Gage R&R How Many Parts . The appraisers measure the same set of parts in a randomized. A common standard for a continuous gr&r study is to use 10 parts, measured by 3 different people, 3 times each,. Repeatability is the variation between successive measurements of the same. What is a good gage r&r value?. Gage r&r focuses on two key aspects of measurement: Gage r&r, a critical tool in lean six sigma, is composed of two main components: Gage repeatability and reproducibility (gage r&r) is defined as the method to find how much of the process variation is due to the measurement equipment and measurement. Tips for a successful gage r&r. We’ll focus on the %contribution for gager&r, which tells us how much of the variation in your process can be attributed to your. Typically, these studies use two or three appraisers and 5 to 10 parts. A typical attribute gage r&r study involves multiple operators, parts, and repeated measurements of the same part by each.

from www.goskills.com

Gage r&r focuses on two key aspects of measurement: The appraisers measure the same set of parts in a randomized. Tips for a successful gage r&r. Typically, these studies use two or three appraisers and 5 to 10 parts. A common standard for a continuous gr&r study is to use 10 parts, measured by 3 different people, 3 times each,. A typical attribute gage r&r study involves multiple operators, parts, and repeated measurements of the same part by each. Gage r&r, a critical tool in lean six sigma, is composed of two main components: Repeatability is the variation between successive measurements of the same. We’ll focus on the %contribution for gager&r, which tells us how much of the variation in your process can be attributed to your. Gage repeatability and reproducibility (gage r&r) is defined as the method to find how much of the process variation is due to the measurement equipment and measurement.

The Basics of Gage R&R GoSkills

Gage R&R How Many Parts Repeatability is the variation between successive measurements of the same. A common standard for a continuous gr&r study is to use 10 parts, measured by 3 different people, 3 times each,. Gage repeatability and reproducibility (gage r&r) is defined as the method to find how much of the process variation is due to the measurement equipment and measurement. Gage r&r, a critical tool in lean six sigma, is composed of two main components: We’ll focus on the %contribution for gager&r, which tells us how much of the variation in your process can be attributed to your. A typical attribute gage r&r study involves multiple operators, parts, and repeated measurements of the same part by each. Repeatability is the variation between successive measurements of the same. Typically, these studies use two or three appraisers and 5 to 10 parts. The appraisers measure the same set of parts in a randomized. Gage r&r focuses on two key aspects of measurement: What is a good gage r&r value?. Tips for a successful gage r&r.

From www.sifo-medical.com

Conducting a Gage R&R Study with Minitab (Explained with a Practical Gage R&R How Many Parts Gage r&r focuses on two key aspects of measurement: Gage r&r, a critical tool in lean six sigma, is composed of two main components: What is a good gage r&r value?. Tips for a successful gage r&r. Gage repeatability and reproducibility (gage r&r) is defined as the method to find how much of the process variation is due to the. Gage R&R How Many Parts.

From www.talcottridge.com

Quick and Easy Continuous Variable Gage R&R Test Talcott Ridge Consulting Gage R&R How Many Parts Repeatability is the variation between successive measurements of the same. We’ll focus on the %contribution for gager&r, which tells us how much of the variation in your process can be attributed to your. Gage r&r focuses on two key aspects of measurement: Gage repeatability and reproducibility (gage r&r) is defined as the method to find how much of the process. Gage R&R How Many Parts.

From slideplayer.com

Gage R&R. ppt download Gage R&R How Many Parts A typical attribute gage r&r study involves multiple operators, parts, and repeated measurements of the same part by each. Repeatability is the variation between successive measurements of the same. Typically, these studies use two or three appraisers and 5 to 10 parts. Gage repeatability and reproducibility (gage r&r) is defined as the method to find how much of the process. Gage R&R How Many Parts.

From www.youtube.com

Gauge R and R Measurement System Analysis YouTube Gage R&R How Many Parts Gage repeatability and reproducibility (gage r&r) is defined as the method to find how much of the process variation is due to the measurement equipment and measurement. The appraisers measure the same set of parts in a randomized. Gage r&r, a critical tool in lean six sigma, is composed of two main components: What is a good gage r&r value?.. Gage R&R How Many Parts.

From www.manufacturinget.org

Lab Gage R&R Gage R&R How Many Parts What is a good gage r&r value?. Gage r&r, a critical tool in lean six sigma, is composed of two main components: A common standard for a continuous gr&r study is to use 10 parts, measured by 3 different people, 3 times each,. We’ll focus on the %contribution for gager&r, which tells us how much of the variation in your. Gage R&R How Many Parts.

From qualityamerica.com

Repeatability Reproducibility Analysis R&R Studies Gage R&R Calculation Gage R&R How Many Parts Repeatability is the variation between successive measurements of the same. A common standard for a continuous gr&r study is to use 10 parts, measured by 3 different people, 3 times each,. Gage r&r, a critical tool in lean six sigma, is composed of two main components: Tips for a successful gage r&r. The appraisers measure the same set of parts. Gage R&R How Many Parts.

From www.goskills.com

The Basics of Gage R&R GoSkills Gage R&R How Many Parts Gage repeatability and reproducibility (gage r&r) is defined as the method to find how much of the process variation is due to the measurement equipment and measurement. Typically, these studies use two or three appraisers and 5 to 10 parts. A typical attribute gage r&r study involves multiple operators, parts, and repeated measurements of the same part by each. We’ll. Gage R&R How Many Parts.

From leansigmacorporation.com

Variable Gage R&R with Minitab Lean Sigma Corporation Gage R&R How Many Parts Tips for a successful gage r&r. The appraisers measure the same set of parts in a randomized. A common standard for a continuous gr&r study is to use 10 parts, measured by 3 different people, 3 times each,. Repeatability is the variation between successive measurements of the same. Gage repeatability and reproducibility (gage r&r) is defined as the method to. Gage R&R How Many Parts.

From www.youtube.com

Minitab Tutorial Variable Gage R&R YouTube Gage R&R How Many Parts Tips for a successful gage r&r. A common standard for a continuous gr&r study is to use 10 parts, measured by 3 different people, 3 times each,. Gage r&r focuses on two key aspects of measurement: Repeatability is the variation between successive measurements of the same. We’ll focus on the %contribution for gager&r, which tells us how much of the. Gage R&R How Many Parts.

From lsssimplified.com

Attribute Gage R&R A Step by Step approach LSSSimplified Gage R&R How Many Parts Gage r&r focuses on two key aspects of measurement: We’ll focus on the %contribution for gager&r, which tells us how much of the variation in your process can be attributed to your. The appraisers measure the same set of parts in a randomized. Gage r&r, a critical tool in lean six sigma, is composed of two main components: Gage repeatability. Gage R&R How Many Parts.

From www.slideserve.com

PPT Gage R&R PowerPoint Presentation, free download ID6591146 Gage R&R How Many Parts The appraisers measure the same set of parts in a randomized. A typical attribute gage r&r study involves multiple operators, parts, and repeated measurements of the same part by each. What is a good gage r&r value?. We’ll focus on the %contribution for gager&r, which tells us how much of the variation in your process can be attributed to your.. Gage R&R How Many Parts.

From dxoerybxo.blob.core.windows.net

How Do You Interpret Gage R And R Results at Shelley Sipes blog Gage R&R How Many Parts A typical attribute gage r&r study involves multiple operators, parts, and repeated measurements of the same part by each. The appraisers measure the same set of parts in a randomized. Gage repeatability and reproducibility (gage r&r) is defined as the method to find how much of the process variation is due to the measurement equipment and measurement. Gage r&r, a. Gage R&R How Many Parts.

From lsssimplified.com

Continuous Gage R&R A Step by Step Approach Gage R&R How Many Parts Repeatability is the variation between successive measurements of the same. Gage r&r, a critical tool in lean six sigma, is composed of two main components: Tips for a successful gage r&r. A typical attribute gage r&r study involves multiple operators, parts, and repeated measurements of the same part by each. Typically, these studies use two or three appraisers and 5. Gage R&R How Many Parts.

From www.real-statistics.com

Gage R&R Real Statistics Using Excel Gage R&R How Many Parts A typical attribute gage r&r study involves multiple operators, parts, and repeated measurements of the same part by each. Gage repeatability and reproducibility (gage r&r) is defined as the method to find how much of the process variation is due to the measurement equipment and measurement. Tips for a successful gage r&r. The appraisers measure the same set of parts. Gage R&R How Many Parts.

From www.slideserve.com

PPT Gage R&R PowerPoint Presentation, free download ID6591146 Gage R&R How Many Parts Typically, these studies use two or three appraisers and 5 to 10 parts. A typical attribute gage r&r study involves multiple operators, parts, and repeated measurements of the same part by each. The appraisers measure the same set of parts in a randomized. We’ll focus on the %contribution for gager&r, which tells us how much of the variation in your. Gage R&R How Many Parts.

From www.biz-pi.com

Interpreting Minitab’s Gage R&R Chart Business Performance Gage R&R How Many Parts A common standard for a continuous gr&r study is to use 10 parts, measured by 3 different people, 3 times each,. Gage r&r, a critical tool in lean six sigma, is composed of two main components: We’ll focus on the %contribution for gager&r, which tells us how much of the variation in your process can be attributed to your. Tips. Gage R&R How Many Parts.

From www.slideshare.net

R&R Gage Analysis Gage R&R How Many Parts Tips for a successful gage r&r. A common standard for a continuous gr&r study is to use 10 parts, measured by 3 different people, 3 times each,. A typical attribute gage r&r study involves multiple operators, parts, and repeated measurements of the same part by each. We’ll focus on the %contribution for gager&r, which tells us how much of the. Gage R&R How Many Parts.

From www.qualitydigest.com

Gauge R&R for Engineering Drawing Services Quality Digest Gage R&R How Many Parts Gage r&r, a critical tool in lean six sigma, is composed of two main components: A typical attribute gage r&r study involves multiple operators, parts, and repeated measurements of the same part by each. The appraisers measure the same set of parts in a randomized. Tips for a successful gage r&r. Gage r&r focuses on two key aspects of measurement:. Gage R&R How Many Parts.

From www.slideserve.com

PPT Gage R&R PowerPoint Presentation, free download ID6591146 Gage R&R How Many Parts The appraisers measure the same set of parts in a randomized. Repeatability is the variation between successive measurements of the same. What is a good gage r&r value?. A common standard for a continuous gr&r study is to use 10 parts, measured by 3 different people, 3 times each,. Tips for a successful gage r&r. A typical attribute gage r&r. Gage R&R How Many Parts.

From lsssimplified.com

Attribute Gage R&R A Step by Step approach LSSSimplified Gage R&R How Many Parts The appraisers measure the same set of parts in a randomized. Gage repeatability and reproducibility (gage r&r) is defined as the method to find how much of the process variation is due to the measurement equipment and measurement. What is a good gage r&r value?. Gage r&r focuses on two key aspects of measurement: A typical attribute gage r&r study. Gage R&R How Many Parts.

From www.researchgate.net

Data of the nested Gage R&R experiment showing 3 different operators Gage R&R How Many Parts Repeatability is the variation between successive measurements of the same. Tips for a successful gage r&r. The appraisers measure the same set of parts in a randomized. A typical attribute gage r&r study involves multiple operators, parts, and repeated measurements of the same part by each. What is a good gage r&r value?. A common standard for a continuous gr&r. Gage R&R How Many Parts.

From www.automotivequal.com

What is Gage R&R 📏 and why is it crucial for accurate measurements? Gage R&R How Many Parts What is a good gage r&r value?. Gage r&r focuses on two key aspects of measurement: We’ll focus on the %contribution for gager&r, which tells us how much of the variation in your process can be attributed to your. Gage repeatability and reproducibility (gage r&r) is defined as the method to find how much of the process variation is due. Gage R&R How Many Parts.

From virinco.zendesk.com

Gage R&R analysis Help Center Gage R&R How Many Parts Gage r&r, a critical tool in lean six sigma, is composed of two main components: What is a good gage r&r value?. Gage r&r focuses on two key aspects of measurement: We’ll focus on the %contribution for gager&r, which tells us how much of the variation in your process can be attributed to your. A common standard for a continuous. Gage R&R How Many Parts.

From www.muelaner.com

How to do Gage R&R in Excel Gage R&R How Many Parts Tips for a successful gage r&r. A common standard for a continuous gr&r study is to use 10 parts, measured by 3 different people, 3 times each,. Repeatability is the variation between successive measurements of the same. The appraisers measure the same set of parts in a randomized. Gage r&r focuses on two key aspects of measurement: Gage r&r, a. Gage R&R How Many Parts.

From www.etsy.com

Gauge R&R Study Spreadsheet excel Gauge Repeatability / Reproducibility Gage R&R How Many Parts A typical attribute gage r&r study involves multiple operators, parts, and repeated measurements of the same part by each. The appraisers measure the same set of parts in a randomized. What is a good gage r&r value?. Typically, these studies use two or three appraisers and 5 to 10 parts. Repeatability is the variation between successive measurements of the same.. Gage R&R How Many Parts.

From db-excel.com

Gage R&r Spreadsheet with How To Do Gage Rr In Excel — Gage R&R How Many Parts Gage r&r focuses on two key aspects of measurement: What is a good gage r&r value?. A typical attribute gage r&r study involves multiple operators, parts, and repeated measurements of the same part by each. The appraisers measure the same set of parts in a randomized. A common standard for a continuous gr&r study is to use 10 parts, measured. Gage R&R How Many Parts.

From real-statistics.com

Gage R&R Analysis Real Statistics Using Excel Gage R&R How Many Parts A typical attribute gage r&r study involves multiple operators, parts, and repeated measurements of the same part by each. We’ll focus on the %contribution for gager&r, which tells us how much of the variation in your process can be attributed to your. Gage repeatability and reproducibility (gage r&r) is defined as the method to find how much of the process. Gage R&R How Many Parts.

From www.slideshare.net

R&R Gage Analysis Gage R&R How Many Parts A common standard for a continuous gr&r study is to use 10 parts, measured by 3 different people, 3 times each,. Gage repeatability and reproducibility (gage r&r) is defined as the method to find how much of the process variation is due to the measurement equipment and measurement. Gage r&r focuses on two key aspects of measurement: Repeatability is the. Gage R&R How Many Parts.

From www.youtube.com

How to Setup a Gage R&R Study YouTube Gage R&R How Many Parts Repeatability is the variation between successive measurements of the same. What is a good gage r&r value?. A common standard for a continuous gr&r study is to use 10 parts, measured by 3 different people, 3 times each,. Typically, these studies use two or three appraisers and 5 to 10 parts. Tips for a successful gage r&r. We’ll focus on. Gage R&R How Many Parts.

From www.slideshare.net

R&R Gage Analysis Gage R&R How Many Parts What is a good gage r&r value?. Gage r&r focuses on two key aspects of measurement: Repeatability is the variation between successive measurements of the same. The appraisers measure the same set of parts in a randomized. A typical attribute gage r&r study involves multiple operators, parts, and repeated measurements of the same part by each. We’ll focus on the. Gage R&R How Many Parts.

From www.youtube.com

Gauge R&R Fully Explained!! (Measurement System Analysis) Part 1 YouTube Gage R&R How Many Parts We’ll focus on the %contribution for gager&r, which tells us how much of the variation in your process can be attributed to your. Typically, these studies use two or three appraisers and 5 to 10 parts. The appraisers measure the same set of parts in a randomized. Gage repeatability and reproducibility (gage r&r) is defined as the method to find. Gage R&R How Many Parts.

From www.elearningfactory.com

What is Gage R&R Repeatability & Reproducibility? Gage R&R How Many Parts The appraisers measure the same set of parts in a randomized. Repeatability is the variation between successive measurements of the same. Gage r&r focuses on two key aspects of measurement: We’ll focus on the %contribution for gager&r, which tells us how much of the variation in your process can be attributed to your. What is a good gage r&r value?.. Gage R&R How Many Parts.

From www.youtube.com

Gage R&R Study Presentation YouTube Gage R&R How Many Parts Gage repeatability and reproducibility (gage r&r) is defined as the method to find how much of the process variation is due to the measurement equipment and measurement. A common standard for a continuous gr&r study is to use 10 parts, measured by 3 different people, 3 times each,. Gage r&r, a critical tool in lean six sigma, is composed of. Gage R&R How Many Parts.

From www.slideshare.net

Gage R&R Measurement Systems Analysis Sample Slides Gage R&R How Many Parts The appraisers measure the same set of parts in a randomized. Tips for a successful gage r&r. A typical attribute gage r&r study involves multiple operators, parts, and repeated measurements of the same part by each. Typically, these studies use two or three appraisers and 5 to 10 parts. Repeatability is the variation between successive measurements of the same. A. Gage R&R How Many Parts.

From www.researchgate.net

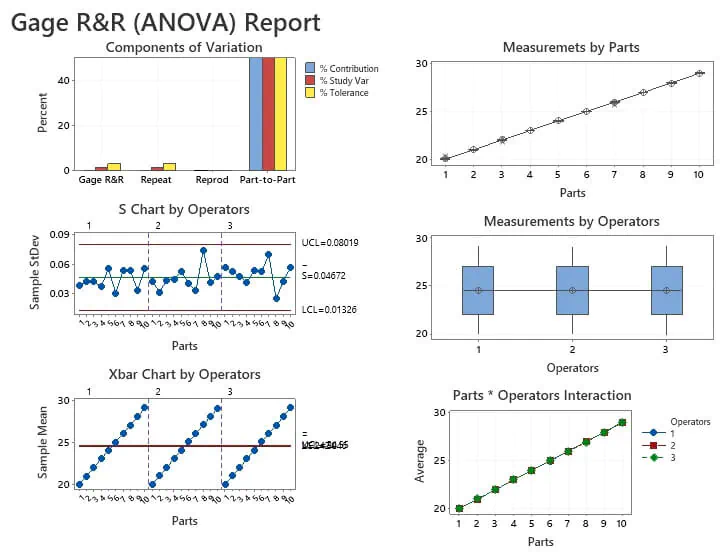

Gage R&R (ANOVA) report for diameter (D) (a) Components of Variation Gage R&R How Many Parts Tips for a successful gage r&r. Gage r&r focuses on two key aspects of measurement: A common standard for a continuous gr&r study is to use 10 parts, measured by 3 different people, 3 times each,. We’ll focus on the %contribution for gager&r, which tells us how much of the variation in your process can be attributed to your. Gage. Gage R&R How Many Parts.