Liner Pitting . You can also buy liner protective additive separately and add it to the standard coolant. Liner pitting can develop within 500 hours of operation under. the pitting can and will cause stress risers to develop in the liner, potentially leading to cracks and premature liner failure. Be careful to avoid topping off. The process by which liners can be pitted (and eventually perforated) is often called. Are you having trouble with pitting in your liners? Read our blog, engine sleeve / liner pitting explained to learn more. the 250 hour engine dynamometer test, approved by astm international, quantified the amount of cylinder liner pitting caused by cavitation. liner pitting can develop within 500 hours of operation under severe conditions when plain water is used as a coolant. liners are protected from pitting by elements in the sca. pitting of wet cylinder liners is a continual threat in many diesel engines. Increased air can enter the cooling system through cooling system leaks and/or a faulty radiator cap. a couple of things can help prevent liner pitting. engine conditions that affect liner pitting. An increase in air bubbles in a cooling system can increase the potential for cavitation erosion (pitting) of metal surfaces.

from www.unifiedalloys.com

Increased air can enter the cooling system through cooling system leaks and/or a faulty radiator cap. Are you having trouble with pitting in your liners? engine conditions that affect liner pitting. the 250 hour engine dynamometer test, approved by astm international, quantified the amount of cylinder liner pitting caused by cavitation. liner pitting can develop within 500 hours of operation under severe conditions when plain water is used as a coolant. the pitting can and will cause stress risers to develop in the liner, potentially leading to cracks and premature liner failure. Read our blog, engine sleeve / liner pitting explained to learn more. learn how proper diesel engine cooling system maintenance helps prevent engine cylinder wall/liner pitting, cavitation erosion and corrosion. The process by which liners can be pitted (and eventually perforated) is often called. An increase in air bubbles in a cooling system can increase the potential for cavitation erosion (pitting) of metal surfaces.

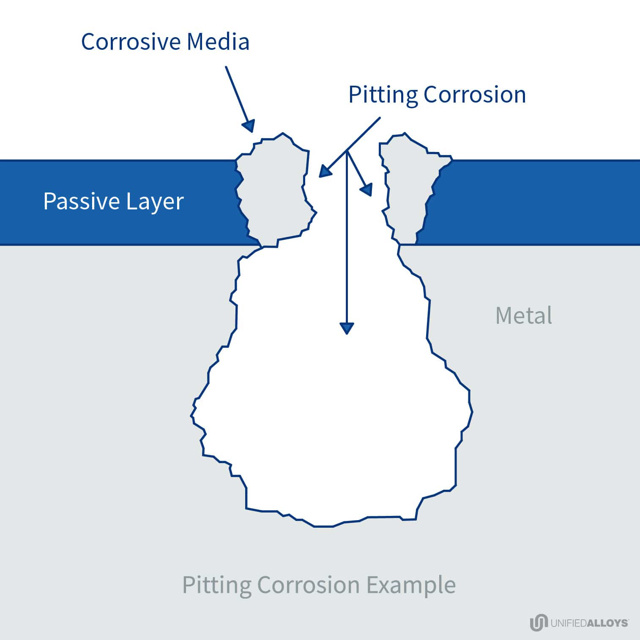

What is A Pitting Resistance Equivalent Number (PREN)? Unified Alloys

Liner Pitting Are you having trouble with pitting in your liners? Read our blog, engine sleeve / liner pitting explained to learn more. You can also buy liner protective additive separately and add it to the standard coolant. engine conditions that affect liner pitting. the pitting can and will cause stress risers to develop in the liner, potentially leading to cracks and premature liner failure. liner pitting can develop within 500 hours of operation under severe conditions when plain water is used as a coolant. the 250 hour engine dynamometer test, approved by astm international, quantified the amount of cylinder liner pitting caused by cavitation. Liner pitting can develop within 500 hours of operation under. liners are protected from pitting by elements in the sca. pitting of wet cylinder liners is a continual threat in many diesel engines. The process by which liners can be pitted (and eventually perforated) is often called. Be careful to avoid topping off. Increased air can enter the cooling system through cooling system leaks and/or a faulty radiator cap. a couple of things can help prevent liner pitting. An increase in air bubbles in a cooling system can increase the potential for cavitation erosion (pitting) of metal surfaces. Are you having trouble with pitting in your liners?

From highwayandheavyparts.com

Diesel Engine Cylinder Sleeve/Liner Pitting Symptoms and Prevention Liner Pitting The process by which liners can be pitted (and eventually perforated) is often called. Read our blog, engine sleeve / liner pitting explained to learn more. a couple of things can help prevent liner pitting. Increased air can enter the cooling system through cooling system leaks and/or a faulty radiator cap. the pitting can and will cause stress. Liner Pitting.

From www.desertcart.lk

Buy Cummins Filtration FLEETGUARD COOLANTS DCA70L (4 PCS/Box) Online at Liner Pitting engine conditions that affect liner pitting. learn how proper diesel engine cooling system maintenance helps prevent engine cylinder wall/liner pitting, cavitation erosion and corrosion. a couple of things can help prevent liner pitting. pitting of wet cylinder liners is a continual threat in many diesel engines. the pitting can and will cause stress risers to. Liner Pitting.

From www.youtube.com

Pitting on the liner water dripping from liner what could be the Liner Pitting Are you having trouble with pitting in your liners? a couple of things can help prevent liner pitting. liner pitting can develop within 500 hours of operation under severe conditions when plain water is used as a coolant. the 250 hour engine dynamometer test, approved by astm international, quantified the amount of cylinder liner pitting caused by. Liner Pitting.

From www.belzona.com

Engines and Casings Reforming and Protective Materials Liner Pitting liner pitting can develop within 500 hours of operation under severe conditions when plain water is used as a coolant. You can also buy liner protective additive separately and add it to the standard coolant. the pitting can and will cause stress risers to develop in the liner, potentially leading to cracks and premature liner failure. liners. Liner Pitting.

From www.ddcoatings.co.uk

What is Pitting Corrosion? How to detect and treat pitting corrosion? Liner Pitting engine conditions that affect liner pitting. An increase in air bubbles in a cooling system can increase the potential for cavitation erosion (pitting) of metal surfaces. liners are protected from pitting by elements in the sca. Be careful to avoid topping off. a couple of things can help prevent liner pitting. You can also buy liner protective. Liner Pitting.

From penray.com

Cavitation In Cooling Sytems Penray Liner Pitting Increased air can enter the cooling system through cooling system leaks and/or a faulty radiator cap. An increase in air bubbles in a cooling system can increase the potential for cavitation erosion (pitting) of metal surfaces. a couple of things can help prevent liner pitting. pitting of wet cylinder liners is a continual threat in many diesel engines.. Liner Pitting.

From www.noordeman.com.au

Cavitation Erosion Electrolysis on Wet Liners Noordeman Diesel Liner Pitting You can also buy liner protective additive separately and add it to the standard coolant. An increase in air bubbles in a cooling system can increase the potential for cavitation erosion (pitting) of metal surfaces. pitting of wet cylinder liners is a continual threat in many diesel engines. learn how proper diesel engine cooling system maintenance helps prevent. Liner Pitting.

From www.desertcart.ae

Buy PATIKIL 50mm/1.97" Foam Lid Liner, 150 Pack PS Foam Resistant Liner Pitting Liner pitting can develop within 500 hours of operation under. The process by which liners can be pitted (and eventually perforated) is often called. a couple of things can help prevent liner pitting. Be careful to avoid topping off. learn how proper diesel engine cooling system maintenance helps prevent engine cylinder wall/liner pitting, cavitation erosion and corrosion. . Liner Pitting.

From www.bigmacktrucks.com

ENDT 673 Liner has pitting, I don't know how??? Engine and Liner Pitting The process by which liners can be pitted (and eventually perforated) is often called. Are you having trouble with pitting in your liners? a couple of things can help prevent liner pitting. the 250 hour engine dynamometer test, approved by astm international, quantified the amount of cylinder liner pitting caused by cavitation. Increased air can enter the cooling. Liner Pitting.

From pittsburghpower.com

Liner Pitting, Dry Fuel & More Pittsburgh Power Liner Pitting learn how proper diesel engine cooling system maintenance helps prevent engine cylinder wall/liner pitting, cavitation erosion and corrosion. liners are protected from pitting by elements in the sca. Increased air can enter the cooling system through cooling system leaks and/or a faulty radiator cap. Read our blog, engine sleeve / liner pitting explained to learn more. the. Liner Pitting.

From n-news.com

piston pitting NNews Liner Pitting An increase in air bubbles in a cooling system can increase the potential for cavitation erosion (pitting) of metal surfaces. The process by which liners can be pitted (and eventually perforated) is often called. Liner pitting can develop within 500 hours of operation under. a couple of things can help prevent liner pitting. pitting of wet cylinder liners. Liner Pitting.

From www.southeasternequip.com

How to Avoid Liner Pitting Southeastern Equipment Southeastern Liner Pitting An increase in air bubbles in a cooling system can increase the potential for cavitation erosion (pitting) of metal surfaces. The process by which liners can be pitted (and eventually perforated) is often called. engine conditions that affect liner pitting. the pitting can and will cause stress risers to develop in the liner, potentially leading to cracks and. Liner Pitting.

From www.youtube.com

What is cylinder liner? YouTube Liner Pitting Increased air can enter the cooling system through cooling system leaks and/or a faulty radiator cap. You can also buy liner protective additive separately and add it to the standard coolant. The process by which liners can be pitted (and eventually perforated) is often called. a couple of things can help prevent liner pitting. liners are protected from. Liner Pitting.

From www.tenfourmagazine.com

Liner Pitting, Dry Fuel & More 104 Magazine Liner Pitting The process by which liners can be pitted (and eventually perforated) is often called. You can also buy liner protective additive separately and add it to the standard coolant. An increase in air bubbles in a cooling system can increase the potential for cavitation erosion (pitting) of metal surfaces. engine conditions that affect liner pitting. Increased air can enter. Liner Pitting.

From facts.net

12 Fascinating Facts About Pitting Corrosion Liner Pitting pitting of wet cylinder liners is a continual threat in many diesel engines. Increased air can enter the cooling system through cooling system leaks and/or a faulty radiator cap. liner pitting can develop within 500 hours of operation under severe conditions when plain water is used as a coolant. An increase in air bubbles in a cooling system. Liner Pitting.

From www.bigmacktrucks.com

ENDT 673 Liner has pitting, I don't know how??? Engine and Liner Pitting Increased air can enter the cooling system through cooling system leaks and/or a faulty radiator cap. the 250 hour engine dynamometer test, approved by astm international, quantified the amount of cylinder liner pitting caused by cavitation. Be careful to avoid topping off. the pitting can and will cause stress risers to develop in the liner, potentially leading to. Liner Pitting.

From www.bigmacktrucks.com

ENDT 673 Liner has pitting, I don't know how??? Engine and Liner Pitting Liner pitting can develop within 500 hours of operation under. pitting of wet cylinder liners is a continual threat in many diesel engines. learn how proper diesel engine cooling system maintenance helps prevent engine cylinder wall/liner pitting, cavitation erosion and corrosion. Read our blog, engine sleeve / liner pitting explained to learn more. liner pitting can develop. Liner Pitting.

From community.fmca.com

Cylinder Liner Pitting Caused By Nontreatment Of Coolant Engines Liner Pitting liners are protected from pitting by elements in the sca. learn how proper diesel engine cooling system maintenance helps prevent engine cylinder wall/liner pitting, cavitation erosion and corrosion. the pitting can and will cause stress risers to develop in the liner, potentially leading to cracks and premature liner failure. You can also buy liner protective additive separately. Liner Pitting.

From www.gordonengland.co.uk

freshwater corrosion, pitting and erosion Liner Pitting learn how proper diesel engine cooling system maintenance helps prevent engine cylinder wall/liner pitting, cavitation erosion and corrosion. An increase in air bubbles in a cooling system can increase the potential for cavitation erosion (pitting) of metal surfaces. the pitting can and will cause stress risers to develop in the liner, potentially leading to cracks and premature liner. Liner Pitting.

From highseashydraulics.com

Pitting High Seas Hydraulics Liner Pitting An increase in air bubbles in a cooling system can increase the potential for cavitation erosion (pitting) of metal surfaces. Read our blog, engine sleeve / liner pitting explained to learn more. pitting of wet cylinder liners is a continual threat in many diesel engines. liners are protected from pitting by elements in the sca. You can also. Liner Pitting.

From www.researchgate.net

(Color online) Mechanistic model of Si pitting at relevant process Liner Pitting Be careful to avoid topping off. the 250 hour engine dynamometer test, approved by astm international, quantified the amount of cylinder liner pitting caused by cavitation. learn how proper diesel engine cooling system maintenance helps prevent engine cylinder wall/liner pitting, cavitation erosion and corrosion. An increase in air bubbles in a cooling system can increase the potential for. Liner Pitting.

From www.diningandcooking.com

Pitting in sides of all American pressure canner Dining and Cooking Liner Pitting Liner pitting can develop within 500 hours of operation under. liner pitting can develop within 500 hours of operation under severe conditions when plain water is used as a coolant. the pitting can and will cause stress risers to develop in the liner, potentially leading to cracks and premature liner failure. learn how proper diesel engine cooling. Liner Pitting.

From www.vehicleservicepros.com

Cooling System Issues Vehicle Service Pros Liner Pitting engine conditions that affect liner pitting. liners are protected from pitting by elements in the sca. liner pitting can develop within 500 hours of operation under severe conditions when plain water is used as a coolant. the 250 hour engine dynamometer test, approved by astm international, quantified the amount of cylinder liner pitting caused by cavitation.. Liner Pitting.

From www.unifiedalloys.com

What is A Pitting Resistance Equivalent Number (PREN)? Unified Alloys Liner Pitting Liner pitting can develop within 500 hours of operation under. Read our blog, engine sleeve / liner pitting explained to learn more. the 250 hour engine dynamometer test, approved by astm international, quantified the amount of cylinder liner pitting caused by cavitation. Are you having trouble with pitting in your liners? liners are protected from pitting by elements. Liner Pitting.

From amarineblog.com

Pitting corrosions AMARINE Liner Pitting engine conditions that affect liner pitting. liner pitting can develop within 500 hours of operation under severe conditions when plain water is used as a coolant. liners are protected from pitting by elements in the sca. the pitting can and will cause stress risers to develop in the liner, potentially leading to cracks and premature liner. Liner Pitting.

From www.shutterstock.com

Pitting Corrosion Through Defects On Steel Stock Photo 2265549367 Liner Pitting Read our blog, engine sleeve / liner pitting explained to learn more. a couple of things can help prevent liner pitting. An increase in air bubbles in a cooling system can increase the potential for cavitation erosion (pitting) of metal surfaces. Increased air can enter the cooling system through cooling system leaks and/or a faulty radiator cap. learn. Liner Pitting.

From www.rvtechmag.com

Diesel Engine Coolants Liner Pitting learn how proper diesel engine cooling system maintenance helps prevent engine cylinder wall/liner pitting, cavitation erosion and corrosion. Read our blog, engine sleeve / liner pitting explained to learn more. An increase in air bubbles in a cooling system can increase the potential for cavitation erosion (pitting) of metal surfaces. Are you having trouble with pitting in your liners?. Liner Pitting.

From www.scribd.com

Cause and Prevention of Pitting in Cylinder Liners PDF Liner Pitting Liner pitting can develop within 500 hours of operation under. a couple of things can help prevent liner pitting. You can also buy liner protective additive separately and add it to the standard coolant. the 250 hour engine dynamometer test, approved by astm international, quantified the amount of cylinder liner pitting caused by cavitation. liners are protected. Liner Pitting.

From motormission.com

Rusted Pitted & Corroded Cylinder Revealed After Boring Motor Mission Liner Pitting Liner pitting can develop within 500 hours of operation under. Increased air can enter the cooling system through cooling system leaks and/or a faulty radiator cap. learn how proper diesel engine cooling system maintenance helps prevent engine cylinder wall/liner pitting, cavitation erosion and corrosion. pitting of wet cylinder liners is a continual threat in many diesel engines. . Liner Pitting.

From www.youtube.com

Coolant can DESTROY your Engine faster than Bad Oil. Cavitation and Liner Pitting liner pitting can develop within 500 hours of operation under severe conditions when plain water is used as a coolant. Liner pitting can develop within 500 hours of operation under. pitting of wet cylinder liners is a continual threat in many diesel engines. Be careful to avoid topping off. The process by which liners can be pitted (and. Liner Pitting.

From www.911metallurgist.com

Grinding Mill Liner & Ball Corrosion Rate Liner Pitting the 250 hour engine dynamometer test, approved by astm international, quantified the amount of cylinder liner pitting caused by cavitation. An increase in air bubbles in a cooling system can increase the potential for cavitation erosion (pitting) of metal surfaces. pitting of wet cylinder liners is a continual threat in many diesel engines. You can also buy liner. Liner Pitting.

From ceblnyxe.blob.core.windows.net

Cylinder Liner Cavitation Erosion at Gary Ford blog Liner Pitting Be careful to avoid topping off. Liner pitting can develop within 500 hours of operation under. Read our blog, engine sleeve / liner pitting explained to learn more. engine conditions that affect liner pitting. The process by which liners can be pitted (and eventually perforated) is often called. the 250 hour engine dynamometer test, approved by astm international,. Liner Pitting.

From www.materialsperformance.com

Pitting Repairs for HighTemperature/HighPressure Process Vessels Liner Pitting liner pitting can develop within 500 hours of operation under severe conditions when plain water is used as a coolant. pitting of wet cylinder liners is a continual threat in many diesel engines. Increased air can enter the cooling system through cooling system leaks and/or a faulty radiator cap. An increase in air bubbles in a cooling system. Liner Pitting.

From www.proadditives.com

Will RMI25 prevent cylinder liner pitting and erosion in diesel Liner Pitting engine conditions that affect liner pitting. the pitting can and will cause stress risers to develop in the liner, potentially leading to cracks and premature liner failure. learn how proper diesel engine cooling system maintenance helps prevent engine cylinder wall/liner pitting, cavitation erosion and corrosion. Read our blog, engine sleeve / liner pitting explained to learn more.. Liner Pitting.

From www.researchgate.net

(Color online) Mechanistic model of Si pitting at relevant process Liner Pitting An increase in air bubbles in a cooling system can increase the potential for cavitation erosion (pitting) of metal surfaces. Increased air can enter the cooling system through cooling system leaks and/or a faulty radiator cap. learn how proper diesel engine cooling system maintenance helps prevent engine cylinder wall/liner pitting, cavitation erosion and corrosion. You can also buy liner. Liner Pitting.