Valve Seat Hardfacing . Valve sealing surface has a certain high hardness is to avoid hard sundries in the medium pad and scratch. Valve internals such as seats and closure members can be at high risk of erosion, abrasion. Hard facing (hf)—applying harder material to vulnerable parts—can mitigate such damage. Monel valves seats hardfacing and bonnet bolting system. Both parts (seat and wedge) to be required for hardfacing is usually for confirmed abrasive (not just corrosive) medium. Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear, corrosion, galling and cavitation damage. I'm glad to share the following hint regarding valve bonnets bolting. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c).

from www.slideserve.com

I'm glad to share the following hint regarding valve bonnets bolting. Hard facing (hf)—applying harder material to vulnerable parts—can mitigate such damage. Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear, corrosion, galling and cavitation damage. Valve internals such as seats and closure members can be at high risk of erosion, abrasion. Both parts (seat and wedge) to be required for hardfacing is usually for confirmed abrasive (not just corrosive) medium. Monel valves seats hardfacing and bonnet bolting system. Valve sealing surface has a certain high hardness is to avoid hard sundries in the medium pad and scratch. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c).

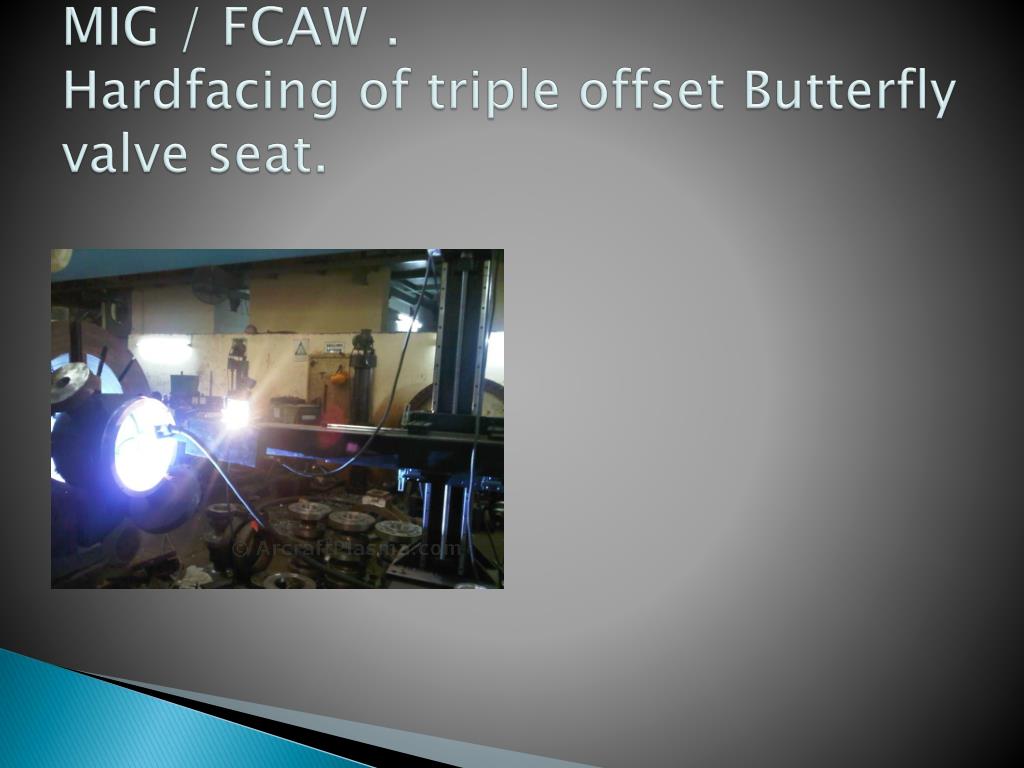

PPT Welding and Hardfacing Automation PowerPoint Presentation, free

Valve Seat Hardfacing Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear, corrosion, galling and cavitation damage. Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear, corrosion, galling and cavitation damage. Hard facing (hf)—applying harder material to vulnerable parts—can mitigate such damage. Valve internals such as seats and closure members can be at high risk of erosion, abrasion. Valve sealing surface has a certain high hardness is to avoid hard sundries in the medium pad and scratch. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c). Monel valves seats hardfacing and bonnet bolting system. I'm glad to share the following hint regarding valve bonnets bolting. Both parts (seat and wedge) to be required for hardfacing is usually for confirmed abrasive (not just corrosive) medium.

From www.slideserve.com

PPT Welding and Hardfacing Automation PowerPoint Presentation, free Valve Seat Hardfacing Monel valves seats hardfacing and bonnet bolting system. Both parts (seat and wedge) to be required for hardfacing is usually for confirmed abrasive (not just corrosive) medium. I'm glad to share the following hint regarding valve bonnets bolting. Valve sealing surface has a certain high hardness is to avoid hard sundries in the medium pad and scratch. The stellite hardfacing. Valve Seat Hardfacing.

From dannysengineportal.com

Valve Seats Installing And Grinding Valve Seats Learn The Basics Valve Seat Hardfacing The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c). Monel valves seats hardfacing and bonnet bolting system. Hard facing (hf)—applying harder material to vulnerable parts—can mitigate such damage. Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear, corrosion, galling and cavitation damage.. Valve Seat Hardfacing.

From www.semanticscholar.org

Corrosion Performance of Valve Seat Hardfacing Materials in Amine Valve Seat Hardfacing Both parts (seat and wedge) to be required for hardfacing is usually for confirmed abrasive (not just corrosive) medium. Valve sealing surface has a certain high hardness is to avoid hard sundries in the medium pad and scratch. Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear, corrosion, galling and cavitation damage.. Valve Seat Hardfacing.

From www.youtube.com

Valve Seat Welding YouTube Valve Seat Hardfacing Both parts (seat and wedge) to be required for hardfacing is usually for confirmed abrasive (not just corrosive) medium. Monel valves seats hardfacing and bonnet bolting system. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c). Internal parts of valves, such as seats and closures, can be at high risk. Valve Seat Hardfacing.

From seed2020.en.made-in-china.com

Hardfacing Wear Resistance Valve Plug Valve Seat with Stellite 6 on 316 Valve Seat Hardfacing Monel valves seats hardfacing and bonnet bolting system. Both parts (seat and wedge) to be required for hardfacing is usually for confirmed abrasive (not just corrosive) medium. I'm glad to share the following hint regarding valve bonnets bolting. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c). Valve sealing surface. Valve Seat Hardfacing.

From stymir.com

Valve Seat Hard Facing ( PTAW) STYM Engine Valves Valve Seat Hardfacing Monel valves seats hardfacing and bonnet bolting system. Both parts (seat and wedge) to be required for hardfacing is usually for confirmed abrasive (not just corrosive) medium. Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear, corrosion, galling and cavitation damage. I'm glad to share the following hint regarding valve bonnets bolting.. Valve Seat Hardfacing.

From zfavalves.com

Wafer Butterfly Valve Hard Back Seat ZFA Valves Manufacturer Valve Seat Hardfacing The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c). Hard facing (hf)—applying harder material to vulnerable parts—can mitigate such damage. Valve internals such as seats and closure members can be at high risk of erosion, abrasion. Valve sealing surface has a certain high hardness is to avoid hard sundries in. Valve Seat Hardfacing.

From www.slideserve.com

PPT Welding and Hardfacing Automation PowerPoint Presentation, free Valve Seat Hardfacing Valve internals such as seats and closure members can be at high risk of erosion, abrasion. Monel valves seats hardfacing and bonnet bolting system. Hard facing (hf)—applying harder material to vulnerable parts—can mitigate such damage. Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear, corrosion, galling and cavitation damage. Both parts (seat. Valve Seat Hardfacing.

From www.primoautomation.com

"CLADDING HARDFACING OVERLAY EQUIPMENTS GALLERY" Valve Seat Hardfacing I'm glad to share the following hint regarding valve bonnets bolting. Monel valves seats hardfacing and bonnet bolting system. Both parts (seat and wedge) to be required for hardfacing is usually for confirmed abrasive (not just corrosive) medium. Valve internals such as seats and closure members can be at high risk of erosion, abrasion. Hard facing (hf)—applying harder material to. Valve Seat Hardfacing.

From www.researchgate.net

(a) Photograph showing the appearance of the valve piece in asreceived Valve Seat Hardfacing I'm glad to share the following hint regarding valve bonnets bolting. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c). Hard facing (hf)—applying harder material to vulnerable parts—can mitigate such damage. Valve sealing surface has a certain high hardness is to avoid hard sundries in the medium pad and scratch.. Valve Seat Hardfacing.

From www.avweld.com.au

Hardfacing Laser Cladding, Hardfacing, Repairs Valve Seat Hardfacing Hard facing (hf)—applying harder material to vulnerable parts—can mitigate such damage. I'm glad to share the following hint regarding valve bonnets bolting. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c). Monel valves seats hardfacing and bonnet bolting system. Valve sealing surface has a certain high hardness is to avoid. Valve Seat Hardfacing.

From www.weldedalloy.com

Hardfacing Welding Cobalt Chrome Powder Stellite 1 For Valve Seats Valve Seat Hardfacing Valve internals such as seats and closure members can be at high risk of erosion, abrasion. Monel valves seats hardfacing and bonnet bolting system. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c). Hard facing (hf)—applying harder material to vulnerable parts—can mitigate such damage. I'm glad to share the following. Valve Seat Hardfacing.

From www.semanticscholar.org

Corrosion Performance of Valve Seat Hardfacing Materials in Amine Valve Seat Hardfacing I'm glad to share the following hint regarding valve bonnets bolting. Monel valves seats hardfacing and bonnet bolting system. Valve sealing surface has a certain high hardness is to avoid hard sundries in the medium pad and scratch. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c). Hard facing (hf)—applying. Valve Seat Hardfacing.

From www.scantechlaser.com

Hard Facing of Valve Seats Scantech Laser Valve Seat Hardfacing Hard facing (hf)—applying harder material to vulnerable parts—can mitigate such damage. Valve sealing surface has a certain high hardness is to avoid hard sundries in the medium pad and scratch. Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear, corrosion, galling and cavitation damage. Monel valves seats hardfacing and bonnet bolting system.. Valve Seat Hardfacing.

From www.scribd.com

Stellite (Stellite 6, Stellite 21) Composition, Properties, Deloro Valve Seat Hardfacing Valve sealing surface has a certain high hardness is to avoid hard sundries in the medium pad and scratch. Both parts (seat and wedge) to be required for hardfacing is usually for confirmed abrasive (not just corrosive) medium. Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear, corrosion, galling and cavitation damage.. Valve Seat Hardfacing.

From www.youtube.com

Offset valve guides and valve seat blending explained YouTube Valve Seat Hardfacing Valve internals such as seats and closure members can be at high risk of erosion, abrasion. Hard facing (hf)—applying harder material to vulnerable parts—can mitigate such damage. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c). Internal parts of valves, such as seats and closures, can be at high risk. Valve Seat Hardfacing.

From www.avweld.com.au

Hardfacing AVWELD Hardfacing Valve Seat Hardfacing Valve sealing surface has a certain high hardness is to avoid hard sundries in the medium pad and scratch. Valve internals such as seats and closure members can be at high risk of erosion, abrasion. Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear, corrosion, galling and cavitation damage. Monel valves seats. Valve Seat Hardfacing.

From ambco.co.uk

AMB Capabilities Valve Seat Hardfacing Monel valves seats hardfacing and bonnet bolting system. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c). Valve internals such as seats and closure members can be at high risk of erosion, abrasion. Hard facing (hf)—applying harder material to vulnerable parts—can mitigate such damage. Both parts (seat and wedge) to. Valve Seat Hardfacing.

From www.semanticscholar.org

Figure 1 from Optimization of Process Parameter in Seat Hardfacing Valve Seat Hardfacing Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear, corrosion, galling and cavitation damage. Both parts (seat and wedge) to be required for hardfacing is usually for confirmed abrasive (not just corrosive) medium. Valve internals such as seats and closure members can be at high risk of erosion, abrasion. I'm glad to. Valve Seat Hardfacing.

From www.fpe.com.my

Valve Plug & Valve Seat Hastelloy Hardfacing on Valve Plug & Valve Seat Valve Seat Hardfacing Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear, corrosion, galling and cavitation damage. I'm glad to share the following hint regarding valve bonnets bolting. Both parts (seat and wedge) to be required for hardfacing is usually for confirmed abrasive (not just corrosive) medium. Valve sealing surface has a certain high hardness. Valve Seat Hardfacing.

From www.fpe.com.my

Valve Plug & Valve Seat Hastelloy Hardfacing on Valve Plug & Valve Seat Valve Seat Hardfacing Valve internals such as seats and closure members can be at high risk of erosion, abrasion. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c). Monel valves seats hardfacing and bonnet bolting system. Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear,. Valve Seat Hardfacing.

From www.fpe.com.my

Valve Plug & Valve Seat Hastelloy Hardfacing on Valve Plug & Valve Seat Valve Seat Hardfacing Valve internals such as seats and closure members can be at high risk of erosion, abrasion. Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear, corrosion, galling and cavitation damage. Monel valves seats hardfacing and bonnet bolting system. Both parts (seat and wedge) to be required for hardfacing is usually for confirmed. Valve Seat Hardfacing.

From www.fpe.com.my

Valve Plug & Valve Seat Hastelloy Hardfacing on Valve Plug & Valve Seat Valve Seat Hardfacing I'm glad to share the following hint regarding valve bonnets bolting. Valve internals such as seats and closure members can be at high risk of erosion, abrasion. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c). Both parts (seat and wedge) to be required for hardfacing is usually for confirmed. Valve Seat Hardfacing.

From www.steelstruct.com.au

Hardfacing Steelstruct Engineering Valve Seat Hardfacing Monel valves seats hardfacing and bonnet bolting system. Hard facing (hf)—applying harder material to vulnerable parts—can mitigate such damage. Valve internals such as seats and closure members can be at high risk of erosion, abrasion. I'm glad to share the following hint regarding valve bonnets bolting. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at. Valve Seat Hardfacing.

From www.ipcvalves.com

How to pick the right material for valve seat IPC Valves Valve Seat Hardfacing Hard facing (hf)—applying harder material to vulnerable parts—can mitigate such damage. Monel valves seats hardfacing and bonnet bolting system. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c). Valve sealing surface has a certain high hardness is to avoid hard sundries in the medium pad and scratch. I'm glad to. Valve Seat Hardfacing.

From www.alloysint.com.au

Nickel & Cobalt Based Alloys International Valve Seat Hardfacing I'm glad to share the following hint regarding valve bonnets bolting. Valve internals such as seats and closure members can be at high risk of erosion, abrasion. Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear, corrosion, galling and cavitation damage. The stellite hardfacing overlays provide excellent mechanical wear resistance and good. Valve Seat Hardfacing.

From www.avweld.com.au

Welding hardfacing onto a rotary valve rotor AVWELD Hardfacing Valve Seat Hardfacing Valve internals such as seats and closure members can be at high risk of erosion, abrasion. Valve sealing surface has a certain high hardness is to avoid hard sundries in the medium pad and scratch. Monel valves seats hardfacing and bonnet bolting system. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to. Valve Seat Hardfacing.

From www.fpe.com.my

Valve Plug & Valve Seat Hastelloy Hardfacing on Valve Plug & Valve Seat Valve Seat Hardfacing Monel valves seats hardfacing and bonnet bolting system. Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear, corrosion, galling and cavitation damage. I'm glad to share the following hint regarding valve bonnets bolting. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c).. Valve Seat Hardfacing.

From www.fpe.com.my

Valve Plug & Valve Seat Hastelloy Hardfacing on Valve Plug & Valve Seat Valve Seat Hardfacing Hard facing (hf)—applying harder material to vulnerable parts—can mitigate such damage. Valve sealing surface has a certain high hardness is to avoid hard sundries in the medium pad and scratch. Both parts (seat and wedge) to be required for hardfacing is usually for confirmed abrasive (not just corrosive) medium. Internal parts of valves, such as seats and closures, can be. Valve Seat Hardfacing.

From www.fpe.com.my

Valve Plug & Valve Seat Hastelloy Hardfacing on Valve Plug & Valve Seat Valve Seat Hardfacing The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c). Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear, corrosion, galling and cavitation damage. Monel valves seats hardfacing and bonnet bolting system. Both parts (seat and wedge) to be required for hardfacing is. Valve Seat Hardfacing.

From www.fpe.com.my

Valve Plug & Valve Seat Hastelloy Hardfacing on Valve Plug & Valve Seat Valve Seat Hardfacing Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear, corrosion, galling and cavitation damage. Valve sealing surface has a certain high hardness is to avoid hard sundries in the medium pad and scratch. Monel valves seats hardfacing and bonnet bolting system. Both parts (seat and wedge) to be required for hardfacing is. Valve Seat Hardfacing.

From www.weldedalloy.com

Hardfacing Welding Cobalt Chrome Powder Stellite 1 For Valve Seats Valve Seat Hardfacing Valve internals such as seats and closure members can be at high risk of erosion, abrasion. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c). Internal parts of valves, such as seats and closures, can be at high risk for erosion, wear, corrosion, galling and cavitation damage. Monel valves seats. Valve Seat Hardfacing.

From overlayweld.com

Valve hardfacing Plasma hardfacing valve industry applications. Valve Seat Hardfacing Valve sealing surface has a certain high hardness is to avoid hard sundries in the medium pad and scratch. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c). Hard facing (hf)—applying harder material to vulnerable parts—can mitigate such damage. Both parts (seat and wedge) to be required for hardfacing is. Valve Seat Hardfacing.

From www.slideserve.com

PPT Welding and Hardfacing Automation PowerPoint Presentation, free Valve Seat Hardfacing Valve internals such as seats and closure members can be at high risk of erosion, abrasion. I'm glad to share the following hint regarding valve bonnets bolting. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c). Hard facing (hf)—applying harder material to vulnerable parts—can mitigate such damage. Monel valves seats. Valve Seat Hardfacing.

From www.reliavalve.com

Stellite Seat Ball Valve Relia Valves Valve Seat Hardfacing Valve internals such as seats and closure members can be at high risk of erosion, abrasion. Monel valves seats hardfacing and bonnet bolting system. I'm glad to share the following hint regarding valve bonnets bolting. The stellite hardfacing overlays provide excellent mechanical wear resistance and good corrosion resistance at temperatures up to 1200°f (649°c). Valve sealing surface has a certain. Valve Seat Hardfacing.