Cupola Furnace Emissions . Work practices—the foundry mact now requires that during periods of “off blast,” cupola melting furnaces must reduce. Wfi has also made efforts to reduce co 2 emissions at other plants in accordance with the equipment at each location, and have cut co 2. Cupola furnace is a type of melting furnace commonly used in foundries to make cast iron from pig iron charge which consists of pig iron,. Fuel is burnt with air introduced by blast air. For the iron, you measure temperature, chemistry and volume. The 3 most common furnaces used in the iron foundry industry are cupolas, electric arc, and electric induction furnaces. Are you getting too much or too little iron based on the. The cupola furnace at plant 23 consists of a vertical steel shell with a refractory brick lining. Emission reduction efforts include the use of bag houses, wet scrubbers, and afterburners to reduce particulates, carbon monoxide (co) and vocs in. Direct emissions cupola melting results in direct emissions of co 2 from the combustion of coke. This process creates substantially more.

from www.slideshare.net

For the iron, you measure temperature, chemistry and volume. Emission reduction efforts include the use of bag houses, wet scrubbers, and afterburners to reduce particulates, carbon monoxide (co) and vocs in. Work practices—the foundry mact now requires that during periods of “off blast,” cupola melting furnaces must reduce. Are you getting too much or too little iron based on the. The 3 most common furnaces used in the iron foundry industry are cupolas, electric arc, and electric induction furnaces. This process creates substantially more. Fuel is burnt with air introduced by blast air. The cupola furnace at plant 23 consists of a vertical steel shell with a refractory brick lining. Cupola furnace is a type of melting furnace commonly used in foundries to make cast iron from pig iron charge which consists of pig iron,. Direct emissions cupola melting results in direct emissions of co 2 from the combustion of coke.

Cupola furnaces

Cupola Furnace Emissions Are you getting too much or too little iron based on the. The cupola furnace at plant 23 consists of a vertical steel shell with a refractory brick lining. Cupola furnace is a type of melting furnace commonly used in foundries to make cast iron from pig iron charge which consists of pig iron,. This process creates substantially more. Fuel is burnt with air introduced by blast air. Work practices—the foundry mact now requires that during periods of “off blast,” cupola melting furnaces must reduce. Direct emissions cupola melting results in direct emissions of co 2 from the combustion of coke. Emission reduction efforts include the use of bag houses, wet scrubbers, and afterburners to reduce particulates, carbon monoxide (co) and vocs in. Are you getting too much or too little iron based on the. The 3 most common furnaces used in the iron foundry industry are cupolas, electric arc, and electric induction furnaces. Wfi has also made efforts to reduce co 2 emissions at other plants in accordance with the equipment at each location, and have cut co 2. For the iron, you measure temperature, chemistry and volume.

From www.heat-furnace.com

Supply 2 Ton Hot Air Cupola Furnace for Casting Cupola Furnace Emissions The cupola furnace at plant 23 consists of a vertical steel shell with a refractory brick lining. Emission reduction efforts include the use of bag houses, wet scrubbers, and afterburners to reduce particulates, carbon monoxide (co) and vocs in. Fuel is burnt with air introduced by blast air. The 3 most common furnaces used in the iron foundry industry are. Cupola Furnace Emissions.

From mechanicaljungle.com

What Is Cupola Furnace? Cupola Furnace Design । Cupola Construction Purpose of Cupola Cupola Furnace Emissions Are you getting too much or too little iron based on the. Fuel is burnt with air introduced by blast air. For the iron, you measure temperature, chemistry and volume. Cupola furnace is a type of melting furnace commonly used in foundries to make cast iron from pig iron charge which consists of pig iron,. The cupola furnace at plant. Cupola Furnace Emissions.

From msvs-dei.vlabs.ac.in

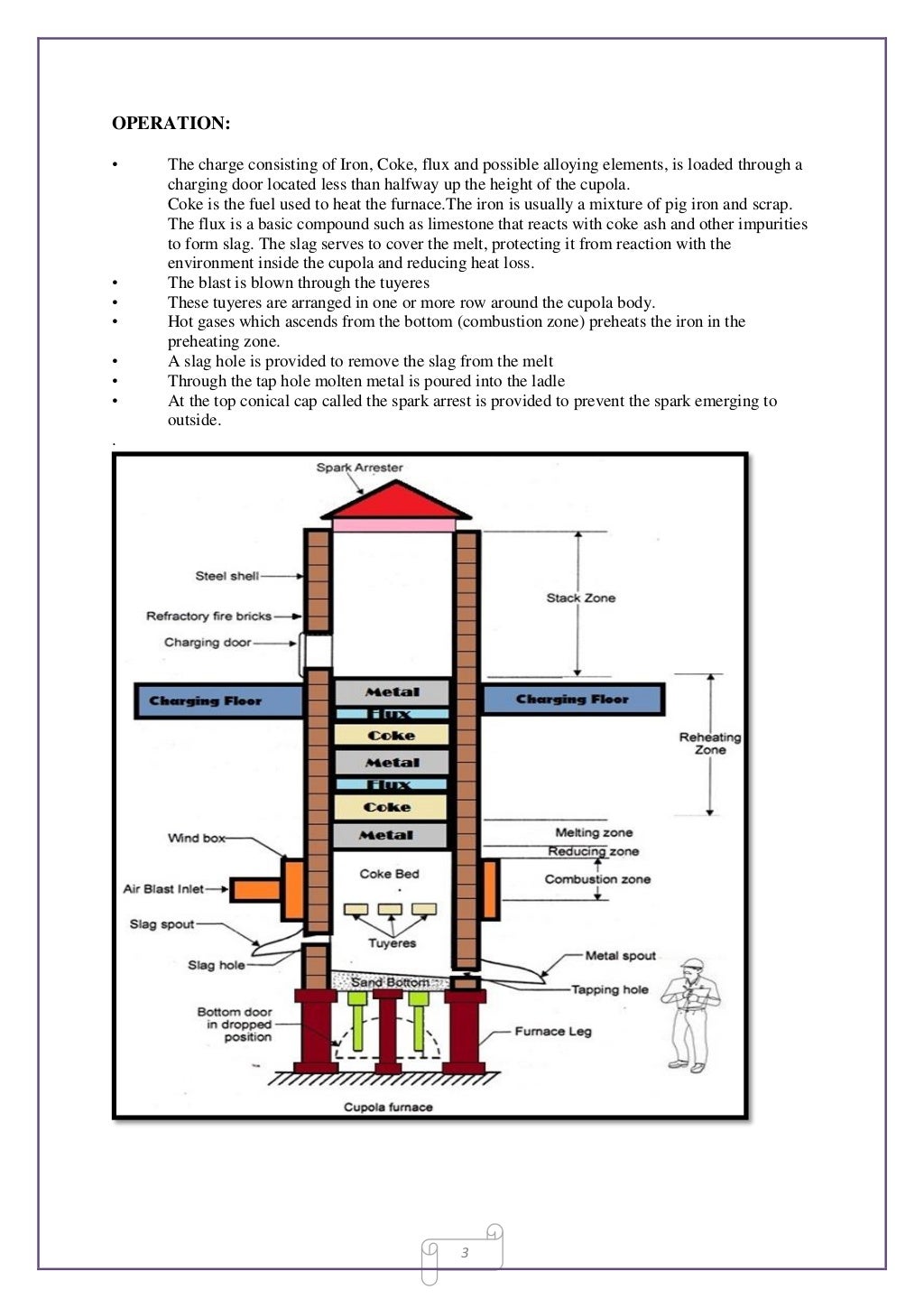

Manufacturing ProcessesI Cupola Furnace Emissions Emission reduction efforts include the use of bag houses, wet scrubbers, and afterburners to reduce particulates, carbon monoxide (co) and vocs in. Work practices—the foundry mact now requires that during periods of “off blast,” cupola melting furnaces must reduce. Direct emissions cupola melting results in direct emissions of co 2 from the combustion of coke. Are you getting too much. Cupola Furnace Emissions.

From www.circuitdiagram.co

Cupola Furnace Schematic Diagram Circuit Diagram Cupola Furnace Emissions Are you getting too much or too little iron based on the. Emission reduction efforts include the use of bag houses, wet scrubbers, and afterburners to reduce particulates, carbon monoxide (co) and vocs in. The 3 most common furnaces used in the iron foundry industry are cupolas, electric arc, and electric induction furnaces. Cupola furnace is a type of melting. Cupola Furnace Emissions.

From www.scribd.com

Cupola Furnace Building Materials Chemical Substances Cupola Furnace Emissions Cupola furnace is a type of melting furnace commonly used in foundries to make cast iron from pig iron charge which consists of pig iron,. This process creates substantially more. Wfi has also made efforts to reduce co 2 emissions at other plants in accordance with the equipment at each location, and have cut co 2. Work practices—the foundry mact. Cupola Furnace Emissions.

From www.refratechnik.com

Refratechnik Cupola furnaces Cupola Furnace Emissions The cupola furnace at plant 23 consists of a vertical steel shell with a refractory brick lining. Emission reduction efforts include the use of bag houses, wet scrubbers, and afterburners to reduce particulates, carbon monoxide (co) and vocs in. Wfi has also made efforts to reduce co 2 emissions at other plants in accordance with the equipment at each location,. Cupola Furnace Emissions.

From go.gale.com

Fine and ultrafine emission dynamics from a ferrous foundry cupola furnace Document Gale Cupola Furnace Emissions Emission reduction efforts include the use of bag houses, wet scrubbers, and afterburners to reduce particulates, carbon monoxide (co) and vocs in. Fuel is burnt with air introduced by blast air. Wfi has also made efforts to reduce co 2 emissions at other plants in accordance with the equipment at each location, and have cut co 2. For the iron,. Cupola Furnace Emissions.

From extrudesign.com

How Molten Metal is Prepared in Cupola Furnace? ExtruDesign Cupola Furnace Emissions Fuel is burnt with air introduced by blast air. Work practices—the foundry mact now requires that during periods of “off blast,” cupola melting furnaces must reduce. The 3 most common furnaces used in the iron foundry industry are cupolas, electric arc, and electric induction furnaces. Cupola furnace is a type of melting furnace commonly used in foundries to make cast. Cupola Furnace Emissions.

From www.youtube.com

CUPOLA FURNACE ! LEARN AND GROW YouTube Cupola Furnace Emissions Fuel is burnt with air introduced by blast air. Cupola furnace is a type of melting furnace commonly used in foundries to make cast iron from pig iron charge which consists of pig iron,. Are you getting too much or too little iron based on the. Emission reduction efforts include the use of bag houses, wet scrubbers, and afterburners to. Cupola Furnace Emissions.

From vdocuments.mx

Cupola Furnace [PPT Powerpoint] Cupola Furnace Emissions Are you getting too much or too little iron based on the. Direct emissions cupola melting results in direct emissions of co 2 from the combustion of coke. Work practices—the foundry mact now requires that during periods of “off blast,” cupola melting furnaces must reduce. Cupola furnace is a type of melting furnace commonly used in foundries to make cast. Cupola Furnace Emissions.

From www.youtube.com

Cupola Furnace Working Animation Casting Process Manufacturing Processes Lecture by Shubham Cupola Furnace Emissions Cupola furnace is a type of melting furnace commonly used in foundries to make cast iron from pig iron charge which consists of pig iron,. Are you getting too much or too little iron based on the. Wfi has also made efforts to reduce co 2 emissions at other plants in accordance with the equipment at each location, and have. Cupola Furnace Emissions.

From gdmtechnics.com

Cupola Furnace Working Efficiency by Steam Injection Cupola Furnace Emissions The cupola furnace at plant 23 consists of a vertical steel shell with a refractory brick lining. The 3 most common furnaces used in the iron foundry industry are cupolas, electric arc, and electric induction furnaces. Cupola furnace is a type of melting furnace commonly used in foundries to make cast iron from pig iron charge which consists of pig. Cupola Furnace Emissions.

From www.studypool.com

SOLUTION Mfp u 1 s 5 metal casting process melting furnacess blast and cupola furnaces Studypool Cupola Furnace Emissions Fuel is burnt with air introduced by blast air. This process creates substantially more. The 3 most common furnaces used in the iron foundry industry are cupolas, electric arc, and electric induction furnaces. Cupola furnace is a type of melting furnace commonly used in foundries to make cast iron from pig iron charge which consists of pig iron,. For the. Cupola Furnace Emissions.

From www.heat-furnace.com

1 Ton Hot Air Cupola Furnace for Melting and Casting Cupola Furnace Emissions Emission reduction efforts include the use of bag houses, wet scrubbers, and afterburners to reduce particulates, carbon monoxide (co) and vocs in. Cupola furnace is a type of melting furnace commonly used in foundries to make cast iron from pig iron charge which consists of pig iron,. The cupola furnace at plant 23 consists of a vertical steel shell with. Cupola Furnace Emissions.

From www.circuitdiagram.co

Schematic Diagram Of Cupola Furnace Circuit Diagram Cupola Furnace Emissions Direct emissions cupola melting results in direct emissions of co 2 from the combustion of coke. Emission reduction efforts include the use of bag houses, wet scrubbers, and afterburners to reduce particulates, carbon monoxide (co) and vocs in. This process creates substantially more. Work practices—the foundry mact now requires that during periods of “off blast,” cupola melting furnaces must reduce.. Cupola Furnace Emissions.

From www.researchgate.net

(PDF) Smelting in cupola furnace for recarburization of direct reduction iron (DRI) Cupola Furnace Emissions The 3 most common furnaces used in the iron foundry industry are cupolas, electric arc, and electric induction furnaces. Fuel is burnt with air introduced by blast air. For the iron, you measure temperature, chemistry and volume. Emission reduction efforts include the use of bag houses, wet scrubbers, and afterburners to reduce particulates, carbon monoxide (co) and vocs in. Wfi. Cupola Furnace Emissions.

From go.gale.com

Fine and ultrafine emission dynamics from a ferrous foundry cupola furnace Document Gale Cupola Furnace Emissions The 3 most common furnaces used in the iron foundry industry are cupolas, electric arc, and electric induction furnaces. Fuel is burnt with air introduced by blast air. For the iron, you measure temperature, chemistry and volume. Direct emissions cupola melting results in direct emissions of co 2 from the combustion of coke. Cupola furnace is a type of melting. Cupola Furnace Emissions.

From www.youtube.com

Cupola Furnace II Construction and Working II Components Functions II Various types of Zones II Cupola Furnace Emissions Cupola furnace is a type of melting furnace commonly used in foundries to make cast iron from pig iron charge which consists of pig iron,. The 3 most common furnaces used in the iron foundry industry are cupolas, electric arc, and electric induction furnaces. For the iron, you measure temperature, chemistry and volume. Work practices—the foundry mact now requires that. Cupola Furnace Emissions.

From www.ecands.com

Cupola Melt System Supplier & Cupola Furnace Services EC&S, Inc. Cupola Furnace Emissions The cupola furnace at plant 23 consists of a vertical steel shell with a refractory brick lining. This process creates substantially more. Work practices—the foundry mact now requires that during periods of “off blast,” cupola melting furnaces must reduce. Wfi has also made efforts to reduce co 2 emissions at other plants in accordance with the equipment at each location,. Cupola Furnace Emissions.

From www.youtube.com

Cupola Furnace An Overview YouTube Cupola Furnace Emissions The cupola furnace at plant 23 consists of a vertical steel shell with a refractory brick lining. Wfi has also made efforts to reduce co 2 emissions at other plants in accordance with the equipment at each location, and have cut co 2. Emission reduction efforts include the use of bag houses, wet scrubbers, and afterburners to reduce particulates, carbon. Cupola Furnace Emissions.

From www.researchgate.net

Structural scheme of the cupola furnace from control aspect Download Scientific Diagram Cupola Furnace Emissions Cupola furnace is a type of melting furnace commonly used in foundries to make cast iron from pig iron charge which consists of pig iron,. Work practices—the foundry mact now requires that during periods of “off blast,” cupola melting furnaces must reduce. Fuel is burnt with air introduced by blast air. Wfi has also made efforts to reduce co 2. Cupola Furnace Emissions.

From dizz.com

Cupola Furnace Working principle, Construction & Applications (With PDF) Cupola Furnace Emissions For the iron, you measure temperature, chemistry and volume. Emission reduction efforts include the use of bag houses, wet scrubbers, and afterburners to reduce particulates, carbon monoxide (co) and vocs in. Direct emissions cupola melting results in direct emissions of co 2 from the combustion of coke. The cupola furnace at plant 23 consists of a vertical steel shell with. Cupola Furnace Emissions.

From pt.slideshare.net

Cupola furnace Cupola Furnace Emissions The 3 most common furnaces used in the iron foundry industry are cupolas, electric arc, and electric induction furnaces. Fuel is burnt with air introduced by blast air. Cupola furnace is a type of melting furnace commonly used in foundries to make cast iron from pig iron charge which consists of pig iron,. Emission reduction efforts include the use of. Cupola Furnace Emissions.

From in.pinterest.com

Cupola Furnace How To Build A Popular Cupola Furnace 5 Stages Of Iron Melting Furnace Cupola Furnace Emissions Emission reduction efforts include the use of bag houses, wet scrubbers, and afterburners to reduce particulates, carbon monoxide (co) and vocs in. The cupola furnace at plant 23 consists of a vertical steel shell with a refractory brick lining. The 3 most common furnaces used in the iron foundry industry are cupolas, electric arc, and electric induction furnaces. This process. Cupola Furnace Emissions.

From www.heat-furnace.com

Supply 2 Ton Hot Air Cupola Furnace for Casting Cupola Furnace Emissions Are you getting too much or too little iron based on the. Fuel is burnt with air introduced by blast air. The cupola furnace at plant 23 consists of a vertical steel shell with a refractory brick lining. Cupola furnace is a type of melting furnace commonly used in foundries to make cast iron from pig iron charge which consists. Cupola Furnace Emissions.

From www.researchgate.net

Cupola blast furnace. The vertical cupola blast furnace is basically a... Download Scientific Cupola Furnace Emissions Emission reduction efforts include the use of bag houses, wet scrubbers, and afterburners to reduce particulates, carbon monoxide (co) and vocs in. Wfi has also made efforts to reduce co 2 emissions at other plants in accordance with the equipment at each location, and have cut co 2. Are you getting too much or too little iron based on the.. Cupola Furnace Emissions.

From www.researchgate.net

Scheme of cupola furnace with associated infrastructure, connected with... Download Scientific Cupola Furnace Emissions Cupola furnace is a type of melting furnace commonly used in foundries to make cast iron from pig iron charge which consists of pig iron,. Fuel is burnt with air introduced by blast air. The cupola furnace at plant 23 consists of a vertical steel shell with a refractory brick lining. Work practices—the foundry mact now requires that during periods. Cupola Furnace Emissions.

From thors.com

Cupola Furnace Fundamentals Course Cupola Furnace Emissions Cupola furnace is a type of melting furnace commonly used in foundries to make cast iron from pig iron charge which consists of pig iron,. This process creates substantially more. Fuel is burnt with air introduced by blast air. The 3 most common furnaces used in the iron foundry industry are cupolas, electric arc, and electric induction furnaces. The cupola. Cupola Furnace Emissions.

From learnmechanical.com

Cupola Furnace Working principle, Construction & Applications (With PDF) Cupola Furnace Emissions Direct emissions cupola melting results in direct emissions of co 2 from the combustion of coke. The 3 most common furnaces used in the iron foundry industry are cupolas, electric arc, and electric induction furnaces. The cupola furnace at plant 23 consists of a vertical steel shell with a refractory brick lining. Emission reduction efforts include the use of bag. Cupola Furnace Emissions.

From www.ecands.com

Cupola Melt System Supplier & Cupola Furnace Services EC&S, Inc. Cupola Furnace Emissions Wfi has also made efforts to reduce co 2 emissions at other plants in accordance with the equipment at each location, and have cut co 2. For the iron, you measure temperature, chemistry and volume. Cupola furnace is a type of melting furnace commonly used in foundries to make cast iron from pig iron charge which consists of pig iron,.. Cupola Furnace Emissions.

From www.slideshare.net

Cupola furnaces Cupola Furnace Emissions Direct emissions cupola melting results in direct emissions of co 2 from the combustion of coke. Emission reduction efforts include the use of bag houses, wet scrubbers, and afterburners to reduce particulates, carbon monoxide (co) and vocs in. The 3 most common furnaces used in the iron foundry industry are cupolas, electric arc, and electric induction furnaces. Wfi has also. Cupola Furnace Emissions.

From www.researchgate.net

Cupola blast furnace. The vertical cupola blast furnace is basically a... Download Scientific Cupola Furnace Emissions Fuel is burnt with air introduced by blast air. This process creates substantially more. For the iron, you measure temperature, chemistry and volume. Work practices—the foundry mact now requires that during periods of “off blast,” cupola melting furnaces must reduce. Direct emissions cupola melting results in direct emissions of co 2 from the combustion of coke. Cupola furnace is a. Cupola Furnace Emissions.

From alchetron.com

Cupola furnace Alchetron, The Free Social Encyclopedia Cupola Furnace Emissions Cupola furnace is a type of melting furnace commonly used in foundries to make cast iron from pig iron charge which consists of pig iron,. The cupola furnace at plant 23 consists of a vertical steel shell with a refractory brick lining. Work practices—the foundry mact now requires that during periods of “off blast,” cupola melting furnaces must reduce. Are. Cupola Furnace Emissions.

From www.slideserve.com

PPT Melting Processes PowerPoint Presentation, free download ID2182609 Cupola Furnace Emissions The 3 most common furnaces used in the iron foundry industry are cupolas, electric arc, and electric induction furnaces. Fuel is burnt with air introduced by blast air. Wfi has also made efforts to reduce co 2 emissions at other plants in accordance with the equipment at each location, and have cut co 2. Emission reduction efforts include the use. Cupola Furnace Emissions.

From www.slideshare.net

Cupola furnaces PDF Cupola Furnace Emissions The 3 most common furnaces used in the iron foundry industry are cupolas, electric arc, and electric induction furnaces. Cupola furnace is a type of melting furnace commonly used in foundries to make cast iron from pig iron charge which consists of pig iron,. Emission reduction efforts include the use of bag houses, wet scrubbers, and afterburners to reduce particulates,. Cupola Furnace Emissions.