Seal Oil Pump Function . These seals are installed at the location where the shaft enters. Prevent leakage of sealed lubricant from inside. Mechanical seals are precision, dynamic devices that are used to seal process fluids from the environment and have been. Mechanical seals are devices that accommodate a rotating shaft while containing and preventing the fluid from leaking out of the enclosed housing. The seal oil system prevents gas from leaking out of the compressor case. Oil seals hold immense importance across various industries as they serve as vital components in maintaining the functionality and durability of machinery. Oil seals, also known as radial shaft seals or shaft seals, are indispensable components in hydraulic pumps and motors. Prevent entry of dust and foreign. Mechanical seals are components that keep the pumped fluid (or “pumpage”) confined to the pump casing. 8.46 is a schematic of a typical seal oil system working in. Sealing devices serve the following functions:

from mechanicalengineeringsite.com

These seals are installed at the location where the shaft enters. 8.46 is a schematic of a typical seal oil system working in. Oil seals hold immense importance across various industries as they serve as vital components in maintaining the functionality and durability of machinery. Oil seals, also known as radial shaft seals or shaft seals, are indispensable components in hydraulic pumps and motors. Prevent leakage of sealed lubricant from inside. Prevent entry of dust and foreign. Mechanical seals are devices that accommodate a rotating shaft while containing and preventing the fluid from leaking out of the enclosed housing. The seal oil system prevents gas from leaking out of the compressor case. Mechanical seals are components that keep the pumped fluid (or “pumpage”) confined to the pump casing. Sealing devices serve the following functions:

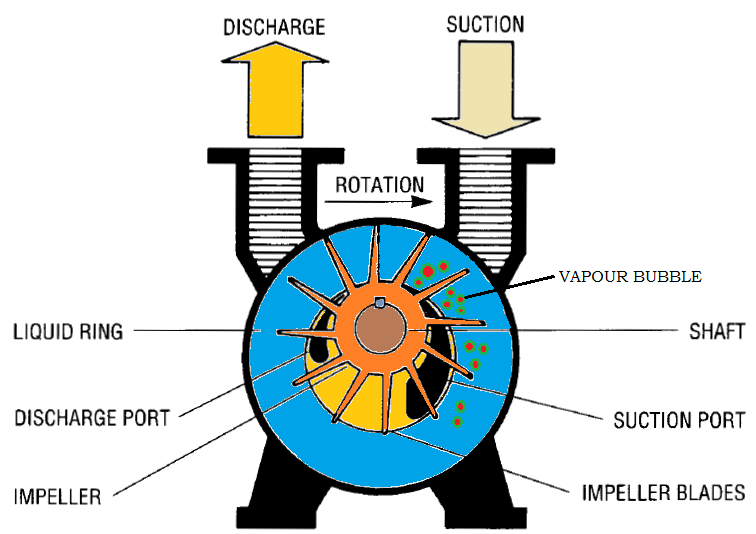

Liquid Ring Vacuum Pump Working Principle and Pumping System

Seal Oil Pump Function These seals are installed at the location where the shaft enters. The seal oil system prevents gas from leaking out of the compressor case. Sealing devices serve the following functions: Oil seals, also known as radial shaft seals or shaft seals, are indispensable components in hydraulic pumps and motors. Mechanical seals are components that keep the pumped fluid (or “pumpage”) confined to the pump casing. Prevent entry of dust and foreign. 8.46 is a schematic of a typical seal oil system working in. Mechanical seals are precision, dynamic devices that are used to seal process fluids from the environment and have been. Prevent leakage of sealed lubricant from inside. Oil seals hold immense importance across various industries as they serve as vital components in maintaining the functionality and durability of machinery. Mechanical seals are devices that accommodate a rotating shaft while containing and preventing the fluid from leaking out of the enclosed housing. These seals are installed at the location where the shaft enters.

From www.barnwell.co.uk

What are Oil Seals Guide to what an Oil Seal is used for Barnwell Seal Oil Pump Function Mechanical seals are precision, dynamic devices that are used to seal process fluids from the environment and have been. Prevent entry of dust and foreign. Oil seals hold immense importance across various industries as they serve as vital components in maintaining the functionality and durability of machinery. The seal oil system prevents gas from leaking out of the compressor case.. Seal Oil Pump Function.

From hxentjnxw.blob.core.windows.net

How To Seal Oil Pump at Annie Barrera blog Seal Oil Pump Function Oil seals, also known as radial shaft seals or shaft seals, are indispensable components in hydraulic pumps and motors. Prevent leakage of sealed lubricant from inside. The seal oil system prevents gas from leaking out of the compressor case. Oil seals hold immense importance across various industries as they serve as vital components in maintaining the functionality and durability of. Seal Oil Pump Function.

From jmpblog.squarespace.com

How to Pick a Centrifugal Pump Part 7 Mechanical Seal Components and Seal Oil Pump Function Mechanical seals are components that keep the pumped fluid (or “pumpage”) confined to the pump casing. Mechanical seals are precision, dynamic devices that are used to seal process fluids from the environment and have been. The seal oil system prevents gas from leaking out of the compressor case. Prevent entry of dust and foreign. 8.46 is a schematic of a. Seal Oil Pump Function.

From www.iqsdirectory.com

Vacuum Pump What Is It? How Does It Work? Types Of Pumps Seal Oil Pump Function The seal oil system prevents gas from leaking out of the compressor case. Sealing devices serve the following functions: Mechanical seals are precision, dynamic devices that are used to seal process fluids from the environment and have been. Mechanical seals are devices that accommodate a rotating shaft while containing and preventing the fluid from leaking out of the enclosed housing.. Seal Oil Pump Function.

From www.alibaba.com

Tcv Type Fkm Fpm Material Oil Seals With 17*30*7 Mm Size For Hydraulic Seal Oil Pump Function Sealing devices serve the following functions: Oil seals, also known as radial shaft seals or shaft seals, are indispensable components in hydraulic pumps and motors. Prevent leakage of sealed lubricant from inside. 8.46 is a schematic of a typical seal oil system working in. The seal oil system prevents gas from leaking out of the compressor case. Mechanical seals are. Seal Oil Pump Function.

From eriks.com

Guide to oil seals for your application Seal Oil Pump Function These seals are installed at the location where the shaft enters. Oil seals, also known as radial shaft seals or shaft seals, are indispensable components in hydraulic pumps and motors. The seal oil system prevents gas from leaking out of the compressor case. Mechanical seals are precision, dynamic devices that are used to seal process fluids from the environment and. Seal Oil Pump Function.

From engineeringlearn.com

Engineering Learn Page 22 of 49 Seal Oil Pump Function Oil seals, also known as radial shaft seals or shaft seals, are indispensable components in hydraulic pumps and motors. Mechanical seals are devices that accommodate a rotating shaft while containing and preventing the fluid from leaking out of the enclosed housing. Oil seals hold immense importance across various industries as they serve as vital components in maintaining the functionality and. Seal Oil Pump Function.

From www.ess4solutions.com

Seal Support Systems for Oil and Gas — ESS Pump & Seal Seal Oil Pump Function Mechanical seals are components that keep the pumped fluid (or “pumpage”) confined to the pump casing. These seals are installed at the location where the shaft enters. Sealing devices serve the following functions: Prevent leakage of sealed lubricant from inside. Mechanical seals are precision, dynamic devices that are used to seal process fluids from the environment and have been. Prevent. Seal Oil Pump Function.

From www.mechanical-knowledge.com

Introduction To Centrifugal Pumps Pdf Seal Oil Pump Function Mechanical seals are devices that accommodate a rotating shaft while containing and preventing the fluid from leaking out of the enclosed housing. Oil seals, also known as radial shaft seals or shaft seals, are indispensable components in hydraulic pumps and motors. Sealing devices serve the following functions: Oil seals hold immense importance across various industries as they serve as vital. Seal Oil Pump Function.

From www.youtube.com

Oil Seals Installation YouTube Seal Oil Pump Function Mechanical seals are precision, dynamic devices that are used to seal process fluids from the environment and have been. Oil seals hold immense importance across various industries as they serve as vital components in maintaining the functionality and durability of machinery. These seals are installed at the location where the shaft enters. Prevent leakage of sealed lubricant from inside. 8.46. Seal Oil Pump Function.

From www.titusco.com

CDR Pompe Lined Mechanical Seal Process Centrifugal Pumps Seal Oil Pump Function Mechanical seals are components that keep the pumped fluid (or “pumpage”) confined to the pump casing. Prevent entry of dust and foreign. Oil seals, also known as radial shaft seals or shaft seals, are indispensable components in hydraulic pumps and motors. Prevent leakage of sealed lubricant from inside. The seal oil system prevents gas from leaking out of the compressor. Seal Oil Pump Function.

From www.hydrauliccylindersinc.com

Installing Hydraulic Cylinder Seals Cylinder Maintenance Seal Oil Pump Function These seals are installed at the location where the shaft enters. Sealing devices serve the following functions: Prevent leakage of sealed lubricant from inside. Oil seals hold immense importance across various industries as they serve as vital components in maintaining the functionality and durability of machinery. Mechanical seals are devices that accommodate a rotating shaft while containing and preventing the. Seal Oil Pump Function.

From hojojoj.se

S&S, oil seal oil pump drive shaft Hojojoj Seal Oil Pump Function Mechanical seals are precision, dynamic devices that are used to seal process fluids from the environment and have been. Sealing devices serve the following functions: The seal oil system prevents gas from leaking out of the compressor case. 8.46 is a schematic of a typical seal oil system working in. Prevent entry of dust and foreign. Mechanical seals are components. Seal Oil Pump Function.

From mechasource.blogspot.com

An Introduction To Mechanical Seal Seal Oil Pump Function Oil seals, also known as radial shaft seals or shaft seals, are indispensable components in hydraulic pumps and motors. Mechanical seals are devices that accommodate a rotating shaft while containing and preventing the fluid from leaking out of the enclosed housing. These seals are installed at the location where the shaft enters. Oil seals hold immense importance across various industries. Seal Oil Pump Function.

From mechanicalengineeringsite.com

Liquid Ring Vacuum Pump Working Principle and Pumping System Seal Oil Pump Function Prevent leakage of sealed lubricant from inside. Oil seals hold immense importance across various industries as they serve as vital components in maintaining the functionality and durability of machinery. Prevent entry of dust and foreign. Oil seals, also known as radial shaft seals or shaft seals, are indispensable components in hydraulic pumps and motors. Sealing devices serve the following functions:. Seal Oil Pump Function.

From www.trakter.com

SEAL OIL PUMP Seal Oil Pump Function Oil seals, also known as radial shaft seals or shaft seals, are indispensable components in hydraulic pumps and motors. Mechanical seals are components that keep the pumped fluid (or “pumpage”) confined to the pump casing. Prevent entry of dust and foreign. Sealing devices serve the following functions: Mechanical seals are precision, dynamic devices that are used to seal process fluids. Seal Oil Pump Function.

From www.researchgate.net

1. Main components of a centrifugal pump (Taken from [47]) Download Seal Oil Pump Function Mechanical seals are precision, dynamic devices that are used to seal process fluids from the environment and have been. These seals are installed at the location where the shaft enters. 8.46 is a schematic of a typical seal oil system working in. Mechanical seals are components that keep the pumped fluid (or “pumpage”) confined to the pump casing. Oil seals. Seal Oil Pump Function.

From www.youtube.com

hydraulic pump or motors oil seals factory YouTube Seal Oil Pump Function Mechanical seals are components that keep the pumped fluid (or “pumpage”) confined to the pump casing. The seal oil system prevents gas from leaking out of the compressor case. Prevent entry of dust and foreign. These seals are installed at the location where the shaft enters. 8.46 is a schematic of a typical seal oil system working in. Mechanical seals. Seal Oil Pump Function.

From somarmotor.com

Oil Pump Housing Seal Somar Motor LLC Seal Oil Pump Function Oil seals, also known as radial shaft seals or shaft seals, are indispensable components in hydraulic pumps and motors. Prevent entry of dust and foreign. Oil seals hold immense importance across various industries as they serve as vital components in maintaining the functionality and durability of machinery. Mechanical seals are devices that accommodate a rotating shaft while containing and preventing. Seal Oil Pump Function.

From www.youtube.com

Oil Ring Vacuum pump working principleChemicalMahi YouTube Seal Oil Pump Function The seal oil system prevents gas from leaking out of the compressor case. These seals are installed at the location where the shaft enters. Oil seals hold immense importance across various industries as they serve as vital components in maintaining the functionality and durability of machinery. Sealing devices serve the following functions: Prevent leakage of sealed lubricant from inside. Oil. Seal Oil Pump Function.

From www.carid.com

National® Toyota Camry 2002 Polyacrylate Oil Pump Seal Seal Oil Pump Function Sealing devices serve the following functions: Mechanical seals are devices that accommodate a rotating shaft while containing and preventing the fluid from leaking out of the enclosed housing. 8.46 is a schematic of a typical seal oil system working in. Mechanical seals are components that keep the pumped fluid (or “pumpage”) confined to the pump casing. These seals are installed. Seal Oil Pump Function.

From www.pumpsandsystems.com

Determine the Best Piping Plan for Supporting Mechanical Seals in Seal Oil Pump Function Mechanical seals are components that keep the pumped fluid (or “pumpage”) confined to the pump casing. Oil seals hold immense importance across various industries as they serve as vital components in maintaining the functionality and durability of machinery. Prevent entry of dust and foreign. Oil seals, also known as radial shaft seals or shaft seals, are indispensable components in hydraulic. Seal Oil Pump Function.

From info.craneengineering.net

Mechanical Seal Basics Learn How Mechanical Seals For Pumps Work Seal Oil Pump Function Oil seals, also known as radial shaft seals or shaft seals, are indispensable components in hydraulic pumps and motors. These seals are installed at the location where the shaft enters. Mechanical seals are devices that accommodate a rotating shaft while containing and preventing the fluid from leaking out of the enclosed housing. Mechanical seals are components that keep the pumped. Seal Oil Pump Function.

From www.zenithoriental.com

MECHANICAL SEAL zenithoriental Seal Oil Pump Function These seals are installed at the location where the shaft enters. The seal oil system prevents gas from leaking out of the compressor case. 8.46 is a schematic of a typical seal oil system working in. Mechanical seals are precision, dynamic devices that are used to seal process fluids from the environment and have been. Oil seals, also known as. Seal Oil Pump Function.

From www.youtube.com

How Compressor Gas Seal System Works? YouTube Seal Oil Pump Function The seal oil system prevents gas from leaking out of the compressor case. Prevent entry of dust and foreign. Sealing devices serve the following functions: These seals are installed at the location where the shaft enters. Prevent leakage of sealed lubricant from inside. Mechanical seals are precision, dynamic devices that are used to seal process fluids from the environment and. Seal Oil Pump Function.

From empoweringpumps.com

Sealing HighSpeed Shafts in Turbomachinery [Fluid Sealing Association Seal Oil Pump Function Prevent leakage of sealed lubricant from inside. Mechanical seals are devices that accommodate a rotating shaft while containing and preventing the fluid from leaking out of the enclosed housing. The seal oil system prevents gas from leaking out of the compressor case. Oil seals, also known as radial shaft seals or shaft seals, are indispensable components in hydraulic pumps and. Seal Oil Pump Function.

From 209yota1.com

1GR 2UZ 1UR Front Oil Pump Seal Genuine 20002022 Yota1 Performance, Inc. Seal Oil Pump Function Oil seals, also known as radial shaft seals or shaft seals, are indispensable components in hydraulic pumps and motors. 8.46 is a schematic of a typical seal oil system working in. Prevent leakage of sealed lubricant from inside. The seal oil system prevents gas from leaking out of the compressor case. Mechanical seals are components that keep the pumped fluid. Seal Oil Pump Function.

From www.amazon.co.uk

Professional VITON Oil Seal for Hydraulic Oil Pump Motor BAFSL1SF Seal Oil Pump Function Mechanical seals are devices that accommodate a rotating shaft while containing and preventing the fluid from leaking out of the enclosed housing. Sealing devices serve the following functions: Mechanical seals are components that keep the pumped fluid (or “pumpage”) confined to the pump casing. Mechanical seals are precision, dynamic devices that are used to seal process fluids from the environment. Seal Oil Pump Function.

From www.pump-mechanicalseals.com

105U Industrial Mechanical Seals 35mm Submersible Pump Seal Seal Oil Pump Function Mechanical seals are precision, dynamic devices that are used to seal process fluids from the environment and have been. Mechanical seals are devices that accommodate a rotating shaft while containing and preventing the fluid from leaking out of the enclosed housing. These seals are installed at the location where the shaft enters. Mechanical seals are components that keep the pumped. Seal Oil Pump Function.

From www.grampuspump.com

Multiusability Sewage Submersible Pump(Oil Type Motor) Seal Oil Pump Function Prevent entry of dust and foreign. The seal oil system prevents gas from leaking out of the compressor case. 8.46 is a schematic of a typical seal oil system working in. Oil seals hold immense importance across various industries as they serve as vital components in maintaining the functionality and durability of machinery. Mechanical seals are precision, dynamic devices that. Seal Oil Pump Function.

From www.hagaseals.com

INSTALLATION AND USE OF MECHANICAL SEALS FOR PUMPS Ningbo Haga Pump Seal Oil Pump Function Mechanical seals are devices that accommodate a rotating shaft while containing and preventing the fluid from leaking out of the enclosed housing. The seal oil system prevents gas from leaking out of the compressor case. Sealing devices serve the following functions: Prevent entry of dust and foreign. 8.46 is a schematic of a typical seal oil system working in. Prevent. Seal Oil Pump Function.

From engineeringlearn.com

What is Mechanical Seal? Types of Mechanical Seals for Centrifugal Seal Oil Pump Function Prevent leakage of sealed lubricant from inside. Mechanical seals are components that keep the pumped fluid (or “pumpage”) confined to the pump casing. Prevent entry of dust and foreign. 8.46 is a schematic of a typical seal oil system working in. Sealing devices serve the following functions: Mechanical seals are precision, dynamic devices that are used to seal process fluids. Seal Oil Pump Function.

From www.trakter.com

SEAL OIL PUMP Seal Oil Pump Function The seal oil system prevents gas from leaking out of the compressor case. Prevent entry of dust and foreign. Mechanical seals are precision, dynamic devices that are used to seal process fluids from the environment and have been. Oil seals, also known as radial shaft seals or shaft seals, are indispensable components in hydraulic pumps and motors. Mechanical seals are. Seal Oil Pump Function.

From www.carid.com

National® 710485 Automatic Transmission Oil Pump Seal Seal Oil Pump Function These seals are installed at the location where the shaft enters. Mechanical seals are devices that accommodate a rotating shaft while containing and preventing the fluid from leaking out of the enclosed housing. Prevent entry of dust and foreign. Prevent leakage of sealed lubricant from inside. Oil seals hold immense importance across various industries as they serve as vital components. Seal Oil Pump Function.

From www.amazon.ca

TCV High Pressure Oil Seal 31.77X50.75X11mm VITON Rotary Shaft Seal for Seal Oil Pump Function Sealing devices serve the following functions: Prevent leakage of sealed lubricant from inside. Mechanical seals are precision, dynamic devices that are used to seal process fluids from the environment and have been. These seals are installed at the location where the shaft enters. Oil seals hold immense importance across various industries as they serve as vital components in maintaining the. Seal Oil Pump Function.