Carbide Insert Wear Analysis . When tools begin to reach the end of their lifecycle, or when an event has impacted them, the wear on the tool can create specific. The flank wear rate of carbide insert in metal cutting is predicted by a new model which combined cutting mechanics simulation. Learn the cause and solution to the most common insert wear problems. It is the easiest to identify and predict among tool. Utilize the tungaloy insert wear chart to quickly identify the root cause of. This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. In machining, flank wear is the most common and desirable type of tool wear.

from www.cnccarbide-inserts.com

Learn the cause and solution to the most common insert wear problems. In machining, flank wear is the most common and desirable type of tool wear. It is the easiest to identify and predict among tool. When tools begin to reach the end of their lifecycle, or when an event has impacted them, the wear on the tool can create specific. The flank wear rate of carbide insert in metal cutting is predicted by a new model which combined cutting mechanics simulation. Utilize the tungaloy insert wear chart to quickly identify the root cause of. This paper presents a comparative study of the influence of two machining environments in the tool wear and surface.

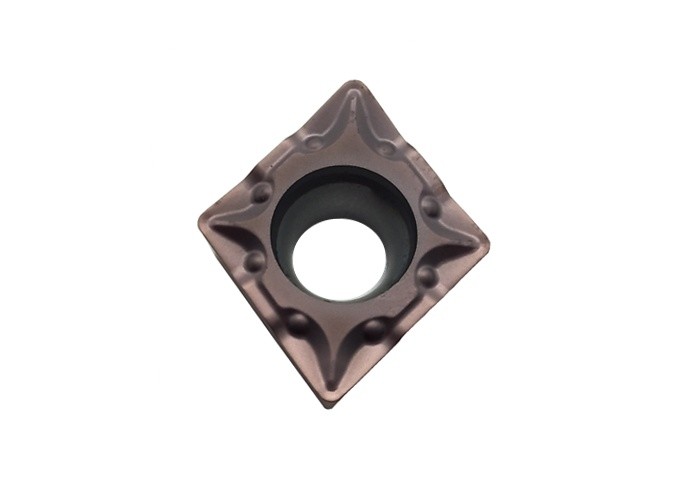

Professional CCMT Carbide Inserts Wear Resistance CCMT120408OTM

Carbide Insert Wear Analysis Learn the cause and solution to the most common insert wear problems. It is the easiest to identify and predict among tool. The flank wear rate of carbide insert in metal cutting is predicted by a new model which combined cutting mechanics simulation. This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. Learn the cause and solution to the most common insert wear problems. Utilize the tungaloy insert wear chart to quickly identify the root cause of. When tools begin to reach the end of their lifecycle, or when an event has impacted them, the wear on the tool can create specific. In machining, flank wear is the most common and desirable type of tool wear.

From www.insertcarbide.com

High Wear Resistant CNC Tungsten Carbide Inserts 100 Raw Material Carbide Insert Wear Analysis In machining, flank wear is the most common and desirable type of tool wear. This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. Utilize the tungaloy insert wear chart to quickly identify the root cause of. When tools begin to reach the end of their lifecycle, or when an event. Carbide Insert Wear Analysis.

From www.cnccarbide-inserts.com

Professional CCMT Carbide Inserts Wear Resistance CCMT120408OTM Carbide Insert Wear Analysis Learn the cause and solution to the most common insert wear problems. Utilize the tungaloy insert wear chart to quickly identify the root cause of. This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. It is the easiest to identify and predict among tool. The flank wear rate of carbide. Carbide Insert Wear Analysis.

From www.zzbetter.com

Tungsten Carbide Wear Inserts for Downhole Tool Dressing Carbide Insert Wear Analysis This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. In machining, flank wear is the most common and desirable type of tool wear. The flank wear rate of carbide insert in metal cutting is predicted by a new model which combined cutting mechanics simulation. It is the easiest to identify. Carbide Insert Wear Analysis.

From huanatools.com

Complete application of carbide Inserts Huana Tools Carbide Insert Wear Analysis Utilize the tungaloy insert wear chart to quickly identify the root cause of. When tools begin to reach the end of their lifecycle, or when an event has impacted them, the wear on the tool can create specific. The flank wear rate of carbide insert in metal cutting is predicted by a new model which combined cutting mechanics simulation. This. Carbide Insert Wear Analysis.

From www.researchgate.net

(PDF) Analysis of forces, roughness, wear and temperature in turning Carbide Insert Wear Analysis The flank wear rate of carbide insert in metal cutting is predicted by a new model which combined cutting mechanics simulation. This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. Learn the cause and solution to the most common insert wear problems. In machining, flank wear is the most common. Carbide Insert Wear Analysis.

From www.youtube.com

Regrinding carbide inserts YouTube Carbide Insert Wear Analysis The flank wear rate of carbide insert in metal cutting is predicted by a new model which combined cutting mechanics simulation. This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. Learn the cause and solution to the most common insert wear problems. Utilize the tungaloy insert wear chart to quickly. Carbide Insert Wear Analysis.

From www.mdpi.com

An Evaluation of the Tool Wear of Ceramic and Coated Carbide Inserts in Carbide Insert Wear Analysis Utilize the tungaloy insert wear chart to quickly identify the root cause of. It is the easiest to identify and predict among tool. When tools begin to reach the end of their lifecycle, or when an event has impacted them, the wear on the tool can create specific. Learn the cause and solution to the most common insert wear problems.. Carbide Insert Wear Analysis.

From profiletech.com

Carbide Inserts Profile Technology Carbide Insert Wear Analysis Learn the cause and solution to the most common insert wear problems. It is the easiest to identify and predict among tool. Utilize the tungaloy insert wear chart to quickly identify the root cause of. The flank wear rate of carbide insert in metal cutting is predicted by a new model which combined cutting mechanics simulation. When tools begin to. Carbide Insert Wear Analysis.

From www.wodenco.com

How to Select the Right Carbide Inserts The Ultimate Guide Wodenco Carbide Insert Wear Analysis This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. Utilize the tungaloy insert wear chart to quickly identify the root cause of. It is the easiest to identify and predict among tool. When tools begin to reach the end of their lifecycle, or when an event has impacted them, the. Carbide Insert Wear Analysis.

From www.mdpi.com

Symmetry Free FullText Methodology for Measuring the Cutting Carbide Insert Wear Analysis This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. When tools begin to reach the end of their lifecycle, or when an event has impacted them, the wear on the tool can create specific. Utilize the tungaloy insert wear chart to quickly identify the root cause of. Learn the cause. Carbide Insert Wear Analysis.

From www.researchgate.net

(PDF) Characterization and performance of AlTiN, AlTiCrN, TiN/TiAlN PVD Carbide Insert Wear Analysis It is the easiest to identify and predict among tool. This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. In machining, flank wear is the most common and desirable type of tool wear. Utilize the tungaloy insert wear chart to quickly identify the root cause of. Learn the cause and. Carbide Insert Wear Analysis.

From www.zzbetter.com

Tungsten Carbide Wear Inserts for Downhole Tool Dressing Carbide Insert Wear Analysis The flank wear rate of carbide insert in metal cutting is predicted by a new model which combined cutting mechanics simulation. When tools begin to reach the end of their lifecycle, or when an event has impacted them, the wear on the tool can create specific. In machining, flank wear is the most common and desirable type of tool wear.. Carbide Insert Wear Analysis.

From ostoncarbide.en.made-in-china.com

Yg8c Tungsten Carbide Wear Accessory Inserts for Decanting Centrifuge Carbide Insert Wear Analysis In machining, flank wear is the most common and desirable type of tool wear. When tools begin to reach the end of their lifecycle, or when an event has impacted them, the wear on the tool can create specific. This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. Utilize the. Carbide Insert Wear Analysis.

From www.estoolcarbide.com

How To Understand The Type Of Carbide Inserts Carbide Insert Wear Analysis Learn the cause and solution to the most common insert wear problems. This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. It is the easiest to identify and predict among tool. In machining, flank wear is the most common and desirable type of tool wear. When tools begin to reach. Carbide Insert Wear Analysis.

From journals.sagepub.com

Effect of cutting speed on chip formation and wear mechanisms of coated Carbide Insert Wear Analysis Learn the cause and solution to the most common insert wear problems. In machining, flank wear is the most common and desirable type of tool wear. This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. It is the easiest to identify and predict among tool. When tools begin to reach. Carbide Insert Wear Analysis.

From www.wodenco.com

How to Select the Right Carbide Inserts The Ultimate Guide Wodenco Carbide Insert Wear Analysis The flank wear rate of carbide insert in metal cutting is predicted by a new model which combined cutting mechanics simulation. Utilize the tungaloy insert wear chart to quickly identify the root cause of. In machining, flank wear is the most common and desirable type of tool wear. Learn the cause and solution to the most common insert wear problems.. Carbide Insert Wear Analysis.

From link.springer.com

Wear Mechanism of Cemented Carbide Tool in High Speed Milling of Carbide Insert Wear Analysis The flank wear rate of carbide insert in metal cutting is predicted by a new model which combined cutting mechanics simulation. Utilize the tungaloy insert wear chart to quickly identify the root cause of. In machining, flank wear is the most common and desirable type of tool wear. It is the easiest to identify and predict among tool. When tools. Carbide Insert Wear Analysis.

From www.researchgate.net

SEM analysis images of cutting tools Figure 6 shows the SEM analysis Carbide Insert Wear Analysis When tools begin to reach the end of their lifecycle, or when an event has impacted them, the wear on the tool can create specific. The flank wear rate of carbide insert in metal cutting is predicted by a new model which combined cutting mechanics simulation. In machining, flank wear is the most common and desirable type of tool wear.. Carbide Insert Wear Analysis.

From www.bddrill.com.au

Carbide Inserts HighQuality Cutting Tools for Precision Machining Carbide Insert Wear Analysis When tools begin to reach the end of their lifecycle, or when an event has impacted them, the wear on the tool can create specific. Utilize the tungaloy insert wear chart to quickly identify the root cause of. Learn the cause and solution to the most common insert wear problems. This paper presents a comparative study of the influence of. Carbide Insert Wear Analysis.

From www.researchgate.net

Quantitative analysis on crater wear of cemented carbide inserts when Carbide Insert Wear Analysis This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. When tools begin to reach the end of their lifecycle, or when an event has impacted them, the wear on the tool can create specific. Learn the cause and solution to the most common insert wear problems. Utilize the tungaloy insert. Carbide Insert Wear Analysis.

From www.zzbetter.com

Tungsten Carbide Wear Inserts for Downhole Tool Dressing Carbide Insert Wear Analysis Learn the cause and solution to the most common insert wear problems. In machining, flank wear is the most common and desirable type of tool wear. It is the easiest to identify and predict among tool. When tools begin to reach the end of their lifecycle, or when an event has impacted them, the wear on the tool can create. Carbide Insert Wear Analysis.

From rdbarrett.co.uk

How to Identify Carbide Inserts R.D. Barrett Carbide Insert Wear Analysis In machining, flank wear is the most common and desirable type of tool wear. The flank wear rate of carbide insert in metal cutting is predicted by a new model which combined cutting mechanics simulation. Learn the cause and solution to the most common insert wear problems. Utilize the tungaloy insert wear chart to quickly identify the root cause of.. Carbide Insert Wear Analysis.

From www.researchgate.net

(PDF) Influence of Lead Angle Variation on the Coated Carbide Inserts Carbide Insert Wear Analysis Utilize the tungaloy insert wear chart to quickly identify the root cause of. When tools begin to reach the end of their lifecycle, or when an event has impacted them, the wear on the tool can create specific. In machining, flank wear is the most common and desirable type of tool wear. This paper presents a comparative study of the. Carbide Insert Wear Analysis.

From www.mdpi.com

Symmetry Free FullText Methodology for Measuring the Cutting Carbide Insert Wear Analysis It is the easiest to identify and predict among tool. Learn the cause and solution to the most common insert wear problems. In machining, flank wear is the most common and desirable type of tool wear. When tools begin to reach the end of their lifecycle, or when an event has impacted them, the wear on the tool can create. Carbide Insert Wear Analysis.

From www.linkedin.com

The General Analysis of FAQ on Carbide Inserts Carbide Insert Wear Analysis Learn the cause and solution to the most common insert wear problems. When tools begin to reach the end of their lifecycle, or when an event has impacted them, the wear on the tool can create specific. This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. Utilize the tungaloy insert. Carbide Insert Wear Analysis.

From www.linkedin.com

Carbide Inserts Wear Failure and Solutions Carbide Insert Wear Analysis It is the easiest to identify and predict among tool. This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. In machining, flank wear is the most common and desirable type of tool wear. Learn the cause and solution to the most common insert wear problems. When tools begin to reach. Carbide Insert Wear Analysis.

From ponasa.condesan-ecoandes.org

Carbide Insert Identification Chart Ponasa Carbide Insert Wear Analysis In machining, flank wear is the most common and desirable type of tool wear. When tools begin to reach the end of their lifecycle, or when an event has impacted them, the wear on the tool can create specific. The flank wear rate of carbide insert in metal cutting is predicted by a new model which combined cutting mechanics simulation.. Carbide Insert Wear Analysis.

From huanatools.com

How To Make The Carbide Inserts? Huana Tools Carbide Insert Wear Analysis Utilize the tungaloy insert wear chart to quickly identify the root cause of. Learn the cause and solution to the most common insert wear problems. This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. It is the easiest to identify and predict among tool. When tools begin to reach the. Carbide Insert Wear Analysis.

From www.zzbetter.com

Tungsten Carbide Wear Inserts for Downhole Tool Dressing Carbide Insert Wear Analysis This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. In machining, flank wear is the most common and desirable type of tool wear. Learn the cause and solution to the most common insert wear problems. When tools begin to reach the end of their lifecycle, or when an event has. Carbide Insert Wear Analysis.

From www.mdpi.com

Coatings Free FullText Machining GX2CrNiMoN2674 DSS Alloy Wear Carbide Insert Wear Analysis Utilize the tungaloy insert wear chart to quickly identify the root cause of. In machining, flank wear is the most common and desirable type of tool wear. The flank wear rate of carbide insert in metal cutting is predicted by a new model which combined cutting mechanics simulation. It is the easiest to identify and predict among tool. This paper. Carbide Insert Wear Analysis.

From www.academia.edu

(PDF) Tool wear analysis in milling of medium carbon steel with coated Carbide Insert Wear Analysis Learn the cause and solution to the most common insert wear problems. When tools begin to reach the end of their lifecycle, or when an event has impacted them, the wear on the tool can create specific. In machining, flank wear is the most common and desirable type of tool wear. It is the easiest to identify and predict among. Carbide Insert Wear Analysis.

From huanatools.com

How to choose the right carbide turning insert Huana Tools Carbide Insert Wear Analysis When tools begin to reach the end of their lifecycle, or when an event has impacted them, the wear on the tool can create specific. Utilize the tungaloy insert wear chart to quickly identify the root cause of. It is the easiest to identify and predict among tool. Learn the cause and solution to the most common insert wear problems.. Carbide Insert Wear Analysis.

From www.researchgate.net

Typical tool inserts wear patterns [5]. Download Scientific Diagram Carbide Insert Wear Analysis Learn the cause and solution to the most common insert wear problems. This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. Utilize the tungaloy insert wear chart to quickly identify the root cause of. It is the easiest to identify and predict among tool. In machining, flank wear is the. Carbide Insert Wear Analysis.

From www.scribd.com

Carbide Inserts Wear Failure Modes PDF Wear Machining Carbide Insert Wear Analysis This paper presents a comparative study of the influence of two machining environments in the tool wear and surface. When tools begin to reach the end of their lifecycle, or when an event has impacted them, the wear on the tool can create specific. It is the easiest to identify and predict among tool. In machining, flank wear is the. Carbide Insert Wear Analysis.

From www.mdpi.com

Coatings Free FullText Comparative Evaluation of Coated Carbide Carbide Insert Wear Analysis In machining, flank wear is the most common and desirable type of tool wear. The flank wear rate of carbide insert in metal cutting is predicted by a new model which combined cutting mechanics simulation. Utilize the tungaloy insert wear chart to quickly identify the root cause of. Learn the cause and solution to the most common insert wear problems.. Carbide Insert Wear Analysis.