Lmf Ladle Furnace . In this study, a mathematical modeling method was employed to investigate the effect of refractory configurations on the ladle shell. Typically, there is argon bubbling from the ladle bottom to circulate the steel and to. The ladle metallurgy furnace (lmf) is fully responsible for the process of homogenization of composition of alloy elements and temperature,. This relieves the primary steelmaking furnace of. Ladle furnace (lf) refining is one of the key procedures in steelmaking process and has been widely used in steelmaking plants for. Ladle metallurgical furnaces (lmfs) play a pivotal role in meeting the metallurgical requirements of steel mills. The installation for heating is called ladle furnace (lf). A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle.

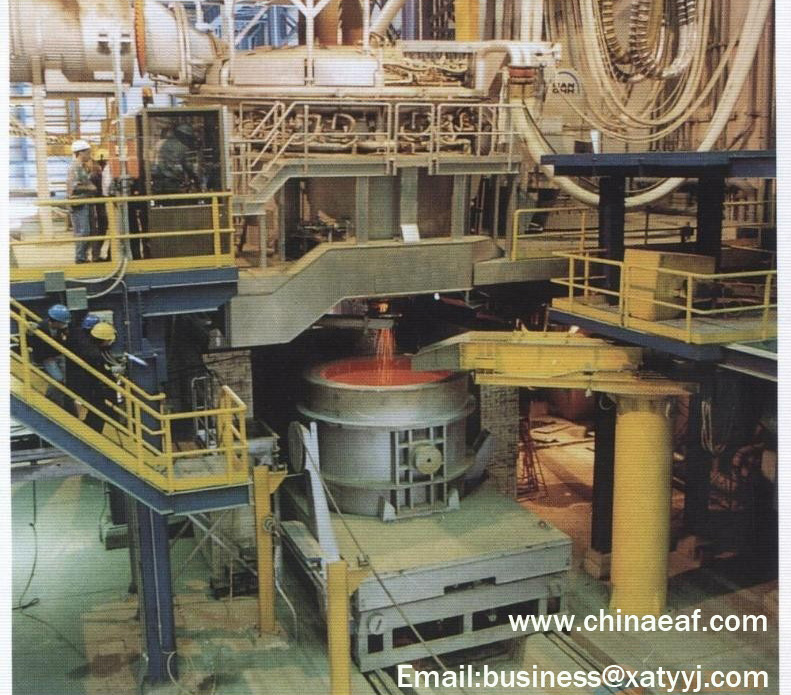

from www.chinaeaf.com

Ladle metallurgical furnaces (lmfs) play a pivotal role in meeting the metallurgical requirements of steel mills. Ladle furnace (lf) refining is one of the key procedures in steelmaking process and has been widely used in steelmaking plants for. The ladle metallurgy furnace (lmf) is fully responsible for the process of homogenization of composition of alloy elements and temperature,. In this study, a mathematical modeling method was employed to investigate the effect of refractory configurations on the ladle shell. Typically, there is argon bubbling from the ladle bottom to circulate the steel and to. A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle. The installation for heating is called ladle furnace (lf). This relieves the primary steelmaking furnace of.

Ladle refining furnace,LF Refining Furnace,refining furnace,LF FurnaceXi’an Tengye

Lmf Ladle Furnace In this study, a mathematical modeling method was employed to investigate the effect of refractory configurations on the ladle shell. Typically, there is argon bubbling from the ladle bottom to circulate the steel and to. Ladle metallurgical furnaces (lmfs) play a pivotal role in meeting the metallurgical requirements of steel mills. The ladle metallurgy furnace (lmf) is fully responsible for the process of homogenization of composition of alloy elements and temperature,. A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle. Ladle furnace (lf) refining is one of the key procedures in steelmaking process and has been widely used in steelmaking plants for. The installation for heating is called ladle furnace (lf). This relieves the primary steelmaking furnace of. In this study, a mathematical modeling method was employed to investigate the effect of refractory configurations on the ladle shell.

From www.electrotherment.com

Electrotherm (Ladle) Refining Furnaces Electrotherm Engineering & Technologies Steel Lmf Ladle Furnace Typically, there is argon bubbling from the ladle bottom to circulate the steel and to. The installation for heating is called ladle furnace (lf). A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle. Ladle furnace (lf) refining is one of the key procedures in steelmaking process. Lmf Ladle Furnace.

From tenova.com

Ladle Furnace (LF/LMF) and Trimming Station Tenova Lmf Ladle Furnace In this study, a mathematical modeling method was employed to investigate the effect of refractory configurations on the ladle shell. A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle. Ladle metallurgical furnaces (lmfs) play a pivotal role in meeting the metallurgical requirements of steel mills. Ladle. Lmf Ladle Furnace.

From www.dufercotp.com

LMF Twin solution for the ladle furnace of San Zeno Naviglio Lmf Ladle Furnace Ladle furnace (lf) refining is one of the key procedures in steelmaking process and has been widely used in steelmaking plants for. In this study, a mathematical modeling method was employed to investigate the effect of refractory configurations on the ladle shell. Typically, there is argon bubbling from the ladle bottom to circulate the steel and to. The ladle metallurgy. Lmf Ladle Furnace.

From www.youtube.com

Ladle Metallurgy Furnace YouTube Lmf Ladle Furnace This relieves the primary steelmaking furnace of. A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle. The installation for heating is called ladle furnace (lf). In this study, a mathematical modeling method was employed to investigate the effect of refractory configurations on the ladle shell. Ladle. Lmf Ladle Furnace.

From www.ecplaza.net

LF Ladle Refining Furnace Xi'an Tengye Metallurgical Engineering Co., Ltd Lmf Ladle Furnace Typically, there is argon bubbling from the ladle bottom to circulate the steel and to. Ladle metallurgical furnaces (lmfs) play a pivotal role in meeting the metallurgical requirements of steel mills. A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle. In this study, a mathematical modeling. Lmf Ladle Furnace.

From www.hanrm.com

Ladle Refining Furnace ( LRF) Melting Furnace for Sale Lmf Ladle Furnace A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle. The installation for heating is called ladle furnace (lf). Typically, there is argon bubbling from the ladle bottom to circulate the steel and to. Ladle metallurgical furnaces (lmfs) play a pivotal role in meeting the metallurgical requirements. Lmf Ladle Furnace.

From www.dufercotp.com

LMF Twin solution for the ladle furnace of San Zeno Naviglio Lmf Ladle Furnace A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle. This relieves the primary steelmaking furnace of. The installation for heating is called ladle furnace (lf). Ladle metallurgical furnaces (lmfs) play a pivotal role in meeting the metallurgical requirements of steel mills. Ladle furnace (lf) refining is. Lmf Ladle Furnace.

From reibus.com

Ladle Metallurgy Furnaces Reibus International Lmf Ladle Furnace The installation for heating is called ladle furnace (lf). The ladle metallurgy furnace (lmf) is fully responsible for the process of homogenization of composition of alloy elements and temperature,. In this study, a mathematical modeling method was employed to investigate the effect of refractory configurations on the ladle shell. Ladle metallurgical furnaces (lmfs) play a pivotal role in meeting the. Lmf Ladle Furnace.

From www.siderengineering.com

Ladle Furnace Sider Engineering S.p.A. Lmf Ladle Furnace The ladle metallurgy furnace (lmf) is fully responsible for the process of homogenization of composition of alloy elements and temperature,. In this study, a mathematical modeling method was employed to investigate the effect of refractory configurations on the ladle shell. A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining. Lmf Ladle Furnace.

From www.eafabcorp.com

Different Technologies for Ladle Metallurgical Furnaces (LMF) Lmf Ladle Furnace A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle. The installation for heating is called ladle furnace (lf). Ladle metallurgical furnaces (lmfs) play a pivotal role in meeting the metallurgical requirements of steel mills. This relieves the primary steelmaking furnace of. Typically, there is argon bubbling. Lmf Ladle Furnace.

From tenova.com

Ladle Furnace (LF/LMF) and Trimming Station Tenova Lmf Ladle Furnace In this study, a mathematical modeling method was employed to investigate the effect of refractory configurations on the ladle shell. Ladle furnace (lf) refining is one of the key procedures in steelmaking process and has been widely used in steelmaking plants for. Typically, there is argon bubbling from the ladle bottom to circulate the steel and to. A ladle metallurgy. Lmf Ladle Furnace.

From www.thyssenkrupp-steel.com

Investing in the future thyssenkrupp to build new ladle furnace in Duisburg expansion of Lmf Ladle Furnace Ladle metallurgical furnaces (lmfs) play a pivotal role in meeting the metallurgical requirements of steel mills. The ladle metallurgy furnace (lmf) is fully responsible for the process of homogenization of composition of alloy elements and temperature,. A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle. Ladle. Lmf Ladle Furnace.

From www.alibaba.com

10t160t Ladle Refining Furnace Lf High Efficient Ladle Refining Furnaces For Competitive Price Lmf Ladle Furnace A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle. The ladle metallurgy furnace (lmf) is fully responsible for the process of homogenization of composition of alloy elements and temperature,. Ladle furnace (lf) refining is one of the key procedures in steelmaking process and has been widely. Lmf Ladle Furnace.

From www.eafccmmachine.com

Ladle Melt Furnace For Steelmaking Lmf Ladle Furnace The installation for heating is called ladle furnace (lf). Ladle furnace (lf) refining is one of the key procedures in steelmaking process and has been widely used in steelmaking plants for. Typically, there is argon bubbling from the ladle bottom to circulate the steel and to. This relieves the primary steelmaking furnace of. Ladle metallurgical furnaces (lmfs) play a pivotal. Lmf Ladle Furnace.

From www.chinaeaf.com

Ladle refining furnace,LF Refining Furnace,refining furnace,LF FurnaceXi’an Tengye Lmf Ladle Furnace In this study, a mathematical modeling method was employed to investigate the effect of refractory configurations on the ladle shell. The ladle metallurgy furnace (lmf) is fully responsible for the process of homogenization of composition of alloy elements and temperature,. Ladle furnace (lf) refining is one of the key procedures in steelmaking process and has been widely used in steelmaking. Lmf Ladle Furnace.

From www.isunsteel.com

2000mm Ladle Refining Furnaces For Molten Lrf Steel Making Refining Complete Equipment Lmf Ladle Furnace In this study, a mathematical modeling method was employed to investigate the effect of refractory configurations on the ladle shell. Ladle metallurgical furnaces (lmfs) play a pivotal role in meeting the metallurgical requirements of steel mills. Typically, there is argon bubbling from the ladle bottom to circulate the steel and to. Ladle furnace (lf) refining is one of the key. Lmf Ladle Furnace.

From zjshenda.en.alibaba.com

qualified steelmaking refining molten steel 25 ton ladle refining furnace(LF) ladle furnace LRF Lmf Ladle Furnace A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle. Typically, there is argon bubbling from the ladle bottom to circulate the steel and to. Ladle furnace (lf) refining is one of the key procedures in steelmaking process and has been widely used in steelmaking plants for.. Lmf Ladle Furnace.

From www.eafabcorp.com

Different Technologies for Ladle Metallurgical Furnaces (LMF) Lmf Ladle Furnace This relieves the primary steelmaking furnace of. In this study, a mathematical modeling method was employed to investigate the effect of refractory configurations on the ladle shell. The installation for heating is called ladle furnace (lf). Ladle furnace (lf) refining is one of the key procedures in steelmaking process and has been widely used in steelmaking plants for. Ladle metallurgical. Lmf Ladle Furnace.

From magazine.primetals.com

TYASA Orders a New Twin Ladle Furnace Lmf Ladle Furnace Ladle metallurgical furnaces (lmfs) play a pivotal role in meeting the metallurgical requirements of steel mills. The ladle metallurgy furnace (lmf) is fully responsible for the process of homogenization of composition of alloy elements and temperature,. The installation for heating is called ladle furnace (lf). Ladle furnace (lf) refining is one of the key procedures in steelmaking process and has. Lmf Ladle Furnace.

From www.isunsteel.com

50 Ton Ladle Refining Furnace Steel Making LRF Metallurgical Melting Equipment Lmf Ladle Furnace A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle. The installation for heating is called ladle furnace (lf). Ladle metallurgical furnaces (lmfs) play a pivotal role in meeting the metallurgical requirements of steel mills. Ladle furnace (lf) refining is one of the key procedures in steelmaking. Lmf Ladle Furnace.

From www.istanbulmachine.com.tr

Ladle Furnace LF Melt Shop Steelmaking Lmf Ladle Furnace In this study, a mathematical modeling method was employed to investigate the effect of refractory configurations on the ladle shell. The installation for heating is called ladle furnace (lf). Ladle metallurgical furnaces (lmfs) play a pivotal role in meeting the metallurgical requirements of steel mills. The ladle metallurgy furnace (lmf) is fully responsible for the process of homogenization of composition. Lmf Ladle Furnace.

From www.eafccmmachine.com

Ladle Metallurgy Furnace Ladle Furnace Lmf Ladle Furnace This relieves the primary steelmaking furnace of. The ladle metallurgy furnace (lmf) is fully responsible for the process of homogenization of composition of alloy elements and temperature,. A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle. Ladle furnace (lf) refining is one of the key procedures. Lmf Ladle Furnace.

From www.made-in-china.com

Ladle Refining Furnace China Lf and Lrf Lmf Ladle Furnace This relieves the primary steelmaking furnace of. A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle. Ladle furnace (lf) refining is one of the key procedures in steelmaking process and has been widely used in steelmaking plants for. The installation for heating is called ladle furnace. Lmf Ladle Furnace.

From www.stggroup.it

Metech STG Ladle Furnace Lmf Ladle Furnace Ladle metallurgical furnaces (lmfs) play a pivotal role in meeting the metallurgical requirements of steel mills. Ladle furnace (lf) refining is one of the key procedures in steelmaking process and has been widely used in steelmaking plants for. The ladle metallurgy furnace (lmf) is fully responsible for the process of homogenization of composition of alloy elements and temperature,. In this. Lmf Ladle Furnace.

From www.chinaeaf.com

Ladle refining furnace,LF Refining Furnace,refining furnace,LF FurnaceXi’an Tengye Lmf Ladle Furnace Typically, there is argon bubbling from the ladle bottom to circulate the steel and to. A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle. The ladle metallurgy furnace (lmf) is fully responsible for the process of homogenization of composition of alloy elements and temperature,. Ladle metallurgical. Lmf Ladle Furnace.

From www.linkedin.com

LF MELTING FURNACE LADLE FURNACE Lmf Ladle Furnace The ladle metallurgy furnace (lmf) is fully responsible for the process of homogenization of composition of alloy elements and temperature,. The installation for heating is called ladle furnace (lf). Typically, there is argon bubbling from the ladle bottom to circulate the steel and to. Ladle furnace (lf) refining is one of the key procedures in steelmaking process and has been. Lmf Ladle Furnace.

From www.youtube.com

LMF / LRF Furnace Process YouTube Lmf Ladle Furnace The installation for heating is called ladle furnace (lf). This relieves the primary steelmaking furnace of. Ladle metallurgical furnaces (lmfs) play a pivotal role in meeting the metallurgical requirements of steel mills. The ladle metallurgy furnace (lmf) is fully responsible for the process of homogenization of composition of alloy elements and temperature,. Ladle furnace (lf) refining is one of the. Lmf Ladle Furnace.

From tenova.com

Ladle Furnace (LF/LMF) and Trimming Station Tenova Lmf Ladle Furnace Ladle furnace (lf) refining is one of the key procedures in steelmaking process and has been widely used in steelmaking plants for. A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle. Ladle metallurgical furnaces (lmfs) play a pivotal role in meeting the metallurgical requirements of steel. Lmf Ladle Furnace.

From www.chinaeaf.com

Ladle refining furnace,LF Refining Furnace,refining furnace,LF FurnaceXi’an Tengye Lmf Ladle Furnace In this study, a mathematical modeling method was employed to investigate the effect of refractory configurations on the ladle shell. A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle. This relieves the primary steelmaking furnace of. The ladle metallurgy furnace (lmf) is fully responsible for the. Lmf Ladle Furnace.

From www.dufercotp.com

LMF Twin solution for the ladle furnace of San Zeno Naviglio Lmf Ladle Furnace In this study, a mathematical modeling method was employed to investigate the effect of refractory configurations on the ladle shell. The installation for heating is called ladle furnace (lf). The ladle metallurgy furnace (lmf) is fully responsible for the process of homogenization of composition of alloy elements and temperature,. Ladle furnace (lf) refining is one of the key procedures in. Lmf Ladle Furnace.

From www.pinterest.com

Ladle Furnace (LF) China factory Furnace, Ladle, Secondary Lmf Ladle Furnace Typically, there is argon bubbling from the ladle bottom to circulate the steel and to. Ladle metallurgical furnaces (lmfs) play a pivotal role in meeting the metallurgical requirements of steel mills. The ladle metallurgy furnace (lmf) is fully responsible for the process of homogenization of composition of alloy elements and temperature,. A ladle metallurgy furnace, better known as the lmf,. Lmf Ladle Furnace.

From www.wxisun.com

LRF Ladle Refining FurnaceMain ApplicationFeaturesSeller Lmf Ladle Furnace The ladle metallurgy furnace (lmf) is fully responsible for the process of homogenization of composition of alloy elements and temperature,. Ladle metallurgical furnaces (lmfs) play a pivotal role in meeting the metallurgical requirements of steel mills. The installation for heating is called ladle furnace (lf). This relieves the primary steelmaking furnace of. Typically, there is argon bubbling from the ladle. Lmf Ladle Furnace.

From www.youtube.com

Steel Ladle Refractory and LMF Operations YouTube Lmf Ladle Furnace Ladle furnace (lf) refining is one of the key procedures in steelmaking process and has been widely used in steelmaking plants for. The installation for heating is called ladle furnace (lf). A ladle metallurgy furnace, better known as the lmf, is used to refine molten steel into specialty grades while remaining in the ladle. The ladle metallurgy furnace (lmf) is. Lmf Ladle Furnace.

From zjshenda.en.alibaba.com

qualified steelmaking refining molten steel 25 ton ladle refining furnace(LF) ladle furnace LRF Lmf Ladle Furnace In this study, a mathematical modeling method was employed to investigate the effect of refractory configurations on the ladle shell. The installation for heating is called ladle furnace (lf). Ladle furnace (lf) refining is one of the key procedures in steelmaking process and has been widely used in steelmaking plants for. Typically, there is argon bubbling from the ladle bottom. Lmf Ladle Furnace.

From www.zbmetaltech.com

LRF Ladle Refining Arc Metallurgy Furnace, Ladle Furnace in Steel Making CHNZBTECH Lmf Ladle Furnace The ladle metallurgy furnace (lmf) is fully responsible for the process of homogenization of composition of alloy elements and temperature,. Ladle furnace (lf) refining is one of the key procedures in steelmaking process and has been widely used in steelmaking plants for. The installation for heating is called ladle furnace (lf). Ladle metallurgical furnaces (lmfs) play a pivotal role in. Lmf Ladle Furnace.