Best Insert For Aluminum Turning . Whatever your component or requirements for surface finish, find highly. Uncoated and pcd grades are the first choices. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Turning inserts and grades for non ferrous materials. Inserts with a positive basic shape and sharp edges should always be used. Choose the right indexable insert for aluminum machining: With a focus on topics including insert types, selection criteria, best practices, and safety considerations, this comprehensive book attempts to shed light on the importance of.

from www.cnccarbideinserts.com

With a focus on topics including insert types, selection criteria, best practices, and safety considerations, this comprehensive book attempts to shed light on the importance of. Whatever your component or requirements for surface finish, find highly. Choose the right indexable insert for aluminum machining: Uncoated and pcd grades are the first choices. Turning inserts and grades for non ferrous materials. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Inserts with a positive basic shape and sharp edges should always be used. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum.

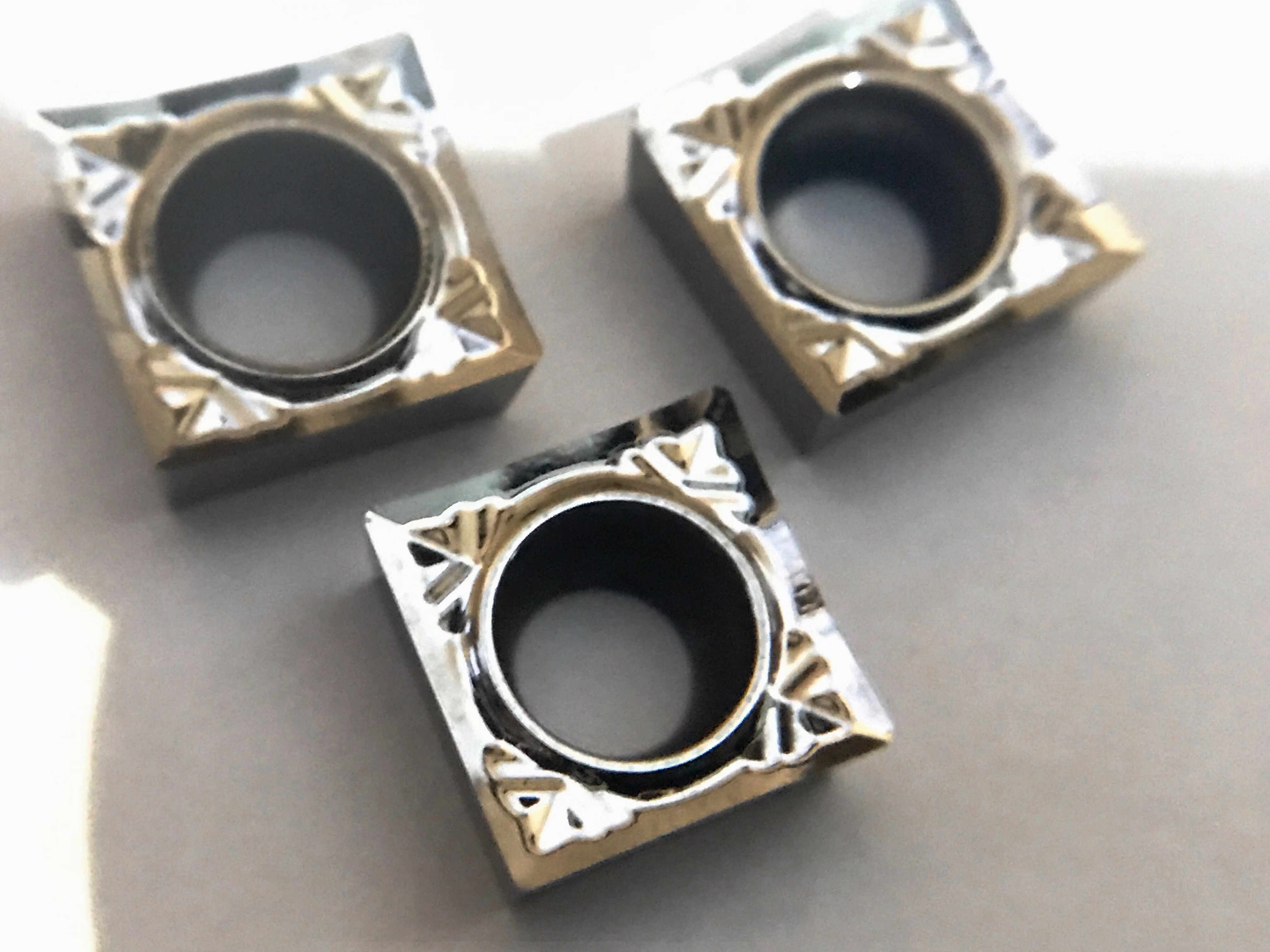

SCGT120408AL Carbide Inserts For Turning Aluminum With Ultrafine Grained Carbide

Best Insert For Aluminum Turning Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. With a focus on topics including insert types, selection criteria, best practices, and safety considerations, this comprehensive book attempts to shed light on the importance of. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Turning inserts and grades for non ferrous materials. Inserts with a positive basic shape and sharp edges should always be used. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Choose the right indexable insert for aluminum machining: Whatever your component or requirements for surface finish, find highly. Uncoated and pcd grades are the first choices.

From www.cnccarbideinserts.com

SCGT120408AL Carbide Inserts For Turning Aluminum With Ultrafine Grained Carbide Best Insert For Aluminum Turning Whatever your component or requirements for surface finish, find highly. Choose the right indexable insert for aluminum machining: Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Uncoated and pcd grades are the first choices. Inserts with a positive basic shape and sharp edges should always be used. Turning inserts and grades for non ferrous. Best Insert For Aluminum Turning.

From solutions.travers.com

Choosing The Right Insert For Aluminum Machining Best Insert For Aluminum Turning Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Turning inserts and grades for non ferrous materials. Uncoated and pcd grades are the first choices. Choose the right indexable insert for aluminum machining: With a focus on topics including. Best Insert For Aluminum Turning.

From www.diytrade.com

Diamond cutting insert VCGT VCMT PCD turning insert for aluminum copper VCGT160404 PCD Best Insert For Aluminum Turning Choose the right indexable insert for aluminum machining: Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Uncoated and pcd grades are the first choices. Turning inserts and grades for non ferrous materials. With a focus on topics including insert types, selection criteria, best practices, and safety. Best Insert For Aluminum Turning.

From www.cutoutiltools.com

China Low Price Best Insert For Turning Aluminum Suppliers, Manufacturers, Factory Made in Best Insert For Aluminum Turning Inserts with a positive basic shape and sharp edges should always be used. Choose the right indexable insert for aluminum machining: Uncoated and pcd grades are the first choices. Whatever your component or requirements for surface finish, find highly. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. With a focus on topics including insert. Best Insert For Aluminum Turning.

From www.diytrade.com

Diamond cutting insert PCD turning insert for aluminum copper VCGT160404 PCD insert Best Insert For Aluminum Turning Whatever your component or requirements for surface finish, find highly. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Inserts with a positive basic shape and sharp edges should always be used. Uncoated and pcd grades are the first choices. With a focus on topics including insert types, selection criteria, best practices, and safety considerations,. Best Insert For Aluminum Turning.

From www.desertcart.ae

Buy Carbide Inserts Ccgt060202 Ak H01 Lathe For Metal Turning Tool Center Aluminum Copper Best Insert For Aluminum Turning Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. With a focus on topics including insert types, selection criteria, best practices, and safety considerations, this comprehensive book attempts to shed light on the. Best Insert For Aluminum Turning.

From appl.org

12 Best Insert For Turning Aluminum By 3,028 Reviews Best Insert For Aluminum Turning Uncoated and pcd grades are the first choices. Turning inserts and grades for non ferrous materials. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Choose the right indexable insert for aluminum machining: Whatever your component or requirements for surface finish, find highly. Inserts with a positive basic shape and sharp edges should always be. Best Insert For Aluminum Turning.

From www.aliexpress.com

Buy 10pcs Golden WNMG080404 Carbide Inserts + MWLNR2020K08 Lathe Turning Tool Best Insert For Aluminum Turning Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Whatever your component or requirements for surface finish, find highly. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Inserts with a positive basic shape and sharp edges should always be used. Uncoated. Best Insert For Aluminum Turning.

From www.aliexpress.com

VCGT160408 AK H01 Aluminum turning tools VCGT 160408 Carbide inserts Lathe tools machining Best Insert For Aluminum Turning Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Uncoated and pcd grades are the first choices. With a focus on topics including insert types, selection criteria, best practices, and safety considerations, this comprehensive book attempts to shed light. Best Insert For Aluminum Turning.

From www.cnccarbideinserts.com

SCGT120408AL Carbide Inserts For Turning Aluminum With Ultrafine Grained Carbide Best Insert For Aluminum Turning Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Inserts with a positive basic shape and sharp edges should always be used. Turning inserts and grades for non ferrous materials. Uncoated and pcd grades are the first choices. Understanding the material properties and machining conditions is crucial. Best Insert For Aluminum Turning.

From www.indiamart.com

Aluminum Turning Insert, For CNC Machine at Rs 60 in Delhi ID 24303701030 Best Insert For Aluminum Turning Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. With a focus on topics including insert types, selection criteria, best practices, and safety considerations, this comprehensive book attempts to shed light on the importance of. Whatever your component or requirements for surface finish, find highly. Turning inserts and grades for non ferrous materials.. Best Insert For Aluminum Turning.

From www.cnccarbideinserts.com

APGT1604PDER Aluminum Turning Inserts With Large Front Angle Sharp Edge For Milling Best Insert For Aluminum Turning Choose the right indexable insert for aluminum machining: Inserts with a positive basic shape and sharp edges should always be used. Uncoated and pcd grades are the first choices. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. With a focus on topics including insert types, selection criteria, best practices, and safety considerations,. Best Insert For Aluminum Turning.

From www.estoolcarbide.com

SEHT Aluminum Inserts Best Insert For Aluminum Turning Uncoated and pcd grades are the first choices. With a focus on topics including insert types, selection criteria, best practices, and safety considerations, this comprehensive book attempts to shed light on the importance of. Inserts with a positive basic shape and sharp edges should always be used. Turning inserts and grades for non ferrous materials. Selecting the right turning inserts. Best Insert For Aluminum Turning.

From www.cnccarbideinserts.com

APGT1604PDER Aluminum Turning Inserts With Large Front Angle Sharp Edge For Milling Best Insert For Aluminum Turning With a focus on topics including insert types, selection criteria, best practices, and safety considerations, this comprehensive book attempts to shed light on the importance of. Turning inserts and grades for non ferrous materials. Uncoated and pcd grades are the first choices. Inserts with a positive basic shape and sharp edges should always be used. Understanding the material properties and. Best Insert For Aluminum Turning.

From news.thomasnet.com

Carboloy Introduces New Grade Inserts for Turning Aluminum Best Insert For Aluminum Turning Inserts with a positive basic shape and sharp edges should always be used. Uncoated and pcd grades are the first choices. Turning inserts and grades for non ferrous materials. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. With a focus on topics including insert types, selection. Best Insert For Aluminum Turning.

From www.indiamart.com

Aluminum Insert, For Metal Turning, Size 4 at Rs 276/piece in Ahmedabad ID 17702355288 Best Insert For Aluminum Turning Choose the right indexable insert for aluminum machining: Whatever your component or requirements for surface finish, find highly. With a focus on topics including insert types, selection criteria, best practices, and safety considerations, this comprehensive book attempts to shed light on the importance of. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Turning inserts. Best Insert For Aluminum Turning.

From huanatools.com

How to choose the right carbide turning insert Huana Tools Best Insert For Aluminum Turning Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Inserts with a positive basic shape and sharp edges should always be used. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Whatever your component or requirements for surface finish, find highly. Choose. Best Insert For Aluminum Turning.

From www.buyustools.com

CAT DCGT070204ALH01,Turning insert for aluminum Pack of 10 buyustools Best Insert For Aluminum Turning Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Choose the right indexable insert for aluminum machining: Whatever your component or requirements for surface finish, find highly. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Selecting the right turning inserts involves considering multiple factors, including insert shape,. Best Insert For Aluminum Turning.

From www.cutoutiltools.com

China Low Price Best Insert For Turning Aluminum Suppliers, Manufacturers, Factory Made in Best Insert For Aluminum Turning Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Choose the right indexable insert for aluminum machining: Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum.. Best Insert For Aluminum Turning.

From www.bossgoo.com

Tungsten Carbide Insert For Aluminum Turning Application, High Quality Tungsten Carbide Insert Best Insert For Aluminum Turning Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Inserts with a positive basic shape and sharp edges should always be used. Uncoated and pcd grades are the first choices. Turning inserts and grades for non ferrous materials. With a focus on topics including insert types, selection criteria, best practices, and safety considerations,. Best Insert For Aluminum Turning.

From www.estoolcarbide.com

SNMG Sharpening Carbide Inserts for Aluminum Cutting Best Insert For Aluminum Turning Turning inserts and grades for non ferrous materials. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. With a focus on topics including insert types, selection criteria, best practices, and safety considerations, this comprehensive book attempts to shed light. Best Insert For Aluminum Turning.

From www.rvnewmaterial.com

Carbide Insert VBGT160402 VBGT160404 VBGT160408 AK H01 Aluminum Turning Lathe Tool Best Insert For Aluminum Turning Inserts with a positive basic shape and sharp edges should always be used. Choose the right indexable insert for aluminum machining: With a focus on topics including insert types, selection criteria, best practices, and safety considerations, this comprehensive book attempts to shed light on the importance of. Uncoated and pcd grades are the first choices. Learn what insert geometry, chip. Best Insert For Aluminum Turning.

From www.aliexpress.com

CCGT09T308 1PCS Turning Inserts Metal Ceramic Turning Insert For Aluminum Lathe Machine Cutter Best Insert For Aluminum Turning Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. With a focus on topics including insert types, selection criteria, best practices, and safety considerations, this comprehensive book attempts to shed light on the importance of. Inserts with a positive basic shape and sharp edges should always be used. Uncoated and pcd grades are the first. Best Insert For Aluminum Turning.

From www.optcuttingtools.com

Best Diamond Insert Manufacturer and Supplier, Factory OPT Best Insert For Aluminum Turning Uncoated and pcd grades are the first choices. Turning inserts and grades for non ferrous materials. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting. Best Insert For Aluminum Turning.

From www.shop-apt.co.uk

VCGT 160404 ALC AK10 Carbide Inserts for Turning Ground and Polished for Aluminium Unitip Best Insert For Aluminum Turning With a focus on topics including insert types, selection criteria, best practices, and safety considerations, this comprehensive book attempts to shed light on the importance of. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Uncoated and pcd grades are the first choices. Choose the right indexable insert for aluminum machining: Inserts with. Best Insert For Aluminum Turning.

From www.densotools.com

best insert for turning aluminum Save 50 cost for you Best Insert For Aluminum Turning Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Turning inserts and grades for non ferrous materials. Choose the right indexable insert for aluminum machining: Whatever your component or requirements for surface finish, find highly. With a focus on. Best Insert For Aluminum Turning.

From www.aliexpress.com

Vnmg160408ha H01 Doublesided 35 Degree Cermet Aluminum Insert Insert Vnmg160408 External Best Insert For Aluminum Turning Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Inserts with a positive basic shape and sharp edges should always be used. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Uncoated and pcd grades are the first choices. Choose the right indexable insert for aluminum machining: Selecting. Best Insert For Aluminum Turning.

From www.cnccarbideinserts.com

SCGT120408AL Carbide Inserts For Turning Aluminum With Ultrafine Grained Carbide Best Insert For Aluminum Turning With a focus on topics including insert types, selection criteria, best practices, and safety considerations, this comprehensive book attempts to shed light on the importance of. Choose the right indexable insert for aluminum machining: Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Uncoated and pcd grades. Best Insert For Aluminum Turning.

From www.cnccarbide-inserts.com

DCGT11T304TK Aluminum Turning Inserts Size Customized For External Turning Tool Best Insert For Aluminum Turning Choose the right indexable insert for aluminum machining: Whatever your component or requirements for surface finish, find highly. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Selecting the right turning inserts involves considering multiple factors, including insert shape,. Best Insert For Aluminum Turning.

From www.shop-apt.co.uk

Turning Set 72° 30' 16x16 Shank with 10 VCGT 110304 Inserts for Aluminium Associated Production Best Insert For Aluminum Turning With a focus on topics including insert types, selection criteria, best practices, and safety considerations, this comprehensive book attempts to shed light on the importance of. Choose the right indexable insert for aluminum machining: Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Selecting the right turning inserts involves considering multiple factors, including insert shape,. Best Insert For Aluminum Turning.

From www.cnccarbide-inserts.com

CCGT120404AK CCGT Insert , Aluminum Turning Inserts For External Turning Tool Best Insert For Aluminum Turning Turning inserts and grades for non ferrous materials. Inserts with a positive basic shape and sharp edges should always be used. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Uncoated and pcd grades are the first choices. With. Best Insert For Aluminum Turning.

From cnsinometal.en.made-in-china.com

Aluminum Turning Inserts (CCGT09T3) China Carbide Inserts for Aluminium and Aluminum Turning Best Insert For Aluminum Turning Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Uncoated and pcd grades are the first choices. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. With a focus on topics including insert types, selection criteria, best practices, and safety considerations, this. Best Insert For Aluminum Turning.

From www.insertcarbide.com

CNMG120408 Colorful Coating Aluminum Turning Carbide Inserts Best Insert For Aluminum Turning Turning inserts and grades for non ferrous materials. With a focus on topics including insert types, selection criteria, best practices, and safety considerations, this comprehensive book attempts to shed light on the importance of. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Choose the right indexable. Best Insert For Aluminum Turning.

From www.cnccarbideinserts.com

APGT1604PDER Aluminum Turning Inserts With Large Front Angle Sharp Edge For Milling Best Insert For Aluminum Turning Whatever your component or requirements for surface finish, find highly. Uncoated and pcd grades are the first choices. Choose the right indexable insert for aluminum machining: Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Inserts with a positive. Best Insert For Aluminum Turning.

From www.cnccarbideinserts.com

TCGT16T304AL Aluminum Turning Inserts With Precision Grinding Large Rake Angle Best Insert For Aluminum Turning Choose the right indexable insert for aluminum machining: Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Turning inserts and grades for non ferrous materials. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. With a focus on topics including insert types, selection criteria, best practices, and safety. Best Insert For Aluminum Turning.