Offset Printing Ink Density . One of the most common issues in offset printing is incorrect ink density. Optimum density for ink is determined by measuring the amount of contrast obtained in the 3/4 tone. If you are just starting to use densitometers,. Too much ink can cause smudging and drying problems,. It is essentially the measurement of how dark and ink is. Ink density in offset printing is the measurement light that is reflected from an ink. Follow the suggestions below to reduce ink saturation extremes on your printed pages. All printing methods, including offset,. Unlike flexography or gravure printing methods, offset allows more control over ink density adjustments during production. Discover the essential technical aspects of offset printing ink that directly impact print quality and color richness. Table 1 shows some typical solid density values for three common printing conditions.

from www.slideserve.com

Unlike flexography or gravure printing methods, offset allows more control over ink density adjustments during production. Optimum density for ink is determined by measuring the amount of contrast obtained in the 3/4 tone. Too much ink can cause smudging and drying problems,. All printing methods, including offset,. It is essentially the measurement of how dark and ink is. Ink density in offset printing is the measurement light that is reflected from an ink. Discover the essential technical aspects of offset printing ink that directly impact print quality and color richness. Follow the suggestions below to reduce ink saturation extremes on your printed pages. One of the most common issues in offset printing is incorrect ink density. If you are just starting to use densitometers,.

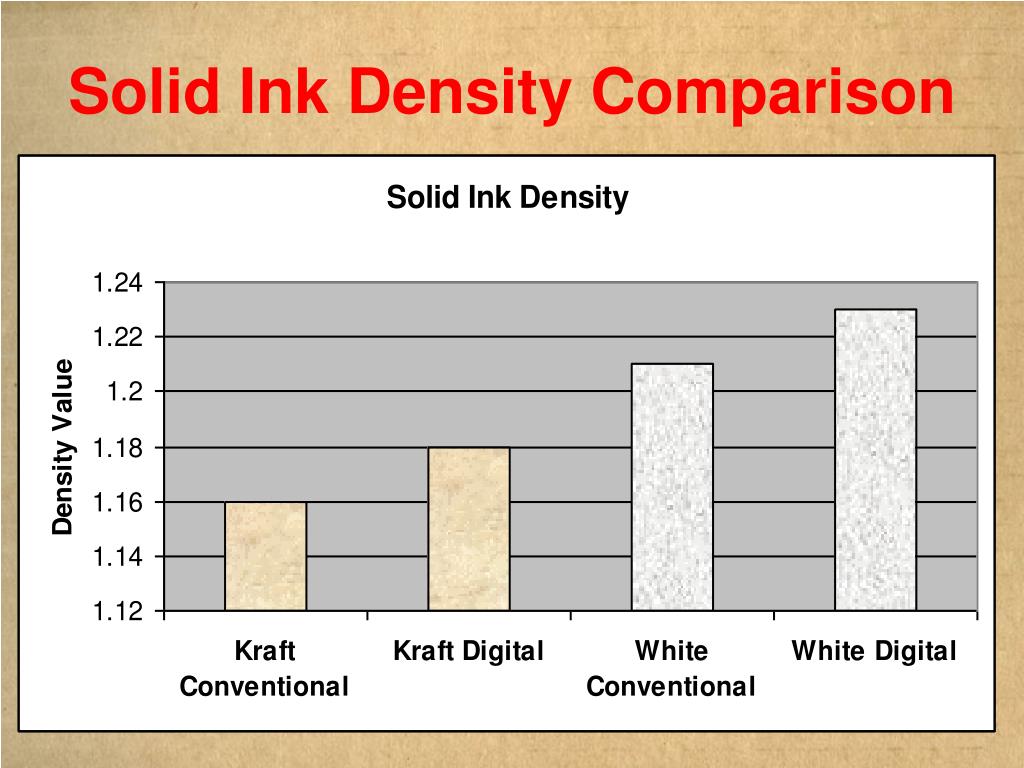

PPT Corrugated Postprint Conventional or Digital? PowerPoint Presentation ID207278

Offset Printing Ink Density One of the most common issues in offset printing is incorrect ink density. Discover the essential technical aspects of offset printing ink that directly impact print quality and color richness. One of the most common issues in offset printing is incorrect ink density. Follow the suggestions below to reduce ink saturation extremes on your printed pages. If you are just starting to use densitometers,. It is essentially the measurement of how dark and ink is. Too much ink can cause smudging and drying problems,. Table 1 shows some typical solid density values for three common printing conditions. Ink density in offset printing is the measurement light that is reflected from an ink. All printing methods, including offset,. Optimum density for ink is determined by measuring the amount of contrast obtained in the 3/4 tone. Unlike flexography or gravure printing methods, offset allows more control over ink density adjustments during production.

From www.cadlink.com

See How Much Ink Is Enough With Ink Density Test Pages Offset Printing Ink Density Too much ink can cause smudging and drying problems,. One of the most common issues in offset printing is incorrect ink density. Optimum density for ink is determined by measuring the amount of contrast obtained in the 3/4 tone. Ink density in offset printing is the measurement light that is reflected from an ink. All printing methods, including offset,. If. Offset Printing Ink Density.

From diasinh.com.vn

What is Ink Density in Offset Printing? Địa Sinh Offset Printing Ink Density It is essentially the measurement of how dark and ink is. Table 1 shows some typical solid density values for three common printing conditions. Unlike flexography or gravure printing methods, offset allows more control over ink density adjustments during production. Too much ink can cause smudging and drying problems,. All printing methods, including offset,. If you are just starting to. Offset Printing Ink Density.

From www.slideserve.com

PPT Corrugated Postprint Conventional or Digital? PowerPoint Presentation ID207278 Offset Printing Ink Density Discover the essential technical aspects of offset printing ink that directly impact print quality and color richness. One of the most common issues in offset printing is incorrect ink density. Optimum density for ink is determined by measuring the amount of contrast obtained in the 3/4 tone. Ink density in offset printing is the measurement light that is reflected from. Offset Printing Ink Density.

From www.youtube.com

What is Ink Density? YouTube Offset Printing Ink Density Too much ink can cause smudging and drying problems,. Ink density in offset printing is the measurement light that is reflected from an ink. Discover the essential technical aspects of offset printing ink that directly impact print quality and color richness. All printing methods, including offset,. One of the most common issues in offset printing is incorrect ink density. If. Offset Printing Ink Density.

From www.printarea.cn

Supply High Density UV Led Offset Ink Wholesale Factory Print Area Technology Co., Ltd Offset Printing Ink Density Follow the suggestions below to reduce ink saturation extremes on your printed pages. Optimum density for ink is determined by measuring the amount of contrast obtained in the 3/4 tone. Ink density in offset printing is the measurement light that is reflected from an ink. All printing methods, including offset,. It is essentially the measurement of how dark and ink. Offset Printing Ink Density.

From www.youtube.com

SpectroDens Precise Print Color and Density Measurement and Scanning YouTube Offset Printing Ink Density Discover the essential technical aspects of offset printing ink that directly impact print quality and color richness. One of the most common issues in offset printing is incorrect ink density. It is essentially the measurement of how dark and ink is. Unlike flexography or gravure printing methods, offset allows more control over ink density adjustments during production. Follow the suggestions. Offset Printing Ink Density.

From www.offsetprinting.info

What is Ink Density in Offset Printing? Offset Printing Ink Density Ink density in offset printing is the measurement light that is reflected from an ink. Too much ink can cause smudging and drying problems,. Follow the suggestions below to reduce ink saturation extremes on your printed pages. Table 1 shows some typical solid density values for three common printing conditions. Unlike flexography or gravure printing methods, offset allows more control. Offset Printing Ink Density.

From evergreen-printing.com

How Offset Printing Works Evergreen Printing Offset Printing Ink Density It is essentially the measurement of how dark and ink is. Follow the suggestions below to reduce ink saturation extremes on your printed pages. Optimum density for ink is determined by measuring the amount of contrast obtained in the 3/4 tone. Table 1 shows some typical solid density values for three common printing conditions. Discover the essential technical aspects of. Offset Printing Ink Density.

From www.jenningsprint.com.au

How Does Offset Printing Work Jennings Print Offset Printing Ink Density It is essentially the measurement of how dark and ink is. Too much ink can cause smudging and drying problems,. One of the most common issues in offset printing is incorrect ink density. Discover the essential technical aspects of offset printing ink that directly impact print quality and color richness. Unlike flexography or gravure printing methods, offset allows more control. Offset Printing Ink Density.

From zlq-sublimation.en.made-in-china.com

Process Color Offset Printing Ink of Sheet Fed Offset Printing Inks China Pantone Color Sheet Offset Printing Ink Density Too much ink can cause smudging and drying problems,. It is essentially the measurement of how dark and ink is. Ink density in offset printing is the measurement light that is reflected from an ink. Discover the essential technical aspects of offset printing ink that directly impact print quality and color richness. All printing methods, including offset,. Table 1 shows. Offset Printing Ink Density.

From www.slideshare.net

Printing as a Means of Paper Testing Offset Printing Ink Density One of the most common issues in offset printing is incorrect ink density. Table 1 shows some typical solid density values for three common printing conditions. Unlike flexography or gravure printing methods, offset allows more control over ink density adjustments during production. Follow the suggestions below to reduce ink saturation extremes on your printed pages. If you are just starting. Offset Printing Ink Density.

From www.offsetprinting.info

Offset Printing Ink Properties Offset Printing Ink Density Optimum density for ink is determined by measuring the amount of contrast obtained in the 3/4 tone. One of the most common issues in offset printing is incorrect ink density. Unlike flexography or gravure printing methods, offset allows more control over ink density adjustments during production. It is essentially the measurement of how dark and ink is. Follow the suggestions. Offset Printing Ink Density.

From printmakersfriend.com

Instructions PrintMaker's Friend Offset Printing Ink Density If you are just starting to use densitometers,. Unlike flexography or gravure printing methods, offset allows more control over ink density adjustments during production. Optimum density for ink is determined by measuring the amount of contrast obtained in the 3/4 tone. Discover the essential technical aspects of offset printing ink that directly impact print quality and color richness. Table 1. Offset Printing Ink Density.

From inkjetinsight.com

Objective Inkjet Measures Optical Density Inkjet Insight Offset Printing Ink Density Too much ink can cause smudging and drying problems,. Follow the suggestions below to reduce ink saturation extremes on your printed pages. One of the most common issues in offset printing is incorrect ink density. Optimum density for ink is determined by measuring the amount of contrast obtained in the 3/4 tone. It is essentially the measurement of how dark. Offset Printing Ink Density.

From www.researchgate.net

(PDF) Investigation of the effects of different ink density values on color gamut in offset printing Offset Printing Ink Density It is essentially the measurement of how dark and ink is. Table 1 shows some typical solid density values for three common printing conditions. Optimum density for ink is determined by measuring the amount of contrast obtained in the 3/4 tone. One of the most common issues in offset printing is incorrect ink density. If you are just starting to. Offset Printing Ink Density.

From www.jenningsprint.com.au

How Does Offset Printing Work Jennings Print Offset Printing Ink Density Unlike flexography or gravure printing methods, offset allows more control over ink density adjustments during production. All printing methods, including offset,. Table 1 shows some typical solid density values for three common printing conditions. Follow the suggestions below to reduce ink saturation extremes on your printed pages. Discover the essential technical aspects of offset printing ink that directly impact print. Offset Printing Ink Density.

From www.rittagraf.com

Offset Inks for Engraving and Lithography Rittagraf Offset Printing Ink Density Optimum density for ink is determined by measuring the amount of contrast obtained in the 3/4 tone. It is essentially the measurement of how dark and ink is. Discover the essential technical aspects of offset printing ink that directly impact print quality and color richness. Follow the suggestions below to reduce ink saturation extremes on your printed pages. One of. Offset Printing Ink Density.

From www.printarea.cn

The Basic Principle and Process of Offset Printing Offset Printing Ink Density It is essentially the measurement of how dark and ink is. Optimum density for ink is determined by measuring the amount of contrast obtained in the 3/4 tone. Follow the suggestions below to reduce ink saturation extremes on your printed pages. Too much ink can cause smudging and drying problems,. Ink density in offset printing is the measurement light that. Offset Printing Ink Density.

From lithoartprinters.com

Offset Printing Litho Art Printers Offset Printing Ink Density Table 1 shows some typical solid density values for three common printing conditions. Unlike flexography or gravure printing methods, offset allows more control over ink density adjustments during production. One of the most common issues in offset printing is incorrect ink density. Ink density in offset printing is the measurement light that is reflected from an ink. Follow the suggestions. Offset Printing Ink Density.

From www.youtube.com

What is ink density in offset printing? මොකක් ද මේ ඉන්ක් ඩෙන්සිටි කියන්නේ? YouTube Offset Printing Ink Density Unlike flexography or gravure printing methods, offset allows more control over ink density adjustments during production. Table 1 shows some typical solid density values for three common printing conditions. It is essentially the measurement of how dark and ink is. One of the most common issues in offset printing is incorrect ink density. Follow the suggestions below to reduce ink. Offset Printing Ink Density.

From www.printcraft.com.au

Offset and Digital Printer Inks Explained Offset Printing Ink Density If you are just starting to use densitometers,. All printing methods, including offset,. Too much ink can cause smudging and drying problems,. Unlike flexography or gravure printing methods, offset allows more control over ink density adjustments during production. Follow the suggestions below to reduce ink saturation extremes on your printed pages. One of the most common issues in offset printing. Offset Printing Ink Density.

From www.youtube.com

How To Produce Offset Ink YouTube Offset Printing Ink Density Optimum density for ink is determined by measuring the amount of contrast obtained in the 3/4 tone. All printing methods, including offset,. Discover the essential technical aspects of offset printing ink that directly impact print quality and color richness. Too much ink can cause smudging and drying problems,. If you are just starting to use densitometers,. It is essentially the. Offset Printing Ink Density.

From offsetprintingtechnology.com

offset inks on press Offset printing technology Offset lithography Offset Printing Ink Density If you are just starting to use densitometers,. Discover the essential technical aspects of offset printing ink that directly impact print quality and color richness. Follow the suggestions below to reduce ink saturation extremes on your printed pages. Table 1 shows some typical solid density values for three common printing conditions. Ink density in offset printing is the measurement light. Offset Printing Ink Density.

From www.offsetprinting.info

What is Ink Density in Offset Printing? Offset Printing Ink Density One of the most common issues in offset printing is incorrect ink density. Optimum density for ink is determined by measuring the amount of contrast obtained in the 3/4 tone. Discover the essential technical aspects of offset printing ink that directly impact print quality and color richness. It is essentially the measurement of how dark and ink is. Unlike flexography. Offset Printing Ink Density.

From www.printarea.cn

Offset Ink, UV Offset Ink, Security Ink Suppliers Foshan Yinya Technology Co., Ltd Offset Printing Ink Density One of the most common issues in offset printing is incorrect ink density. Optimum density for ink is determined by measuring the amount of contrast obtained in the 3/4 tone. Follow the suggestions below to reduce ink saturation extremes on your printed pages. It is essentially the measurement of how dark and ink is. Unlike flexography or gravure printing methods,. Offset Printing Ink Density.

From www.xrite.com

Offset Printing Ink Formulation XRite Blog Offset Printing Ink Density All printing methods, including offset,. Too much ink can cause smudging and drying problems,. Discover the essential technical aspects of offset printing ink that directly impact print quality and color richness. Unlike flexography or gravure printing methods, offset allows more control over ink density adjustments during production. Follow the suggestions below to reduce ink saturation extremes on your printed pages.. Offset Printing Ink Density.

From www.youtube.com

Mixing of offset printing ink.【FineCause】 YouTube Offset Printing Ink Density Discover the essential technical aspects of offset printing ink that directly impact print quality and color richness. Unlike flexography or gravure printing methods, offset allows more control over ink density adjustments during production. Optimum density for ink is determined by measuring the amount of contrast obtained in the 3/4 tone. Table 1 shows some typical solid density values for three. Offset Printing Ink Density.

From www.researchgate.net

(PDF) Optimization of Ink Density for the Widest Color Gamut in a Lithographic Printing Process Offset Printing Ink Density Ink density in offset printing is the measurement light that is reflected from an ink. One of the most common issues in offset printing is incorrect ink density. It is essentially the measurement of how dark and ink is. Too much ink can cause smudging and drying problems,. Optimum density for ink is determined by measuring the amount of contrast. Offset Printing Ink Density.

From www.youtube.com

Semiautomatic ink density control for offset printing presses. YouTube Offset Printing Ink Density Ink density in offset printing is the measurement light that is reflected from an ink. Too much ink can cause smudging and drying problems,. One of the most common issues in offset printing is incorrect ink density. Table 1 shows some typical solid density values for three common printing conditions. Discover the essential technical aspects of offset printing ink that. Offset Printing Ink Density.

From www.offsetprinting.info

Types of Offset Printing Inks Offset Printing Ink Density Table 1 shows some typical solid density values for three common printing conditions. If you are just starting to use densitometers,. Too much ink can cause smudging and drying problems,. Optimum density for ink is determined by measuring the amount of contrast obtained in the 3/4 tone. Unlike flexography or gravure printing methods, offset allows more control over ink density. Offset Printing Ink Density.

From www.offsetprinting.info

Type of Offset Printing Ink Drying Offset Printing Ink Density If you are just starting to use densitometers,. Unlike flexography or gravure printing methods, offset allows more control over ink density adjustments during production. Table 1 shows some typical solid density values for three common printing conditions. One of the most common issues in offset printing is incorrect ink density. Optimum density for ink is determined by measuring the amount. Offset Printing Ink Density.

From www.firebirdprint.com

offset ink, printing ink,CMYK ink, Offset printing ink Offset Printing Ink Density Unlike flexography or gravure printing methods, offset allows more control over ink density adjustments during production. Table 1 shows some typical solid density values for three common printing conditions. It is essentially the measurement of how dark and ink is. One of the most common issues in offset printing is incorrect ink density. All printing methods, including offset,. Discover the. Offset Printing Ink Density.

From www.researchgate.net

(PDF) Investigation of the effects of different ink density values on color gamut in offset printing Offset Printing Ink Density One of the most common issues in offset printing is incorrect ink density. If you are just starting to use densitometers,. Follow the suggestions below to reduce ink saturation extremes on your printed pages. All printing methods, including offset,. It is essentially the measurement of how dark and ink is. Unlike flexography or gravure printing methods, offset allows more control. Offset Printing Ink Density.

From www.semanticscholar.org

[PDF] Investigation of the effects of different ink density values on color gamut in offset Offset Printing Ink Density One of the most common issues in offset printing is incorrect ink density. All printing methods, including offset,. It is essentially the measurement of how dark and ink is. If you are just starting to use densitometers,. Too much ink can cause smudging and drying problems,. Table 1 shows some typical solid density values for three common printing conditions. Discover. Offset Printing Ink Density.

From www.offsetprinting.info

The Offset Printing Densitometer What You Need to Know Offset Printing Ink Density Ink density in offset printing is the measurement light that is reflected from an ink. Follow the suggestions below to reduce ink saturation extremes on your printed pages. Table 1 shows some typical solid density values for three common printing conditions. Unlike flexography or gravure printing methods, offset allows more control over ink density adjustments during production. All printing methods,. Offset Printing Ink Density.