Sheet Metal Trimming Operation . Stretch forming is a sheet metal forming process in which the sheet metal is intentionally stretched and simultaneously bent to have the shape. This document discusses sheet metal cutting operations. Trimming is the removal of excess metal from a stamped part to allow the part to reach the finished stage or to prepare it for. Trimming in sheet metal manufacturing refers to the process of removing excess material from a sheet metal blank after forming. This operation provides a smooth edge and accurate dimension to the part, making it more functional and aesthetically pleasing. It describes the cutting mechanism as a shearing action between sharp cutting edges of a punch and die. In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed part. Sheet metal cutting operations remove the sheet metal material from larger sheets by applying high forces on the cutting edge. It is a crucial step that helps to achieve the desired size, shape, and finish, ensuring the manufactured parts conform to strict industry standards. The cutting tool (punch & die, or shearing blade) cuts the material if the applied shear stress exceeds the material’s shear strength. The main features of trimming operations are: Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product.

from www.scentstrategy.com

The main features of trimming operations are: Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. Sheet metal cutting operations remove the sheet metal material from larger sheets by applying high forces on the cutting edge. It is a crucial step that helps to achieve the desired size, shape, and finish, ensuring the manufactured parts conform to strict industry standards. The cutting tool (punch & die, or shearing blade) cuts the material if the applied shear stress exceeds the material’s shear strength. It describes the cutting mechanism as a shearing action between sharp cutting edges of a punch and die. In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed part. Trimming in sheet metal manufacturing refers to the process of removing excess material from a sheet metal blank after forming. This operation provides a smooth edge and accurate dimension to the part, making it more functional and aesthetically pleasing. Stretch forming is a sheet metal forming process in which the sheet metal is intentionally stretched and simultaneously bent to have the shape.

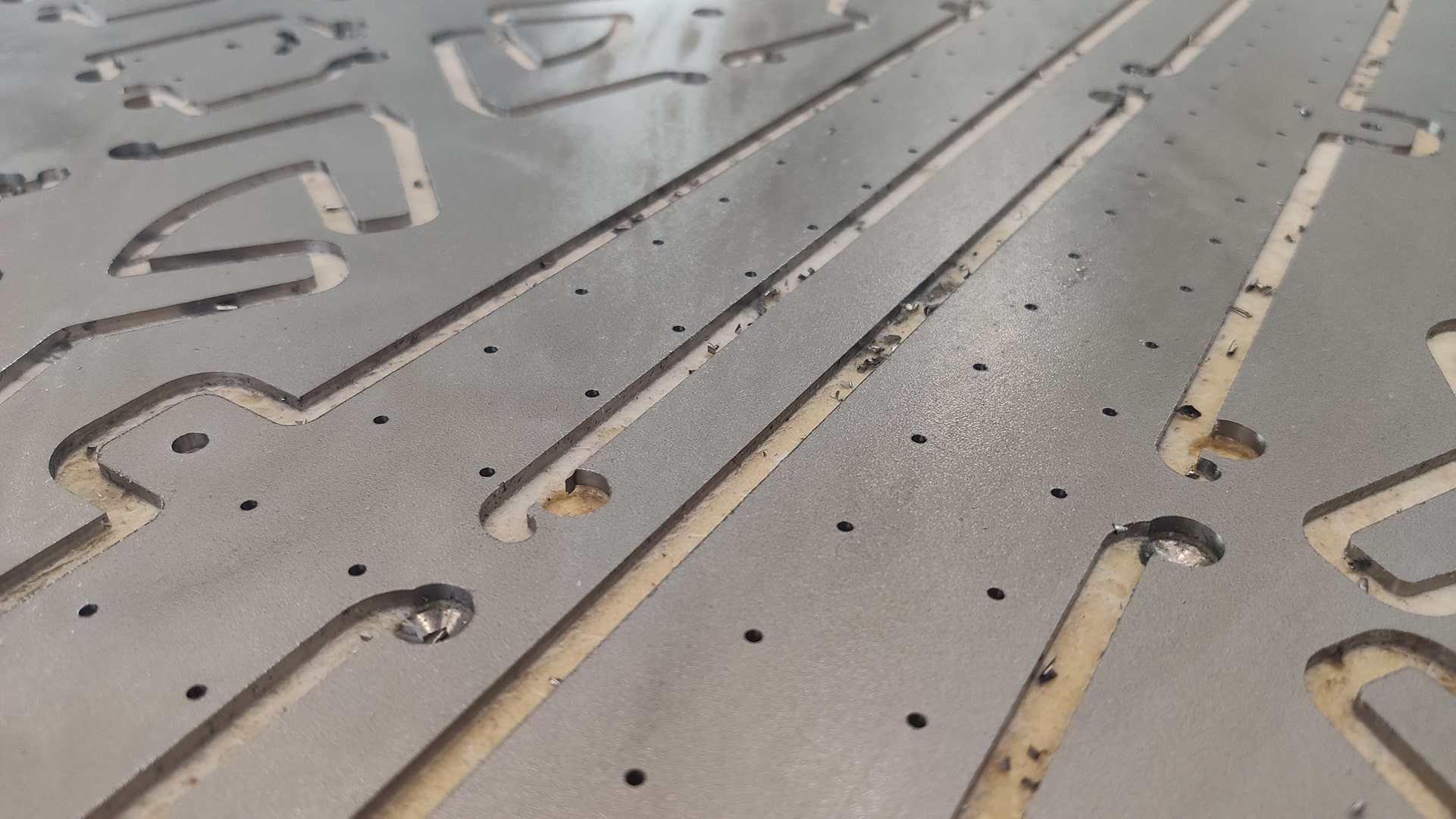

routers Most effective way to cut slots into sheetmetals Home

Sheet Metal Trimming Operation Trimming is the removal of excess metal from a stamped part to allow the part to reach the finished stage or to prepare it for. In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed part. Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. It is a crucial step that helps to achieve the desired size, shape, and finish, ensuring the manufactured parts conform to strict industry standards. This document discusses sheet metal cutting operations. Trimming is the removal of excess metal from a stamped part to allow the part to reach the finished stage or to prepare it for. It describes the cutting mechanism as a shearing action between sharp cutting edges of a punch and die. The cutting tool (punch & die, or shearing blade) cuts the material if the applied shear stress exceeds the material’s shear strength. The main features of trimming operations are: Stretch forming is a sheet metal forming process in which the sheet metal is intentionally stretched and simultaneously bent to have the shape. This operation provides a smooth edge and accurate dimension to the part, making it more functional and aesthetically pleasing. Sheet metal cutting operations remove the sheet metal material from larger sheets by applying high forces on the cutting edge. Trimming in sheet metal manufacturing refers to the process of removing excess material from a sheet metal blank after forming.

From www.youtube.com

SHEARING OPERATION IN PRESS WORKING NOTCHING PERFORATING NIBBLING LANCING SLITTIN Sheet Metal Trimming Operation In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed part. It is a crucial step that helps to achieve the desired size, shape, and finish, ensuring the manufactured parts conform to strict industry standards. Trimming is the removal of excess metal from a stamped part to allow the part to. Sheet Metal Trimming Operation.

From stampingdesign.com

What Is Sheet Metal Stamping Process ? Sheet Metal Trimming Operation Trimming in sheet metal manufacturing refers to the process of removing excess material from a sheet metal blank after forming. Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. Trimming is the removal of excess metal from a stamped part to allow the part to reach the finished stage or to. Sheet Metal Trimming Operation.

From www.vigneshpolymers.com

Sheet Metal Stamping Vignesh Polymers Sheet Metal Trimming Operation The main features of trimming operations are: This operation provides a smooth edge and accurate dimension to the part, making it more functional and aesthetically pleasing. This document discusses sheet metal cutting operations. Trimming in sheet metal manufacturing refers to the process of removing excess material from a sheet metal blank after forming. The cutting tool (punch & die, or. Sheet Metal Trimming Operation.

From www.youtube.com

TRIMMING SHEET METAL OPERATION ANUNIVERSE 22 YouTube Sheet Metal Trimming Operation This operation provides a smooth edge and accurate dimension to the part, making it more functional and aesthetically pleasing. It describes the cutting mechanism as a shearing action between sharp cutting edges of a punch and die. It is a crucial step that helps to achieve the desired size, shape, and finish, ensuring the manufactured parts conform to strict industry. Sheet Metal Trimming Operation.

From www.slideserve.com

PPT Sheet Metalworking PowerPoint Presentation, free download ID6713883 Sheet Metal Trimming Operation It is a crucial step that helps to achieve the desired size, shape, and finish, ensuring the manufactured parts conform to strict industry standards. The main features of trimming operations are: Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. Sheet metal cutting operations remove the sheet metal material from larger. Sheet Metal Trimming Operation.

From www.youtube.com

Sheet metal cutting operations(punching & blanking) YouTube Sheet Metal Trimming Operation This operation provides a smooth edge and accurate dimension to the part, making it more functional and aesthetically pleasing. Trimming is the removal of excess metal from a stamped part to allow the part to reach the finished stage or to prepare it for. The cutting tool (punch & die, or shearing blade) cuts the material if the applied shear. Sheet Metal Trimming Operation.

From www.thelibraryofmanufacturing.com

Sheet Metal Cutting Sheet Metal Trimming Operation It is a crucial step that helps to achieve the desired size, shape, and finish, ensuring the manufactured parts conform to strict industry standards. This document discusses sheet metal cutting operations. The cutting tool (punch & die, or shearing blade) cuts the material if the applied shear stress exceeds the material’s shear strength. In the realm of sheet metal manufacturing,. Sheet Metal Trimming Operation.

From thelibraryofmanufacturing.com

Trimming Of Parts Sheet Metal Trimming Operation Stretch forming is a sheet metal forming process in which the sheet metal is intentionally stretched and simultaneously bent to have the shape. Sheet metal cutting operations remove the sheet metal material from larger sheets by applying high forces on the cutting edge. This document discusses sheet metal cutting operations. Trimming is a critical process in sheet metal manufacturing, ensuring. Sheet Metal Trimming Operation.

From proleantech.com

Different Types of Trimming Operations in Sheet Metal Manufacturing Sheet Metal Trimming Operation This operation provides a smooth edge and accurate dimension to the part, making it more functional and aesthetically pleasing. This document discusses sheet metal cutting operations. In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed part. Sheet metal cutting operations remove the sheet metal material from larger sheets by applying. Sheet Metal Trimming Operation.

From www.iqsdirectory.com

Metal Stamping What Is It? How Is It Used? Types Of Sheet Metal Trimming Operation This document discusses sheet metal cutting operations. Trimming in sheet metal manufacturing refers to the process of removing excess material from a sheet metal blank after forming. It is a crucial step that helps to achieve the desired size, shape, and finish, ensuring the manufactured parts conform to strict industry standards. Trimming is the removal of excess metal from a. Sheet Metal Trimming Operation.

From www.youtube.com

Shearing Process Die Cutting Sheet metal Metal Forming PPT ENGINEERING STUDY MATERIALS Sheet Metal Trimming Operation The cutting tool (punch & die, or shearing blade) cuts the material if the applied shear stress exceeds the material’s shear strength. The main features of trimming operations are: It is a crucial step that helps to achieve the desired size, shape, and finish, ensuring the manufactured parts conform to strict industry standards. Stretch forming is a sheet metal forming. Sheet Metal Trimming Operation.

From www.slideserve.com

PPT SHEET METAL FORMING PROCESS / PRESS WORKING OF SHEET METALS PowerPoint Presentation ID Sheet Metal Trimming Operation Trimming in sheet metal manufacturing refers to the process of removing excess material from a sheet metal blank after forming. Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. This operation provides a smooth edge and accurate dimension to the part, making it more functional and aesthetically pleasing. Sheet metal cutting. Sheet Metal Trimming Operation.

From www.slideserve.com

PPT Sheet Metal Forming PowerPoint Presentation, free download ID5354499 Sheet Metal Trimming Operation Trimming in sheet metal manufacturing refers to the process of removing excess material from a sheet metal blank after forming. The cutting tool (punch & die, or shearing blade) cuts the material if the applied shear stress exceeds the material’s shear strength. Sheet metal cutting operations remove the sheet metal material from larger sheets by applying high forces on the. Sheet Metal Trimming Operation.

From www.slideserve.com

PPT Sheet Metal Forming PowerPoint Presentation, free download ID5354499 Sheet Metal Trimming Operation Stretch forming is a sheet metal forming process in which the sheet metal is intentionally stretched and simultaneously bent to have the shape. The cutting tool (punch & die, or shearing blade) cuts the material if the applied shear stress exceeds the material’s shear strength. Sheet metal cutting operations remove the sheet metal material from larger sheets by applying high. Sheet Metal Trimming Operation.

From www.theengineerspost.com

9 Different Types of Sheet Metal Operations with Diagram & PDF Sheet Metal Trimming Operation This operation provides a smooth edge and accurate dimension to the part, making it more functional and aesthetically pleasing. It describes the cutting mechanism as a shearing action between sharp cutting edges of a punch and die. Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. Trimming is the removal of. Sheet Metal Trimming Operation.

From proleantech.com

Different Types of Trimming Operations in Sheet Metal Manufacturing Sheet Metal Trimming Operation Trimming is the removal of excess metal from a stamped part to allow the part to reach the finished stage or to prepare it for. Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. This operation provides a smooth edge and accurate dimension to the part, making it more functional and. Sheet Metal Trimming Operation.

From www.scentstrategy.com

routers Most effective way to cut slots into sheetmetals Home Sheet Metal Trimming Operation Trimming in sheet metal manufacturing refers to the process of removing excess material from a sheet metal blank after forming. Trimming is the removal of excess metal from a stamped part to allow the part to reach the finished stage or to prepare it for. It is a crucial step that helps to achieve the desired size, shape, and finish,. Sheet Metal Trimming Operation.

From www.iqsdirectory.com

Die Stamping What is it? Process, Steps, Progressive vs. Transfer Sheet Metal Trimming Operation The main features of trimming operations are: This document discusses sheet metal cutting operations. It is a crucial step that helps to achieve the desired size, shape, and finish, ensuring the manufactured parts conform to strict industry standards. Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. Trimming in sheet metal. Sheet Metal Trimming Operation.

From vdocuments.mx

2.4 SHEET METAL OPERATION Wikispaces · PDF file2.4 SHEET METAL OPERATION • Nibbling This Sheet Metal Trimming Operation The cutting tool (punch & die, or shearing blade) cuts the material if the applied shear stress exceeds the material’s shear strength. Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. This operation provides a smooth edge and accurate dimension to the part, making it more functional and aesthetically pleasing. It. Sheet Metal Trimming Operation.

From www.designtechacademy.com

Design Tech Academy Press Operation 2 (Piercing, Straightening & Trimming ) Sheet Metal Trimming Operation In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed part. Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. The main features of trimming operations are: Trimming in sheet metal manufacturing refers to the process of removing excess material from a. Sheet Metal Trimming Operation.

From www.slideserve.com

PPT Sheet Metalworking PowerPoint Presentation, free download ID6713883 Sheet Metal Trimming Operation In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed part. Trimming in sheet metal manufacturing refers to the process of removing excess material from a sheet metal blank after forming. This document discusses sheet metal cutting operations. This operation provides a smooth edge and accurate dimension to the part, making. Sheet Metal Trimming Operation.

From proleantech.com

The Importance of Trimming Operations in Sheet Metal Manufacturing Sheet Metal Trimming Operation It describes the cutting mechanism as a shearing action between sharp cutting edges of a punch and die. This document discusses sheet metal cutting operations. The main features of trimming operations are: It is a crucial step that helps to achieve the desired size, shape, and finish, ensuring the manufactured parts conform to strict industry standards. Stretch forming is a. Sheet Metal Trimming Operation.

From www.slideshare.net

Sheet metaloperations Sheet Metal Trimming Operation In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed part. Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. The main features of trimming operations are: Trimming is the removal of excess metal from a stamped part to allow the part. Sheet Metal Trimming Operation.

From edmontonrealestateinvestmentblog.com

The Last Guide to Sheet Metal Forming You Will Ever Need (2022) Sheet Metal Trimming Operation It is a crucial step that helps to achieve the desired size, shape, and finish, ensuring the manufactured parts conform to strict industry standards. Trimming in sheet metal manufacturing refers to the process of removing excess material from a sheet metal blank after forming. Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the. Sheet Metal Trimming Operation.

From questtech.ca

Sheet Metal Forming Process Techniques QuestTech Precision Inc. Sheet Metal Trimming Operation It is a crucial step that helps to achieve the desired size, shape, and finish, ensuring the manufactured parts conform to strict industry standards. The main features of trimming operations are: This operation provides a smooth edge and accurate dimension to the part, making it more functional and aesthetically pleasing. In the realm of sheet metal manufacturing, trimming is a. Sheet Metal Trimming Operation.

From caddomain.blogspot.com

Sheet Metal Operation CAD ENGINEERING Sheet Metal Trimming Operation In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed part. It describes the cutting mechanism as a shearing action between sharp cutting edges of a punch and die. Trimming in sheet metal manufacturing refers to the process of removing excess material from a sheet metal blank after forming. The main. Sheet Metal Trimming Operation.

From stampingsimulation.com

Improve Your Sheet Metal Trimming Process Through Simulation Sheet Metal Trimming Operation In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed part. It describes the cutting mechanism as a shearing action between sharp cutting edges of a punch and die. The cutting tool (punch & die, or shearing blade) cuts the material if the applied shear stress exceeds the material’s shear strength.. Sheet Metal Trimming Operation.

From proleantech.com

A Comprehensive Guide of Trimming Process CNC Machining Service, Rapid prototyping Sheet Metal Trimming Operation Sheet metal cutting operations remove the sheet metal material from larger sheets by applying high forces on the cutting edge. Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. Trimming is the removal of excess metal from a stamped part to allow the part to reach the finished stage or to. Sheet Metal Trimming Operation.

From proleantech.com

A Comprehensive Guide of Trimming Process CNC Machining Service, Rapid prototyping Sheet Metal Trimming Operation This operation provides a smooth edge and accurate dimension to the part, making it more functional and aesthetically pleasing. Stretch forming is a sheet metal forming process in which the sheet metal is intentionally stretched and simultaneously bent to have the shape. Sheet metal cutting operations remove the sheet metal material from larger sheets by applying high forces on the. Sheet Metal Trimming Operation.

From www.artofit.org

9 different types of sheet metal operations with diagram pdf Artofit Sheet Metal Trimming Operation Sheet metal cutting operations remove the sheet metal material from larger sheets by applying high forces on the cutting edge. It is a crucial step that helps to achieve the desired size, shape, and finish, ensuring the manufactured parts conform to strict industry standards. The cutting tool (punch & die, or shearing blade) cuts the material if the applied shear. Sheet Metal Trimming Operation.

From www.thelibraryofmanufacturing.com

Sheet Metal Cutting Sheet Metal Trimming Operation Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. Trimming is the removal of excess metal from a stamped part to allow the part to reach the finished stage or to prepare it for. Stretch forming is a sheet metal forming process in which the sheet metal is intentionally stretched and. Sheet Metal Trimming Operation.

From www.youtube.com

Cutting process Types / Stamping Operation / Sheet Metal YouTube Sheet Metal Trimming Operation Stretch forming is a sheet metal forming process in which the sheet metal is intentionally stretched and simultaneously bent to have the shape. Trimming in sheet metal manufacturing refers to the process of removing excess material from a sheet metal blank after forming. This operation provides a smooth edge and accurate dimension to the part, making it more functional and. Sheet Metal Trimming Operation.

From www.youtube.com

SHEET METAL TRIMMING MACHINE OPERATION YouTube Sheet Metal Trimming Operation The cutting tool (punch & die, or shearing blade) cuts the material if the applied shear stress exceeds the material’s shear strength. Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. This document discusses sheet metal cutting operations. Trimming in sheet metal manufacturing refers to the process of removing excess material. Sheet Metal Trimming Operation.

From www.designtechacademy.com

Design Tech Academy Press Operation 2 (Piercing, Straightening & Trimming ) Sheet Metal Trimming Operation It describes the cutting mechanism as a shearing action between sharp cutting edges of a punch and die. Trimming in sheet metal manufacturing refers to the process of removing excess material from a sheet metal blank after forming. Trimming is the removal of excess metal from a stamped part to allow the part to reach the finished stage or to. Sheet Metal Trimming Operation.

From www.slideserve.com

PPT SHEET METAL OPERATIONS PowerPoint Presentation, free download ID9684631 Sheet Metal Trimming Operation The main features of trimming operations are: The cutting tool (punch & die, or shearing blade) cuts the material if the applied shear stress exceeds the material’s shear strength. Stretch forming is a sheet metal forming process in which the sheet metal is intentionally stretched and simultaneously bent to have the shape. Trimming is the removal of excess metal from. Sheet Metal Trimming Operation.