Water Jet Troubleshooting . Check if it’s needed to replace orifice or water stream is not focused (change nozzle) 5. Learn all about our extensive range of wardjet cnc waterjets. The nozzle body contains a jewel that requires regular cleaning. Each of these issues not only impacts the cutting quality but also the reliability. Check if there is any leaking in the water process flow. If you use hard water or water with a high density of impurities, it can lead to clogs or failure of the machine. Poor water quality can damage components and affect operation. Check if there is enough pressure (consistent 45 psi or above) for inlet water supply. Replace the orifice assembly if damaged. I’ve listed some of the common problems that waterjet cutting machines face and included some troubleshooting tips for. The hole in the jewel is very small,. Discover how to prevent common issues like abrasive buildup and. 5 tips for troubleshooting your waterjet. Check if the small water pump (optional) is working normally. Improperly maintained machines can even lead to injury of operators.

from jetpumpzukazuka.blogspot.com

Improperly maintained machines can even lead to injury of operators. The hole in the jewel is very small,. The nozzle body contains a jewel that requires regular cleaning. Each of these issues not only impacts the cutting quality but also the reliability. Check if there is enough pressure (consistent 45 psi or above) for inlet water supply. Check if it’s needed to replace orifice or water stream is not focused (change nozzle) 5. Discover how to prevent common issues like abrasive buildup and. Replace the orifice assembly if damaged. I’ve listed some of the common problems that waterjet cutting machines face and included some troubleshooting tips for. Check if there is any leaking in the water process flow.

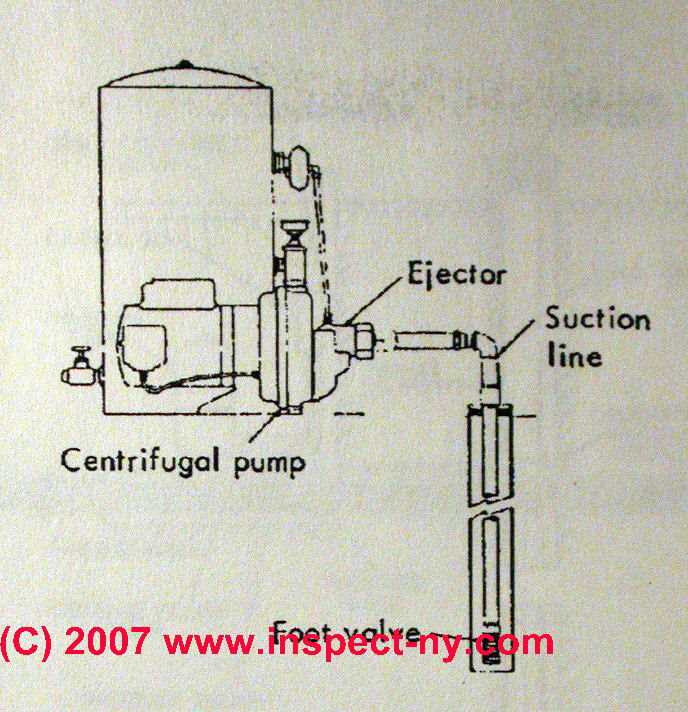

Jet Pump Shallow Well Jet Pump Troubleshooting

Water Jet Troubleshooting Clean the orifice and nozzle body. Discover how to prevent common issues like abrasive buildup and. Improperly maintained machines can even lead to injury of operators. Check if there is any leaking in the water process flow. Check if there is enough pressure (consistent 45 psi or above) for inlet water supply. Check if it’s needed to replace orifice or water stream is not focused (change nozzle) 5. Poor water quality can damage components and affect operation. Check if the small water pump (optional) is working normally. Learn all about our extensive range of wardjet cnc waterjets. 5 tips for troubleshooting your waterjet. Replace the orifice assembly if damaged. Clean the orifice and nozzle body. If you use hard water or water with a high density of impurities, it can lead to clogs or failure of the machine. Each of these issues not only impacts the cutting quality but also the reliability. The hole in the jewel is very small,. The nozzle body contains a jewel that requires regular cleaning.

From diagramweb.net

Everbilt Shallow Well Jet Pump Wiring Diagram Troubleshooting Water Jet Troubleshooting Each of these issues not only impacts the cutting quality but also the reliability. Clean the orifice and nozzle body. The hole in the jewel is very small,. Check if there is enough pressure (consistent 45 psi or above) for inlet water supply. Check if there is any leaking in the water process flow. Check if the small water pump. Water Jet Troubleshooting.

From suginocorp.com

Common Deburring Methods Sugino Corp. Water Jet Troubleshooting The hole in the jewel is very small,. Discover how to prevent common issues like abrasive buildup and. Improperly maintained machines can even lead to injury of operators. Clean the orifice and nozzle body. 5 tips for troubleshooting your waterjet. If you use hard water or water with a high density of impurities, it can lead to clogs or failure. Water Jet Troubleshooting.

From www.reddit.com

Waterjet Precision troubleshooting r/Waterjet_Channel Water Jet Troubleshooting Poor water quality can damage components and affect operation. The hole in the jewel is very small,. Check if there is enough pressure (consistent 45 psi or above) for inlet water supply. I’ve listed some of the common problems that waterjet cutting machines face and included some troubleshooting tips for. Each of these issues not only impacts the cutting quality. Water Jet Troubleshooting.

From www.youtube.com

Robotic waterjet troubleshooting YouTube Water Jet Troubleshooting Each of these issues not only impacts the cutting quality but also the reliability. Discover how to prevent common issues like abrasive buildup and. Learn all about our extensive range of wardjet cnc waterjets. I’ve listed some of the common problems that waterjet cutting machines face and included some troubleshooting tips for. Improperly maintained machines can even lead to injury. Water Jet Troubleshooting.

From fixmywaterjet.com

Training Gulf Coat Industrial Services Water Jet Troubleshooting Clean the orifice and nozzle body. I’ve listed some of the common problems that waterjet cutting machines face and included some troubleshooting tips for. Check if there is any leaking in the water process flow. Replace the orifice assembly if damaged. Improperly maintained machines can even lead to injury of operators. 5 tips for troubleshooting your waterjet. The nozzle body. Water Jet Troubleshooting.

From www.iqsdirectory.com

Water Jet Cutting What Is It? How Does It Work? Types, Uses Water Jet Troubleshooting Each of these issues not only impacts the cutting quality but also the reliability. Check if it’s needed to replace orifice or water stream is not focused (change nozzle) 5. Learn all about our extensive range of wardjet cnc waterjets. 5 tips for troubleshooting your waterjet. I’ve listed some of the common problems that waterjet cutting machines face and included. Water Jet Troubleshooting.

From ivycnc.com

Water Jet Maintenance A Comprehensive Guide For Keeping Your Machine Water Jet Troubleshooting Poor water quality can damage components and affect operation. I’ve listed some of the common problems that waterjet cutting machines face and included some troubleshooting tips for. The hole in the jewel is very small,. Discover how to prevent common issues like abrasive buildup and. Learn all about our extensive range of wardjet cnc waterjets. Replace the orifice assembly if. Water Jet Troubleshooting.

From www.youtube.com

Troubleshooting a Jet Pump Low Pressure or Flow YouTube Water Jet Troubleshooting Check if it’s needed to replace orifice or water stream is not focused (change nozzle) 5. Check if there is any leaking in the water process flow. Discover how to prevent common issues like abrasive buildup and. Check if there is enough pressure (consistent 45 psi or above) for inlet water supply. The hole in the jewel is very small,.. Water Jet Troubleshooting.

From circuitlibrebozos.z14.web.core.windows.net

Myers Jet Pump Troubleshooting Water Jet Troubleshooting If you use hard water or water with a high density of impurities, it can lead to clogs or failure of the machine. Check if there is enough pressure (consistent 45 psi or above) for inlet water supply. I’ve listed some of the common problems that waterjet cutting machines face and included some troubleshooting tips for. Check if it’s needed. Water Jet Troubleshooting.

From www.slideshare.net

Shallow well jet pumps troubleshooting Water Jet Troubleshooting Learn all about our extensive range of wardjet cnc waterjets. If you use hard water or water with a high density of impurities, it can lead to clogs or failure of the machine. Clean the orifice and nozzle body. Check if there is any leaking in the water process flow. I’ve listed some of the common problems that waterjet cutting. Water Jet Troubleshooting.

From machmotion.com

Is Troubleshooting Your Flow Waterjet Costing You? MachMotion Water Jet Troubleshooting The nozzle body contains a jewel that requires regular cleaning. I’ve listed some of the common problems that waterjet cutting machines face and included some troubleshooting tips for. Replace the orifice assembly if damaged. The hole in the jewel is very small,. Check if there is enough pressure (consistent 45 psi or above) for inlet water supply. 5 tips for. Water Jet Troubleshooting.

From wiringsunflower.z21.web.core.windows.net

Utilitech Jet Pump Parts Water Jet Troubleshooting Clean the orifice and nozzle body. The nozzle body contains a jewel that requires regular cleaning. Check if there is any leaking in the water process flow. Learn all about our extensive range of wardjet cnc waterjets. Each of these issues not only impacts the cutting quality but also the reliability. Check if it’s needed to replace orifice or water. Water Jet Troubleshooting.

From www.youtube.com

Omax WaterJet Troubleshooting YouTube Water Jet Troubleshooting Check if there is any leaking in the water process flow. I’ve listed some of the common problems that waterjet cutting machines face and included some troubleshooting tips for. Clean the orifice and nozzle body. Each of these issues not only impacts the cutting quality but also the reliability. Check if there is enough pressure (consistent 45 psi or above). Water Jet Troubleshooting.

From www.thefabricator.com

Six tips for waterjet troubleshooting and repair Water Jet Troubleshooting Each of these issues not only impacts the cutting quality but also the reliability. Improperly maintained machines can even lead to injury of operators. 5 tips for troubleshooting your waterjet. Check if the small water pump (optional) is working normally. Check if there is any leaking in the water process flow. Poor water quality can damage components and affect operation.. Water Jet Troubleshooting.

From machmotion.com

Is Troubleshooting Your Flow Waterjet Costing You? MachMotion Water Jet Troubleshooting 5 tips for troubleshooting your waterjet. Learn all about our extensive range of wardjet cnc waterjets. Poor water quality can damage components and affect operation. Check if there is enough pressure (consistent 45 psi or above) for inlet water supply. The nozzle body contains a jewel that requires regular cleaning. Improperly maintained machines can even lead to injury of operators.. Water Jet Troubleshooting.

From schematron.org

Everbilt Shallow Well Jet Pump Wiring Diagram For 110v Troubleshooting Water Jet Troubleshooting The hole in the jewel is very small,. Improperly maintained machines can even lead to injury of operators. The nozzle body contains a jewel that requires regular cleaning. 5 tips for troubleshooting your waterjet. Poor water quality can damage components and affect operation. Replace the orifice assembly if damaged. I’ve listed some of the common problems that waterjet cutting machines. Water Jet Troubleshooting.

From wiringall.com

Everbilt Shallow Well Jet Pump Wiring Diagram For 110v Troubleshooting Water Jet Troubleshooting Learn all about our extensive range of wardjet cnc waterjets. Check if it’s needed to replace orifice or water stream is not focused (change nozzle) 5. Clean the orifice and nozzle body. Check if the small water pump (optional) is working normally. The hole in the jewel is very small,. Check if there is any leaking in the water process. Water Jet Troubleshooting.

From needaplumberinc.com

Clear Clogged and Slow Drains with Water Jetting Service Need a Water Jet Troubleshooting Check if there is enough pressure (consistent 45 psi or above) for inlet water supply. Check if there is any leaking in the water process flow. Replace the orifice assembly if damaged. I’ve listed some of the common problems that waterjet cutting machines face and included some troubleshooting tips for. Check if it’s needed to replace orifice or water stream. Water Jet Troubleshooting.

From blog.thepipingmart.com

Advantages and Disadvantages of Water Jet Machining Water Jet Troubleshooting Poor water quality can damage components and affect operation. The nozzle body contains a jewel that requires regular cleaning. Improperly maintained machines can even lead to injury of operators. Check if there is any leaking in the water process flow. Each of these issues not only impacts the cutting quality but also the reliability. Replace the orifice assembly if damaged.. Water Jet Troubleshooting.

From www.wardjet.com

Waterjet University Chapter 3 How Waterjet Cutting Works Water Jet Troubleshooting The nozzle body contains a jewel that requires regular cleaning. 5 tips for troubleshooting your waterjet. Check if there is any leaking in the water process flow. Learn all about our extensive range of wardjet cnc waterjets. Improperly maintained machines can even lead to injury of operators. Clean the orifice and nozzle body. Poor water quality can damage components and. Water Jet Troubleshooting.

From www.youtube.com

How to prewash garments with the Active WaterJet on your Top Load Water Jet Troubleshooting The hole in the jewel is very small,. If you use hard water or water with a high density of impurities, it can lead to clogs or failure of the machine. Poor water quality can damage components and affect operation. Discover how to prevent common issues like abrasive buildup and. Check if there is any leaking in the water process. Water Jet Troubleshooting.

From swaterjet.com

Water jet Cutting Pressure How Strong It Is? Same Waterjet Water Jet Troubleshooting If you use hard water or water with a high density of impurities, it can lead to clogs or failure of the machine. 5 tips for troubleshooting your waterjet. Clean the orifice and nozzle body. Improperly maintained machines can even lead to injury of operators. Each of these issues not only impacts the cutting quality but also the reliability. Check. Water Jet Troubleshooting.

From www.downunderspiritteam.com.au

Inferior Sparrow operator high pressure water cutter Duty Exactly Water Jet Troubleshooting Each of these issues not only impacts the cutting quality but also the reliability. Discover how to prevent common issues like abrasive buildup and. Improperly maintained machines can even lead to injury of operators. I’ve listed some of the common problems that waterjet cutting machines face and included some troubleshooting tips for. The hole in the jewel is very small,.. Water Jet Troubleshooting.

From ivycnc.com

Waterjet Cutting Accuracy A Guide To Achieving Precision Cuts IVYCNC Water Jet Troubleshooting Discover how to prevent common issues like abrasive buildup and. Replace the orifice assembly if damaged. The hole in the jewel is very small,. Poor water quality can damage components and affect operation. If you use hard water or water with a high density of impurities, it can lead to clogs or failure of the machine. Improperly maintained machines can. Water Jet Troubleshooting.

From arironllc.com

How Accurate is Water Jet Cutting? Water Jet Troubleshooting The hole in the jewel is very small,. Check if there is any leaking in the water process flow. The nozzle body contains a jewel that requires regular cleaning. Learn all about our extensive range of wardjet cnc waterjets. I’ve listed some of the common problems that waterjet cutting machines face and included some troubleshooting tips for. Poor water quality. Water Jet Troubleshooting.

From waterjetting.org.uk

Research Heralds ‘Step Change’ in Water Jet Injury Care Water Jetting Water Jet Troubleshooting Learn all about our extensive range of wardjet cnc waterjets. Clean the orifice and nozzle body. The hole in the jewel is very small,. Each of these issues not only impacts the cutting quality but also the reliability. Discover how to prevent common issues like abrasive buildup and. The nozzle body contains a jewel that requires regular cleaning. If you. Water Jet Troubleshooting.

From www.boltontool.com

Waterjet Flow 87K Bleeddown Valve Repair Kit 015084 Toolots Water Jet Troubleshooting Check if it’s needed to replace orifice or water stream is not focused (change nozzle) 5. I’ve listed some of the common problems that waterjet cutting machines face and included some troubleshooting tips for. Replace the orifice assembly if damaged. If you use hard water or water with a high density of impurities, it can lead to clogs or failure. Water Jet Troubleshooting.

From www.leron.nl

Waterjet operator Leron Water Jet Troubleshooting The nozzle body contains a jewel that requires regular cleaning. Check if there is enough pressure (consistent 45 psi or above) for inlet water supply. Check if the small water pump (optional) is working normally. Improperly maintained machines can even lead to injury of operators. 5 tips for troubleshooting your waterjet. I’ve listed some of the common problems that waterjet. Water Jet Troubleshooting.

From allwaterjet.com

Water Jet Head Spare Part On Off Valve Repair Kit for BFT Water Jet Troubleshooting The nozzle body contains a jewel that requires regular cleaning. Poor water quality can damage components and affect operation. Replace the orifice assembly if damaged. Check if there is any leaking in the water process flow. Improperly maintained machines can even lead to injury of operators. Learn all about our extensive range of wardjet cnc waterjets. 5 tips for troubleshooting. Water Jet Troubleshooting.

From www.instructables.com

Pier 9 Troubleshooting OMAX Waterjet Morning Startup Routine 6 Steps Water Jet Troubleshooting 5 tips for troubleshooting your waterjet. I’ve listed some of the common problems that waterjet cutting machines face and included some troubleshooting tips for. Improperly maintained machines can even lead to injury of operators. Learn all about our extensive range of wardjet cnc waterjets. Discover how to prevent common issues like abrasive buildup and. Check if it’s needed to replace. Water Jet Troubleshooting.

From jetpumpzukazuka.blogspot.com

Jet Pump Shallow Well Jet Pump Troubleshooting Water Jet Troubleshooting Replace the orifice assembly if damaged. Check if there is enough pressure (consistent 45 psi or above) for inlet water supply. Check if it’s needed to replace orifice or water stream is not focused (change nozzle) 5. If you use hard water or water with a high density of impurities, it can lead to clogs or failure of the machine.. Water Jet Troubleshooting.

From www.youtube.com

Troubleshoot & Repair Water Jet / Mengesan Kerosakan & Membaiki Water Water Jet Troubleshooting 5 tips for troubleshooting your waterjet. Check if it’s needed to replace orifice or water stream is not focused (change nozzle) 5. Discover how to prevent common issues like abrasive buildup and. The nozzle body contains a jewel that requires regular cleaning. I’ve listed some of the common problems that waterjet cutting machines face and included some troubleshooting tips for.. Water Jet Troubleshooting.

From www.researchgate.net

Behaviour of water jet in submerged cutting conditions and 3d drawing Water Jet Troubleshooting Learn all about our extensive range of wardjet cnc waterjets. I’ve listed some of the common problems that waterjet cutting machines face and included some troubleshooting tips for. Poor water quality can damage components and affect operation. The hole in the jewel is very small,. Discover how to prevent common issues like abrasive buildup and. Check if there is any. Water Jet Troubleshooting.

From www.rcworst.com

Troubleshooting a Jet Pump Low Pressure or Flow Water Jet Troubleshooting The hole in the jewel is very small,. 5 tips for troubleshooting your waterjet. Check if the small water pump (optional) is working normally. Discover how to prevent common issues like abrasive buildup and. Poor water quality can damage components and affect operation. The nozzle body contains a jewel that requires regular cleaning. If you use hard water or water. Water Jet Troubleshooting.

From www.thefabricator.com

Six tips for waterjet troubleshooting and repair Water Jet Troubleshooting Each of these issues not only impacts the cutting quality but also the reliability. Check if the small water pump (optional) is working normally. Discover how to prevent common issues like abrasive buildup and. Clean the orifice and nozzle body. Poor water quality can damage components and affect operation. Check if there is any leaking in the water process flow.. Water Jet Troubleshooting.