Cutting Insert Grade Chart . When it comes to cutting tool selection, machinists have three basic choices: Relatively large insert size provides better stability. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of suitable grades and. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for productive. Heavy machining requires a carbide insert size of above ic 25mm. Regardless of component size, material or design, the insert grade you use can make all the difference in your manufacturing productivity. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Always select a carbide insert size based on the specific application needs and space for cutting tools in the application. Detailed information on turning inserts identification.

from www.mscdirect.com

This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for productive. Always select a carbide insert size based on the specific application needs and space for cutting tools in the application. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of suitable grades and. Heavy machining requires a carbide insert size of above ic 25mm. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Regardless of component size, material or design, the insert grade you use can make all the difference in your manufacturing productivity. Detailed information on turning inserts identification. When it comes to cutting tool selection, machinists have three basic choices: Relatively large insert size provides better stability.

Turning Inserts

Cutting Insert Grade Chart Regardless of component size, material or design, the insert grade you use can make all the difference in your manufacturing productivity. Always select a carbide insert size based on the specific application needs and space for cutting tools in the application. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of suitable grades and. Regardless of component size, material or design, the insert grade you use can make all the difference in your manufacturing productivity. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Relatively large insert size provides better stability. When it comes to cutting tool selection, machinists have three basic choices: Heavy machining requires a carbide insert size of above ic 25mm. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Detailed information on turning inserts identification. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for productive.

From sumicarbide.com

WEZ Series 90° Shoulder Milling Cutter for General Purpose Machining Cutting Insert Grade Chart Relatively large insert size provides better stability. When it comes to cutting tool selection, machinists have three basic choices: Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of suitable grades and. Regardless of component size, material or design, the insert grade you use can make all the difference in your manufacturing. Cutting Insert Grade Chart.

From mungfali.com

Insert Nomenclature Chart Cutting Insert Grade Chart Always select a carbide insert size based on the specific application needs and space for cutting tools in the application. Detailed information on turning inserts identification. Regardless of component size, material or design, the insert grade you use can make all the difference in your manufacturing productivity. This article will explain why the middle choice— indexable turning, milling, and drilling. Cutting Insert Grade Chart.

From mavink.com

Mitsubishi Insert Grade Chart Cutting Insert Grade Chart Detailed information on turning inserts identification. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. When it comes to cutting tool selection, machinists have three basic choices: This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for productive. Selection of optimum inserts for. Cutting Insert Grade Chart.

From mungfali.com

Insert Nomenclature Chart Cutting Insert Grade Chart When it comes to cutting tool selection, machinists have three basic choices: Relatively large insert size provides better stability. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for productive. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. Cutting Insert Grade Chart.

From www.winstarcutting.com

Insert Grades Winstar Cutting Technologies Corp Cutting Insert Grade Chart In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Detailed information on turning inserts identification. When it comes to cutting tool selection, machinists have three basic choices: Regardless of component size, material or design, the insert grade you use can make all the difference in your manufacturing productivity. Heavy machining requires a. Cutting Insert Grade Chart.

From www.machiningdoctor.com

GC1210 Carbide Grade Data Sheet (Machining Doctor) Cutting Insert Grade Chart Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. When it comes to cutting tool selection, machinists have three basic choices: Heavy machining requires a carbide insert size of above ic 25mm. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often. Cutting Insert Grade Chart.

From www.carbideanddiamondtooling.com

OFER 070405 TN LT30 Carbide Inserts MultiMaterial 1 Grade for all Cutting Insert Grade Chart This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for productive. When it comes to cutting tool selection, machinists have three basic choices: Regardless of component size, material or design, the insert grade you use can make all the difference in your manufacturing productivity. Always select a carbide insert size based. Cutting Insert Grade Chart.

From www.winstarcutting.com

Insert Grades Winstar Cutting Technologies Corp Cutting Insert Grade Chart Always select a carbide insert size based on the specific application needs and space for cutting tools in the application. When it comes to cutting tool selection, machinists have three basic choices: Heavy machining requires a carbide insert size of above ic 25mm. Relatively large insert size provides better stability. Detailed information on turning inserts identification. Regardless of component size,. Cutting Insert Grade Chart.

From walter.jnterry.com

Walter turning insert grade chart Technology Walter Carbide inserts Cutting Insert Grade Chart Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of suitable grades and. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for productive. When it comes to cutting tool selection, machinists have three basic choices: Regardless of component size, material or design,. Cutting Insert Grade Chart.

From totimetools.com

SANDVIK GRADES DESCRIPTION Cutting Insert Grade Chart When it comes to cutting tool selection, machinists have three basic choices: Regardless of component size, material or design, the insert grade you use can make all the difference in your manufacturing productivity. Heavy machining requires a carbide insert size of above ic 25mm. Detailed information on turning inserts identification. In addition to an overview of cutting tools, safety and. Cutting Insert Grade Chart.

From www.mscdirect.com

Milling Inserts Cutting Insert Grade Chart Regardless of component size, material or design, the insert grade you use can make all the difference in your manufacturing productivity. Relatively large insert size provides better stability. Detailed information on turning inserts identification. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for productive. Heavy machining requires a carbide insert. Cutting Insert Grade Chart.

From www.carbidedepot.com

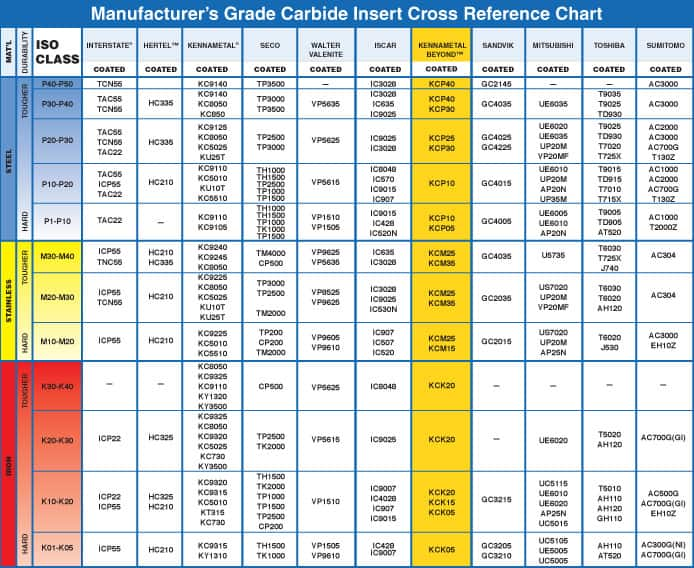

Carbide Insert Grade Comparison Chart Cutting Insert Grade Chart When it comes to cutting tool selection, machinists have three basic choices: In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Heavy machining requires a carbide insert size of above ic 25mm. Detailed information on turning inserts identification. Regardless of component size, material or design, the insert grade you use can make. Cutting Insert Grade Chart.

From www.swisscuttools.com

Technical Information SwissCut Cutting Insert Grade Chart Relatively large insert size provides better stability. Heavy machining requires a carbide insert size of above ic 25mm. Detailed information on turning inserts identification. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of suitable. Cutting Insert Grade Chart.

From www.kennametal.com

Selecting Carbide Inserts for Metalworking Kennametal Cutting Insert Grade Chart Detailed information on turning inserts identification. Always select a carbide insert size based on the specific application needs and space for cutting tools in the application. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best. Cutting Insert Grade Chart.

From gofir.co.id

TURNING INSERT GRADE TABLE 1 DISTRIBUTOR RESMI CUTTING TOOLS YG1 Cutting Insert Grade Chart This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for productive. Always select a carbide insert size based on the specific application needs and space for cutting tools in the application. Relatively large insert size provides better stability. Regardless of component size, material or design, the insert grade you use can. Cutting Insert Grade Chart.

From mavink.com

Iso Insert Grade Chart Cutting Insert Grade Chart Heavy machining requires a carbide insert size of above ic 25mm. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for productive. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Relatively large insert size provides better stability. Always select a carbide insert. Cutting Insert Grade Chart.

From ponasa.condesan-ecoandes.org

Carbide Insert Identification Chart Ponasa Cutting Insert Grade Chart Regardless of component size, material or design, the insert grade you use can make all the difference in your manufacturing productivity. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for productive. When it comes to cutting tool selection, machinists have three basic choices: Selection of optimum inserts for turning the. Cutting Insert Grade Chart.

From www.mmc-carbide.com

GRADES FOR TURNING / TURNING APPLICATION RANGE Technical Info Cutting Insert Grade Chart Relatively large insert size provides better stability. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for productive. Regardless of component size, material or design, the carbide insert grade you use can make all. Cutting Insert Grade Chart.

From www.pinterest.co.uk

TNMG inserts Pesquisa Google Tableros de herramientas, Herramientas Cutting Insert Grade Chart Detailed information on turning inserts identification. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for productive. Heavy machining requires a carbide insert size of above ic 25mm. Regardless. Cutting Insert Grade Chart.

From mavink.com

Iso Insert Grade Chart Cutting Insert Grade Chart Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of suitable grades and. Detailed information on turning inserts identification. When it comes to cutting tool selection, machinists have three basic choices: Always select a carbide insert size based on the specific application needs and space for cutting tools in the application. Relatively. Cutting Insert Grade Chart.

From www.winstarcutting.com

Insert Grades Winstar Cutting Technologies Corp Cutting Insert Grade Chart Detailed information on turning inserts identification. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for productive. Regardless of component size, material or design, the insert grade you use. Cutting Insert Grade Chart.

From www.winstarcutting.com

Insert Grades Winstar Cutting Technologies Corp Cutting Insert Grade Chart Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Always select a carbide insert size based on the specific application needs and space for cutting tools in the application. This. Cutting Insert Grade Chart.

From www.mscdirect.com

Turning Inserts Cutting Insert Grade Chart Regardless of component size, material or design, the insert grade you use can make all the difference in your manufacturing productivity. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for productive. Relatively large insert size provides better stability. When it comes to cutting tool selection, machinists have three basic choices:. Cutting Insert Grade Chart.

From walter.jnterry.com

Walter turning insert grade chart Technology Walter Carbide inserts Cutting Insert Grade Chart Relatively large insert size provides better stability. When it comes to cutting tool selection, machinists have three basic choices: Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Detailed information on turning inserts identification. Selection of optimum inserts for turning the following diagrams show for each work. Cutting Insert Grade Chart.

From www.toollink.co.th

Toollink Co., Ltd. Shape&Size Toollink Co., Ltd. Cutting Insert Grade Chart Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Regardless of component size, material or design, the insert grade you use can make all the difference in your manufacturing productivity.. Cutting Insert Grade Chart.

From www.mmc-carbide.com

Turning Inserts Identification Technical Info/Cutting Formula Cutting Insert Grade Chart In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Regardless of component size, material or design, the insert grade you use can make all the difference in your manufacturing productivity.. Cutting Insert Grade Chart.

From www.swisscuttools.com

Turning Inserts Designation SystemISO SwissCut Cutting Insert Grade Chart Detailed information on turning inserts identification. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Relatively large insert size provides better stability. Heavy machining requires a carbide insert size of above ic 25mm. In addition to an overview of cutting tools, safety and precautions, information on calculation. Cutting Insert Grade Chart.

From mungfali.com

Lathe Insert Identification Chart Cutting Insert Grade Chart Detailed information on turning inserts identification. Regardless of component size, material or design, the insert grade you use can make all the difference in your manufacturing productivity. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for productive. When it comes to cutting tool selection, machinists have three basic choices: Always. Cutting Insert Grade Chart.

From www.wecancarbide.com

CVD Grade Comparison Chart WeCan Cutting Tools Co., Ltd. Cutting Insert Grade Chart Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Always select a carbide insert size based on the specific application needs and space for cutting tools in the application. Regardless of component size, material or design, the insert grade you use can make all the difference in. Cutting Insert Grade Chart.

From www.ctemag.com

Understanding the Identification System for Indexable Inserts Cutting Cutting Insert Grade Chart Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Detailed information on turning inserts identification. Heavy machining requires a carbide insert size of above ic 25mm. Always select a carbide insert size based on the specific application needs and space for cutting tools in the application. When. Cutting Insert Grade Chart.

From www.winstarcutting.com

Insert Grades Winstar Cutting Technologies Corp. 萬事達切削科技鎢鋼銑刀, 鎢鋼刀片, 鎢鋼鑽頭 Cutting Insert Grade Chart Regardless of component size, material or design, the insert grade you use can make all the difference in your manufacturing productivity. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Heavy machining requires a carbide insert size of above ic 25mm. Selection of optimum inserts for turning. Cutting Insert Grade Chart.

From www.cutwel.co.uk

How to select the best Turning Insert & Grade for your job Cutwel Ltd Cutting Insert Grade Chart In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of suitable grades and. This article will explain why the middle choice— indexable turning, milling, and drilling tools—is often the best choice for productive. Regardless of. Cutting Insert Grade Chart.

From bceweb.org

Tungsten Carbide Grade Chart A Visual Reference of Charts Chart Master Cutting Insert Grade Chart Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of suitable grades and. Relatively large insert size provides better stability. Detailed information on turning inserts identification. When it comes to cutting tool selection, machinists have three basic choices: Always select a carbide insert size based on the specific application needs and space. Cutting Insert Grade Chart.

From mavink.com

Insert Designation Chart Cutting Insert Grade Chart Detailed information on turning inserts identification. When it comes to cutting tool selection, machinists have three basic choices: Always select a carbide insert size based on the specific application needs and space for cutting tools in the application. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Relatively large insert size provides. Cutting Insert Grade Chart.

From www.shangintool.com

ISO Designations For Insert|Hon Jan Cutting Tools Co., LTD. Cutting Insert Grade Chart Always select a carbide insert size based on the specific application needs and space for cutting tools in the application. Relatively large insert size provides better stability. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Selection of optimum inserts for turning the following diagrams show for. Cutting Insert Grade Chart.