Types Of Welding Tape . Suitable for stainless, carbon, duplex and chrome steels as well as other metals. Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. Compatible with mig, tig, and stick welding. Apply 200 amp tape to thin welds on aluminum, cast iron, nickel and copper alloys, and steel. Woven fiberglass and malleable aluminum tape. Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their melting points.

from www.amazon.co.uk

Apply 200 amp tape to thin welds on aluminum, cast iron, nickel and copper alloys, and steel. Woven fiberglass and malleable aluminum tape. Compatible with mig, tig, and stick welding. Suitable for stainless, carbon, duplex and chrome steels as well as other metals. As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their melting points. Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap.

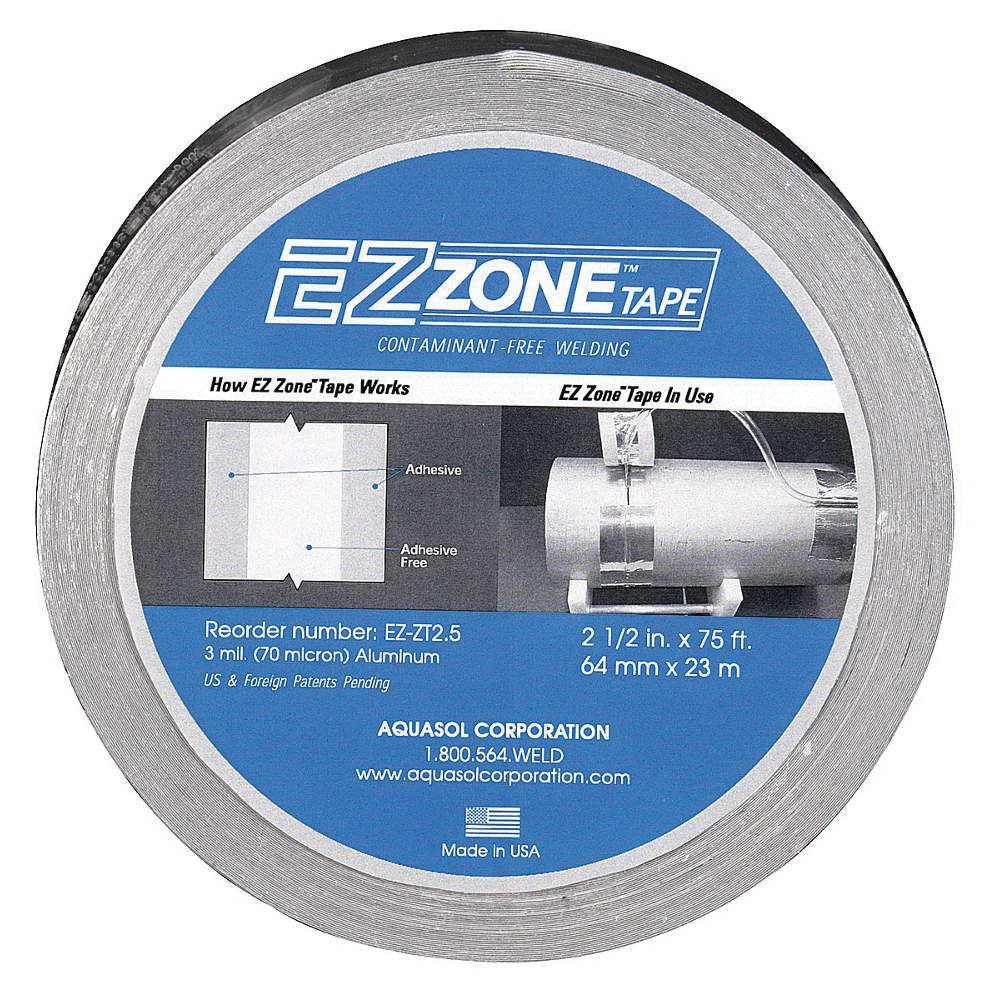

Aquasol EZZT2.5 EZ Zone Welding Tape 21/2 Inch x 75 Feet Amazon.co

Types Of Welding Tape Compatible with mig, tig, and stick welding. Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. Compatible with mig, tig, and stick welding. Woven fiberglass and malleable aluminum tape. Apply 200 amp tape to thin welds on aluminum, cast iron, nickel and copper alloys, and steel. Suitable for stainless, carbon, duplex and chrome steels as well as other metals. As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their melting points.

From eziil.com

5 Types of Welding Positions 1g, 2f, 3g, 4g... Types Of Welding Tape Compatible with mig, tig, and stick welding. Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. Suitable for stainless, carbon, duplex and chrome steels as well as other metals.. Types Of Welding Tape.

From www.youtube.com

🔥 Welding with Ceramic Back Tape YouTube Types Of Welding Tape As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their melting points. Suitable for stainless, carbon, duplex and chrome steels as well as other metals. Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. Compatible with. Types Of Welding Tape.

From stock.adobe.com

Types of welding joints, metal welding Stock Vector Adobe Stock Types Of Welding Tape Woven fiberglass and malleable aluminum tape. Compatible with mig, tig, and stick welding. Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their melting points. Suitable for. Types Of Welding Tape.

From www.nepal.ubuy.com

Buy JOUNJIP Plastic Welding Rods 7 Types of Welding Plastic (PP PU ABS Types Of Welding Tape Compatible with mig, tig, and stick welding. As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their melting points. Suitable for stainless, carbon, duplex and chrome steels as well as other metals. Apply 200 amp tape to thin welds on aluminum, cast iron, nickel. Types Of Welding Tape.

From rickyswelding.com

What Are The Common Types Of Welding? Ricky's Welding Equipment Types Of Welding Tape Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. Apply 200 amp tape to thin welds on aluminum, cast iron, nickel and copper alloys, and steel. Woven fiberglass and. Types Of Welding Tape.

From blog.huntingdonfusion.com

Weld Backing Tape Huntingdon Fusion Techniques HFT Weld Purging Types Of Welding Tape Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. Apply 200 amp tape to thin welds on aluminum, cast iron, nickel and copper alloys, and steel. Woven fiberglass and malleable aluminum tape. As you know, welding is a strong joining process in which two metal parts. Types Of Welding Tape.

From www.studypool.com

SOLUTION Welded connections and types of weld joints dss Studypool Types Of Welding Tape As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their melting points. Suitable for stainless, carbon, duplex and chrome steels as well as other metals. Woven fiberglass and malleable aluminum tape. Stick this flexible tape to the back of welding seams to contain spatter. Types Of Welding Tape.

From www.alibaba.com

Industrial Ceramic Welding Backing Tape For Welding Buy Industrial Types Of Welding Tape Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. Compatible with mig, tig, and stick welding. Suitable for stainless, carbon, duplex and chrome steels as well as other metals. Woven fiberglass and malleable aluminum tape. As you know, welding is a strong joining process in which two metal parts join together to. Types Of Welding Tape.

From dir.indiamart.com

Welding Tape at Best Price in India Types Of Welding Tape Compatible with mig, tig, and stick welding. Woven fiberglass and malleable aluminum tape. Apply 200 amp tape to thin welds on aluminum, cast iron, nickel and copper alloys, and steel. Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. Ez zone tape innovatively offers the perfect. Types Of Welding Tape.

From kirtanesahilsk.blogspot.com

Types of welding joints Types Of Welding Tape Suitable for stainless, carbon, duplex and chrome steels as well as other metals. Woven fiberglass and malleable aluminum tape. Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals. Types Of Welding Tape.

From www.artofit.org

Types of welding defects causes and remedies Artofit Types Of Welding Tape As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their melting points. Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. Compatible with mig, tig, and stick welding. Stick this flexible tape to the back of. Types Of Welding Tape.

From www.alibaba.com

Backing Tape Ceramic Welding For Backing Weld Buy Backing Tape Types Of Welding Tape Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. Suitable for stainless, carbon, duplex and chrome steels as well as other metals. Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. Apply 200 amp tape to thin welds. Types Of Welding Tape.

From weldingofwelders.com

Welding Joints and their Types Welding Basics Types Of Welding Tape As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their melting points. Woven fiberglass and malleable aluminum tape. Apply 200 amp tape to thin welds on aluminum, cast iron, nickel and copper alloys, and steel. Stick this flexible tape to the back of welding. Types Of Welding Tape.

From www.vrogue.co

Types Of Welding Methods vrogue.co Types Of Welding Tape Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. Suitable for stainless, carbon, duplex and chrome steels as well as other metals. Woven fiberglass and malleable aluminum tape. Compatible. Types Of Welding Tape.

From marinerspointpro.com

Types Of welding Joints Marinerspoint Pro Types Of Welding Tape Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. Suitable for stainless, carbon, duplex and chrome steels as well as other metals. Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. As you know, welding is a strong. Types Of Welding Tape.

From www.alibaba.com

Hvac Fireproof Aluminum Foil Welding Tape Buy Aluminum Foil Welding Types Of Welding Tape Suitable for stainless, carbon, duplex and chrome steels as well as other metals. Woven fiberglass and malleable aluminum tape. Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. As you know, welding is a strong joining process in which two metal parts join together to form. Types Of Welding Tape.

From dir.indiamart.com

Welding Tape at Best Price in India Types Of Welding Tape Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their melting points. Suitable for stainless, carbon, duplex and chrome steels as. Types Of Welding Tape.

From www.amazon.co.uk

Aquasol EZZT2.5 EZ Zone Welding Tape 21/2 Inch x 75 Feet Amazon.co Types Of Welding Tape Apply 200 amp tape to thin welds on aluminum, cast iron, nickel and copper alloys, and steel. Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. As you know,. Types Of Welding Tape.

From weldingofwelders.com

Undercut in Welding Welding of Welders Types Of Welding Tape Compatible with mig, tig, and stick welding. As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their melting points. Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. Apply 200. Types Of Welding Tape.

From www.svb24.com

Multi Purpose Selfwelding Tape / black only 9,50 € SVB Types Of Welding Tape Compatible with mig, tig, and stick welding. Suitable for stainless, carbon, duplex and chrome steels as well as other metals. Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. Apply 200 amp tape to thin welds on aluminum, cast iron, nickel and copper alloys, and steel. Woven fiberglass and malleable aluminum tape.. Types Of Welding Tape.

From xkldase.edu.vn

Aggregate more than 133 backing ring in welding best xkldase.edu.vn Types Of Welding Tape As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their melting points. Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. Suitable for stainless, carbon, duplex and chrome steels as. Types Of Welding Tape.

From aerchs.en.made-in-china.com

PTFE Coated Fiberglass teflon Tape, High Temperature Tape, Drying Types Of Welding Tape Woven fiberglass and malleable aluminum tape. Suitable for stainless, carbon, duplex and chrome steels as well as other metals. Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals. Types Of Welding Tape.

From www.supertechservices.in

Purge gas retaining tape for welding Aquasol purging products Purging Types Of Welding Tape Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their melting points. Ez zone tape innovatively offers the perfect solution for. Types Of Welding Tape.

From www.artofit.org

Types of welding welding process Artofit Types Of Welding Tape Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. Woven fiberglass and malleable aluminum tape. Apply 200 amp tape to thin welds on aluminum, cast iron, nickel and copper alloys, and steel. Compatible with mig, tig, and stick welding. Suitable for stainless, carbon, duplex and chrome. Types Of Welding Tape.

From tigbrush.com

Various Types of Welding Joints and Their Uses TIG Brush Types Of Welding Tape Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. Apply 200 amp tape to thin welds on aluminum, cast iron, nickel and copper alloys, and steel. As you know,. Types Of Welding Tape.

From www.tricancorp.ca

Fabric Bond Welding Tape 7/8" x 100yd Black Types Of Welding Tape Apply 200 amp tape to thin welds on aluminum, cast iron, nickel and copper alloys, and steel. Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their. Types Of Welding Tape.

From justram.com

Weld Backing Tape to reduce welding time and welding costs. Types Of Welding Tape Compatible with mig, tig, and stick welding. As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their melting points. Apply 200 amp tape to thin welds on aluminum, cast iron, nickel and copper alloys, and steel. Ez zone tape innovatively offers the perfect solution. Types Of Welding Tape.

From www.youtube.com

Types of Welding MIG Welding, TIG Welding, Stick Welding & Flux Cored Types Of Welding Tape Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. Woven fiberglass and malleable aluminum tape. Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. Compatible with mig, tig, and stick welding. As you know, welding is a strong. Types Of Welding Tape.

From focusonallergies.com

Types of PTFE tape, Uses/Applications, Features and Benefits (2022) Types Of Welding Tape As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their melting points. Apply 200 amp tape to thin welds on aluminum, cast iron, nickel and copper alloys, and steel. Stick this flexible tape to the back of welding seams to contain spatter and prevent. Types Of Welding Tape.

From www.ararimpex.com

WELD BACK UP STRIPS AND TAPE Arar Ceramic Weld Back Tape Co2 Welding Types Of Welding Tape Apply 200 amp tape to thin welds on aluminum, cast iron, nickel and copper alloys, and steel. Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their. Types Of Welding Tape.

From www.globalweldingsupplies.co.nz

WELDarc® Aluminium Foil Tape for Purging Seal. Global Welding Supplies Types Of Welding Tape Suitable for stainless, carbon, duplex and chrome steels as well as other metals. Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. Ez zone tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap. Woven fiberglass and malleable aluminum tape. Compatible. Types Of Welding Tape.

From www.youtube.com

How to Apply Welding Tape YouTube Types Of Welding Tape As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their melting points. Apply 200 amp tape to thin welds on aluminum, cast iron, nickel and copper alloys, and steel. Suitable for stainless, carbon, duplex and chrome steels as well as other metals. Woven fiberglass. Types Of Welding Tape.

From makemoneywelding.com

MIG Welding Wire Essentials A Guide to Types & Uses Types Of Welding Tape Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their melting points. Woven fiberglass and malleable aluminum tape. Ez zone tape. Types Of Welding Tape.

From www.alibaba.com

Hvac Fireproof Aluminum Foil Welding Tape Buy Aluminum Foil Welding Types Of Welding Tape As you know, welding is a strong joining process in which two metal parts join together to form one part by heating the metals to their melting points. Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. Woven fiberglass and malleable aluminum tape. Ez zone tape. Types Of Welding Tape.

From www.cmw.cc

316L Stainless Steel Pipe Welding Central Maintenance and Welding Types Of Welding Tape Suitable for stainless, carbon, duplex and chrome steels as well as other metals. Compatible with mig, tig, and stick welding. Woven fiberglass and malleable aluminum tape. Stick this flexible tape to the back of welding seams to contain spatter and prevent oxygen, water vapor, and other gases from weakening. Apply 200 amp tape to thin welds on aluminum, cast iron,. Types Of Welding Tape.