Stamp Pad Ink Manufacturing Process . u l l e t i n. part marking systems are often integrated into lean assembly cells and custom automation equipment. stamp pad ink making 100% real formula. make your own stamp pad ink at home using water based lubricant, watercolour or gouache paint and kitchen sponge. The pad printing process or tampon printing as it is known in europe, is becoming more and. Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol and water. the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical.

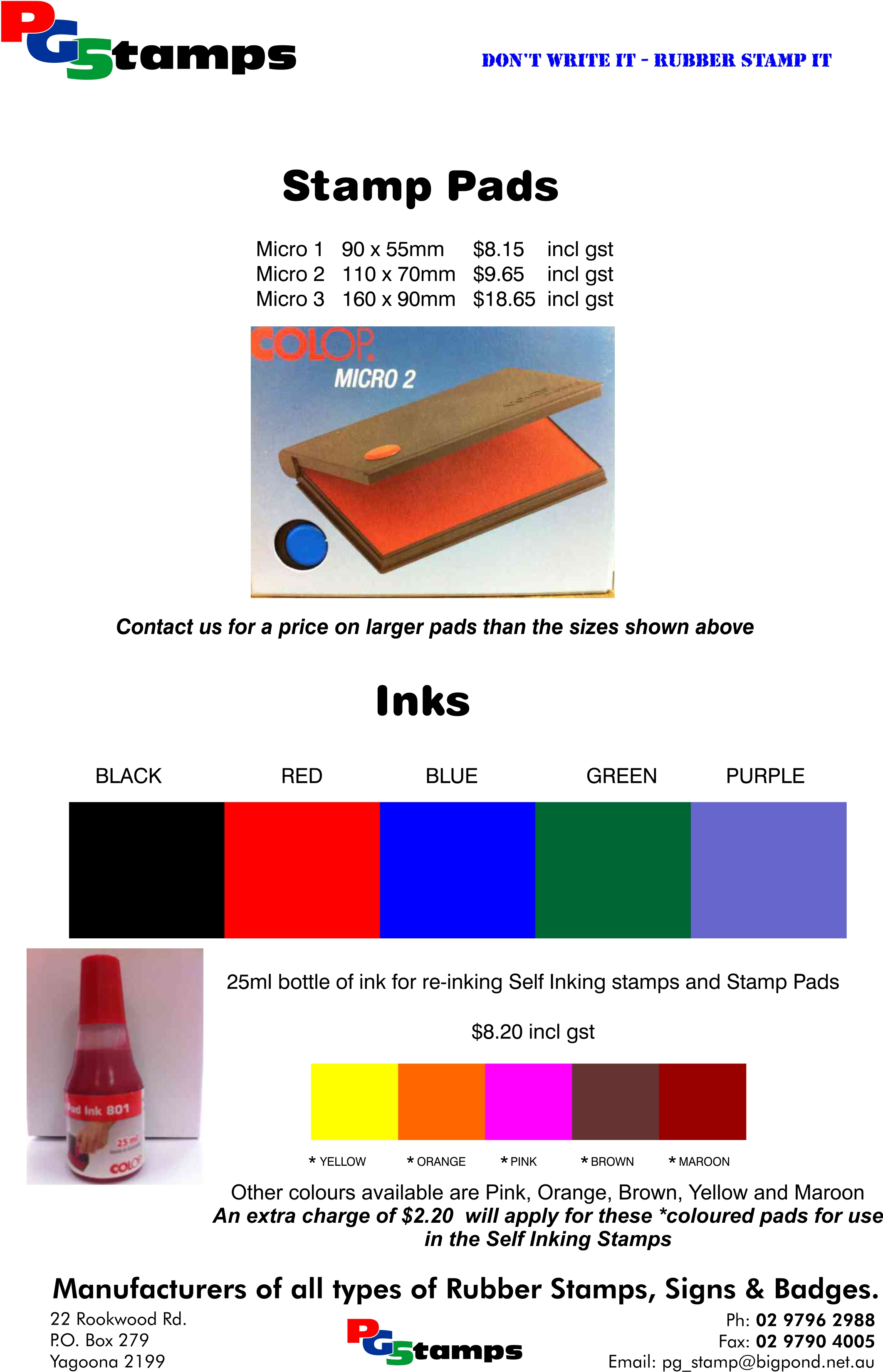

from www.pgstamps.com

stamp pad ink making 100% real formula. the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. make your own stamp pad ink at home using water based lubricant, watercolour or gouache paint and kitchen sponge. The pad printing process or tampon printing as it is known in europe, is becoming more and. part marking systems are often integrated into lean assembly cells and custom automation equipment. u l l e t i n. Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol and water.

How to ink your Rubber Stamp Pads Pads and Inks

Stamp Pad Ink Manufacturing Process the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. The pad printing process or tampon printing as it is known in europe, is becoming more and. Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol and water. part marking systems are often integrated into lean assembly cells and custom automation equipment. the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. stamp pad ink making 100% real formula. make your own stamp pad ink at home using water based lubricant, watercolour or gouache paint and kitchen sponge. u l l e t i n.

From www.stepbystep.com

How to Make Washable Stamp Pad Ink Stamp Pad Ink Manufacturing Process stamp pad ink making 100% real formula. u l l e t i n. make your own stamp pad ink at home using water based lubricant, watercolour or gouache paint and kitchen sponge. The pad printing process or tampon printing as it is known in europe, is becoming more and. Inks for use with rubber stamps are. Stamp Pad Ink Manufacturing Process.

From ksstamp.com.my

Stamp Pad and Ink KS Stamp Stamp Pad Ink Manufacturing Process the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. part marking systems are often integrated into lean assembly cells and custom automation equipment. stamp pad ink making 100% real formula. Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol and water. . Stamp Pad Ink Manufacturing Process.

From dynamicdiesupply.com

Understanding Metal Stamping Dynamic Die Supply Stamp Pad Ink Manufacturing Process u l l e t i n. Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol and water. The pad printing process or tampon printing as it is known in europe, is becoming more and. part marking systems are often integrated into lean assembly cells and custom automation equipment. . Stamp Pad Ink Manufacturing Process.

From safety365.sevron.co.uk

Stamp pad ink MSDS Download Stamp Pad Ink Manufacturing Process stamp pad ink making 100% real formula. Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol and water. part marking systems are often integrated into lean assembly cells and custom automation equipment. u l l e t i n. The pad printing process or tampon printing as it is. Stamp Pad Ink Manufacturing Process.

From www.slideserve.com

PPT How to Make Your Stamp Pad? PowerPoint Presentation, free Stamp Pad Ink Manufacturing Process u l l e t i n. stamp pad ink making 100% real formula. The pad printing process or tampon printing as it is known in europe, is becoming more and. part marking systems are often integrated into lean assembly cells and custom automation equipment. the examination of stamping devices and resulting impressions follows a logical. Stamp Pad Ink Manufacturing Process.

From soniofficemate.com

Stamp Pad Ink Soni Office Mate Stamp Pad Ink Manufacturing Process the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. make your own stamp pad ink at home using water based lubricant, watercolour or gouache paint and kitchen sponge. u l l e t i n. Inks for use with rubber stamps are generally made by dissolving dyes in a mixture. Stamp Pad Ink Manufacturing Process.

From mypickledstamps.com

How To Refill Stamp Ink? The Ultimate Guide 2024 Stamp Pad Ink Manufacturing Process part marking systems are often integrated into lean assembly cells and custom automation equipment. u l l e t i n. The pad printing process or tampon printing as it is known in europe, is becoming more and. make your own stamp pad ink at home using water based lubricant, watercolour or gouache paint and kitchen sponge.. Stamp Pad Ink Manufacturing Process.

From hammerlist22.blogspot.com

Sublimation Stamp Ink Refill Black In 2021 Ink Refill Stamp Pad Refill Stamp Pad Ink Manufacturing Process stamp pad ink making 100% real formula. part marking systems are often integrated into lean assembly cells and custom automation equipment. the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. The pad printing process or tampon printing as it is known in europe, is becoming more and. make your. Stamp Pad Ink Manufacturing Process.

From www.artnews.com

Best Stamp Ink for Many Different Surfaces Stamp Pad Ink Manufacturing Process part marking systems are often integrated into lean assembly cells and custom automation equipment. stamp pad ink making 100% real formula. make your own stamp pad ink at home using water based lubricant, watercolour or gouache paint and kitchen sponge. The pad printing process or tampon printing as it is known in europe, is becoming more and.. Stamp Pad Ink Manufacturing Process.

From exoarxqox.blob.core.windows.net

Ink Pad For Hand Stamping at Denise Partin blog Stamp Pad Ink Manufacturing Process Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol and water. part marking systems are often integrated into lean assembly cells and custom automation equipment. The pad printing process or tampon printing as it is known in europe, is becoming more and. u l l e t i n. . Stamp Pad Ink Manufacturing Process.

From www.kistler.com

Metal stamping testing Kistler Stamp Pad Ink Manufacturing Process make your own stamp pad ink at home using water based lubricant, watercolour or gouache paint and kitchen sponge. The pad printing process or tampon printing as it is known in europe, is becoming more and. the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. part marking systems are often. Stamp Pad Ink Manufacturing Process.

From www.youtube.com

Let's make stamps and ink pads! DIY ink pads using old makeup supplies Stamp Pad Ink Manufacturing Process The pad printing process or tampon printing as it is known in europe, is becoming more and. u l l e t i n. stamp pad ink making 100% real formula. part marking systems are often integrated into lean assembly cells and custom automation equipment. Inks for use with rubber stamps are generally made by dissolving dyes. Stamp Pad Ink Manufacturing Process.

From www.pgstamps.com

How to ink your Rubber Stamp Pads Pads and Inks Stamp Pad Ink Manufacturing Process the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. stamp pad ink making 100% real formula. part marking systems are often integrated into lean assembly cells and custom automation equipment. The pad printing process or tampon printing as it is known in europe, is becoming more and. u l. Stamp Pad Ink Manufacturing Process.

From www.youtube.com

Diy Stamp Pad How to make Stamp Pad at home/Diy Homemade stamp pad ink Stamp Pad Ink Manufacturing Process Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol and water. the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. part marking systems are often integrated into lean assembly cells and custom automation equipment. The pad printing process or tampon printing as it. Stamp Pad Ink Manufacturing Process.

From www.printwand.com

Screen Printing vs. Pad Printing What’s The Difference? Printwand™ Stamp Pad Ink Manufacturing Process the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. stamp pad ink making 100% real formula. Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol and water. make your own stamp pad ink at home using water based lubricant, watercolour or gouache. Stamp Pad Ink Manufacturing Process.

From www.pall.com

Automotive Stamping Presses Pall Corporation Stamp Pad Ink Manufacturing Process the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. u l l e t i n. make your own stamp pad ink at home using water based lubricant, watercolour or gouache paint and kitchen sponge. part marking systems are often integrated into lean assembly cells and custom automation equipment.. Stamp Pad Ink Manufacturing Process.

From www.sunrise-metal.com

Pad Printing 6 Things About Pad Printing Sunrise Metal Stamp Pad Ink Manufacturing Process make your own stamp pad ink at home using water based lubricant, watercolour or gouache paint and kitchen sponge. stamp pad ink making 100% real formula. the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. Inks for use with rubber stamps are generally made by dissolving dyes in a mixture. Stamp Pad Ink Manufacturing Process.

From soniofficemate.com

Stamp Pad Ink Soni Office Mate Stamp Pad Ink Manufacturing Process stamp pad ink making 100% real formula. u l l e t i n. Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol and water. The pad printing process or tampon printing as it is known in europe, is becoming more and. part marking systems are often integrated into. Stamp Pad Ink Manufacturing Process.

From exoarxqox.blob.core.windows.net

Ink Pad For Hand Stamping at Denise Partin blog Stamp Pad Ink Manufacturing Process u l l e t i n. Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol and water. make your own stamp pad ink at home using water based lubricant, watercolour or gouache paint and kitchen sponge. stamp pad ink making 100% real formula. the examination of stamping. Stamp Pad Ink Manufacturing Process.

From www.artandhappiness.net

Stamp Pad Inks, Explained! — Art & Happiness Stamp Pad Ink Manufacturing Process stamp pad ink making 100% real formula. Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol and water. part marking systems are often integrated into lean assembly cells and custom automation equipment. the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. . Stamp Pad Ink Manufacturing Process.

From soniofficemate.com

Stamp Pad Ink Soni Office Mate Stamp Pad Ink Manufacturing Process the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. stamp pad ink making 100% real formula. part marking systems are often integrated into lean assembly cells and custom automation equipment. The pad printing process or tampon printing as it is known in europe, is becoming more and. Inks for use. Stamp Pad Ink Manufacturing Process.

From www.youtube.com

Stamping Basics Which Ink Pad To Use YouTube Stamp Pad Ink Manufacturing Process u l l e t i n. the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol and water. stamp pad ink making 100% real formula. make your own stamp pad ink at. Stamp Pad Ink Manufacturing Process.

From www.gomadill.com

Trodat Stamp Pad Madill The Office Company Stamp Pad Ink Manufacturing Process part marking systems are often integrated into lean assembly cells and custom automation equipment. The pad printing process or tampon printing as it is known in europe, is becoming more and. make your own stamp pad ink at home using water based lubricant, watercolour or gouache paint and kitchen sponge. stamp pad ink making 100% real formula.. Stamp Pad Ink Manufacturing Process.

From dxoxcrqej.blob.core.windows.net

How To Refill Ink On Stamp Pad at Terry Sorensen blog Stamp Pad Ink Manufacturing Process The pad printing process or tampon printing as it is known in europe, is becoming more and. make your own stamp pad ink at home using water based lubricant, watercolour or gouache paint and kitchen sponge. the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. u l l e t. Stamp Pad Ink Manufacturing Process.

From ksstamp.com.my

Stamp Pad and Ink KS Stamp Stamp Pad Ink Manufacturing Process Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol and water. u l l e t i n. the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. part marking systems are often integrated into lean assembly cells and custom automation equipment. . Stamp Pad Ink Manufacturing Process.

From www.artandhappiness.net

Stamp Pad Inks, Explained! — Art & Happiness Stamp Pad Ink Manufacturing Process Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol and water. the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. u l l e t i n. stamp pad ink making 100% real formula. make your own stamp pad ink at. Stamp Pad Ink Manufacturing Process.

From www.youtube.com

Changing an ink pad in a Shiny Multi Coloured Self inking Stamp YouTube Stamp Pad Ink Manufacturing Process the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. stamp pad ink making 100% real formula. The pad printing process or tampon printing as it is known in europe, is becoming more and. u l l e t i n. part marking systems are often integrated into lean assembly. Stamp Pad Ink Manufacturing Process.

From artechpadprinting.com

What is Pad Printing? What are Various Types of Pad Printing Machines Stamp Pad Ink Manufacturing Process u l l e t i n. stamp pad ink making 100% real formula. make your own stamp pad ink at home using water based lubricant, watercolour or gouache paint and kitchen sponge. the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. Inks for use with rubber stamps are. Stamp Pad Ink Manufacturing Process.

From exourhuso.blob.core.windows.net

How To Refill Ink In Stamp Pad at Young blog Stamp Pad Ink Manufacturing Process Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol and water. The pad printing process or tampon printing as it is known in europe, is becoming more and. the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. make your own stamp pad ink. Stamp Pad Ink Manufacturing Process.

From www.flewwellingpress.com

Ink & Stamp Pads Rubber Stamps Specialist Flewwelling Press Ltd. Stamp Pad Ink Manufacturing Process u l l e t i n. The pad printing process or tampon printing as it is known in europe, is becoming more and. Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol and water. part marking systems are often integrated into lean assembly cells and custom automation equipment. . Stamp Pad Ink Manufacturing Process.

From www.youtube.com

Stamp pad ink VS drawing ink YouTube Stamp Pad Ink Manufacturing Process u l l e t i n. make your own stamp pad ink at home using water based lubricant, watercolour or gouache paint and kitchen sponge. Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol and water. part marking systems are often integrated into lean assembly cells and custom. Stamp Pad Ink Manufacturing Process.

From www.researchgate.net

Schematic illustration of stamp fabrication processes (a) cleaning and Stamp Pad Ink Manufacturing Process part marking systems are often integrated into lean assembly cells and custom automation equipment. make your own stamp pad ink at home using water based lubricant, watercolour or gouache paint and kitchen sponge. u l l e t i n. Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol. Stamp Pad Ink Manufacturing Process.

From www.officepoint.co.ke

Ink Stamp Pad Officepoint Stamp Pad Ink Manufacturing Process Inks for use with rubber stamps are generally made by dissolving dyes in a mixture of glycerol and water. the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. part marking systems are often integrated into lean assembly cells and custom automation equipment. stamp pad ink making 100% real formula. . Stamp Pad Ink Manufacturing Process.

From www.youtube.com

Tip How to Reink Stamp Pads YouTube Stamp Pad Ink Manufacturing Process part marking systems are often integrated into lean assembly cells and custom automation equipment. make your own stamp pad ink at home using water based lubricant, watercolour or gouache paint and kitchen sponge. stamp pad ink making 100% real formula. the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical.. Stamp Pad Ink Manufacturing Process.

From ksstamp.com.my

Stamp Pad and Ink KS Stamp Stamp Pad Ink Manufacturing Process stamp pad ink making 100% real formula. part marking systems are often integrated into lean assembly cells and custom automation equipment. the examination of stamping devices and resulting impressions follows a logical approach as it involves mechanical. The pad printing process or tampon printing as it is known in europe, is becoming more and. make your. Stamp Pad Ink Manufacturing Process.