Veneer Cutting Process . The process of cutting the veneer from the log varies depending upon the pattern desired, the log itself, where from the tree it’s being. Entire log is peeled producing a continuous ribbon of veneer. In rotary cut, the veneers are peeled from a log like paper. — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. there are 3 main slicing methods as shown below. — wood veneer can be cut in several ways, each producing a unique grain pattern and aesthetic. Quarter cut or straight grain veneer is sliced to produce a very linear grain. — the four common cuts for veneer are rotary, plain sliced, quarter sliced and rift cut.

from veneerlamination.weebly.com

In rotary cut, the veneers are peeled from a log like paper. — the four common cuts for veneer are rotary, plain sliced, quarter sliced and rift cut. — wood veneer can be cut in several ways, each producing a unique grain pattern and aesthetic. — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. The process of cutting the veneer from the log varies depending upon the pattern desired, the log itself, where from the tree it’s being. there are 3 main slicing methods as shown below. Quarter cut or straight grain veneer is sliced to produce a very linear grain. Entire log is peeled producing a continuous ribbon of veneer.

Step by Step Process Veneer laminating curved forms

Veneer Cutting Process — wood veneer can be cut in several ways, each producing a unique grain pattern and aesthetic. Entire log is peeled producing a continuous ribbon of veneer. there are 3 main slicing methods as shown below. In rotary cut, the veneers are peeled from a log like paper. — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. Quarter cut or straight grain veneer is sliced to produce a very linear grain. — the four common cuts for veneer are rotary, plain sliced, quarter sliced and rift cut. — wood veneer can be cut in several ways, each producing a unique grain pattern and aesthetic. The process of cutting the veneer from the log varies depending upon the pattern desired, the log itself, where from the tree it’s being.

From www.youtube.com

Veneer Cut Method YouTube Veneer Cutting Process Entire log is peeled producing a continuous ribbon of veneer. — the four common cuts for veneer are rotary, plain sliced, quarter sliced and rift cut. there are 3 main slicing methods as shown below. — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. In rotary cut,. Veneer Cutting Process.

From www.craiulmuntilor.com

Veneer cutting methods Veneer Timber Logs Craiul Muntilor Veneer Cutting Process — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. Entire log is peeled producing a continuous ribbon of veneer. there are 3 main slicing methods as shown below. In rotary cut, the veneers are peeled from a log like paper. Quarter cut or straight grain veneer is sliced. Veneer Cutting Process.

From www.linearfinewoodworking.com

Design Process Linear Fine Woodworking Phoenix AZ Veneer Cutting Process — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. — wood veneer can be cut in several ways, each producing a unique grain pattern and aesthetic. — the four common cuts for veneer are rotary, plain sliced, quarter sliced and rift cut. The process of cutting the. Veneer Cutting Process.

From naturalveneers.com

What are Various Cutting Methodologies Possible in Wood & Veneers...? Veneer Cutting Process Entire log is peeled producing a continuous ribbon of veneer. In rotary cut, the veneers are peeled from a log like paper. Quarter cut or straight grain veneer is sliced to produce a very linear grain. — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. there are 3. Veneer Cutting Process.

From blog.buildllc.com

Veneering 101 BUILD Blog Veneer Cutting Process Quarter cut or straight grain veneer is sliced to produce a very linear grain. there are 3 main slicing methods as shown below. — wood veneer can be cut in several ways, each producing a unique grain pattern and aesthetic. — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood. Veneer Cutting Process.

From estoniantimber.ee

Manufacturing Process of Veneer and Plywood Estonian Timber Veneer Cutting Process — the four common cuts for veneer are rotary, plain sliced, quarter sliced and rift cut. In rotary cut, the veneers are peeled from a log like paper. — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. there are 3 main slicing methods as shown below. The. Veneer Cutting Process.

From www.researchgate.net

Rotary peeling of veneer, and radial (R), longitudinal (L) and Veneer Cutting Process — the four common cuts for veneer are rotary, plain sliced, quarter sliced and rift cut. there are 3 main slicing methods as shown below. In rotary cut, the veneers are peeled from a log like paper. The process of cutting the veneer from the log varies depending upon the pattern desired, the log itself, where from the. Veneer Cutting Process.

From www.youtube.com

Wood Veneer Methods And Techniques For Beginners VeneerFactory Veneer Cutting Process The process of cutting the veneer from the log varies depending upon the pattern desired, the log itself, where from the tree it’s being. there are 3 main slicing methods as shown below. Quarter cut or straight grain veneer is sliced to produce a very linear grain. Entire log is peeled producing a continuous ribbon of veneer. —. Veneer Cutting Process.

From www.awi-wa.com

Veneer Cutting & Slicing Characteristics Architectural Woods Veneer Cutting Process there are 3 main slicing methods as shown below. — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. — the four common cuts for veneer are rotary, plain sliced, quarter sliced and rift cut. Quarter cut or straight grain veneer is sliced to produce a very linear. Veneer Cutting Process.

From www.architectureanddesign.com.au

Rotary peeling or slicing Different ways to cut veneer Architecture Veneer Cutting Process — wood veneer can be cut in several ways, each producing a unique grain pattern and aesthetic. Quarter cut or straight grain veneer is sliced to produce a very linear grain. there are 3 main slicing methods as shown below. Entire log is peeled producing a continuous ribbon of veneer. — veneer production is a meticulous process. Veneer Cutting Process.

From blog.buildllc.com

Veneering 101 BUILD Blog Veneer Cutting Process — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. Entire log is peeled producing a continuous ribbon of veneer. The process of cutting the veneer from the log varies depending upon the pattern desired, the log itself, where from the tree it’s being. — the four common cuts. Veneer Cutting Process.

From readveneersltd.co.uk

Real Wood Veneer Cuts Read Veneers Essex Veneer Cutting Process Entire log is peeled producing a continuous ribbon of veneer. — the four common cuts for veneer are rotary, plain sliced, quarter sliced and rift cut. — wood veneer can be cut in several ways, each producing a unique grain pattern and aesthetic. there are 3 main slicing methods as shown below. The process of cutting the. Veneer Cutting Process.

From veneerlamination.weebly.com

Step by Step Process Veneer laminating curved forms Veneer Cutting Process The process of cutting the veneer from the log varies depending upon the pattern desired, the log itself, where from the tree it’s being. — the four common cuts for veneer are rotary, plain sliced, quarter sliced and rift cut. — wood veneer can be cut in several ways, each producing a unique grain pattern and aesthetic. . Veneer Cutting Process.

From www.lawcris.co.uk

Veneer Decorative Surfaces Veneer Cutting Process there are 3 main slicing methods as shown below. — the four common cuts for veneer are rotary, plain sliced, quarter sliced and rift cut. In rotary cut, the veneers are peeled from a log like paper. Quarter cut or straight grain veneer is sliced to produce a very linear grain. Entire log is peeled producing a continuous. Veneer Cutting Process.

From www.woodworkingnetwork.com

Illustrated guide of veneer cutting methods Woodworking Network Veneer Cutting Process — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. Quarter cut or straight grain veneer is sliced to produce a very linear grain. The process of cutting the veneer from the log varies depending upon the pattern desired, the log itself, where from the tree it’s being. Entire log. Veneer Cutting Process.

From www.hardwood-guys.com

Rotary Cut vs Flat Cut Veneers Veneer Cutting Process Entire log is peeled producing a continuous ribbon of veneer. there are 3 main slicing methods as shown below. — the four common cuts for veneer are rotary, plain sliced, quarter sliced and rift cut. In rotary cut, the veneers are peeled from a log like paper. — wood veneer can be cut in several ways, each. Veneer Cutting Process.

From gharpedia.com

Manufacturing Process of Wood Veneer Veneer Cutting Process — the four common cuts for veneer are rotary, plain sliced, quarter sliced and rift cut. — wood veneer can be cut in several ways, each producing a unique grain pattern and aesthetic. there are 3 main slicing methods as shown below. Entire log is peeled producing a continuous ribbon of veneer. — veneer production is. Veneer Cutting Process.

From www.sagaveneers.com

SAGA VENEES Veneer Cutting Process Quarter cut or straight grain veneer is sliced to produce a very linear grain. — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. — wood veneer can be cut in several ways, each producing a unique grain pattern and aesthetic. The process of cutting the veneer from the. Veneer Cutting Process.

From www.youtube.com

How to Cut Veneer with Hand Tools YouTube Veneer Cutting Process The process of cutting the veneer from the log varies depending upon the pattern desired, the log itself, where from the tree it’s being. In rotary cut, the veneers are peeled from a log like paper. — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. there are 3. Veneer Cutting Process.

From www.youtube.com

Logging and Veneer Process (no narration) YouTube Veneer Cutting Process Entire log is peeled producing a continuous ribbon of veneer. — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. Quarter cut or straight grain veneer is sliced to produce a very linear grain. The process of cutting the veneer from the log varies depending upon the pattern desired, the. Veneer Cutting Process.

From heitink.us

Learn About Our Wood Veneer Process Heitink Architectural Veneer and Veneer Cutting Process In rotary cut, the veneers are peeled from a log like paper. — the four common cuts for veneer are rotary, plain sliced, quarter sliced and rift cut. — wood veneer can be cut in several ways, each producing a unique grain pattern and aesthetic. Quarter cut or straight grain veneer is sliced to produce a very linear. Veneer Cutting Process.

From www.youtube.com

Rotary veneer cutting machine;veneer peeling line;veneer stacker;wood Veneer Cutting Process In rotary cut, the veneers are peeled from a log like paper. Entire log is peeled producing a continuous ribbon of veneer. — wood veneer can be cut in several ways, each producing a unique grain pattern and aesthetic. there are 3 main slicing methods as shown below. The process of cutting the veneer from the log varies. Veneer Cutting Process.

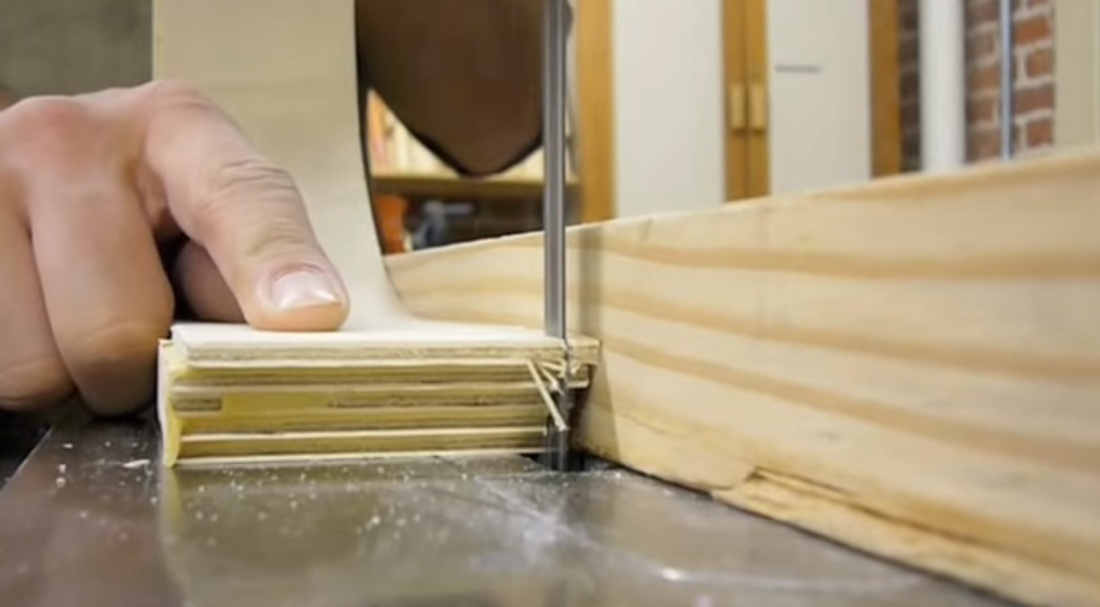

From www.popularwoodworking.com

Three Ways to Joint Veneer Edges Popular Woodworking Veneer Cutting Process The process of cutting the veneer from the log varies depending upon the pattern desired, the log itself, where from the tree it’s being. Quarter cut or straight grain veneer is sliced to produce a very linear grain. — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. —. Veneer Cutting Process.

From decor-plywood.com

Rotarycut beech veneer Producer, Decor Veneer Cutting Process The process of cutting the veneer from the log varies depending upon the pattern desired, the log itself, where from the tree it’s being. Entire log is peeled producing a continuous ribbon of veneer. In rotary cut, the veneers are peeled from a log like paper. — the four common cuts for veneer are rotary, plain sliced, quarter sliced. Veneer Cutting Process.

From plywoodexpress.com

Veneer Cuts — Plywood Express Veneer Cutting Process — the four common cuts for veneer are rotary, plain sliced, quarter sliced and rift cut. — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. Quarter cut or straight grain veneer is sliced to produce a very linear grain. The process of cutting the veneer from the log. Veneer Cutting Process.

From www.youtube.com

veneer peeling process veneer rotary cutting machine plywood Veneer Cutting Process — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. Entire log is peeled producing a continuous ribbon of veneer. The process of cutting the veneer from the log varies depending upon the pattern desired, the log itself, where from the tree it’s being. In rotary cut, the veneers are. Veneer Cutting Process.

From www.youtube.com

Manufacturing Process of Veneer and Plywood;veneer peeling machine;log Veneer Cutting Process The process of cutting the veneer from the log varies depending upon the pattern desired, the log itself, where from the tree it’s being. there are 3 main slicing methods as shown below. — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. In rotary cut, the veneers are. Veneer Cutting Process.

From www.youtube.com

isode 17 What are the Best Tools for Cutting & Trimming Wood Veneer Cutting Process Quarter cut or straight grain veneer is sliced to produce a very linear grain. there are 3 main slicing methods as shown below. Entire log is peeled producing a continuous ribbon of veneer. The process of cutting the veneer from the log varies depending upon the pattern desired, the log itself, where from the tree it’s being. —. Veneer Cutting Process.

From mydentistpasadena.com

The Veneer Procedure Explained In 3 Basic Stages Pasadena Dentist Veneer Cutting Process In rotary cut, the veneers are peeled from a log like paper. — wood veneer can be cut in several ways, each producing a unique grain pattern and aesthetic. Entire log is peeled producing a continuous ribbon of veneer. — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in.. Veneer Cutting Process.

From www.youtube.com

Very basic veneer cutting YouTube Veneer Cutting Process — the four common cuts for veneer are rotary, plain sliced, quarter sliced and rift cut. The process of cutting the veneer from the log varies depending upon the pattern desired, the log itself, where from the tree it’s being. — wood veneer can be cut in several ways, each producing a unique grain pattern and aesthetic. Entire. Veneer Cutting Process.

From heitink.us

Learn About Our Wood Veneer Process Heitink Architectural Veneer and Veneer Cutting Process — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. In rotary cut, the veneers are peeled from a log like paper. there are 3 main slicing methods as shown below. The process of cutting the veneer from the log varies depending upon the pattern desired, the log itself,. Veneer Cutting Process.

From goimprovehome.com

How To Cut Wood Veneer Without Chipping? Full Guide With Pro Tips Veneer Cutting Process — wood veneer can be cut in several ways, each producing a unique grain pattern and aesthetic. — the four common cuts for veneer are rotary, plain sliced, quarter sliced and rift cut. — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. there are 3 main. Veneer Cutting Process.

From hunsply.com

Veneer Processing Hunsply Veneer Cutting Process Entire log is peeled producing a continuous ribbon of veneer. there are 3 main slicing methods as shown below. — the four common cuts for veneer are rotary, plain sliced, quarter sliced and rift cut. Quarter cut or straight grain veneer is sliced to produce a very linear grain. — veneer production is a meticulous process that. Veneer Cutting Process.

From www.woodworkingnetwork.com

Illustrated guide of veneer cutting methods Woodworking Network Veneer Cutting Process — wood veneer can be cut in several ways, each producing a unique grain pattern and aesthetic. there are 3 main slicing methods as shown below. Entire log is peeled producing a continuous ribbon of veneer. The process of cutting the veneer from the log varies depending upon the pattern desired, the log itself, where from the tree. Veneer Cutting Process.

From www.veneerhub.com

The Veneer Cutting Process Veneer Hub Veneer Cutting Process — wood veneer can be cut in several ways, each producing a unique grain pattern and aesthetic. In rotary cut, the veneers are peeled from a log like paper. — veneer production is a meticulous process that transforms raw logs into thin, beautiful sheets of wood used in. — the four common cuts for veneer are rotary,. Veneer Cutting Process.