Electric Vehicle Differential Design . This article comprehensively reviews the components and advances in the various technologies employed in electric vehicles to achieve efficiency in motion and. The use of an electric differential (ed) constitutes a technological advance in vehicle design along with the concept of more electric vehicles. At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. In a conventional ev, a single electric motor powers the car through reduction gears and the mechanical differential (md). The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation.

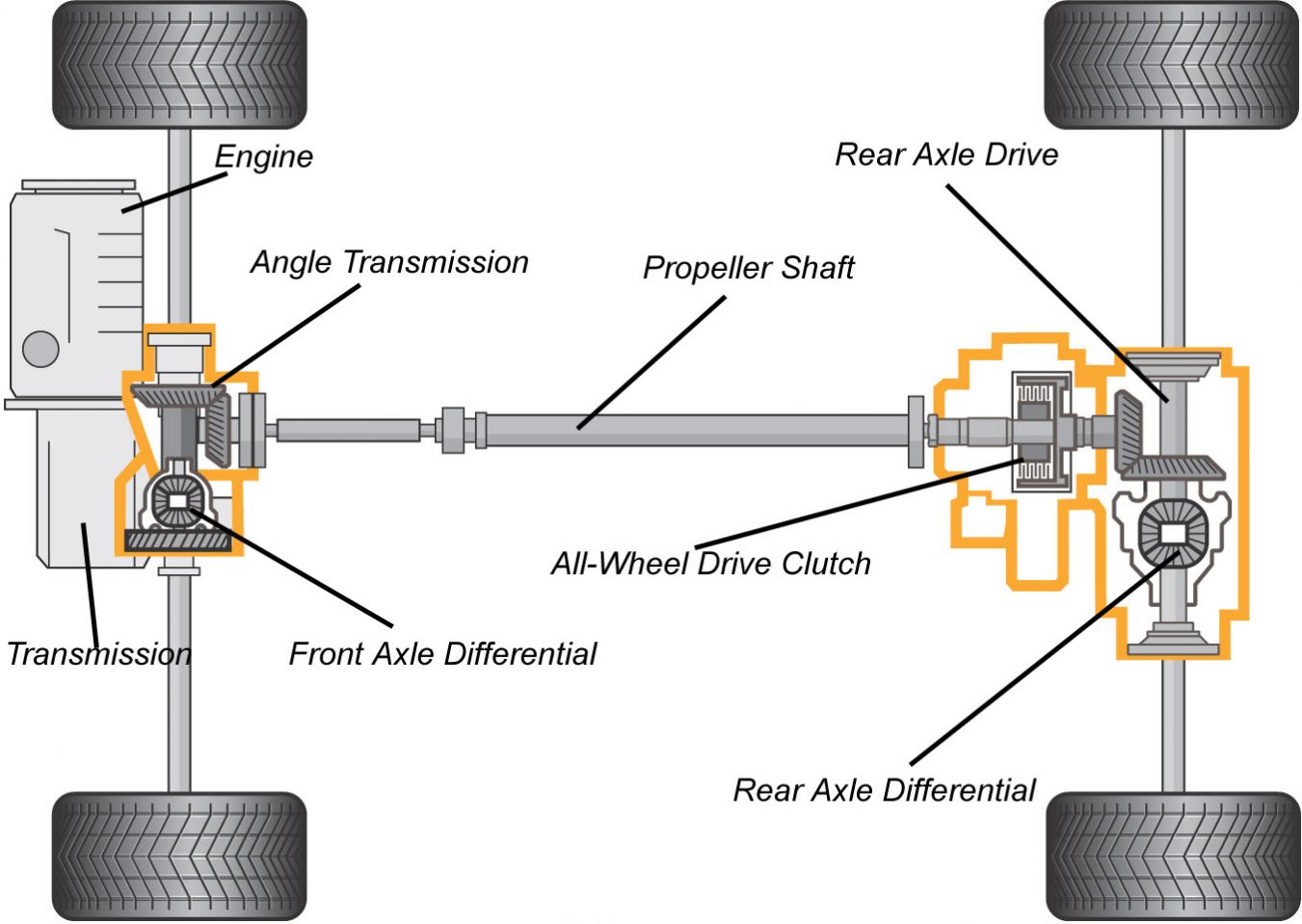

from www.alltrac.net

This article comprehensively reviews the components and advances in the various technologies employed in electric vehicles to achieve efficiency in motion and. At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. In a conventional ev, a single electric motor powers the car through reduction gears and the mechanical differential (md). The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. The use of an electric differential (ed) constitutes a technological advance in vehicle design along with the concept of more electric vehicles.

• View topic Variable F/R torque split (to 50/50) idea

Electric Vehicle Differential Design This article comprehensively reviews the components and advances in the various technologies employed in electric vehicles to achieve efficiency in motion and. The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. The use of an electric differential (ed) constitutes a technological advance in vehicle design along with the concept of more electric vehicles. In a conventional ev, a single electric motor powers the car through reduction gears and the mechanical differential (md). This article comprehensively reviews the components and advances in the various technologies employed in electric vehicles to achieve efficiency in motion and. At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution.

From www.geartechnology.com

Double Differential for Electric Vehicle and Hybrid Transmissions Electric Vehicle Differential Design The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. This article comprehensively reviews the components and advances in the various technologies employed in electric vehicles to achieve efficiency in motion and. In a conventional ev, a single electric motor powers the car through reduction gears and the mechanical differential (md). At low. Electric Vehicle Differential Design.

From electricautoguides.com

How Do Electric Car Differentials Work? Electric Auto Guides Electric Vehicle Differential Design The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. In a conventional ev, a single electric motor powers the car through reduction gears and the mechanical differential (md). The use of an electric differential (ed) constitutes a technological advance in vehicle design along with the concept of more electric vehicles. At low. Electric Vehicle Differential Design.

From www.youtube.com

How to make a powerful Electric Car 60 km/h Using Homemade Differential Electric Vehicle Differential Design At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. The use of an electric differential (ed) constitutes a technological advance in vehicle design along with the concept of more electric vehicles. This article comprehensively reviews the components and advances. Electric Vehicle Differential Design.

From www.youtube.com

Differential How does it work? YouTube Electric Vehicle Differential Design The use of an electric differential (ed) constitutes a technological advance in vehicle design along with the concept of more electric vehicles. At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. The increasing demand for electric vehicles (evs) is. Electric Vehicle Differential Design.

From asnizam60.blogspot.com

AUTOMOTIF.STUDY DIFFERENTIAL FUNGSI, PRINSIP KERJA, DAN KLASIFIKASI Electric Vehicle Differential Design The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. In a conventional ev, a single electric motor powers the car through reduction gears and the mechanical differential (md). At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger. Electric Vehicle Differential Design.

From www.mdpi.com

Applied Sciences Free FullText On the Innovation Design for Two Electric Vehicle Differential Design At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. In a conventional ev, a single electric motor powers the car through reduction. Electric Vehicle Differential Design.

From www.youtube.com

How a Differential works ? YouTube Electric Vehicle Differential Design The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. This article comprehensively reviews the components and advances in the various technologies employed in electric vehicles to achieve efficiency in motion and. In a conventional ev, a single electric motor powers the car through reduction gears and the mechanical differential (md). At low. Electric Vehicle Differential Design.

From www.aam.com

AAM’s TracRite® Differentials Help Enhance Electric Vehicle Performance Electric Vehicle Differential Design The use of an electric differential (ed) constitutes a technological advance in vehicle design along with the concept of more electric vehicles. The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must. Electric Vehicle Differential Design.

From innovationdiscoveries.space

Electronic Limited Slip Differential (eLSD) Electric Vehicle Differential Design This article comprehensively reviews the components and advances in the various technologies employed in electric vehicles to achieve efficiency in motion and. At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. The use of an electric differential (ed) constitutes. Electric Vehicle Differential Design.

From www.alibaba.com

1500w Electric Rickshaw Differential And Rear Axle Kits For Diversion Electric Vehicle Differential Design At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. In a conventional ev, a single electric motor powers the car through reduction. Electric Vehicle Differential Design.

From file.scirp.org

A Simplified Sliding Mode Controlled Electronic Differential for an Electric Vehicle Differential Design At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. The use of an electric differential (ed) constitutes a technological advance in vehicle. Electric Vehicle Differential Design.

From www.carexpert.com.au

Differentials explained CarExpert Electric Vehicle Differential Design At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. The use of an electric differential (ed) constitutes a technological advance in vehicle design along with the concept of more electric vehicles. This article comprehensively reviews the components and advances. Electric Vehicle Differential Design.

From www.alltrac.net

• View topic Variable F/R torque split (to 50/50) idea Electric Vehicle Differential Design The use of an electric differential (ed) constitutes a technological advance in vehicle design along with the concept of more electric vehicles. The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. This article comprehensively reviews the components and advances in the various technologies employed in electric vehicles to achieve efficiency in motion. Electric Vehicle Differential Design.

From electricautoguides.com

How Do Electric Car Differentials Work? Electric Auto Guides Electric Vehicle Differential Design The use of an electric differential (ed) constitutes a technological advance in vehicle design along with the concept of more electric vehicles. In a conventional ev, a single electric motor powers the car through reduction gears and the mechanical differential (md). The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. At low. Electric Vehicle Differential Design.

From www.tec-science.com

How does a differential gear work? tecscience Electric Vehicle Differential Design The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. This article comprehensively reviews the components and advances in the various technologies employed. Electric Vehicle Differential Design.

From engineeringlearn.com

What is Differential? Types of Differentials, Function & How They Work Electric Vehicle Differential Design The use of an electric differential (ed) constitutes a technological advance in vehicle design along with the concept of more electric vehicles. This article comprehensively reviews the components and advances in the various technologies employed in electric vehicles to achieve efficiency in motion and. The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly. Electric Vehicle Differential Design.

From myimiev.com

eDifferential motor/differential combo for EV Mitsubishi IMiev Forum Electric Vehicle Differential Design This article comprehensively reviews the components and advances in the various technologies employed in electric vehicles to achieve efficiency in motion and. At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. The increasing demand for electric vehicles (evs) is. Electric Vehicle Differential Design.

From cargocollective.com

SAE Hybrid Formula Team(Drive train design) Paul Jingyi Electric Vehicle Differential Design The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. In a conventional ev, a single electric motor powers the car through reduction gears and the mechanical differential (md). The use of an electric differential (ed) constitutes a technological advance in vehicle design along with the concept of more electric vehicles. At low. Electric Vehicle Differential Design.

From www.semanticscholar.org

Figure 3 from Design and Evaluation on Electric Differentials for Electric Vehicle Differential Design The use of an electric differential (ed) constitutes a technological advance in vehicle design along with the concept of more electric vehicles. The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. This article comprehensively reviews the components and advances in the various technologies employed in electric vehicles to achieve efficiency in motion. Electric Vehicle Differential Design.

From www.mdpi.com

Applied Sciences Free FullText Optimal Design and Control of a Two Electric Vehicle Differential Design In a conventional ev, a single electric motor powers the car through reduction gears and the mechanical differential (md). The use of an electric differential (ed) constitutes a technological advance in vehicle design along with the concept of more electric vehicles. At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev. Electric Vehicle Differential Design.

From www.semanticscholar.org

Figure 10 from Design and Evaluation on Electric Differentials for Electric Vehicle Differential Design The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. This article comprehensively reviews the components and advances in the various technologies employed in electric vehicles to achieve efficiency in motion and. In a conventional ev, a single electric motor powers the car through reduction gears and the mechanical differential (md). The use. Electric Vehicle Differential Design.

From www.scribd.com

Design and Evaluation On Electric Differentials For Overactuated Electric Vehicle Differential Design At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. The use of an electric differential (ed) constitutes a technological advance in vehicle design along with the concept of more electric vehicles. The increasing demand for electric vehicles (evs) is. Electric Vehicle Differential Design.

From www.semanticscholar.org

Figure 1 from Design and Evaluation on Electric Differentials for Electric Vehicle Differential Design At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. In a conventional ev, a single electric motor powers the car through reduction gears and the mechanical differential (md). The use of an electric differential (ed) constitutes a technological advance. Electric Vehicle Differential Design.

From www.semanticscholar.org

Figure 4 from Design and Evaluation on Electric Differentials for Electric Vehicle Differential Design This article comprehensively reviews the components and advances in the various technologies employed in electric vehicles to achieve efficiency in motion and. In a conventional ev, a single electric motor powers the car through reduction gears and the mechanical differential (md). At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev. Electric Vehicle Differential Design.

From www.cutawaycreations.com

Land Rover Electronic Rear Differential Cutaway Creations Electric Vehicle Differential Design At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. The use of an electric differential (ed) constitutes a technological advance in vehicle. Electric Vehicle Differential Design.

From www.researchgate.net

(PDF) Design of Electronic Differential System for an Electric Vehicle Electric Vehicle Differential Design The use of an electric differential (ed) constitutes a technological advance in vehicle design along with the concept of more electric vehicles. At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. This article comprehensively reviews the components and advances. Electric Vehicle Differential Design.

From www.alibaba.com

Electric Vehicle Differential Buy Electric Motor Differential Electric Vehicle Differential Design This article comprehensively reviews the components and advances in the various technologies employed in electric vehicles to achieve efficiency in motion and. At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. In a conventional ev, a single electric motor. Electric Vehicle Differential Design.

From www.aliexpress.com

5kW72VTractionMotorDifferentialRearAxleAssemblyElectric Electric Vehicle Differential Design At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. The use of an electric differential (ed) constitutes a technological advance in vehicle. Electric Vehicle Differential Design.

From datai8888.en.made-in-china.com

Differential DC Motor Conversion Kit with Controller and Rear Axle for Electric Vehicle Differential Design At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. In a conventional ev, a single electric motor powers the car through reduction gears and the mechanical differential (md). The increasing demand for electric vehicles (evs) is driven by the. Electric Vehicle Differential Design.

From www.semanticscholar.org

Figure 11 from Design and Evaluation on Electric Differentials for Electric Vehicle Differential Design At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. This article comprehensively reviews the components and advances in the various technologies employed in electric vehicles to achieve efficiency in motion and. The increasing demand for electric vehicles (evs) is. Electric Vehicle Differential Design.

From kissiahwalisun.pages.dev

Differential Electric Vehicle Arlina Celisse Electric Vehicle Differential Design This article comprehensively reviews the components and advances in the various technologies employed in electric vehicles to achieve efficiency in motion and. At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. The use of an electric differential (ed) constitutes. Electric Vehicle Differential Design.

From mungfali.com

Car Differential Diagram Electric Vehicle Differential Design In a conventional ev, a single electric motor powers the car through reduction gears and the mechanical differential (md). At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. The increasing demand for electric vehicles (evs) is driven by the. Electric Vehicle Differential Design.

From www.grainews.ca

How it works the differential Grainews Electric Vehicle Differential Design This article comprehensively reviews the components and advances in the various technologies employed in electric vehicles to achieve efficiency in motion and. In a conventional ev, a single electric motor powers the car through reduction gears and the mechanical differential (md). The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. At low. Electric Vehicle Differential Design.

From www.mdpi.com

Applied Sciences Free FullText A Study on the Control Performance Electric Vehicle Differential Design The increasing demand for electric vehicles (evs) is driven by the urgent need for environmentally friendly transportation. At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. The use of an electric differential (ed) constitutes a technological advance in vehicle. Electric Vehicle Differential Design.

From www.evdesignandmanufacturing.com

Eaton’s Vehicle Group unveils differentials for EVs EV Design Electric Vehicle Differential Design The use of an electric differential (ed) constitutes a technological advance in vehicle design along with the concept of more electric vehicles. At low speeds, the ev motors deliver more torque to the wheels than comparably sized ice vehicles, so ev differentials must be built stronger and stiffer to manage the distribution. In a conventional ev, a single electric motor. Electric Vehicle Differential Design.