Side Milling Depth Of Cut . Axial depth of cut (adoc): This is crucial in operations like milling, where it dictates the side coverage of the cutting tool on the workpiece. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. Side and face cutters offer the most efficient method for milling large volumes of. The depth of the cut, the speed of the cutter’s rotation, and the feed rate of the workpiece are critical parameters that influence. When it comes to milling mild steel, around how much is my max depth of cut should be when using my machine and using 3/8 or 1/2. Depth of cut is a machining parameter that determines the depth at which the cutting tool plunges into the surface of the workpiece to remove material. Also known as step down or cut. Side milling or external milling emerges as the virtuoso, excelling in crafting intricate steps or grooves. Distinguished by varying widths, diameters, and adaptable tooth. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. Groove or slot milling is an operation in which side and face milling is often preferred to end milling.

from toolnotes.com

Distinguished by varying widths, diameters, and adaptable tooth. Depth of cut is a machining parameter that determines the depth at which the cutting tool plunges into the surface of the workpiece to remove material. Side milling or external milling emerges as the virtuoso, excelling in crafting intricate steps or grooves. The depth of the cut, the speed of the cutter’s rotation, and the feed rate of the workpiece are critical parameters that influence. Axial depth of cut (adoc): The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. Also known as step down or cut. Side and face cutters offer the most efficient method for milling large volumes of. Groove or slot milling is an operation in which side and face milling is often preferred to end milling.

Milling Operations ToolNotes

Side Milling Depth Of Cut The depth of the cut, the speed of the cutter’s rotation, and the feed rate of the workpiece are critical parameters that influence. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. When it comes to milling mild steel, around how much is my max depth of cut should be when using my machine and using 3/8 or 1/2. Side milling or external milling emerges as the virtuoso, excelling in crafting intricate steps or grooves. This is crucial in operations like milling, where it dictates the side coverage of the cutting tool on the workpiece. Axial depth of cut (adoc): Side and face cutters offer the most efficient method for milling large volumes of. Groove or slot milling is an operation in which side and face milling is often preferred to end milling. Depth of cut is a machining parameter that determines the depth at which the cutting tool plunges into the surface of the workpiece to remove material. Distinguished by varying widths, diameters, and adaptable tooth. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. The depth of the cut, the speed of the cutter’s rotation, and the feed rate of the workpiece are critical parameters that influence. Also known as step down or cut.

From www.youtube.com

cutting parameter kaise jane vmc programming tutorial cutting Side Milling Depth Of Cut This is crucial in operations like milling, where it dictates the side coverage of the cutting tool on the workpiece. The depth of the cut, the speed of the cutter’s rotation, and the feed rate of the workpiece are critical parameters that influence. When it comes to milling mild steel, around how much is my max depth of cut should. Side Milling Depth Of Cut.

From www.slideserve.com

PPT Cutting Speed, Feed, and Depth of Cut PowerPoint Presentation Side Milling Depth Of Cut Depth of cut is a machining parameter that determines the depth at which the cutting tool plunges into the surface of the workpiece to remove material. Groove or slot milling is an operation in which side and face milling is often preferred to end milling. Side and face cutters offer the most efficient method for milling large volumes of. The. Side Milling Depth Of Cut.

From www.researchgate.net

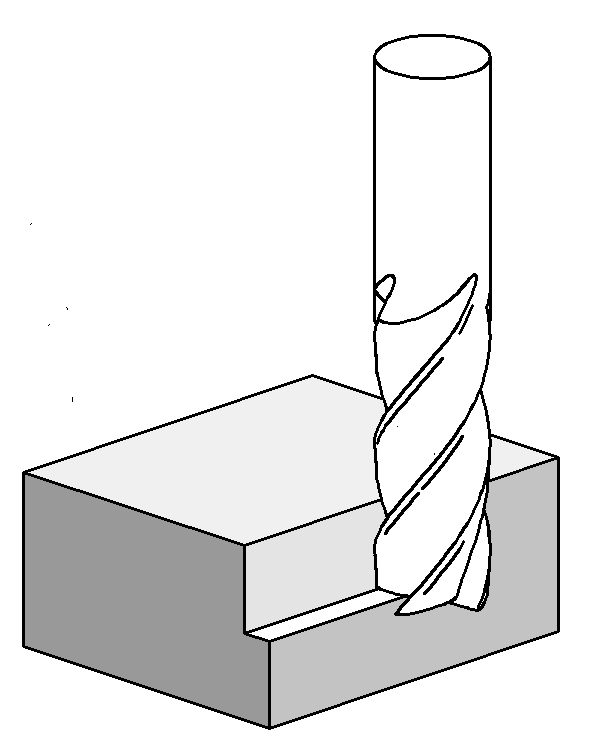

Diagram of side milling process Download Scientific Diagram Side Milling Depth Of Cut This is crucial in operations like milling, where it dictates the side coverage of the cutting tool on the workpiece. Side milling or external milling emerges as the virtuoso, excelling in crafting intricate steps or grooves. Groove or slot milling is an operation in which side and face milling is often preferred to end milling. Side and face cutters offer. Side Milling Depth Of Cut.

From toolnotes.com

Milling Operations ToolNotes Side Milling Depth Of Cut Depth of cut is a machining parameter that determines the depth at which the cutting tool plunges into the surface of the workpiece to remove material. Side milling or external milling emerges as the virtuoso, excelling in crafting intricate steps or grooves. Groove or slot milling is an operation in which side and face milling is often preferred to end. Side Milling Depth Of Cut.

From www.slideserve.com

PPT MANUFACTURING PROCESSES I PowerPoint Presentation, free Side Milling Depth Of Cut Side and face cutters offer the most efficient method for milling large volumes of. Depth of cut is a machining parameter that determines the depth at which the cutting tool plunges into the surface of the workpiece to remove material. Groove or slot milling is an operation in which side and face milling is often preferred to end milling. The. Side Milling Depth Of Cut.

From www.youtube.com

02_04_P4 Calculating Cutting Speed, Feed, and Machining Time for Face Side Milling Depth Of Cut This is crucial in operations like milling, where it dictates the side coverage of the cutting tool on the workpiece. When it comes to milling mild steel, around how much is my max depth of cut should be when using my machine and using 3/8 or 1/2. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a. Side Milling Depth Of Cut.

From www.machinistguides.com

F CNC Code Explained An Easy Intro for Beginners [Feedrate Side Milling Depth Of Cut Side milling or external milling emerges as the virtuoso, excelling in crafting intricate steps or grooves. Groove or slot milling is an operation in which side and face milling is often preferred to end milling. Depth of cut is a machining parameter that determines the depth at which the cutting tool plunges into the surface of the workpiece to remove. Side Milling Depth Of Cut.

From www.slideserve.com

PPT ME 350 Lecture 5 Chapter 22 PowerPoint Presentation, free Side Milling Depth Of Cut Depth of cut is a machining parameter that determines the depth at which the cutting tool plunges into the surface of the workpiece to remove material. This is crucial in operations like milling, where it dictates the side coverage of the cutting tool on the workpiece. Distinguished by varying widths, diameters, and adaptable tooth. The radial depth of cut (ae. Side Milling Depth Of Cut.

From www.youtube.com

1/4" depth of cut in a 17" lathe. YouTube Side Milling Depth Of Cut Groove or slot milling is an operation in which side and face milling is often preferred to end milling. Depth of cut is a machining parameter that determines the depth at which the cutting tool plunges into the surface of the workpiece to remove material. The radial depth of cut (ae or rdoc), is the length that the tool engages. Side Milling Depth Of Cut.

From article.sapub.org

The Impact of Machining Parameters on Peak Power and Energy Consumption Side Milling Depth Of Cut Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. Groove or slot milling is an operation in which side and face milling is often preferred to end milling. Side milling or external milling emerges as the virtuoso, excelling in crafting intricate steps or grooves. Depth of cut. Side Milling Depth Of Cut.

From www.researchgate.net

—Relations between cutting force and depth of cut. Download Side Milling Depth Of Cut Groove or slot milling is an operation in which side and face milling is often preferred to end milling. Side milling or external milling emerges as the virtuoso, excelling in crafting intricate steps or grooves. Distinguished by varying widths, diameters, and adaptable tooth. The depth of the cut, the speed of the cutter’s rotation, and the feed rate of the. Side Milling Depth Of Cut.

From www.youtube.com

Cutting Parameters Cutting Speed, Feed, Depth of cut CNCLearning Side Milling Depth Of Cut The depth of the cut, the speed of the cutter’s rotation, and the feed rate of the workpiece are critical parameters that influence. Distinguished by varying widths, diameters, and adaptable tooth. Depth of cut is a machining parameter that determines the depth at which the cutting tool plunges into the surface of the workpiece to remove material. Axial depth of. Side Milling Depth Of Cut.

From www.researchgate.net

Schematic diagram of instantaneous cutting depth Download Scientific Side Milling Depth Of Cut When it comes to milling mild steel, around how much is my max depth of cut should be when using my machine and using 3/8 or 1/2. This is crucial in operations like milling, where it dictates the side coverage of the cutting tool on the workpiece. Distinguished by varying widths, diameters, and adaptable tooth. Axial depth of cut (adoc):. Side Milling Depth Of Cut.

From sctools.online

Axial Depth of Cut (Milling AP) FM Carbide Side Milling Depth Of Cut The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. This is crucial in operations like milling, where it dictates the side coverage of the cutting tool on the workpiece. Also known as step down or cut. When it comes to. Side Milling Depth Of Cut.

From www.researchgate.net

Effect of radial depth of cut on cutting force and surface profile Side Milling Depth Of Cut Side milling or external milling emerges as the virtuoso, excelling in crafting intricate steps or grooves. Groove or slot milling is an operation in which side and face milling is often preferred to end milling. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial. Side Milling Depth Of Cut.

From www.researchgate.net

The schematic diagram of cutting depth changing in end milling Side Milling Depth Of Cut This is crucial in operations like milling, where it dictates the side coverage of the cutting tool on the workpiece. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. Axial depth of cut (adoc): When it comes to milling mild steel, around how much is my max. Side Milling Depth Of Cut.

From jsmithmoore.com

Cutting speed feed and depth of cut formula Side Milling Depth Of Cut Also known as step down or cut. Depth of cut is a machining parameter that determines the depth at which the cutting tool plunges into the surface of the workpiece to remove material. Side and face cutters offer the most efficient method for milling large volumes of. Groove or slot milling is an operation in which side and face milling. Side Milling Depth Of Cut.

From www.youtube.com

Axial and radial depth of cut in milling operations YouTube Side Milling Depth Of Cut Axial depth of cut (adoc): The depth of the cut, the speed of the cutter’s rotation, and the feed rate of the workpiece are critical parameters that influence. This is crucial in operations like milling, where it dictates the side coverage of the cutting tool on the workpiece. Side milling or external milling emerges as the virtuoso, excelling in crafting. Side Milling Depth Of Cut.

From jsmithmoore.com

Cutting speed feed and depth of cut formula Side Milling Depth Of Cut Groove or slot milling is an operation in which side and face milling is often preferred to end milling. This is crucial in operations like milling, where it dictates the side coverage of the cutting tool on the workpiece. Depth of cut is a machining parameter that determines the depth at which the cutting tool plunges into the surface of. Side Milling Depth Of Cut.

From www.minaprem.com

What is Depth of Cut (DOC) in Machining? Machining Principles Side Milling Depth Of Cut Axial depth of cut (adoc): When it comes to milling mild steel, around how much is my max depth of cut should be when using my machine and using 3/8 or 1/2. Groove or slot milling is an operation in which side and face milling is often preferred to end milling. This is crucial in operations like milling, where it. Side Milling Depth Of Cut.

From riverdeposit.mystrikingly.com

Slot Milling Depth Of Cut Side Milling Depth Of Cut When it comes to milling mild steel, around how much is my max depth of cut should be when using my machine and using 3/8 or 1/2. The depth of the cut, the speed of the cutter’s rotation, and the feed rate of the workpiece are critical parameters that influence. Distinguished by varying widths, diameters, and adaptable tooth. Side and. Side Milling Depth Of Cut.

From www.researchgate.net

A representation of the variable depth of cut Download Scientific Diagram Side Milling Depth Of Cut Axial depth of cut (adoc): Also known as step down or cut. Distinguished by varying widths, diameters, and adaptable tooth. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. This is crucial in operations like milling, where it dictates the. Side Milling Depth Of Cut.

From www.minaprem.com

What is Depth of Cut in Machining? Its Unit, Value, Effects and Selection Side Milling Depth Of Cut Depth of cut is a machining parameter that determines the depth at which the cutting tool plunges into the surface of the workpiece to remove material. Also known as step down or cut. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of. Side Milling Depth Of Cut.

From toolnotes.com

Cutting Parameters for Milling ToolNotes Side Milling Depth Of Cut Axial depth of cut (adoc): Groove or slot milling is an operation in which side and face milling is often preferred to end milling. Side and face cutters offer the most efficient method for milling large volumes of. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts.. Side Milling Depth Of Cut.

From www.slideserve.com

PPT Cutting Speed, Feed, and Depth of Cut PowerPoint Presentation Side Milling Depth Of Cut The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. Groove or slot milling is an operation in which side and face milling is often preferred to end milling. Side milling or external milling emerges as the virtuoso, excelling in crafting. Side Milling Depth Of Cut.

From jsmithmoore.com

Cutting speed feed and depth of cut formula Side Milling Depth Of Cut Also known as step down or cut. Side and face cutters offer the most efficient method for milling large volumes of. This is crucial in operations like milling, where it dictates the side coverage of the cutting tool on the workpiece. Side milling or external milling emerges as the virtuoso, excelling in crafting intricate steps or grooves. When it comes. Side Milling Depth Of Cut.

From jsmithmoore.com

Cutting speed feed and depth of cut formula Side Milling Depth Of Cut This is crucial in operations like milling, where it dictates the side coverage of the cutting tool on the workpiece. The depth of the cut, the speed of the cutter’s rotation, and the feed rate of the workpiece are critical parameters that influence. Axial depth of cut (adoc): Side milling or external milling emerges as the virtuoso, excelling in crafting. Side Milling Depth Of Cut.

From slideplayer.com

Machining Processes Used to Produce Various Shapes Milling ppt download Side Milling Depth Of Cut Side and face cutters offer the most efficient method for milling large volumes of. Distinguished by varying widths, diameters, and adaptable tooth. Depth of cut is a machining parameter that determines the depth at which the cutting tool plunges into the surface of the workpiece to remove material. When it comes to milling mild steel, around how much is my. Side Milling Depth Of Cut.

From www.youtube.com

Speeds Feeds and Depth of Cut for Milling YouTube Side Milling Depth Of Cut Also known as step down or cut. Groove or slot milling is an operation in which side and face milling is often preferred to end milling. When it comes to milling mild steel, around how much is my max depth of cut should be when using my machine and using 3/8 or 1/2. Axial depth of cut (adoc): Side milling. Side Milling Depth Of Cut.

From www.youtube.com

Cutting Speed Feed Depth of Cut Cutting Time of Grinding Machines Side Milling Depth Of Cut The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. Depth of cut is a machining parameter that determines the depth at which the cutting tool plunges into the surface of the workpiece to remove material. Also known as step down. Side Milling Depth Of Cut.

From www.slideshare.net

non traditional machining Side Milling Depth Of Cut Axial depth of cut (adoc): This is crucial in operations like milling, where it dictates the side coverage of the cutting tool on the workpiece. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. Distinguished by varying widths, diameters, and. Side Milling Depth Of Cut.

From engineeringlearn.com

Types of Milling Cutter Tools and Their Uses [with Pictures Side Milling Depth Of Cut Depth of cut is a machining parameter that determines the depth at which the cutting tool plunges into the surface of the workpiece to remove material. Groove or slot milling is an operation in which side and face milling is often preferred to end milling. Axial depth of cut (adoc): Side milling or external milling emerges as the virtuoso, excelling. Side Milling Depth Of Cut.

From www.youtube.com

Machine Technology IV Lesson 5 Use of Plain and Side Milling Cutters on Side Milling Depth Of Cut Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. Distinguished by varying widths, diameters, and adaptable tooth. Also. Side Milling Depth Of Cut.

From www.harveyperformance.com

Diving Into the Depth of Cut In The Loupe Machinist Blog Side Milling Depth Of Cut This is crucial in operations like milling, where it dictates the side coverage of the cutting tool on the workpiece. Distinguished by varying widths, diameters, and adaptable tooth. Groove or slot milling is an operation in which side and face milling is often preferred to end milling. Also known as step down or cut. The radial depth of cut (ae. Side Milling Depth Of Cut.

From www.slideserve.com

PPT CNC Turning PowerPoint Presentation ID6681898 Side Milling Depth Of Cut Axial depth of cut (adoc): The depth of the cut, the speed of the cutter’s rotation, and the feed rate of the workpiece are critical parameters that influence. When it comes to milling mild steel, around how much is my max depth of cut should be when using my machine and using 3/8 or 1/2. Generally, a shallow depth of. Side Milling Depth Of Cut.