Oxy Acetylene Tip Pressure Settings . · stand away from front of regulator · separately and slowly open the oxygen and acetylene. Your fuel and o2 should be pretty close as far as pressures. Operating instruction for setting oxygen and acetylene working pressure: With a rosebud you need to have your acet pressure up. As stated above #1 and #2 tips are plenty. Looks like the o2 is usually about 2 psi more than the acet. Pressure requirements vary by tip size, style and manufacturer. 5 psi acetylene and 5 psi oxy is what i use for 90% of my work. · make sure regulator pressure adjustment screws are backed out! Welding with an oxy acetylene rosebud torch can be challenging, but with the right settings and techniques, you can achieve welding success. This comes straight out of. Before lighting the tip, it’s important to set the regulators and purge. Some would argue that shutting the oxygen off first can cause the little carbon “bunnies” that are created when the acetylene pressure is low enough. · make sure torch valves are closed! Make sure that the regulator adjusting screw is screwed so far out.

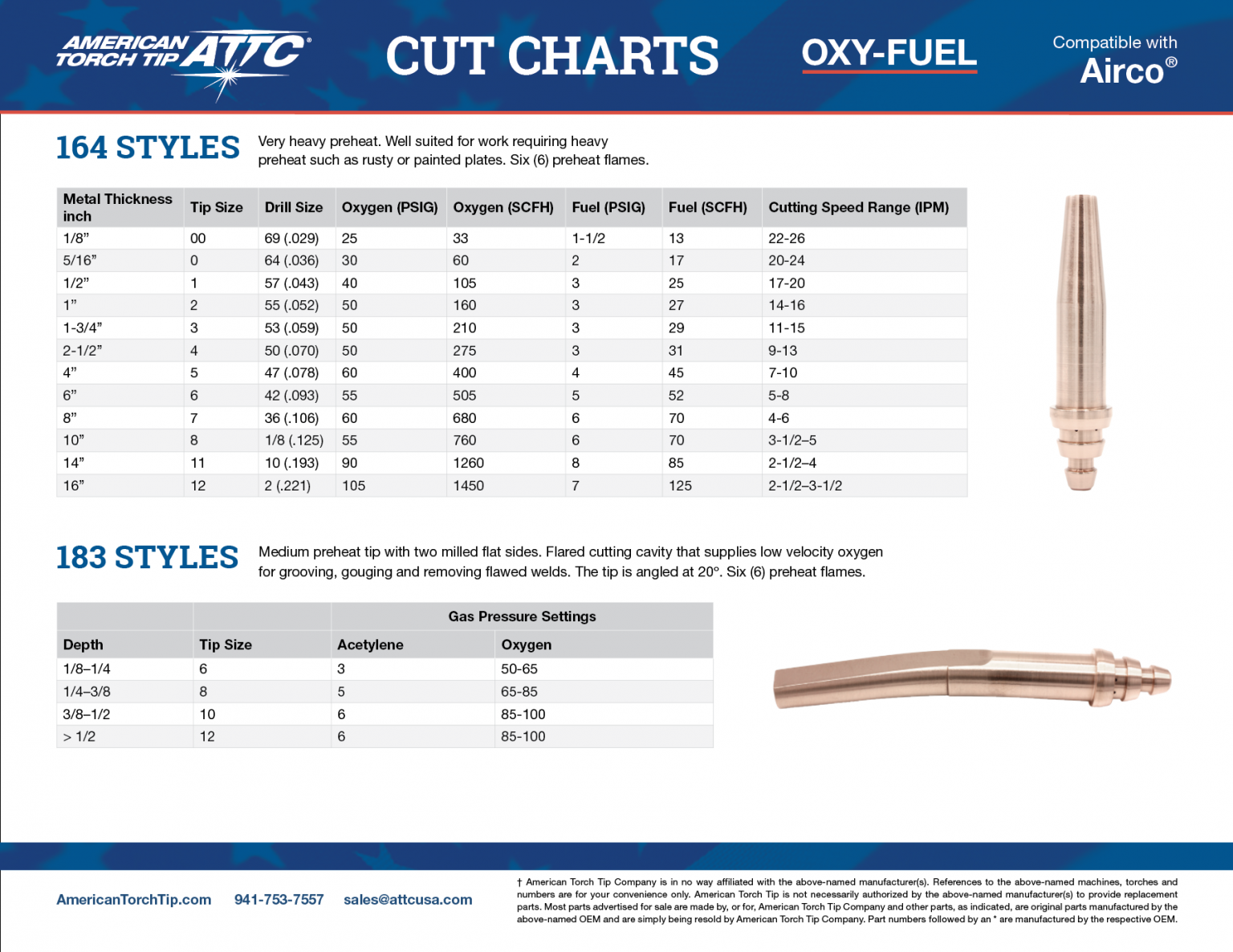

from americantorchtip.com

As stated above #1 and #2 tips are plenty. Operating instruction for setting oxygen and acetylene working pressure: Adjust the regulators for the tip being used. · make sure regulator pressure adjustment screws are backed out! Welding with an oxy acetylene rosebud torch can be challenging, but with the right settings and techniques, you can achieve welding success. · make sure torch valves are closed! Pressure requirements vary by tip size, style and manufacturer. With a rosebud you need to have your acet pressure up. Before lighting the tip, it’s important to set the regulators and purge. 5 psi acetylene and 5 psi oxy is what i use for 90% of my work.

Welding Cut Charts American Torch Tip Cut Charts

Oxy Acetylene Tip Pressure Settings This comes straight out of. Some would argue that shutting the oxygen off first can cause the little carbon “bunnies” that are created when the acetylene pressure is low enough. · stand away from front of regulator · separately and slowly open the oxygen and acetylene. With a rosebud you need to have your acet pressure up. This comes straight out of. Pressure requirements vary by tip size, style and manufacturer. Before lighting the tip, it’s important to set the regulators and purge. Welding with an oxy acetylene rosebud torch can be challenging, but with the right settings and techniques, you can achieve welding success. Looks like the o2 is usually about 2 psi more than the acet. Adjust the regulators for the tip being used. · make sure regulator pressure adjustment screws are backed out! As stated above #1 and #2 tips are plenty. Operating instruction for setting oxygen and acetylene working pressure: 5 psi acetylene and 5 psi oxy is what i use for 90% of my work. Your fuel and o2 should be pretty close as far as pressures. Make sure that the regulator adjusting screw is screwed so far out.

From niamhhenderson.z13.web.core.windows.net

Oxy Acetylene Victor Welding Tip Chart Oxy Acetylene Tip Pressure Settings 5 psi acetylene and 5 psi oxy is what i use for 90% of my work. Pressure requirements vary by tip size, style and manufacturer. · stand away from front of regulator · separately and slowly open the oxygen and acetylene. · make sure torch valves are closed! Before lighting the tip, it’s important to set the regulators and purge.. Oxy Acetylene Tip Pressure Settings.

From americantorchtip.com

Welding Cut Charts American Torch Tip Cut Charts Oxy Acetylene Tip Pressure Settings · make sure regulator pressure adjustment screws are backed out! Your fuel and o2 should be pretty close as far as pressures. Make sure that the regulator adjusting screw is screwed so far out. Pressure requirements vary by tip size, style and manufacturer. Looks like the o2 is usually about 2 psi more than the acet. 5 psi acetylene and. Oxy Acetylene Tip Pressure Settings.

From www.vrogue.co

Oxy Acetylene Cutting Pressure Chart vrogue.co Oxy Acetylene Tip Pressure Settings Operating instruction for setting oxygen and acetylene working pressure: As stated above #1 and #2 tips are plenty. 5 psi acetylene and 5 psi oxy is what i use for 90% of my work. This comes straight out of. Welding with an oxy acetylene rosebud torch can be challenging, but with the right settings and techniques, you can achieve welding. Oxy Acetylene Tip Pressure Settings.

From www.rechargecolorado.org

Oxy Acetylene Pressure Settings Chart Best Picture Of Chart Oxy Acetylene Tip Pressure Settings · make sure regulator pressure adjustment screws are backed out! This comes straight out of. Before lighting the tip, it’s important to set the regulators and purge. Looks like the o2 is usually about 2 psi more than the acet. Operating instruction for setting oxygen and acetylene working pressure: · make sure torch valves are closed! Make sure that the. Oxy Acetylene Tip Pressure Settings.

From woodworkingadvisor.com

Oxy Acetylene Cutting Settings Mastering the Art of Precision Oxy Acetylene Tip Pressure Settings · make sure regulator pressure adjustment screws are backed out! Make sure that the regulator adjusting screw is screwed so far out. Welding with an oxy acetylene rosebud torch can be challenging, but with the right settings and techniques, you can achieve welding success. Operating instruction for setting oxygen and acetylene working pressure: With a rosebud you need to have. Oxy Acetylene Tip Pressure Settings.

From passionplans.com

OxyAcetylene Cutting Torch Pressure Settings & Chart Passion Plans Oxy Acetylene Tip Pressure Settings Welding with an oxy acetylene rosebud torch can be challenging, but with the right settings and techniques, you can achieve welding success. · stand away from front of regulator · separately and slowly open the oxygen and acetylene. Before lighting the tip, it’s important to set the regulators and purge. This comes straight out of. With a rosebud you need. Oxy Acetylene Tip Pressure Settings.

From www.express.fr

The pressure setting for oxyacetylene welding Express Oxy Acetylene Tip Pressure Settings · stand away from front of regulator · separately and slowly open the oxygen and acetylene. Pressure requirements vary by tip size, style and manufacturer. · make sure regulator pressure adjustment screws are backed out! Welding with an oxy acetylene rosebud torch can be challenging, but with the right settings and techniques, you can achieve welding success. Looks like the. Oxy Acetylene Tip Pressure Settings.

From gabrielbruce.z19.web.core.windows.net

Oxyacetylene Cutting Pressure Chart Oxy Acetylene Tip Pressure Settings · stand away from front of regulator · separately and slowly open the oxygen and acetylene. Your fuel and o2 should be pretty close as far as pressures. Looks like the o2 is usually about 2 psi more than the acet. Welding with an oxy acetylene rosebud torch can be challenging, but with the right settings and techniques, you can. Oxy Acetylene Tip Pressure Settings.

From brandonkss.github.io

Oxy Acetylene Cutting Pressure Chart Oxy Acetylene Tip Pressure Settings Pressure requirements vary by tip size, style and manufacturer. · make sure torch valves are closed! · stand away from front of regulator · separately and slowly open the oxygen and acetylene. Some would argue that shutting the oxygen off first can cause the little carbon “bunnies” that are created when the acetylene pressure is low enough. Adjust the regulators. Oxy Acetylene Tip Pressure Settings.

From cognitadesenvolvimento.com.br

oxygen and acetylene pressure settings Oxy Acetylene Tip Pressure Settings Pressure requirements vary by tip size, style and manufacturer. Looks like the o2 is usually about 2 psi more than the acet. Some would argue that shutting the oxygen off first can cause the little carbon “bunnies” that are created when the acetylene pressure is low enough. Operating instruction for setting oxygen and acetylene working pressure: Make sure that the. Oxy Acetylene Tip Pressure Settings.

From www.vrogue.co

Oxy Acetylene Cutting Pressure Chart vrogue.co Oxy Acetylene Tip Pressure Settings Before lighting the tip, it’s important to set the regulators and purge. · stand away from front of regulator · separately and slowly open the oxygen and acetylene. Your fuel and o2 should be pretty close as far as pressures. Operating instruction for setting oxygen and acetylene working pressure: Looks like the o2 is usually about 2 psi more than. Oxy Acetylene Tip Pressure Settings.

From revivalportal.goodwood.com

Oxy Acetylene Torch Settings Chart Oxy Acetylene Tip Pressure Settings · make sure regulator pressure adjustment screws are backed out! Make sure that the regulator adjusting screw is screwed so far out. Your fuel and o2 should be pretty close as far as pressures. Adjust the regulators for the tip being used. Before lighting the tip, it’s important to set the regulators and purge. This comes straight out of. Pressure. Oxy Acetylene Tip Pressure Settings.

From slideplayer.com

OxyAcetylene Safety Awareness ppt download Oxy Acetylene Tip Pressure Settings Pressure requirements vary by tip size, style and manufacturer. Welding with an oxy acetylene rosebud torch can be challenging, but with the right settings and techniques, you can achieve welding success. 5 psi acetylene and 5 psi oxy is what i use for 90% of my work. With a rosebud you need to have your acet pressure up. As stated. Oxy Acetylene Tip Pressure Settings.

From www.rechargecolorado.org

Oxy Acetylene Pressure Settings Chart Best Picture Of Chart Oxy Acetylene Tip Pressure Settings · make sure regulator pressure adjustment screws are backed out! Looks like the o2 is usually about 2 psi more than the acet. Operating instruction for setting oxygen and acetylene working pressure: Before lighting the tip, it’s important to set the regulators and purge. As stated above #1 and #2 tips are plenty. · stand away from front of regulator. Oxy Acetylene Tip Pressure Settings.

From weldingweb.com

oxyacetylene new tip Page 2 Oxy Acetylene Tip Pressure Settings Before lighting the tip, it’s important to set the regulators and purge. Operating instruction for setting oxygen and acetylene working pressure: 5 psi acetylene and 5 psi oxy is what i use for 90% of my work. Welding with an oxy acetylene rosebud torch can be challenging, but with the right settings and techniques, you can achieve welding success. ·. Oxy Acetylene Tip Pressure Settings.

From dat.perueduca.edu.pe

Oxygen Acetylene Torch Settings Chart Printable Templates Free Oxy Acetylene Tip Pressure Settings · make sure regulator pressure adjustment screws are backed out! With a rosebud you need to have your acet pressure up. 5 psi acetylene and 5 psi oxy is what i use for 90% of my work. Adjust the regulators for the tip being used. · stand away from front of regulator · separately and slowly open the oxygen and. Oxy Acetylene Tip Pressure Settings.

From www.wcwelding.com

Cutting Torch Guide Oxy Acetylene Tip Pressure Settings Operating instruction for setting oxygen and acetylene working pressure: With a rosebud you need to have your acet pressure up. Some would argue that shutting the oxygen off first can cause the little carbon “bunnies” that are created when the acetylene pressure is low enough. · stand away from front of regulator · separately and slowly open the oxygen and. Oxy Acetylene Tip Pressure Settings.

From americantorchtip.com

Oxy Fuel Tip Seat Guide American Torch Tip Oxy Acetylene Tip Pressure Settings · make sure torch valves are closed! Operating instruction for setting oxygen and acetylene working pressure: Make sure that the regulator adjusting screw is screwed so far out. · stand away from front of regulator · separately and slowly open the oxygen and acetylene. Welding with an oxy acetylene rosebud torch can be challenging, but with the right settings and. Oxy Acetylene Tip Pressure Settings.

From leaderland.academy

Oxy Acetylene Welding Gauge Settings Buy Sale leaderland.academy Oxy Acetylene Tip Pressure Settings Pressure requirements vary by tip size, style and manufacturer. This comes straight out of. Make sure that the regulator adjusting screw is screwed so far out. Your fuel and o2 should be pretty close as far as pressures. With a rosebud you need to have your acet pressure up. · stand away from front of regulator · separately and slowly. Oxy Acetylene Tip Pressure Settings.

From gabrielbruce.z19.web.core.windows.net

Oxy Acetylene Gas Pressure Settings Oxy Acetylene Tip Pressure Settings Operating instruction for setting oxygen and acetylene working pressure: Before lighting the tip, it’s important to set the regulators and purge. Looks like the o2 is usually about 2 psi more than the acet. · make sure torch valves are closed! Some would argue that shutting the oxygen off first can cause the little carbon “bunnies” that are created when. Oxy Acetylene Tip Pressure Settings.

From gabrielbruce.z19.web.core.windows.net

Oxyacetylene Cutting Pressure Chart Oxy Acetylene Tip Pressure Settings · make sure regulator pressure adjustment screws are backed out! · make sure torch valves are closed! Welding with an oxy acetylene rosebud torch can be challenging, but with the right settings and techniques, you can achieve welding success. Looks like the o2 is usually about 2 psi more than the acet. Operating instruction for setting oxygen and acetylene working. Oxy Acetylene Tip Pressure Settings.

From printablemediakay.z21.web.core.windows.net

Oxy Acetylene Victor Welding Tip Chart Oxy Acetylene Tip Pressure Settings · stand away from front of regulator · separately and slowly open the oxygen and acetylene. With a rosebud you need to have your acet pressure up. Looks like the o2 is usually about 2 psi more than the acet. Welding with an oxy acetylene rosebud torch can be challenging, but with the right settings and techniques, you can achieve. Oxy Acetylene Tip Pressure Settings.

From gabrielatkins.z19.web.core.windows.net

Oxyacetylene Torch Settings Chart Oxy Acetylene Tip Pressure Settings Operating instruction for setting oxygen and acetylene working pressure: · make sure torch valves are closed! Make sure that the regulator adjusting screw is screwed so far out. Before lighting the tip, it’s important to set the regulators and purge. This comes straight out of. Adjust the regulators for the tip being used. Your fuel and o2 should be pretty. Oxy Acetylene Tip Pressure Settings.

From classlibrarymoses.z4.web.core.windows.net

Cutting Torch Settings Chart Oxy Acetylene Tip Pressure Settings Operating instruction for setting oxygen and acetylene working pressure: As stated above #1 and #2 tips are plenty. This comes straight out of. Some would argue that shutting the oxygen off first can cause the little carbon “bunnies” that are created when the acetylene pressure is low enough. With a rosebud you need to have your acet pressure up. Before. Oxy Acetylene Tip Pressure Settings.

From gabrielbruce.z19.web.core.windows.net

Oxygen Acetylene Settings For Cutting Oxy Acetylene Tip Pressure Settings Pressure requirements vary by tip size, style and manufacturer. Operating instruction for setting oxygen and acetylene working pressure: Welding with an oxy acetylene rosebud torch can be challenging, but with the right settings and techniques, you can achieve welding success. Your fuel and o2 should be pretty close as far as pressures. As stated above #1 and #2 tips are. Oxy Acetylene Tip Pressure Settings.

From brandonkss.github.io

Oxy Acetylene Cutting Pressure Chart Oxy Acetylene Tip Pressure Settings Pressure requirements vary by tip size, style and manufacturer. With a rosebud you need to have your acet pressure up. 5 psi acetylene and 5 psi oxy is what i use for 90% of my work. Before lighting the tip, it’s important to set the regulators and purge. Welding with an oxy acetylene rosebud torch can be challenging, but with. Oxy Acetylene Tip Pressure Settings.

From weldingweb.com

Comparing Cutting torch tips; Does a larger size use more fuel gas and Oxy Acetylene Tip Pressure Settings With a rosebud you need to have your acet pressure up. As stated above #1 and #2 tips are plenty. · make sure regulator pressure adjustment screws are backed out! Welding with an oxy acetylene rosebud torch can be challenging, but with the right settings and techniques, you can achieve welding success. Make sure that the regulator adjusting screw is. Oxy Acetylene Tip Pressure Settings.

From gabrielatkins.z19.web.core.windows.net

Oxy Acetylene Pressure Settings Chart Oxy Acetylene Tip Pressure Settings 5 psi acetylene and 5 psi oxy is what i use for 90% of my work. · make sure torch valves are closed! Make sure that the regulator adjusting screw is screwed so far out. Your fuel and o2 should be pretty close as far as pressures. Looks like the o2 is usually about 2 psi more than the acet.. Oxy Acetylene Tip Pressure Settings.

From labbyag.es

Oxy Acetylene Welding Pressure Settings Chart Set Up And Kit Labb by AG Oxy Acetylene Tip Pressure Settings Pressure requirements vary by tip size, style and manufacturer. · stand away from front of regulator · separately and slowly open the oxygen and acetylene. Operating instruction for setting oxygen and acetylene working pressure: With a rosebud you need to have your acet pressure up. · make sure torch valves are closed! Your fuel and o2 should be pretty close. Oxy Acetylene Tip Pressure Settings.

From cognitadesenvolvimento.com.br

oxygen and acetylene pressure settings Oxy Acetylene Tip Pressure Settings With a rosebud you need to have your acet pressure up. Make sure that the regulator adjusting screw is screwed so far out. 5 psi acetylene and 5 psi oxy is what i use for 90% of my work. Welding with an oxy acetylene rosebud torch can be challenging, but with the right settings and techniques, you can achieve welding. Oxy Acetylene Tip Pressure Settings.

From www.mig-welding.co.uk

pressure for oxy acetylene welding thin sheet MIG Welding Forum Oxy Acetylene Tip Pressure Settings With a rosebud you need to have your acet pressure up. Your fuel and o2 should be pretty close as far as pressures. · make sure torch valves are closed! · stand away from front of regulator · separately and slowly open the oxygen and acetylene. Looks like the o2 is usually about 2 psi more than the acet. Welding. Oxy Acetylene Tip Pressure Settings.

From dat.perueduca.edu.pe

Oxy Acetylene Cutting Pressure Chart Printable Templates Free Oxy Acetylene Tip Pressure Settings · stand away from front of regulator · separately and slowly open the oxygen and acetylene. As stated above #1 and #2 tips are plenty. This comes straight out of. Operating instruction for setting oxygen and acetylene working pressure: 5 psi acetylene and 5 psi oxy is what i use for 90% of my work. · make sure torch valves. Oxy Acetylene Tip Pressure Settings.

From www.instructables.com

Setting Up the Oxyacetylene Equipment at Menlo Park 8 Steps Oxy Acetylene Tip Pressure Settings Make sure that the regulator adjusting screw is screwed so far out. Adjust the regulators for the tip being used. Some would argue that shutting the oxygen off first can cause the little carbon “bunnies” that are created when the acetylene pressure is low enough. 5 psi acetylene and 5 psi oxy is what i use for 90% of my. Oxy Acetylene Tip Pressure Settings.

From gabrielbruce.z19.web.core.windows.net

Oxy Acetylene Psi Chart Oxy Acetylene Tip Pressure Settings 5 psi acetylene and 5 psi oxy is what i use for 90% of my work. · make sure torch valves are closed! Adjust the regulators for the tip being used. · stand away from front of regulator · separately and slowly open the oxygen and acetylene. Operating instruction for setting oxygen and acetylene working pressure: Some would argue that. Oxy Acetylene Tip Pressure Settings.

From leaderland.academy

Oxy Acetylene Welding Gauge Settings Buy Sale leaderland.academy Oxy Acetylene Tip Pressure Settings · stand away from front of regulator · separately and slowly open the oxygen and acetylene. Looks like the o2 is usually about 2 psi more than the acet. Adjust the regulators for the tip being used. Welding with an oxy acetylene rosebud torch can be challenging, but with the right settings and techniques, you can achieve welding success. With. Oxy Acetylene Tip Pressure Settings.