Copper Plate Bend Radius.

From www.indiamart.com

Buttweld Copper U Bend, Bend Radius 3D at Rs 75/piece in New Delhi Copper Plate Bend Radius Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum. Learn about them to avoid issues during your design process. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may. Copper Plate Bend Radius.

From www.minifaber.com

Copper bending Minifaber Copper Plate Bend Radius In steel between 0.5 and 0.8 in. Use xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. A simple and rough method to determine the bending. Copper Plate Bend Radius.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Copper Plate Bend Radius A simple and rough method to determine the bending radius is: Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). In steel between 0.5 and 0.8 in. Learn how to bend. Copper Plate Bend Radius.

From nomghost.weebly.com

Copper tube bending radius chart nomghost Copper Plate Bend Radius Use xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects Learn how to bend metal and about bending steel plate and aluminum. A simple and rough method to determine the bending radius is: It is most economical to use a single bend radius throughout the design, but. Copper Plate Bend Radius.

From warret.weebly.com

Copper tube bending radius chart warret Copper Plate Bend Radius Navigate your projects seamlessly with our comprehensive 90° bend radius chart. In steel between 0.5 and 0.8 in. A simple and rough method to determine the bending radius is: Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75. Copper Plate Bend Radius.

From www.merchantsfabrication.com

Understanding Bend Tests & Radius Merchants Fabrication, Inc Copper Plate Bend Radius Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending. Copper Plate Bend Radius.

From metalscut4u.com

How To Bend Sheet Metal The Ultimate Guide Copper Plate Bend Radius Navigate your projects seamlessly with our comprehensive 90° bend radius chart. Learn how to bend metal and about bending steel plate and aluminum. If the plate thickness is less than 6mm, the bending radius. In steel between 0.5 and 0.8 in. Use xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for. Copper Plate Bend Radius.

From www.youtube.com

HOW TO BEND COPPER PIPE part 1 tutorial on how to bend copper tube 90 Copper Plate Bend Radius Learn how to bend metal and about bending steel plate and aluminum. Finding the minimum bend radius for steel or aluminum plate requires a little research. In steel between 0.5 and 0.8 in. Navigate your projects seamlessly with our comprehensive 90° bend radius chart. Learn about them to avoid issues during your design process. Use xometry reference tables for sheet. Copper Plate Bend Radius.

From learningdbpfeifer.z21.web.core.windows.net

Electrical Conduit Bend Radius Chart Copper Plate Bend Radius If the plate thickness is less than 6mm, the bending radius. Finding the minimum bend radius for steel or aluminum plate requires a little research. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness. Copper Plate Bend Radius.

From mavink.com

Sheet Metal Bend Chart Copper Plate Bend Radius A simple and rough method to determine the bending radius is: It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Learn about them to avoid issues during your design process. If the plate thickness is less than 6mm, the bending radius. Finding the minimum bend radius for steel. Copper Plate Bend Radius.

From www.indiamart.com

180 degree Copper Bend, For Plumbing Pipe, Bend Radius 3D at Rs 30 Copper Plate Bend Radius Finding the minimum bend radius for steel or aluminum plate requires a little research. In steel between 0.5 and 0.8 in. Learn about them to avoid issues during your design process. Navigate your projects seamlessly with our comprehensive 90° bend radius chart. Learn how to bend metal and about bending steel plate and aluminum. Thick, grade 350 and 400 may. Copper Plate Bend Radius.

From xometry.eu

Minimum Bend Radius Reference Table For Sheet Metal Xometry Europe Copper Plate Bend Radius Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn about them to avoid issues during your design process. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see. Copper Plate Bend Radius.

From www.approvedsheetmetal.com

Sheet Metal Bend Radius Best Practices (Updated for 2024) ASM Copper Plate Bend Radius A simple and rough method to determine the bending radius is: Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). If the plate thickness is less than 6mm, the bending radius.. Copper Plate Bend Radius.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Copper Plate Bend Radius Finding the minimum bend radius for steel or aluminum plate requires a little research. Navigate your projects seamlessly with our comprehensive 90° bend radius chart. If the plate thickness is less than 6mm, the bending radius. Learn how to bend metal and about bending steel plate and aluminum. Use xometry reference tables for sheet and aluminium to find out which. Copper Plate Bend Radius.

From exozzueaq.blob.core.windows.net

Sheet Metal Bend Radius Calculator at Horace Winfield blog Copper Plate Bend Radius Learn how to bend metal and about bending steel plate and aluminum. If the plate thickness is less than 6mm, the bending radius. It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. In steel between 0.5 and 0.8 in. Learn about them to avoid issues during your design. Copper Plate Bend Radius.

From www.smlease.com

Sheet Metal KFactor, Bend Allowance and Flat Length Calculations Copper Plate Bend Radius Navigate your projects seamlessly with our comprehensive 90° bend radius chart. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). In steel between 0.5 and 0.8 in. Learn about them to. Copper Plate Bend Radius.

From www.krrass.com

How Sheet Metal Bend Radius is Calculated Copper Plate Bend Radius It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. In steel between 0.5 and 0.8 in. A simple and rough method to determine the bending radius is: Learn how to bend metal and about bending steel plate and aluminum. Use xometry reference tables for sheet and aluminium to. Copper Plate Bend Radius.

From www.machinemfg.com

Bend Radius Chart (Steel, Aluminum & Copper) MachineMFG Copper Plate Bend Radius It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). A. Copper Plate Bend Radius.

From www.approvedsheetmetal.com

Sheet Metal Bend Radius Best Practices Approved Sheet Metal Copper Plate Bend Radius Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). If the plate thickness is less than 6mm, the bending radius. A simple and rough method to determine the bending radius is:. Copper Plate Bend Radius.

From web.solacesf.org

Rebar Bending Radius Chart Home Interior Design Copper Plate Bend Radius Use xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects Finding the minimum bend radius for steel or aluminum plate requires a little research. Navigate your projects seamlessly with our comprehensive 90° bend radius chart. Thick, grade 350 and 400 may have a minimum bend radius of. Copper Plate Bend Radius.

From mavink.com

Standard Pipe Bend Radius Chart Copper Plate Bend Radius Finding the minimum bend radius for steel or aluminum plate requires a little research. If the plate thickness is less than 6mm, the bending radius. In steel between 0.5 and 0.8 in. Use xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects Learn how to bend metal. Copper Plate Bend Radius.

From blog.thepipingmart.com

How to Easily Bend Copper Sheet An Overview Copper Plate Bend Radius Learn about them to avoid issues during your design process. It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. In steel between 0.5 and 0.8 in. Navigate your projects seamlessly with our comprehensive 90° bend radius chart. Use xometry reference tables for sheet and aluminium to find out. Copper Plate Bend Radius.

From www.thefabricator.com

Precision sheet metal bending and the V groove Copper Plate Bend Radius Learn about them to avoid issues during your design process. Finding the minimum bend radius for steel or aluminum plate requires a little research. Navigate your projects seamlessly with our comprehensive 90° bend radius chart. A simple and rough method to determine the bending radius is: Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times. Copper Plate Bend Radius.

From metalmaq.shop

Metal sheet bending table Copper Plate Bend Radius Finding the minimum bend radius for steel or aluminum plate requires a little research. In steel between 0.5 and 0.8 in. It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Navigate your projects seamlessly with our comprehensive 90° bend radius chart. A simple and rough method to determine. Copper Plate Bend Radius.

From www.reece.co.nz

Ardent Copper Bend High Pressure 50mm x 90 Degree x 1 Diameter Radius Copper Plate Bend Radius Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). If the plate thickness is less than 6mm, the bending radius. Learn about them to avoid issues during your design process. It. Copper Plate Bend Radius.

From blog.thepipingmart.com

How to Bend Copper Pipe 90 Degrees A StepByStep Guide Copper Plate Bend Radius In steel between 0.5 and 0.8 in. If the plate thickness is less than 6mm, the bending radius. Learn how to bend metal and about bending steel plate and aluminum. Learn about them to avoid issues during your design process. Navigate your projects seamlessly with our comprehensive 90° bend radius chart. Finding the minimum bend radius for steel or aluminum. Copper Plate Bend Radius.