Clean Room Manufacturing Process . There are multiple ways to build and design a cleanroom facility that will meet gmp requirements for the sterile manufacturing of. How to build a cleanroom. This comprehensive cleanroom project guide covers critical planning steps like classification, layout, hepa/ulpa filtration system design, installation,. Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. Find out the differences, requirements, and guidance for gmp and cgmp cleanrooms. The primary objective of a cleanroom is to limit the amount of airborne particles in a given space and keep it as clean as possible. Cleanrooms are controlled environments designed to minimize the presence of contaminants, such as dust, airborne microbes, and chemical vapors. They play a crucial role in various industries, including pharmaceuticals, biotechnology, electronics, and aerospace. Learn about the good manufacturing practices (gmp) and current good manufacturing practices (cgmp) for cleanroom design and production of pharmaceutical products.

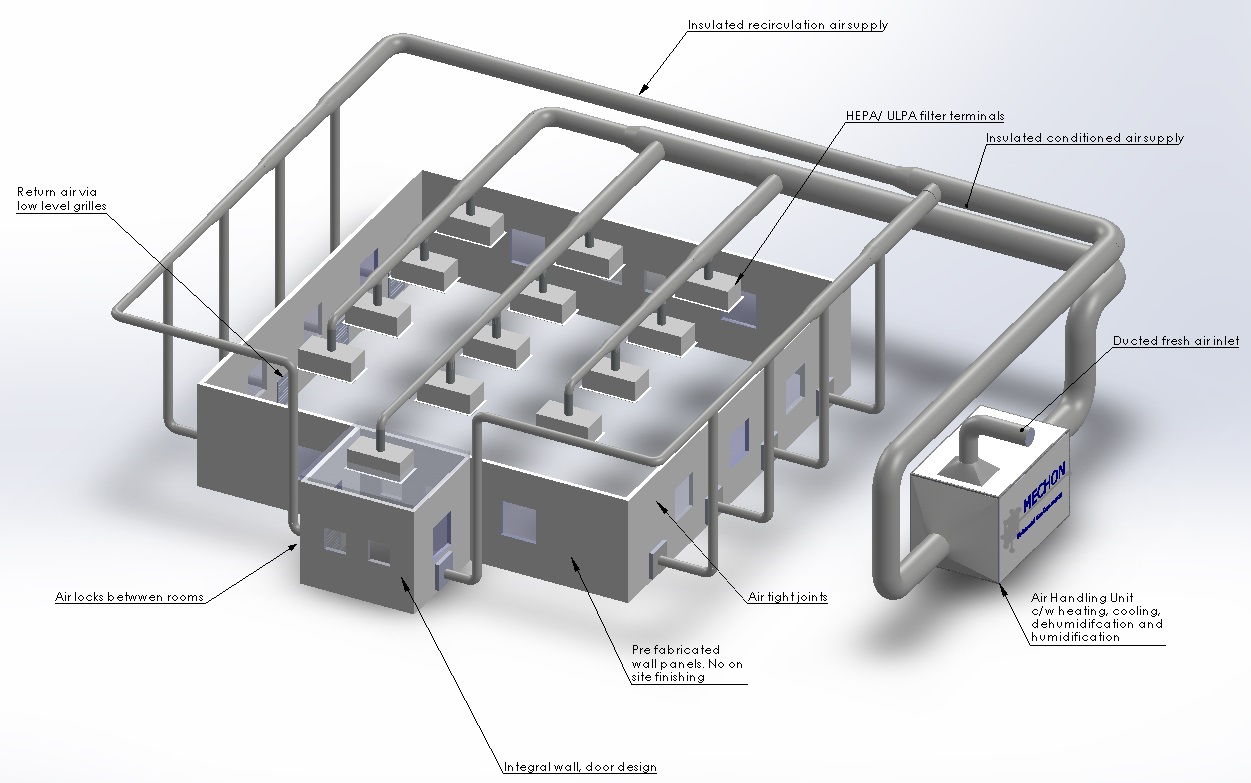

from www.mechon.co.uk

Find out the differences, requirements, and guidance for gmp and cgmp cleanrooms. Learn about the good manufacturing practices (gmp) and current good manufacturing practices (cgmp) for cleanroom design and production of pharmaceutical products. Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. They play a crucial role in various industries, including pharmaceuticals, biotechnology, electronics, and aerospace. This comprehensive cleanroom project guide covers critical planning steps like classification, layout, hepa/ulpa filtration system design, installation,. Cleanrooms are controlled environments designed to minimize the presence of contaminants, such as dust, airborne microbes, and chemical vapors. There are multiple ways to build and design a cleanroom facility that will meet gmp requirements for the sterile manufacturing of. How to build a cleanroom. The primary objective of a cleanroom is to limit the amount of airborne particles in a given space and keep it as clean as possible.

Cleanroom HVAC System Design Guide Process Ventilation Consultants

Clean Room Manufacturing Process Learn about the good manufacturing practices (gmp) and current good manufacturing practices (cgmp) for cleanroom design and production of pharmaceutical products. Find out the differences, requirements, and guidance for gmp and cgmp cleanrooms. Learn about the good manufacturing practices (gmp) and current good manufacturing practices (cgmp) for cleanroom design and production of pharmaceutical products. This comprehensive cleanroom project guide covers critical planning steps like classification, layout, hepa/ulpa filtration system design, installation,. The primary objective of a cleanroom is to limit the amount of airborne particles in a given space and keep it as clean as possible. Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. There are multiple ways to build and design a cleanroom facility that will meet gmp requirements for the sterile manufacturing of. Cleanrooms are controlled environments designed to minimize the presence of contaminants, such as dust, airborne microbes, and chemical vapors. How to build a cleanroom. They play a crucial role in various industries, including pharmaceuticals, biotechnology, electronics, and aerospace.

From www.mecart-cleanrooms.com

Class 10,000 Clean Room for SMT & PCB Manufacturing Clean Room Manufacturing Process They play a crucial role in various industries, including pharmaceuticals, biotechnology, electronics, and aerospace. The primary objective of a cleanroom is to limit the amount of airborne particles in a given space and keep it as clean as possible. Cleanrooms are controlled environments designed to minimize the presence of contaminants, such as dust, airborne microbes, and chemical vapors. Learn about. Clean Room Manufacturing Process.

From www.dreamstime.com

Silicon Wafer Manufacturing Process in a Clean Room Stock Video Video Clean Room Manufacturing Process Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. Find out the differences, requirements, and guidance for gmp and cgmp cleanrooms. There are multiple ways to build and design a cleanroom facility that will meet gmp requirements for the sterile manufacturing of. Cleanrooms are controlled environments designed to minimize the presence of. Clean Room Manufacturing Process.

From www.dreamstime.com

Silicon Wafer Manufacturing Process in a Clean Room Stock Video Video Clean Room Manufacturing Process Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. Cleanrooms are controlled environments designed to minimize the presence of contaminants, such as dust, airborne microbes, and chemical vapors. How to build a cleanroom. Find out the differences, requirements, and guidance for gmp and cgmp cleanrooms. They play a crucial role in various. Clean Room Manufacturing Process.

From www.dreamstime.com

Silicon Wafer Manufacturing Process in a Clean Room Stock Footage Clean Room Manufacturing Process Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. The primary objective of a cleanroom is to limit the amount of airborne particles in a given space and keep it as clean as possible. How to build a cleanroom. There are multiple ways to build and design a cleanroom facility that will. Clean Room Manufacturing Process.

From www.plitek.com

Clean Room Manufacturing Converting Capabilities Plitek Clean Room Manufacturing Process This comprehensive cleanroom project guide covers critical planning steps like classification, layout, hepa/ulpa filtration system design, installation,. There are multiple ways to build and design a cleanroom facility that will meet gmp requirements for the sterile manufacturing of. How to build a cleanroom. Cleanrooms are controlled environments designed to minimize the presence of contaminants, such as dust, airborne microbes, and. Clean Room Manufacturing Process.

From www.slideserve.com

PPT Cleanroom software development PowerPoint Presentation ID769166 Clean Room Manufacturing Process Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. The primary objective of a cleanroom is to limit the amount of airborne particles in a given space and keep it as clean as possible. How to build a cleanroom. This comprehensive cleanroom project guide covers critical planning steps like classification, layout, hepa/ulpa. Clean Room Manufacturing Process.

From www.electronicsandyou.com

What is Cleanroom Cleanroom Basics ISO Class Clean Room Clean Room Manufacturing Process The primary objective of a cleanroom is to limit the amount of airborne particles in a given space and keep it as clean as possible. Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. Cleanrooms are controlled environments designed to minimize the presence of contaminants, such as dust, airborne microbes, and chemical. Clean Room Manufacturing Process.

From www.linkedin.com

Meeting Cleanroom Standards? Clean Room Manufacturing Process This comprehensive cleanroom project guide covers critical planning steps like classification, layout, hepa/ulpa filtration system design, installation,. The primary objective of a cleanroom is to limit the amount of airborne particles in a given space and keep it as clean as possible. Find out the differences, requirements, and guidance for gmp and cgmp cleanrooms. Learn about the good manufacturing practices. Clean Room Manufacturing Process.

From www.cleanroom-industries.com

Cleanroom Basics Clean Room Manufacturing Process There are multiple ways to build and design a cleanroom facility that will meet gmp requirements for the sterile manufacturing of. This comprehensive cleanroom project guide covers critical planning steps like classification, layout, hepa/ulpa filtration system design, installation,. They play a crucial role in various industries, including pharmaceuticals, biotechnology, electronics, and aerospace. How to build a cleanroom. Learn about the. Clean Room Manufacturing Process.

From www.dreamstime.com

Silicon Wafer Manufacturing Process in a Clean Room Stock Video Video Clean Room Manufacturing Process Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. They play a crucial role in various industries, including pharmaceuticals, biotechnology, electronics, and aerospace. How to build a cleanroom. Learn about the good manufacturing practices (gmp) and current good manufacturing practices (cgmp) for cleanroom design and production of pharmaceutical products. The primary objective. Clean Room Manufacturing Process.

From www.dreamstime.com

Silicon Wafer Manufacturing Process in a Clean Room Stock Video Video Clean Room Manufacturing Process Learn about the good manufacturing practices (gmp) and current good manufacturing practices (cgmp) for cleanroom design and production of pharmaceutical products. They play a crucial role in various industries, including pharmaceuticals, biotechnology, electronics, and aerospace. Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. The primary objective of a cleanroom is to. Clean Room Manufacturing Process.

From www.achengineering.com

The World of the Semiconductor Cleanroom ACH Engineering Clean Room Manufacturing Process Find out the differences, requirements, and guidance for gmp and cgmp cleanrooms. The primary objective of a cleanroom is to limit the amount of airborne particles in a given space and keep it as clean as possible. How to build a cleanroom. Cleanrooms are controlled environments designed to minimize the presence of contaminants, such as dust, airborne microbes, and chemical. Clean Room Manufacturing Process.

From www.originltd.com

What is cleanroom manufacturing? Origin Pharma Packaging Clean Room Manufacturing Process Learn about the good manufacturing practices (gmp) and current good manufacturing practices (cgmp) for cleanroom design and production of pharmaceutical products. There are multiple ways to build and design a cleanroom facility that will meet gmp requirements for the sterile manufacturing of. They play a crucial role in various industries, including pharmaceuticals, biotechnology, electronics, and aerospace. Cleanrooms are controlled environments. Clean Room Manufacturing Process.

From www.dreamstime.com

Silicon Wafer Manufacturing Process in a Clean Room Stock Footage Clean Room Manufacturing Process They play a crucial role in various industries, including pharmaceuticals, biotechnology, electronics, and aerospace. Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. Cleanrooms are controlled environments designed to minimize the presence of contaminants, such as dust, airborne microbes, and chemical vapors. Learn about the good manufacturing practices (gmp) and current good. Clean Room Manufacturing Process.

From www.novartis.com

Operators in a clean room Novartis Clean Room Manufacturing Process They play a crucial role in various industries, including pharmaceuticals, biotechnology, electronics, and aerospace. Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. This comprehensive cleanroom project guide covers critical planning steps like classification, layout, hepa/ulpa filtration system design, installation,. How to build a cleanroom. Learn about the good manufacturing practices (gmp). Clean Room Manufacturing Process.

From www.dreamstime.com

Silicon Wafer Manufacturing Process in a Clean Room Stock Footage Clean Room Manufacturing Process There are multiple ways to build and design a cleanroom facility that will meet gmp requirements for the sterile manufacturing of. Learn about the good manufacturing practices (gmp) and current good manufacturing practices (cgmp) for cleanroom design and production of pharmaceutical products. Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. How. Clean Room Manufacturing Process.

From www.dreamstime.com

Silicon Wafer Manufacturing Process in a Clean Room Stock Video Video Clean Room Manufacturing Process They play a crucial role in various industries, including pharmaceuticals, biotechnology, electronics, and aerospace. Cleanrooms are controlled environments designed to minimize the presence of contaminants, such as dust, airborne microbes, and chemical vapors. Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. The primary objective of a cleanroom is to limit the. Clean Room Manufacturing Process.

From www.achengineering.com

Cleanrooms for PPE Manufacturing ACH Engineering Clean Room Manufacturing Process They play a crucial role in various industries, including pharmaceuticals, biotechnology, electronics, and aerospace. There are multiple ways to build and design a cleanroom facility that will meet gmp requirements for the sterile manufacturing of. The primary objective of a cleanroom is to limit the amount of airborne particles in a given space and keep it as clean as possible.. Clean Room Manufacturing Process.

From www.plitek.com

Clean Room Manufacturing Converting Capabilities Plitek Clean Room Manufacturing Process Cleanrooms are controlled environments designed to minimize the presence of contaminants, such as dust, airborne microbes, and chemical vapors. They play a crucial role in various industries, including pharmaceuticals, biotechnology, electronics, and aerospace. Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. How to build a cleanroom. The primary objective of a. Clean Room Manufacturing Process.

From www.dreamstime.com

Silicon Wafer Manufacturing Process in a Clean Room Stock Footage Clean Room Manufacturing Process There are multiple ways to build and design a cleanroom facility that will meet gmp requirements for the sterile manufacturing of. This comprehensive cleanroom project guide covers critical planning steps like classification, layout, hepa/ulpa filtration system design, installation,. How to build a cleanroom. The primary objective of a cleanroom is to limit the amount of airborne particles in a given. Clean Room Manufacturing Process.

From www.dreamstime.com

Silicon Wafer Manufacturing Process in a Clean Room Stock Footage Clean Room Manufacturing Process The primary objective of a cleanroom is to limit the amount of airborne particles in a given space and keep it as clean as possible. There are multiple ways to build and design a cleanroom facility that will meet gmp requirements for the sterile manufacturing of. Learn about the good manufacturing practices (gmp) and current good manufacturing practices (cgmp) for. Clean Room Manufacturing Process.

From www.complianceacuity.com

Production and Process Control ComplianceAcuity Clean Room Manufacturing Process Find out the differences, requirements, and guidance for gmp and cgmp cleanrooms. How to build a cleanroom. They play a crucial role in various industries, including pharmaceuticals, biotechnology, electronics, and aerospace. Learn about the good manufacturing practices (gmp) and current good manufacturing practices (cgmp) for cleanroom design and production of pharmaceutical products. The primary objective of a cleanroom is to. Clean Room Manufacturing Process.

From conceptgroupllc.com

Cleanroom Pipe Insulation for Hygienic Manufacturing Insulon® Tech Clean Room Manufacturing Process Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. They play a crucial role in various industries, including pharmaceuticals, biotechnology, electronics, and aerospace. This comprehensive cleanroom project guide covers critical planning steps like classification, layout, hepa/ulpa filtration system design, installation,. There are multiple ways to build and design a cleanroom facility that. Clean Room Manufacturing Process.

From formaspace.com

Keep Your Semiconductor Cleanroom Running at Peak Performance Formaspace Clean Room Manufacturing Process Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. This comprehensive cleanroom project guide covers critical planning steps like classification, layout, hepa/ulpa filtration system design, installation,. The primary objective of a cleanroom is to limit the amount of airborne particles in a given space and keep it as clean as possible. There. Clean Room Manufacturing Process.

From www.dreamstime.com

Silicon Wafer Manufacturing Process in a Clean Room Stock Video Video Clean Room Manufacturing Process How to build a cleanroom. There are multiple ways to build and design a cleanroom facility that will meet gmp requirements for the sterile manufacturing of. Cleanrooms are controlled environments designed to minimize the presence of contaminants, such as dust, airborne microbes, and chemical vapors. Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to. Clean Room Manufacturing Process.

From www.mechon.co.uk

Cleanroom HVAC System Design Guide Process Ventilation Consultants Clean Room Manufacturing Process How to build a cleanroom. There are multiple ways to build and design a cleanroom facility that will meet gmp requirements for the sterile manufacturing of. Cleanrooms are controlled environments designed to minimize the presence of contaminants, such as dust, airborne microbes, and chemical vapors. Find out the differences, requirements, and guidance for gmp and cgmp cleanrooms. They play a. Clean Room Manufacturing Process.

From www.liveabout.com

Considerations for Building a Clean Room Clean Room Manufacturing Process Learn about the good manufacturing practices (gmp) and current good manufacturing practices (cgmp) for cleanroom design and production of pharmaceutical products. This comprehensive cleanroom project guide covers critical planning steps like classification, layout, hepa/ulpa filtration system design, installation,. Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. The primary objective of a. Clean Room Manufacturing Process.

From www.dreamstime.com

Silicon Wafer Manufacturing Process in a Clean Room Stock Footage Clean Room Manufacturing Process Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. Cleanrooms are controlled environments designed to minimize the presence of contaminants, such as dust, airborne microbes, and chemical vapors. They play a crucial role in various industries, including pharmaceuticals, biotechnology, electronics, and aerospace. There are multiple ways to build and design a cleanroom. Clean Room Manufacturing Process.

From precisionworxpr.com

Clean Room Assembly PrecisionWorx Clean Room Manufacturing Process This comprehensive cleanroom project guide covers critical planning steps like classification, layout, hepa/ulpa filtration system design, installation,. There are multiple ways to build and design a cleanroom facility that will meet gmp requirements for the sterile manufacturing of. Cleanrooms are controlled environments designed to minimize the presence of contaminants, such as dust, airborne microbes, and chemical vapors. Learn about the. Clean Room Manufacturing Process.

From www.dreamstime.com

Semiconductor Manufacturing Process in a Clean Room Stock Footage Clean Room Manufacturing Process Find out the differences, requirements, and guidance for gmp and cgmp cleanrooms. They play a crucial role in various industries, including pharmaceuticals, biotechnology, electronics, and aerospace. How to build a cleanroom. Learn about the good manufacturing practices (gmp) and current good manufacturing practices (cgmp) for cleanroom design and production of pharmaceutical products. Cleanrooms are controlled environments designed to minimize the. Clean Room Manufacturing Process.

From www.cleanroomsolutions.com

Cleanrooms for Semiconductor Production Instant Cleanroom Solutions Clean Room Manufacturing Process How to build a cleanroom. Find out the differences, requirements, and guidance for gmp and cgmp cleanrooms. Learn about the good manufacturing practices (gmp) and current good manufacturing practices (cgmp) for cleanroom design and production of pharmaceutical products. This comprehensive cleanroom project guide covers critical planning steps like classification, layout, hepa/ulpa filtration system design, installation,. They play a crucial role. Clean Room Manufacturing Process.

From www.dreamstime.com

Silicon Wafer Manufacturing Process in a Clean Room Stock Video Video Clean Room Manufacturing Process Cleanrooms are controlled environments designed to minimize the presence of contaminants, such as dust, airborne microbes, and chemical vapors. How to build a cleanroom. Find out the differences, requirements, and guidance for gmp and cgmp cleanrooms. There are multiple ways to build and design a cleanroom facility that will meet gmp requirements for the sterile manufacturing of. Learn about the. Clean Room Manufacturing Process.

From lwfluidmachine.com

Clean Room Manufacturing Clean Room Manufacturing Process Find out the differences, requirements, and guidance for gmp and cgmp cleanrooms. Learn about the good manufacturing practices (gmp) and current good manufacturing practices (cgmp) for cleanroom design and production of pharmaceutical products. The primary objective of a cleanroom is to limit the amount of airborne particles in a given space and keep it as clean as possible. This comprehensive. Clean Room Manufacturing Process.

From www.aesclean.com

Modular Cleanroom Cleaning Protocols AES Clean Technology Clean Room Manufacturing Process How to build a cleanroom. Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. Cleanrooms are controlled environments designed to minimize the presence of contaminants, such as dust, airborne microbes, and chemical vapors. There are multiple ways to build and design a cleanroom facility that will meet gmp requirements for the sterile. Clean Room Manufacturing Process.

From www.dreamstime.com

Silicon Wafer Manufacturing Process in a Clean Room Stock Video Video Clean Room Manufacturing Process The primary objective of a cleanroom is to limit the amount of airborne particles in a given space and keep it as clean as possible. Find out the differences, requirements, and guidance for gmp and cgmp cleanrooms. Cleanrooms must be constructed in stages, starting from standard construction of walls and infrastructure to progressively cleaner. How to build a cleanroom. Cleanrooms. Clean Room Manufacturing Process.