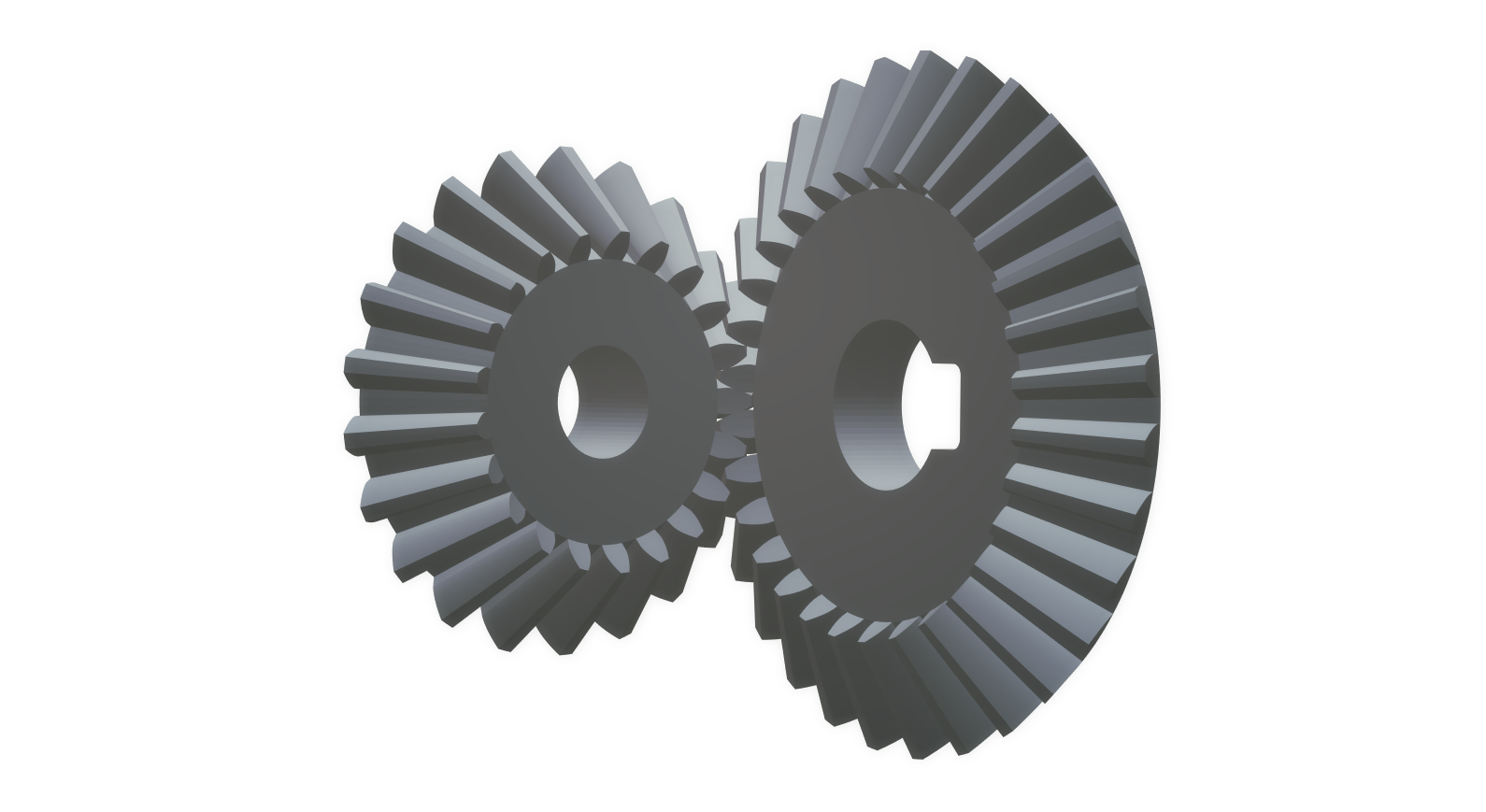

Bevel Gears Also Known As . Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. Their ability to translate rotation. Bevel gears, which are conically shaped and most often mounted on shafts that are 90 degrees apart, but can be. Gear manufacturers produce far more than traditionally shaped spur gears. The ring gear itself is driven by a smaller bevel gear, which is then also called a pinion. The gear teeth of a bevel gear mesh with the teeth of a. With bevel gears, the shape of the gears forms a truncated cone (called pitch. A bevel gear is a type of conically shaped gear that has octoidal teeth. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. B evel gearboxes have been a crucial component in various industries for more than a century.

from www.stlgears.com

With bevel gears, the shape of the gears forms a truncated cone (called pitch. A bevel gear is a type of conically shaped gear that has octoidal teeth. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. B evel gearboxes have been a crucial component in various industries for more than a century. Bevel gears, which are conically shaped and most often mounted on shafts that are 90 degrees apart, but can be. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. Their ability to translate rotation. Gear manufacturers produce far more than traditionally shaped spur gears. The ring gear itself is driven by a smaller bevel gear, which is then also called a pinion. The gear teeth of a bevel gear mesh with the teeth of a.

The Free STL Gear Designer

Bevel Gears Also Known As Bevel gears, which are conically shaped and most often mounted on shafts that are 90 degrees apart, but can be. Bevel gears, which are conically shaped and most often mounted on shafts that are 90 degrees apart, but can be. B evel gearboxes have been a crucial component in various industries for more than a century. A bevel gear is a type of conically shaped gear that has octoidal teeth. The ring gear itself is driven by a smaller bevel gear, which is then also called a pinion. Their ability to translate rotation. The gear teeth of a bevel gear mesh with the teeth of a. With bevel gears, the shape of the gears forms a truncated cone (called pitch. Gear manufacturers produce far more than traditionally shaped spur gears. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts.

From rerev.com

Bevel gear definition and meaning REREV Bevel Gears Also Known As Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. Gear manufacturers produce far more than traditionally shaped spur gears. Bevel gears, which are conically shaped and most often mounted on shafts that are 90 degrees apart, but can be. Unlike cylindrical gears, they offer diverse configurations,. Bevel Gears Also Known As.

From marinerspointpro.com

Types of Bevel Gears and Their Functions Marinerspointpro Bevel Gears Also Known As With bevel gears, the shape of the gears forms a truncated cone (called pitch. The ring gear itself is driven by a smaller bevel gear, which is then also called a pinion. The gear teeth of a bevel gear mesh with the teeth of a. A bevel gear is a type of conically shaped gear that has octoidal teeth. Bevel. Bevel Gears Also Known As.

From www.ais-industrialsupply.com

Bevel Gears Ais Industrialsupply Bevel Gears Also Known As Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. The ring gear itself is driven by a smaller bevel gear, which is then also called a pinion. With bevel gears, the shape of the gears forms a truncated cone (called pitch. The gear teeth of a bevel gear mesh. Bevel Gears Also Known As.

From news.thomasnet.com

Ondrives Precision Bevel Gears Bevel Gears Also Known As Bevel gears, which are conically shaped and most often mounted on shafts that are 90 degrees apart, but can be. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion. Bevel Gears Also Known As.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gears Also Known As The ring gear itself is driven by a smaller bevel gear, which is then also called a pinion. A bevel gear is a type of conically shaped gear that has octoidal teeth. Bevel gears, which are conically shaped and most often mounted on shafts that are 90 degrees apart, but can be. With bevel gears, the shape of the gears. Bevel Gears Also Known As.

From www.minchen-tw.com

STRAIGHT BEVEL GEAR for Agricultural Machinery 2|Bevel Gears Taiwan Bevel Gears Also Known As With bevel gears, the shape of the gears forms a truncated cone (called pitch. Their ability to translate rotation. The gear teeth of a bevel gear mesh with the teeth of a. Bevel gears, which are conically shaped and most often mounted on shafts that are 90 degrees apart, but can be. A bevel gear is a type of conically. Bevel Gears Also Known As.

From www.alamy.com

Bevel gear hires stock photography and images Alamy Bevel Gears Also Known As Bevel gears, which are conically shaped and most often mounted on shafts that are 90 degrees apart, but can be. A bevel gear is a type of conically shaped gear that has octoidal teeth. The gear teeth of a bevel gear mesh with the teeth of a. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth,. Bevel Gears Also Known As.

From www.dreamstime.com

Bevel Gears with a Bronze Insert on a Mandrel after Fabrication on Gear Bevel Gears Also Known As B evel gearboxes have been a crucial component in various industries for more than a century. The gear teeth of a bevel gear mesh with the teeth of a. With bevel gears, the shape of the gears forms a truncated cone (called pitch. Their ability to translate rotation. Gear manufacturers produce far more than traditionally shaped spur gears. Bevel gears,. Bevel Gears Also Known As.

From nmc.go.ke

Bevel Gears Numerical Machining Complex Limited Bevel Gears Also Known As Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. The gear teeth of a bevel gear mesh with the teeth of a. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. A bevel gear is. Bevel Gears Also Known As.

From www.engineersgallery.com

Understand Mechanical Gear Bevel Gear Engineers Gallery Bevel Gears Also Known As Bevel gears, which are conically shaped and most often mounted on shafts that are 90 degrees apart, but can be. Their ability to translate rotation. A bevel gear is a type of conically shaped gear that has octoidal teeth. B evel gearboxes have been a crucial component in various industries for more than a century. Gear manufacturers produce far more. Bevel Gears Also Known As.

From premium-transmission.com

Industries That Commonly Use Bevel Gears Premium Transmission Bevel Gears Also Known As Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. Bevel gears, which are conically shaped and most often mounted on shafts that are 90 degrees apart, but can be. A bevel gear is a type of conically shaped gear that has octoidal teeth. The ring gear. Bevel Gears Also Known As.

From www.godigit.com

What Is a Gear Types, Applications and Working Bevel Gears Also Known As Bevel gears, which are conically shaped and most often mounted on shafts that are 90 degrees apart, but can be. B evel gearboxes have been a crucial component in various industries for more than a century. Their ability to translate rotation. A bevel gear is a type of conically shaped gear that has octoidal teeth. The ring gear itself is. Bevel Gears Also Known As.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gears Also Known As The ring gear itself is driven by a smaller bevel gear, which is then also called a pinion. Bevel gears, which are conically shaped and most often mounted on shafts that are 90 degrees apart, but can be. B evel gearboxes have been a crucial component in various industries for more than a century. Their ability to translate rotation. The. Bevel Gears Also Known As.

From screw-jacks.en.made-in-china.com

Miter Bevel Gearbox Is Also Known as Spiral Bevel Gear Drives, Right Bevel Gears Also Known As Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. The ring gear itself is driven by a smaller bevel gear, which is then also called a pinion. B evel gearboxes have been a crucial component in various industries for more than a century. The gear teeth. Bevel Gears Also Known As.

From www.chamolgear.com

Custom Bevel Gear Manufacturer Since 1968 Bevel Gears Also Known As A bevel gear is a type of conically shaped gear that has octoidal teeth. The ring gear itself is driven by a smaller bevel gear, which is then also called a pinion. The gear teeth of a bevel gear mesh with the teeth of a. B evel gearboxes have been a crucial component in various industries for more than a. Bevel Gears Also Known As.

From theadamscompany.com

Straight Bevel Gears The Adams Company Bevel Gears Also Known As The ring gear itself is driven by a smaller bevel gear, which is then also called a pinion. B evel gearboxes have been a crucial component in various industries for more than a century. The gear teeth of a bevel gear mesh with the teeth of a. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth,. Bevel Gears Also Known As.

From www.alamy.com

Bevel Gears High Resolution Stock Photography and Images Alamy Bevel Gears Also Known As The gear teeth of a bevel gear mesh with the teeth of a. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. Their ability to translate rotation. With bevel gears, the shape of the gears forms a truncated cone (called pitch. Gear manufacturers produce far more than traditionally shaped. Bevel Gears Also Known As.

From www.numerade.com

The figure below shows a countershaft with a helical gear (B), bevel Bevel Gears Also Known As Gear manufacturers produce far more than traditionally shaped spur gears. Their ability to translate rotation. The gear teeth of a bevel gear mesh with the teeth of a. Bevel gears, which are conically shaped and most often mounted on shafts that are 90 degrees apart, but can be. With bevel gears, the shape of the gears forms a truncated cone. Bevel Gears Also Known As.

From www.industrial-gears.com

Bevel Gear Manufacturers Bevel Gear Information Bevel Gears Also Known As Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. Gear manufacturers produce far more than traditionally shaped spur gears. The ring gear itself is driven by a smaller bevel gear, which is then also called a pinion. B evel gearboxes have been a crucial component in various industries for. Bevel Gears Also Known As.

From kineticgears.in

Bevel Gear Gears Bevel Gears Also Known As Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. A bevel gear is a type of conically shaped gear that has octoidal teeth. Gear manufacturers produce far more than traditionally shaped spur gears. Bevel gears, which are conically shaped and most often mounted on shafts that. Bevel Gears Also Known As.

From www.alamy.com

Bevel Gears High Resolution Stock Photography and Images Alamy Bevel Gears Also Known As Their ability to translate rotation. A bevel gear is a type of conically shaped gear that has octoidal teeth. Gear manufacturers produce far more than traditionally shaped spur gears. The ring gear itself is driven by a smaller bevel gear, which is then also called a pinion. Bevel gears, which are conically shaped and most often mounted on shafts that. Bevel Gears Also Known As.

From www.mechanicalbooster.com

Types of Gears Complete Explanation Mechanical Booster Bevel Gears Also Known As With bevel gears, the shape of the gears forms a truncated cone (called pitch. Their ability to translate rotation. The ring gear itself is driven by a smaller bevel gear, which is then also called a pinion. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. The gear teeth. Bevel Gears Also Known As.

From premium-transmission.com

Bevel Gears Archives Premium Blog Bevel Gears Also Known As A bevel gear is a type of conically shaped gear that has octoidal teeth. Gear manufacturers produce far more than traditionally shaped spur gears. Their ability to translate rotation. The ring gear itself is driven by a smaller bevel gear, which is then also called a pinion. The gear teeth of a bevel gear mesh with the teeth of a.. Bevel Gears Also Known As.

From covalomotion.com

Bevel Gear 12DP 20PA Steel Covalo Industries Bevel Gears Also Known As Bevel gears, which are conically shaped and most often mounted on shafts that are 90 degrees apart, but can be. B evel gearboxes have been a crucial component in various industries for more than a century. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. The. Bevel Gears Also Known As.

From www.iqsdirectory.com

Bevel Gear What Are They? How Do They Work? Types and Uses Bevel Gears Also Known As Their ability to translate rotation. The ring gear itself is driven by a smaller bevel gear, which is then also called a pinion. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. B evel gearboxes have been a crucial component in various industries for more than. Bevel Gears Also Known As.

From www.linngear.com

Bevel Gears Linn Gear Manufactures Bevel Gears Also Known As The gear teeth of a bevel gear mesh with the teeth of a. Bevel gears, which are conically shaped and most often mounted on shafts that are 90 degrees apart, but can be. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. B evel gearboxes have been a crucial. Bevel Gears Also Known As.

From blogs.sw.siemens.com

Simulate Bevel Gears Accurately and Efficiently Simcenter Bevel Gears Also Known As The gear teeth of a bevel gear mesh with the teeth of a. Their ability to translate rotation. The ring gear itself is driven by a smaller bevel gear, which is then also called a pinion. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. Bevel gears, characterized by. Bevel Gears Also Known As.

From erc-bpgc.github.io

Gears ERC Handbook Bevel Gears Also Known As B evel gearboxes have been a crucial component in various industries for more than a century. With bevel gears, the shape of the gears forms a truncated cone (called pitch. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. Their ability to translate rotation. Unlike cylindrical. Bevel Gears Also Known As.

From selmec.org.uk

The Theory of Meccano Gears Part 3 — Bevel Gears — South East London Bevel Gears Also Known As With bevel gears, the shape of the gears forms a truncated cone (called pitch. The gear teeth of a bevel gear mesh with the teeth of a. B evel gearboxes have been a crucial component in various industries for more than a century. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of. Bevel Gears Also Known As.

From www.stlgears.com

The Free STL Gear Designer Bevel Gears Also Known As Bevel gears, which are conically shaped and most often mounted on shafts that are 90 degrees apart, but can be. A bevel gear is a type of conically shaped gear that has octoidal teeth. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. B evel gearboxes. Bevel Gears Also Known As.

From www.tradeindia.com

Steel Bevel Gears at Best Price in Sonipat, Haryana Progressive Gear Bevel Gears Also Known As With bevel gears, the shape of the gears forms a truncated cone (called pitch. Their ability to translate rotation. Gear manufacturers produce far more than traditionally shaped spur gears. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. A bevel gear is a type of conically. Bevel Gears Also Known As.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gears Also Known As B evel gearboxes have been a crucial component in various industries for more than a century. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. A bevel gear is a type of conically shaped gear that has octoidal teeth. Gear manufacturers produce far more than traditionally shaped spur gears.. Bevel Gears Also Known As.

From www.unitedgearct.com

Bevel Gears Now Being Cut United Gear & Machine Co., Inc. Bevel Gears Also Known As With bevel gears, the shape of the gears forms a truncated cone (called pitch. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. The gear teeth of a bevel gear mesh with the teeth of a. B evel gearboxes have been a crucial component in various. Bevel Gears Also Known As.

From blogs.sw.siemens.com

Simulate Bevel Gears Accurately and Efficiently Simcenter Bevel Gears Also Known As The ring gear itself is driven by a smaller bevel gear, which is then also called a pinion. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. Their ability to translate rotation. A bevel gear is a type of conically shaped gear that has octoidal teeth.. Bevel Gears Also Known As.

From www.iqsdirectory.com

Bevel Gear What Are They? How Do They Work? Types and Uses Bevel Gears Also Known As B evel gearboxes have been a crucial component in various industries for more than a century. Gear manufacturers produce far more than traditionally shaped spur gears. With bevel gears, the shape of the gears forms a truncated cone (called pitch. The gear teeth of a bevel gear mesh with the teeth of a. Bevel gears, which are conically shaped and. Bevel Gears Also Known As.